Ob-Sided Circuit Boards Prototype Pcb Chaw tsim tshuaj paus

PCB txheej txheem muaj peev xwm

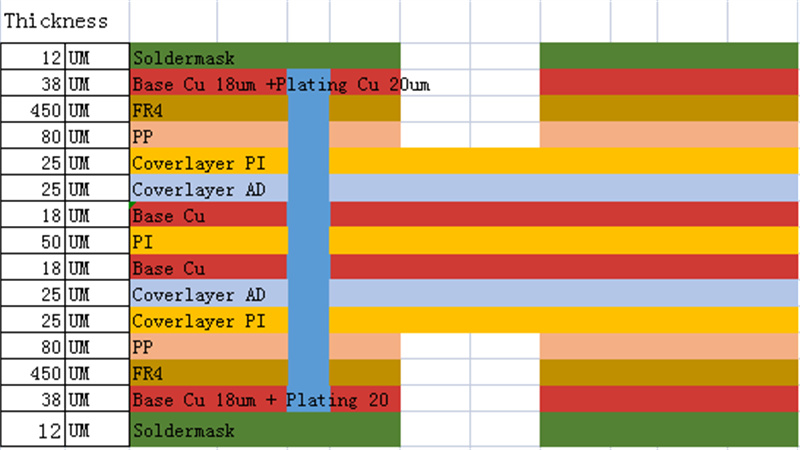

| Tsis muaj. | Qhov project | Technical ntsuas |

| 1 | Txheej | 1-60 (txheej) |

| 2 | Kev ua haujlwm siab tshaj plaws | 545 x 622 mm |

| 3 | Yam tsawg kawg nkaus boardthickness | 4 (txheej) 0.40mm |

| 6 (txheej) 0.60mm | ||

| 8 (txheej) 0.8mm | ||

| 10 (txheej) 1.0mm | ||

| 4 | Yam tsawg kawg kab dav | 0.0762 hli |

| 5 | Qhov sib nrug tsawg kawg nkaus | 0.0762 hli |

| 6 | Yam tsawg kawg nkaus tshuab aperture | 0.15 hli |

| 7 | Qhov phab ntsa tooj liab thickness | 0.015 hli |

| 8 | Metallized aperture kam rau ua | ± 0.05 hli |

| 9 | Non-metallized aperture kam rau ua | ± 0.025 hli |

| 10 | Qhov kam rau ua | ± 0.05 hli |

| 11 | Dimensional kam rau ua | ± 0.076 hli |

| 12 | Yam tsawg kawg nkaus solder choj | 0.08mm ib |

| 13 | Rwb thaiv tsev tsis kam | 1E + 12Ω (ib txwm) |

| 14 | Phaj thickness ratio | 1:10 |

| 15 | Thermal shock | 288 ℃ (4 zaug hauv 10 vib nas this) |

| 16 | Distorted thiab khoov | ≤ 0.7% |

| 17 | Anti-hluav taws xob muaj zog | 1.3KV / hli |

| 18 | Anti-stripping zog | 1.4N / hli |

| 19 | Solder tiv taus hardness | ≥ 6 H |

| 20 | Nplaim retardancy | 94v 0 |

| 21 | Impedance tswj | ± 5% |

Peb ua Circuit Boards Prototyping nrog 15 xyoo kev paub nrog peb cov kws tshaj lij

