16-txheej PCBs muab qhov nyuaj thiab hloov tau los ntawm cov khoom siv hluav taws xob niaj hnub no. Kev txawj tsim thiab kev xaiv ntawm stacking sequences thiab interlayer kev sib txuas txoj kev yog qhov tseem ceeb rau kev ua tau zoo ntawm pawg thawj coj saib. Hauv tsab xov xwm no, peb yuav tshawb xyuas cov kev xav, cov lus qhia, thiab cov kev coj ua zoo tshaj plaws los pab cov tsim qauv thiab cov kws tsim qauv tsim kom muaj txiaj ntsig thiab txhim khu kev qha 16-txheej Circuit Court boards.

1.Kev nkag siab txog lub hauv paus ntawm 16 txheej PCBs Stacking Sequence

1.1 Txhais thiab lub hom phiaj ntawm kev txiav txim stacking

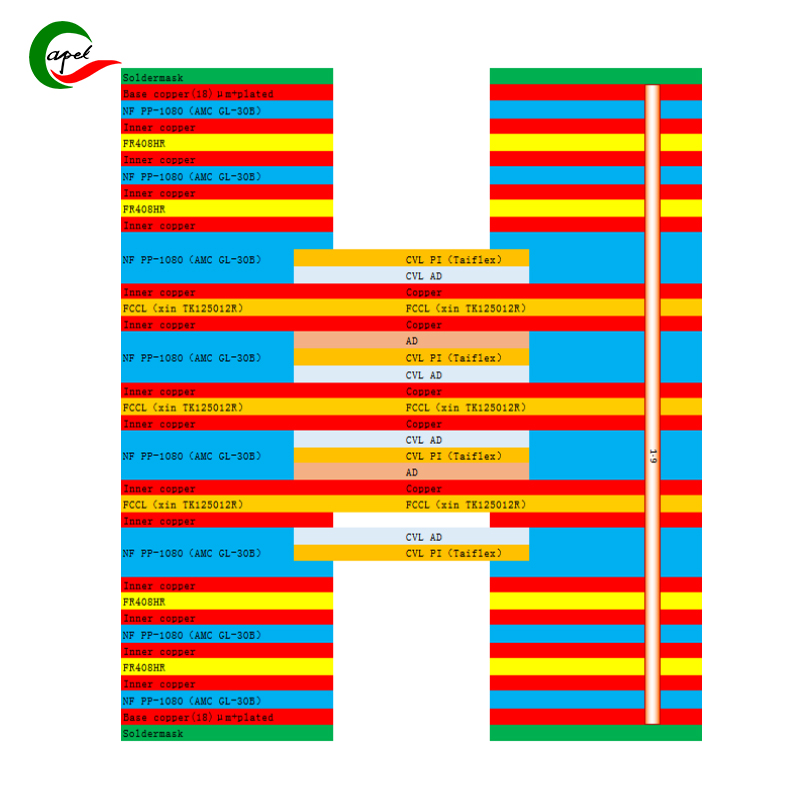

Stacking sequence yog hais txog kev npaj thiab kev txiav txim nyob rau hauv uas cov ntaub ntawv xws li tooj liab thiab insulating txheej yog laminated ua ke los tsim ib tug multi-txheej Circuit Court board.The stacking sequence txiav txim siab qhov chaw ntawm teeb liab txheej, lub hwj chim txheej, hauv av txheej, thiab lwm yam tseem ceeb Cheebtsam nyob rau hauv pawg.

Lub hom phiaj tseem ceeb ntawm cov txheej txheem stacking yog ua kom tiav cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob ntawm lub rooj tsavxwm. Nws ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab lub rooj tsav xwm hauv Circuit Court impedance, teeb liab kev ncaj ncees, kev faib hluav taws xob, kev tswj xyuas thermal, thiab kev tsim khoom. Cov txheej txheem stacking kuj cuam tshuam rau tag nrho cov kev ua tau zoo, kev ntseeg tau, thiab kev tsim khoom ntawm lub rooj tsavxwm.

