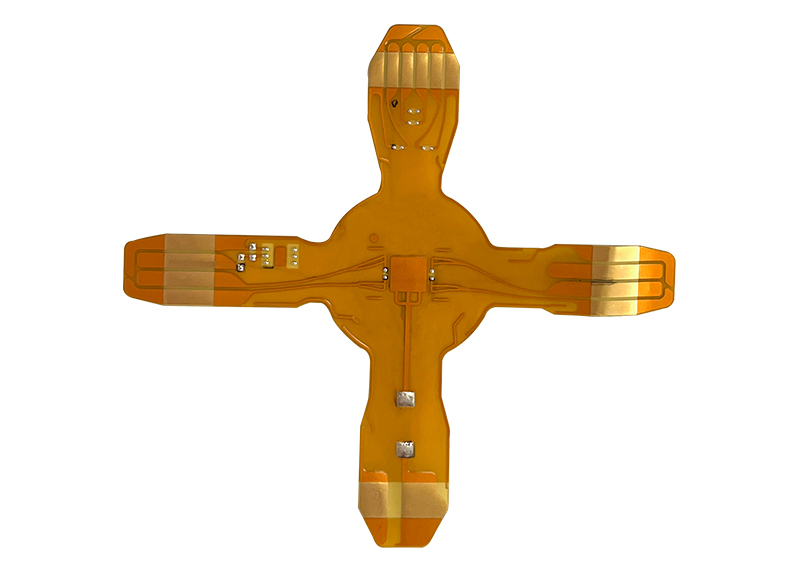

1 Txheej Flex PCB Rau Kev Kho Mob Zoo Nkauj Equipment Cosmetic Instrument-Case

| Kev xav tau | ||||||

| Yam khoom | Ib Sab Flexible pcb | |||||

| Tus naj npawb ntawm txheej | 1 Txheej | |||||

| Kab dav thiab kab sib nrug | 0.1 / 0.1 hli | |||||

| Board thickness | 0.1 hli | |||||

| Tooj Thickness | 18 awm | |||||

| Yam tsawg kawg nkaus Aperture | 0.3mm ib | |||||

| Nplaim Retardant | 94v 0 | |||||

| Kev kho saum npoo | Kub Kub | |||||

| Solder Mask Xim | Daj | |||||

| Kev nruj | / | |||||

| Daim ntawv thov | Cov cuab yeej kho mob | |||||

| Daim ntawv thov Device | Tshuaj pleev ib ce | |||||

Case Study: Technical yam ntxwv thiab kev lag luam cov cuab yeej daws teeb meem

Qhia:Cov ntaub ntawv no yuav tsom mus rau cov kev txawj ntse thiab kev daws teeb meem muaj peev xwm ntawm lub tuam txhab Capel tshwj xeeb hauv kev tsim cov PFC flex pcb, rigid flexible pcb, rigid pcb rau cov cuab yeej siv kho mob siv cov cuab yeej zoo nkauj.

Capel muaj ntau yam kev pabcuam suav nrog kev txiav txim PCB online, kev txiav txim siab PCB tam sim, cov khoom siv PCB, ceev PCB prototyping, PCB qauv sib dhos thiab SMT PCB sib dhos. Cov kev ntsuam xyuas hauv qab no yuav tsom mus rau cov yam ntxwv ntawm nws cov khoom thiab cov teeb meem uas lawv daws tau, thaum tseem qhia txog lub tuam txhab lub zog thiab kev txawj ntse.

Product Description:Cov Capel no ib txheej PFC flex circuits yog rau kev siv khoom siv kho mob. Kev yoog raws, kev ua haujlwm siab thiab kev ntseeg siab ntawm cov circuits no ua rau lawv haum rau siv ntau yam khoom siv kho mob, suav nrog cov cuab yeej zoo nkauj. Kev siv PFC thev naus laus zis ua kom ntseeg tau tias cov khoom siv hluav taws xob tuaj yeem tiv taus qhov kev txav mus tas li thiab flexing cuam tshuam nrog cov cuab yeej no yam tsis muaj kev cuam tshuam rau nws qhov kev ua tau zoo lossis kev ncaj ncees.

