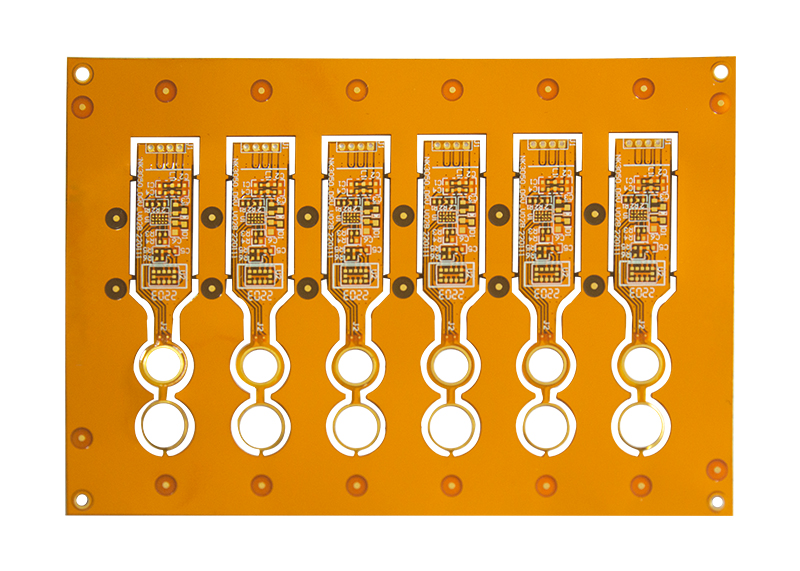

6 Txheej HDI Flexible PCB Rau Industrial Control Sensors-Case

| Kev xav tau | ||||||

| Yam khoom | Ntau HDI Flexible Pcb Board | |||||

| Tus naj npawb ntawm txheej | 6 Txheej | |||||

| Kab dav thiab kab sib nrug | 0.05 / 0.05 hli | |||||

| Board thickness | 0.2 hli | |||||

| Tooj Thickness | 12 awm | |||||

| Yam tsawg kawg nkaus Aperture | 0.1 hli | |||||

| Nplaim Retardant | 94v 0 | |||||

| Kev kho saum npoo | Kub Kub | |||||

| Solder Mask Xim | Daj | |||||

| Kev nruj | Hlau Sheet, FR4 | |||||

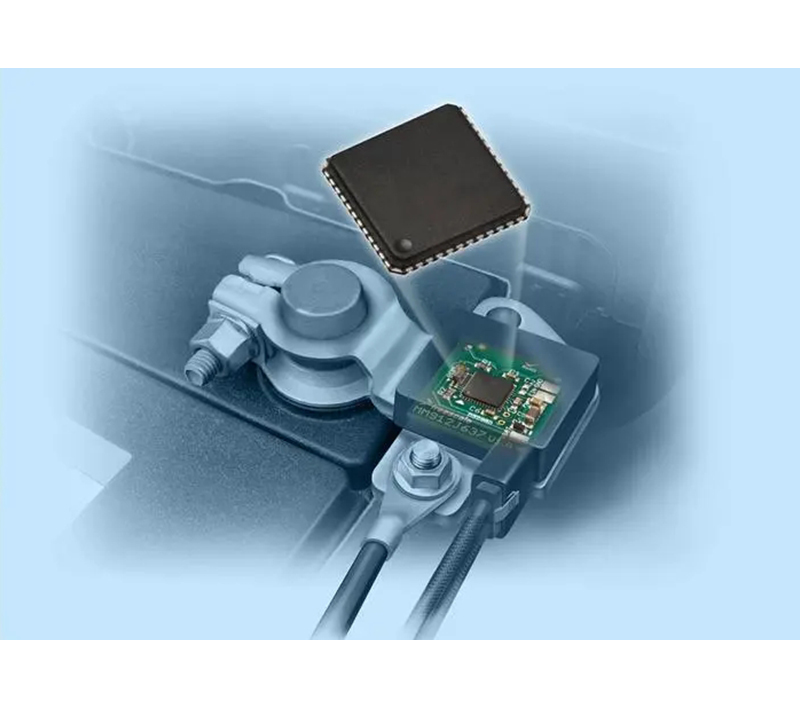

| Daim ntawv thov | Kev Tswj Lag Luam | |||||

| Daim ntawv thov Device | Sensor | |||||

Case Analysis

Capel yog lub tuam txhab tsim khoom tshwj xeeb hauv cov ntawv luam tawm Circuit Board (PCBs). Lawv muab ntau yam kev pabcuam suav nrog PCB fabrication, PCB fabrication thiab sib dhos, HDI

PCB prototyping, ceev tig nruj flex PCB, turnkey PCB los ua ke thiab flex circuit manufacturing. Hauv qhov no, Capel tsom mus rau kev tsim cov 6-txheej HDI hloov pauv PCBs

rau kev tswj kev lag luam, tshwj xeeb tshaj yog siv nrog cov khoom siv sensor.