1.2 Yam tseem ceeb cuam tshuam rau kev tsim cov txheej txheem stacking: Muaj ntau yam los xav txog thaum tsim cov txheej txheem stacking ntawm ib qho

16-txheej PCB:

a) Kev xav txog hluav taws xob:Kev teeb tsa ntawm lub teeb liab, lub zog, thiab cov dav hlau hauv av yuav tsum tau ua kom zoo kom ntseeg tau tias cov teeb liab muaj tseeb, kev tswj xyuas impedance, thiab txo cov electromagnetic cuam tshuam.

b) Thermal kev txiav txim siab:Kev tso kawm ntawm lub zog thiab cov dav hlau hauv av thiab suav nrog cov thermal vias pab kom dissipate tshav kub zoo thiab tswj xyuas qhov zoo tshaj plaws kev khiav hauj lwm kub ntawm cov khoom.

c) Manufacturing txwv:Cov txheej txheem stacking uas tau xaiv yuav tsum coj mus rau hauv tus account lub peev xwm thiab kev txwv ntawm cov txheej txheem tsim khoom PCB, xws li cov khoom muaj, tus lej ntawm cov txheej txheem, xyaum qhov sib piv,thiab alignment raug.

d) Tus nqi optimization:Kev xaiv cov ntaub ntawv, tus lej ntawm cov khaubncaws sab nraud povtseg, thiab pawg-up complexity yuav tsum ua raws li qhov project pob nyiaj siv thaum ua kom ntseeg tau tias qhov kev ua tau zoo thiab kev ntseeg tau.

1.3 Feem ntau hom 16-txheej Circuit Court board stacking sequences: Muaj ntau ntau hom stacking sequences rau 16-txheej

PCB, nyob ntawm seb qhov kev ua tau zoo thiab qhov xav tau. Qee qhov piv txwv xws li:

a) Symmetrical stacking sequence:Cov kab ke no suav nrog muab cov teeb liab txheej sib npaug ntawm lub zog thiab cov txheej hauv av kom ua tiav cov teeb liab kev ncaj ncees, tsawg kawg nkaus crosstalk, thiab sib npaug ntawm cov cua sov.

b) Sequential stacking sequence:Nyob rau hauv no ib theem zuj zus, cov teeb liab txheej yog sequentially ntawm lub hwj chim thiab av txheej. Nws muab kev tswj hwm ntau dua ntawm txheej txheej txheej thiab muaj txiaj ntsig zoo rau kev ua kom tau raws li cov cai tshwj xeeb ntawm kev ntseeg siab.

c) Mixed stacking kev txiav txim:Qhov no suav nrog kev sib xyaw ua ke ntawm symmetrical thiab sequential stacking xaj. Nws tso cai rau customization thiab optimization ntawm layup rau tej qhov chaw ntawm lub rooj tsavxwm.

d) Teeb liab-rhiab heev stacking ib ntus:Cov kab ke no tso cov teeb liab rhiab heev ze rau lub dav hlau hauv av kom muaj suab nrov zoo dua thiab kev sib cais.

2. Kev txiav txim siab tseem ceeb rau 16 txheej PCB Stacking Sequence Xaiv:

2.1 Teeb liab kev ncaj ncees thiab lub hwj chim ncaj ncees txiav txim siab:

Cov txheej txheem stacking muaj qhov cuam tshuam loj rau lub teeb liab kev ncaj ncees thiab lub zog ncaj ncees ntawm lub rooj tsavxwm. Kev tso chaw kom zoo ntawm cov teeb liab thiab lub zog / lub dav hlau hauv av yog qhov tseem ceeb rau kev txo qis kev pheej hmoo ntawm cov teeb liab distortion, suab nrov, thiab cuam tshuam electromagnetic. Cov ntsiab lus tseem ceeb suav nrog:

a) Teeb liab txheej tso chaw:High-ceev teeb liab txheej yuav tsum tau muab tso rau ze rau hauv av dav hlau los muab ib tug tsawg-inductance rov qab txoj kev thiab txo cov suab nrov coupling. Cov teeb liab txheej yuav tsum tau ua tib zoo nteg tawm kom txo cov teeb liab skew thiab ntev sib phim.

b) Fais fab dav hlau faib:Cov txheej txheem stacking yuav tsum xyuas kom muaj lub dav hlau fais fab faib kom txaus los txhawb lub zog ncaj ncees. Lub hwj chim txaus thiab cov dav hlau hauv av yuav tsum tau muab tso rau hauv kev sib tw kom txo qis qis qis, impedance discontinuities, thiab suab nrov coupling.

c) Decoupling Capacitor:Kev tso cai ntawm decoupling capacitors yog ib qho tseem ceeb los xyuas kom meej lub zog txaus thiab txo cov suab nrov ntawm lub hwj chim. Cov txheej txheem stacking yuav tsum muab qhov sib thooj thiab sib thooj ntawm decoupling capacitors rau lub zog thiab hauv av dav hlau.