Kev qhia tshwj xeeb: Cov kev qhia tshwj xeeb ntawm rooj plaub no ib txheej PFC hloov pauv tau muab los ntawm Capel yog raws li hauv qab no:

Kab dav thiab kab sib nrug:

Circuit Court muaj nplua kab dav thiab kab sib nrug ntawm 0.1mm / 0.1mm. Qhov chaw nqaim nqaim tso cai rau kev siv ntom ntom ntom nti thiab muaj peev xwm los sib xyaw ua ke hluav taws xob ua ke hauv qhov chaw muaj kev txwv.

Board thickness:

Lub thickness ntawm lub rooj tsavxwm yog nyias li 0.1 hli, uas yog qhov zoo los txo qhov loj thiab qhov hnyav ntawm cov cuab yeej zoo nkauj. Qhov kev tsim qauv no yog qhov tseem ceeb los txhim kho cov cuab yeej txav tau yooj yim thiab kev ua haujlwm, ua kom yooj yim dua rau cov kws tshaj lij thiab cov neeg siv kawg.

Copper thickness:

Circuit Court siv 18um tooj liab thickness. Qhov no ua kom pom cov khoom siv hluav taws xob zoo tshaj plaws thiab cov teeb liab sib kis thoob plaws hauv Circuit Court, txhawb kev ua haujlwm zoo ntawm cov khoom siv kho mob. Nws kuj tseem pab kom dissipate lub tshav kub generated thaum lub sij hawm cov cuab yeej ua hauj lwm, tiv thaiv tej zaum yuav puas los yog tsis ua hauj lwm.

Yam tsawg kawg nkaus Aperture:

Lub Circuit Court muaj qhov tsawg kawg nkaus aperture ntawm 0.3mm, tso cai rau kev tso ncaj qha ntawm cov khoom. Qhov no tso cai rau ntau yam khoom siv hluav taws xob sib txuas ua ke thaum tuav cov haujlwm uas xav tau rau cov cuab yeej zoo nkauj.

Nplaim retardant:

Kev tsim hluav taws xob ua tau raws li kev lag luam tus qauv nplaim hluav taws kub retardant qib ntawm 94V0. Qhov no ua kom lub voj voog muaj kev tiv thaiv hluav taws kub siab, ua rau nws muaj kev nyab xeeb rau kev siv hauv cov khoom siv kho mob uas qhov kev pheej hmoo ntawm hluav taws kub lossis hluav taws xob yuav tsum raug txo kom tsawg. Kev kho deg:

Lub Circuit Court tau kho nrog immersion kub nto, uas muaj ntau yam zoo. Lub immersion kub nto txhim kho cov hluav taws xob conductivity ntawm Circuit Court, txhim kho solderability, thiab tiv thaiv oxidation thiab corrosion. Qhov kev kho saum npoo no ua kom ntseeg tau qhov kev ua tau zoo thiab txuas ntxiv lub neej kev pabcuam ntawm cov cuab yeej zoo nkauj.

Solder Mask Xim:

Lub Circuit Court yog pleev xim rau xim daj kuj welding xim. Cov txheej ua haujlwm raws li qhov pom kev pom ntawm qhov muaj cov pob qij txha tiv thaiv, kom ntseeg tau tias muaj tseeb thiab muaj txiaj ntsig sib dhos thaum tsim khoom.

Cov teeb meem kev lag luam thiab kev daws teeb meem: Cov cuab yeej siv hauv kev lag luam muab los ntawm Capel zoo daws tau ntau yam teeb meem kev lag luam uas tau ntsib hauv kev tsim ib txheej PFC hloov tau yooj yim rau kev siv khoom siv kho mob:

Muab cov khoom sib xyaw ua ke hauv qhov chaw txwv:

Txoj kab nqaim dav thiab qhov sib nrug ntawm 0.1mm / 0.1mm ua kom cov khoom siv hluav taws xob ua kom yooj yim sib xyaw ua ke hauv qhov loj me ntawm qhov ntsuas kev zoo nkauj. Qhov no daws qhov kev sib tw ntawm kev ua kom haum txhua yam tsim nyog hauv qhov chaw txwv thaum tswj hwm kev ua haujlwm thiab kev ua tau zoo.