4 txheej Flex-Rigid Boards

8 txheej Rigid-Flex PCBs

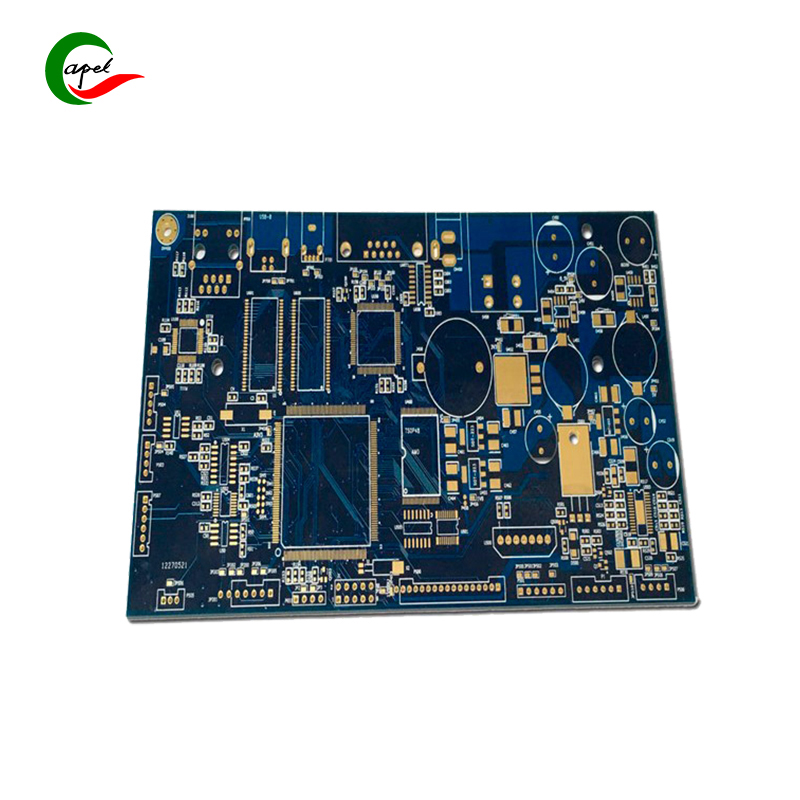

8 txheej HDI Printed Circuit Boards

Cov khoom siv kuaj thiab tshuaj xyuas

Microscope Test

AOI Inspection

2D Kev Xeem

Kev ntsuas impedance

Kev xeem RoHS

Flying Probe

Kab rov tav Tester

Khoov Teste

Peb Circuit Boards Prototyping Service

. Muab kev txhawb nqa kev muag khoom ua ntej thiab tom qab muag;

. Custom mus txog 40 khaubncaws sab nraud povtseg, 1-2days ceev tig txhim khu kev qha prototyping, Component procurement, SMT Assembly;

. Caters rau ob qho khoom siv kho mob, Kev Tswj Lag Luam, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications thiab lwm yam.

. Peb pab pawg engineers thiab cov kws tshawb fawb tau mob siab rau ua kom tiav koj cov kev xav tau nrog precision thiab kev tshaj lij.

Yuav ua li cas los tsim ib lub siab zoo Ob-Sided Circuit Boards?

1. Tsim lub rooj tsavxwm: Siv computer-aided design (CAD) software los tsim cov board layout. Xyuas kom meej tias tus qauv tsim ua tau raws li txhua qhov kev xav tau ntawm cov khoom siv hluav taws xob thiab cov khoom siv, suav nrog cov kab dav dav, qhov sib nrug, thiab qhov chaw tso khoom. Xav txog yam xws li teeb liab kev ncaj ncees, kev faib hluav taws xob, thiab kev tswj xyuas thermal.

2. Prototyping thiab kuaj: Ua ntej loj ntau lawm, nws yog ib qho tseem ceeb heev uas yuav tau tsim ib tug qauv board kom validate tus tsim thiab manufacturing txheej txheem. Ua tib zoo sim cov qauv rau kev ua haujlwm, kev ua haujlwm hluav taws xob, thiab kev sib raug zoo ntawm cov khoom siv los txheeb xyuas cov teeb meem lossis kev txhim kho.

3. Kev Xaiv Cov Khoom Siv: Xaiv cov khoom zoo uas haum rau koj cov kev xav tau ntawm pawg thawj coj saib. Kev xaiv cov khoom siv feem ntau suav nrog FR-4 lossis kub-kub FR-4 rau lub substrate, tooj liab rau cov kab hluav taws xob, thiab lub npog ntsej muag los tiv thaiv cov khoom.

4. Fabricate lub puab txheej: Ua ntej npaj lub puab txheej ntawm lub rooj tsavxwm, uas muaj ob peb kauj ruam:

a. Ntxuav thiab roughen tooj liab clad laminate.

b. Siv ib daim duab nyias nyias nyias nyias rau ntawm qhov chaw tooj liab.

c. Cov yeeb yaj kiab raug pom los ntawm ultraviolet (UV) lub teeb los ntawm cov cuab yeej yees duab uas muaj cov qauv hauv Circuit Court uas xav tau.

d. Cov zaj duab xis yog tsim los tshem tawm cov cheeb tsam uas tsis tau nthuav tawm, tawm hauv cov qauv hauv Circuit Court.

e. Etch exposed tooj liab kom tshem tawm cov khoom tshaj tawm tsuas yog xav tau kab thiab cov ntaub qhwv.