2.2 Thermal tswj thiab cua kub dissipation:

Kev tswj xyuas kom zoo thermal yog qhov tseem ceeb rau kev ua kom lub rooj tsav xwm muaj kev ntseeg siab thiab kev ua haujlwm. Cov txheej txheem stacking yuav tsum coj mus rau hauv tus account qhov kev tso kawm ntawm lub hwj chim thiab av dav hlau, thermal vias, thiab lwm yam cua txias mechanisms. Cov ntsiab lus tseem ceeb suav nrog:

a) Fais fab dav hlau faib:Kev faib tawm txaus ntawm lub zog thiab cov dav hlau hauv av thoob plaws hauv pawg pab cuam ncaj qha tshav kub kom deb ntawm cov khoom rhiab thiab ua kom muaj qhov sib txawv ntawm qhov kub thiab txias thoob plaws lub rooj tsavxwm.

b) Thermal vias:Cov txheej txheem stacking yuav tsum tso cai rau kev ua haujlwm zoo thermal ntawm qhov chaw los pab kom muaj cua sov dissipation los ntawm txheej sab hauv mus rau txheej txheej lossis lub dab dej kub. Qhov no pab tiv thaiv cov chaw kub hauv zos thiab ua kom cov cua sov ua kom zoo.

c) Component qhov chaw:Stacking ib ntus yuav tsum xav txog qhov kev npaj thiab qhov sib thooj ntawm cov khoom cua sov kom tsis txhob muaj cua sov. Kev sib raug zoo ntawm cov khoom siv nrog cov tshuab cua txias xws li cov dab dej kub lossis cov kiv cua yuav tsum tau xav txog.

2.3 Manufacturing txwv thiab nqi optimization:

Cov txheej txheem stacking yuav tsum tau coj mus rau hauv tus account qhov kev txwv ntawm kev tsim khoom thiab cov nqi kho kom zoo, vim tias lawv ua lub luag haujlwm tseem ceeb hauv kev ua tau zoo thiab kev pheej yig ntawm pawg thawj coj. Cov kev txiav txim siab suav nrog:

a) Cov khoom muaj:Cov txheej txheem stacking xaiv yuav tsum ua raws li cov khoom muaj thiab lawv cov kev sib raug zoo nrog cov txheej txheem tsim khoom PCB.

b) Tus naj npawb ntawm cov khaubncaws sab nraud povtseg thiab complexity:Cov txheej txheem stacking yuav tsum tau tsim nyob rau hauv qhov txwv ntawm cov txheej txheem tsim PCB xaiv, suav nrog cov xwm txheej xws li tus lej ntawm cov txheej, xyaum qhov sib piv, thiab qhov tseeb ntawm kev sib dhos.

c) Tus nqi optimization:Cov txheej txheem stacking yuav tsum ua kom zoo dua ntawm kev siv cov khoom siv thiab txo cov kev tsim khoom nyuaj yam tsis muaj kev cuam tshuam qhov kev ua tau zoo thiab kev ntseeg siab. Nws yuav tsum tsom kom txo cov nqi cuam tshuam nrog cov khoom pov tseg, txheej txheem complexity thiab sib dhos.

2.4 Txheej txheej thiab teeb liab crosstalk:

Cov txheej txheem stacking yuav tsum daws teeb meem txheej txheej thiab txo cov teeb liab crosstalk uas tuaj yeem cuam tshuam cov teeb liab kev ncaj ncees. Cov ntsiab lus tseem ceeb suav nrog:

a) Symmetrical stacking:Symmetrical stacking ntawm cov teeb liab txheej ntawm lub hwj chim thiab hauv av txheej yuav pab txo qis kev sib txuas thiab txo cov lus sib dhos.

b) Differential khub routing:Cov txheej txheem stacking yuav tsum tso cai rau cov teeb liab txheej txheej kom raug raws li kev ua haujlwm zoo ntawm cov teeb liab sib txawv ntawm kev kub ceev. Qhov no pab tswj cov teeb liab kev ncaj ncees thiab txo qis kev sib tham.

c) Teeb liab sib cais:Cov txheej txheem stacking yuav tsum xav txog kev sib cais ntawm rhiab analog thiab digital signals kom txo tau crosstalk thiab cuam tshuam.