Flexibility thiab Durability:

Kev siv PFC thev naus laus zis hauv Circuit Court ua kom yooj yim thiab ua haujlwm ntev, tso cai rau lub voj voog kom tiv taus qhov khoov tsis tu ncua thiab txav mus los cuam tshuam nrog cov cuab yeej tshuaj pleev ib ce. Qhov no daws qhov teeb meem ntawm Circuit Court tsis ua hauj lwm lossis kev puas tsuaj vim kev ntxhov siab ntawm cov neeg kho tshuab, yog li ua kom muaj kev ntseeg siab thiab kev pab lub neej ntawm cov cuab yeej.

Thermal Management:

Lub 18um tooj liab tuab ua kom yooj yim dua cov cua sov dissipation nyob rau hauv Circuit Court, tiv thaiv overheating thiab tej zaum yuav puas rau cov khoom hluav taws xob. Qhov no daws teeb meem kev tswj xyuas thermal rau cov khoom siv kho mob, txhim kho kev ua tau zoo tag nrho thiab tiv thaiv kev ua tsis tiav.

Lub tuam txhab muaj zog thiab kev txawj ntse: Capel tau pom ntau lub zog thiab kev txawj ntse hauv kev tsim ib txheej PFC flex circuits rau kev siv khoom siv kho mob:

Kev txawj ntse:

Lub tuam txhab muaj kev paub dav dav thiab kev txawj ntse hauv kev tsim thiab tsim PFC hloov pauv hloov pauv, ua kom nws muab cov kev daws teeb meem tshiab thiab txhim khu kev qha rau kev lag luam khoom siv kho mob. Lawv txoj kev nkag siab ntawm cov khoom siv, kev tsim hluav taws xob thiab cov txheej txheem tsim khoom ua kom cov khoom siv hluav taws xob zoo uas ua tau raws li cov kev cai nruj ntawm kev siv kho mob.

Ntau yam kev pabcuam:

Lub tuam txhab muaj cov kev pabcuam dav dav suav nrog kev txiav txim PCB online, kev txiav txim PCB tam sim, PCB muab, ceev PCB prototyping, PCB qauv sib dhos thiab SMT PCB sib dhos, qhia txog lawv txoj kev cog lus los muab cov kev daws teeb meem kawg rau lawv cov neeg siv khoom. Cov neeg siv khoom xav tau. Qhov kev txawj ntse no ua rau muaj txiaj ntsig zoo thiab ua kom yooj yim kho cov cuab yeej siv hluav taws xob tsim hluav taws xob thiab cov txheej txheem sib dhos.

Customer-centric txoj kev:

Lub tuam txhab tsom mus rau kev muab cov kev daws teeb meem los ua kom tau raws li cov kev xav tau tshwj xeeb thiab cov teeb meem ntawm nws cov neeg siv khoom hauv kev lag luam khoom siv kho mob. Lawv lub peev xwm los muab cov kev daws teeb meem ua ke nrog cov neeg siv khoom zoo tshaj plaws kom ntseeg tau cov neeg siv khoom txaus siab thiab kev koom tes ntev.

Quality Assurance:

Lub tuam txhab ua raws li kev tswj hwm nruj zoo thoob plaws hauv tag nrho cov txheej txheem tsim khoom kom ntseeg tau tias cov khoom siv hluav taws xob zoo. Los ntawm kev xaiv cov khoom siv mus rau qhov kev sim zaum kawg, lawv siv cov txheej txheem kev ruaj ntseg zoo uas ua raws li cov qauv kev lag luam thiab cov kev cai. Cov khoom kub immersed thiab nplaim retardant cov khoom ntxiv qhia tau hais tias lawv txoj kev cog lus los muab cov khoom muaj kev nyab xeeb thiab txhim khu kev qha.

Post lub sij hawm: Sep-09-2023

Rov qab