Cov ntsiab lus kev tsim kho tshiab ntawm txhua qhov khoom parameter yog raws li hauv qab no:

Kab dav thiab kab sib nrug:

Cov kab dav thiab kab sib nrug ntawm PCB tau teev tseg raws li 0.05 / 0.05mm. Qhov no sawv cev rau kev tsim kho tshiab loj rau kev lag luam vim nws tso cai rau miniaturization ntawm high-density circuits thiab cov khoom siv hluav taws xob. Nws ua rau PCBs kom haum raws li kev tsim qauv hauv Circuit Court thiab txhim kho kev ua haujlwm tag nrho.

Board thickness:

Phaj thickness yog teev raws li 0.2 hli. Qhov no tsis tshua muaj profile muab qhov yooj yim xav tau rau cov PCB hloov tau yooj yim, ua rau nws tsim nyog rau cov ntawv thov uas xav tau PCBs yuav tsum tau khoov lossis folded. Lub thinness kuj ua rau lub teeb yuag tag nrho ntawm cov khoom. Copper thickness: tooj liab thickness yog teev raws li 12um. Cov txheej tooj liab nyias no yog ib qho tshiab feature uas tso cai rau kom zoo dua tshav kub dissipation thiab qis tsis kam, txhim kho teeb liab kev ncaj ncees thiab kev ua tau zoo.

Yam tsawg kawg nkaus aperture:

Qhov tsawg kawg nkaus aperture yog teev li 0.1mm. Qhov me me aperture no tso cai rau kev tsim cov qauv zoo nkauj thiab ua kom yooj yim rau kev sib txuas ntawm micro Cheebtsam ntawm PCBs. Nws ua kom cov ntim ntim ntau dua thiab txhim kho kev ua haujlwm.

Nplaim retardant:

PCB cov nplaim hluav taws kub nyhiab yog 94V0, uas yog tus qauv kev lag luam siab. Qhov no ua kom muaj kev nyab xeeb thiab kev ntseeg siab ntawm PCB, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas muaj hluav taws kub.

Kev kho deg:

Lub PCB yog immersed nyob rau hauv kub, muab ib tug nyias thiab txawm kub txheej nyob rau hauv raug tooj liab nto. Qhov saum npoo tiav no muab zoo heev solderability, corrosion kuj, thiab ua kom lub ntsej muag tiaj tus.

Solder Mask Xim:

Capel muaj qhov kev xaiv xim daj ntawm daim npog ntsej muag uas tsis tsuas yog muab lub ntsej muag zoo nkauj tab sis kuj txhim kho qhov sib txawv, muab kev pom zoo dua thaum lub sijhawm sib dhos lossis kev tshuaj xyuas tom ntej.

Kev nruj:

PCB yog tsim los nrog steel phaj thiab FR4 cov khoom siv rau kev sib xyaw ua ke. Qhov no tso cai rau kev hloov pauv hauv qhov hloov pauv ntawm PCB tab sis kev nruj hauv thaj chaw uas xav tau kev txhawb nqa ntxiv. Qhov kev tsim kho tshiab no ua kom ntseeg tau tias PCB tuaj yeem tiv thaiv kev khoov thiab folding yam tsis muaj kev cuam tshuam rau nws txoj haujlwm

Hais txog kev daws teeb meem kev lag luam thiab kev txhim kho khoom siv, Capel xav txog cov ntsiab lus hauv qab no:

Txhim kho Thermal Management:

Raws li cov khoom siv hluav taws xob txuas ntxiv nce hauv qhov nyuaj thiab qhov me me, kev txhim kho thermal tswj yog qhov tseem ceeb. Capel tuaj yeem tsom mus rau kev tsim cov kev daws teeb meem tshiab kom muaj txiaj ntsig zoo rau cov cua sov uas tsim los ntawm PCBs, xws li siv cov dab dej kub lossis siv cov khoom siv siab heev nrog thermal conductivity zoo dua.

Enhanced Signal Integrity:

Raws li qhov xav tau ntawm kev siv high-speed thiab high-frequency loj hlob, yuav tsum muaj kev txhim kho teeb liab kev ncaj ncees. Capel tuaj yeem nqis peev hauv kev tshawb fawb thiab kev tsim kho kom txo qis cov teeb liab poob thiab suab nrov, xws li kev siv cov cuab yeej ua kom muaj kev ncaj ncees simulation cov cuab yeej thiab cov tswv yim.

Advanced saj zawg zog PCB manufacturing technology:

Flexible PCB muaj qhov tshwj xeeb zoo hauv kev yooj yim thiab compactness. Capel tuaj yeem tshawb nrhiav cov thev naus laus zis tsim khoom xws li kev ua laser los tsim cov qauv PCB yooj yim thiab meej. Qhov no tuaj yeem ua rau kev nce qib hauv miniaturization, nce Circuit Court ceev, thiab txhim kho kev ntseeg tau.

Advanced HDI manufacturing technology:

High-density interconnect (HDI) manufacturing technology enables lub miniaturization ntawm cov khoom siv hluav taws xob thaum ua kom ntseeg tau kev ua tau zoo. Capel tuaj yeem nqis peev hauv HDI kev tsim khoom siv thev naus laus zis xws li laser drilling thiab ua ntu zus los txhim kho PCB ntom ntom, kev ntseeg tau thiab kev ua haujlwm tag nrho.

Post lub sij hawm: Sep-09-2023

Rov qab