2.5 impedance tswj thiab RF/microwave kev koom ua ke:

Rau RF/microwave daim ntaub ntawv, cov txheej txheem stacking yog ib qho tseem ceeb kom ua tau raws li impedance tswj thiab kev koom ua ke. Cov ntsiab lus tseem ceeb suav nrog:

a) Tswj impedance:Cov txheej txheem stacking yuav tsum tso cai rau kev tswj hwm impedance tsim, coj mus rau hauv tus account yam xws li kab dav, dielectric thickness, thiab txheej txheej. Qhov no ua kom cov teeb liab nthuav tawm kom raug thiab impedance txuam rau RF/microwave signals.

b) Teeb liab txheej tso chaw:RF/microwave signals yuav tsum tau muab tso rau hauv qhov chaw ze rau txheej txheej kom txo qis kev cuam tshuam los ntawm lwm cov teeb liab thiab muab cov teeb liab nthuav tawm zoo dua.

c) RF tiv thaiv:Cov txheej txheem stacking yuav tsum muaj xws li kev tso chaw hauv av thiab thaiv cov khaubncaws sab nraud povtseg kom cais thiab tiv thaiv RF / microwave signals los ntawm kev cuam tshuam.

3.Interlayer Connection Methods

3.1 Los ntawm qhov, qhov muag tsis pom qhov thiab faus qhov:

Vias tau dav siv hauv cov ntawv luam tawm Circuit Board (PCB) tsim raws li kev sib txuas ntawm cov txheej txheem sib txawv. Lawv tau drilled qhov los ntawm txhua txheej ntawm PCB thiab raug plated los muab hluav taws xob txuas ntxiv. Los ntawm lub qhov muab kev sib txuas hluav taws xob muaj zog thiab yog qhov yooj yim los ua thiab kho. Txawm li cas los xij, lawv xav tau qhov loj me me, uas siv qhov chaw muaj txiaj ntsig ntawm PCB thiab txwv txoj kev xaiv.

Qhov muag tsis pom thiab faus vias yog lwm txoj kev sib txuas sib txuas uas muaj qhov zoo hauv kev siv qhov chaw thiab kev hloov pauv yooj yim.

Qhov muag tsis pom vias yog drilled los ntawm PCB nto thiab xaus rau hauv cov khaubncaws sab nraud povtseg yam tsis tau hla txhua txheej. Lawv tso cai rau kev sib txuas ntawm cov khaubncaws sab nraud povtseg thaum tawm hauv cov khaubncaws sab nraud povtseg tsis cuam tshuam. Qhov no tso cai rau kom siv tau zoo dua ntawm qhov chaw ntawm lub rooj tsavxwm thiab txo tus naj npawb ntawm cov tho qhov. faus vias, ntawm qhov tod tes, yog qhov uas tau kaw tag nrho nyob rau hauv cov khaubncaws sab nraud povtseg ntawm PCB thiab tsis txuas mus rau txheej txheej. Lawv muab kev sib txuas ntawm cov khaubncaws sab nraud povtseg yam tsis muaj kev cuam tshuam rau cov txheej txheem sab nrauv. faus vias muaj ntau qhov chaw txuag tau zoo dua li ntawm qhov-qhov thiab qhov muag tsis pom vim tias lawv tsis siv qhov chaw hauv txheej txheej.

Kev xaiv los ntawm qhov, qhov muag tsis pom, thiab faus vias yog nyob ntawm cov kev cai tshwj xeeb ntawm PCB tsim. Los ntawm qhov feem ntau yog siv rau hauv cov qauv yooj yim los yog qhov twg muaj zog thiab kho kom zoo yog qhov kev txhawj xeeb tseem ceeb. Hauv cov qauv siv high-density uas qhov chaw yog qhov tseem ceeb, xws li cov khoom siv tuav, smartphones, thiab laptops, qhov muag tsis pom thiab faus vias yog nyiam.

3.2 Micropore thiabHDI technology:

Microvias yog cov kab me me (feem ntau tsawg dua 150 microns) uas muab cov kev sib txuas siab sib txuas hauv PCBs. Lawv muab cov txiaj ntsig tseem ceeb hauv miniaturization, teeb liab kev ncaj ncees thiab kev hloov pauv yooj yim.

Microvias tuaj yeem muab faib ua ob hom: dhau-qhov microvias thiab dig muag microvias. Microvias yog tsim los ntawm qhov drilling qhov los ntawm sab saum toj ntawm PCB thiab txuas mus rau txhua txheej. Qhov muag tsis pom microvias, raws li lub npe qhia, tsuas yog txuas mus rau cov txheej txheem sab hauv thiab tsis nkag mus rau txhua txheej.