F. Tshawb xyuas cov txheej txheem sab hauv kom pom qhov tsis xws luag lossis sib txawv ntawm kev tsim.

5. Laminates: Sab hauv txheej yog sib sau ua ke nrog prepreg hauv ib lub xovxwm. Thaum tshav kub kub thiab lub siab yog siv los khi cov khaubncaws sab nraud povtseg thiab tsim ib lub vaj huam sib luag muaj zog. Xyuas kom cov txheej txheej sab hauv raug ua kom zoo thiab sau npe kom tsis txhob muaj qhov tsis zoo.

6. Drilling: Siv lub tshuab drilling precision los laum qhov rau cov khoom sib txuas thiab kev sib txuas. Ntau qhov sib txawv ntawm cov khoom siv laum yog siv raws li cov cai tshwj xeeb. Xyuas kom tseeb qhov tseeb ntawm qhov chaw thiab txoj kab uas hla.

Yuav ua li cas los tsim ib lub siab zoo Ob-Sided Circuit Boards?

7. Electroless Copper Plating: Siv ib txheej nyias ntawm tooj liab rau txhua qhov chaw sab hauv. Cov kauj ruam no ua kom zoo conductivity thiab ua kom cov txheej txheem plating hauv cov kauj ruam tom ntej.

8. Cov txheej txheem txheej txheej txheej: Zoo ib yam li txheej txheej txheej sab hauv, cov yeeb yaj kiab photosensitive qhuav yog coated ntawm txheej tooj liab txheej.

Tso nws rau UV teeb los ntawm cov cuab yeej yees duab saum toj kawg nkaus thiab tsim cov yeeb yaj kiab kom nthuav tawm cov qauv hauv Circuit Court.

9. Txheej txheej etching: Etch cov tooj liab uas tsis tsim nyog rau ntawm txheej txheej, tawm hauv qhov yuav tsum tau muaj kab thiab cov ntaub qhwv.

Tshawb xyuas cov txheej txheej sab nrauv kom pom qhov tsis xws luag lossis sib txawv.

10. Solder Mask thiab Legend Printing: Siv cov khoom siv lub npog ntsej muag los tiv thaiv cov kab tooj liab thiab cov ntaub qhwv thaum tawm hauv cheeb tsam rau kev tiv thaiv. Sau cov lus dab neeg thiab cov cim rau saum thiab hauv qab cov khaubncaws sab nraud povtseg los qhia qhov chaw nyob, polarity, thiab lwm yam ntaub ntawv.

11. Kev Npaj Nto: Kev npaj deg yog siv los tiv thaiv cov tooj liab uas raug oxidation thiab muab ib qho chaw solderable. Cov kev xaiv muaj xws li cua kub leveling (HASL), electroless nickel immersion kub (ENIG), los yog lwm yam kev ua tiav tiav.

12. Routing thiab Forming: PCB panels raug txiav mus rau hauv ib tug boards siv lub routing tshuab los yog V-scribing txheej txheem.

Xyuas kom cov npoo huv si thiab qhov ntev yog qhov tseeb.

13. Kev Ntsuas Hluav Taws Xob: Ua kev ntsuas hluav taws xob xws li kev ntsuas txuas ntxiv, ntsuas kev tiv thaiv, thiab kev txheeb xyuas kev sib cais kom ntseeg tau tias kev ua haujlwm thiab kev ncaj ncees ntawm cov ntaub ntawv tsim tawm.

14. Kev Tswj Xyuas Zoo thiab Kev Tshawb Fawb: Cov boards tiav tau raug tshuaj xyuas kom zoo rau txhua qhov kev tsim khoom xws li luv luv, qhib, misalignments, lossis defects. Siv cov txheej txheem tswj kom zoo kom ua tau raws li cov cai thiab cov qauv.

15. Ntim thiab Shipping: Tom qab lub rooj tsavxwm dhau qhov kev tshuaj xyuas zoo, nws tau ntim khoom kom ruaj ntseg los tiv thaiv kev puas tsuaj thaum thauj khoom.

Xyuas kom muaj daim ntawv lo thiab cov ntaub ntawv kom raug raws thiab txheeb xyuas cov boards.