High-density interconnect (HDI) yog ib qho cuab yeej siv microvias thiab cov txheej txheem kev tsim khoom siab heev kom ua tau zoo dua Circuit Court ceev thiab kev ua haujlwm. HDI thev naus laus zis tso cai rau qhov kev tso kawm ntawm cov khoom me me thiab kev sib tw nruj dua, ua rau cov qauv me me thiab cov teeb liab siab dua. HDI thev naus laus zis muaj ntau qhov zoo dua li niaj hnub PCB thev naus laus zis hauv cov ntsiab lus ntawm miniaturization, txhim kho cov teeb liab tawm, txo cov teeb liab distortion, thiab txhim kho kev ua haujlwm. Nws tso cai rau cov txheej txheem ntau yam nrog ntau lub microvias, yog li ua kom luv luv ntawm kev sib txuas ntev thiab txo cov kab mob parasitic capacitance thiab inductance.

HDI thev naus laus zis tseem ua rau kev siv cov khoom siv siab heev xws li cov laminates siab thiab cov txheej nyias nyias, uas yog qhov tseem ceeb rau kev siv RF/microwave. Nws muab kev tswj hwm impedance zoo dua, txo cov teeb liab poob thiab ua kom ntseeg tau cov teeb liab ceev ceev.

3.3 Interlayer kev sib txuas cov ntaub ntawv thiab cov txheej txheem:

Kev xaiv cov ntaub ntawv sib txuas sib txuas thiab cov txheej txheem yog qhov tseem ceeb los ua kom muaj kev ua tau zoo ntawm hluav taws xob, kev ntseeg siab thiab kev tsim khoom ntawm PCBs. Qee cov khoom siv sib txuas sib txuas thiab cov txheej txheem feem ntau yog:

a) Tooj:Tooj liab yog dav siv nyob rau hauv conductive txheej thiab vias ntawm PCBs vim nws zoo heev conductivity thiab solderability. Nws feem ntau yog plated rau hauv lub qhov los muab kev sib txuas hluav taws xob txhim khu kev qha.

b) Soldering:Cov txheej txheem soldering, xws li yoj soldering lossis reflow soldering, feem ntau yog siv los ua hluav taws xob sib txuas ntawm cov qhov ntawm PCBs thiab lwm yam khoom siv. Siv cov nplaum nplaum rau ntawm qhov thiab siv cov cua sov kom yaj lub solder thiab tsim ib qho kev sib txuas txhim khu kev qha.

c) Electroplating:Cov txheej txheem electroplating xws li electroless tooj liab plating los yog electrolytic tooj liab yog siv rau phaj vias los txhim kho conductivity thiab xyuas kom zoo hluav taws xob sib txuas.

d) Kev sib txuas:Cov txheej txheem kev sib khi, xws li cov nplaum nplaum lossis cov thermocompression bonding, yog siv los koom cov txheej txheem txheej ua ke thiab tsim kev sib cuam tshuam zoo.

e) Cov khoom siv dielectric:Kev xaiv ntawm cov khoom siv dielectric rau PCB stackup yog ib qho tseem ceeb rau kev sib txuas ntawm interlayer. High zaus laminates xws li FR-4 los yog Rogers laminates feem ntau yog siv los xyuas kom meej lub teeb liab zoo thiab txo cov teeb liab poob.

3.4 Hla-sectional tsim thiab lub ntsiab lus:

Kev tsim qauv ntawm cov khoom sib dhos ntawm PCB stackup txiav txim siab cov khoom siv hluav taws xob thiab cov khoom siv sib txuas ntawm cov txheej txheem. Cov kev txiav txim siab tseem ceeb rau kev tsim qauv hla ntu muaj xws li:

a) Txheej txheej:Kev teeb tsa ntawm cov teeb liab, lub zog, thiab cov dav hlau hauv av hauv PCB stackup cuam tshuam cov teeb liab kev ncaj ncees, lub zog ruaj khov, thiab kev cuam tshuam hluav taws xob (EMI). Kev tso kawm kom raug thiab kev ua kom zoo ntawm cov teeb liab txheej nrog lub zog thiab cov dav hlau hauv av pab txo cov suab nrov sib txuas thiab xyuas kom tsis muaj kev rov qab los ntawm inductance.

b) Impedance tswj:Hla-seem tsim yuav tsum coj mus rau hauv tus account tswj impedance yuav tsum tau, tshwj xeeb tshaj yog rau high-ceev digital los yog RF/microwave signals. Qhov no suav nrog kev xaiv tsim nyog ntawm cov khoom siv dielectric thiab thicknesses kom ua tiav cov yam ntxwv xav tau impedance.

c) Thermal tswj:Kev tsim cov ntu ntu yuav tsum xav txog kev siv hluav taws xob zoo thiab kev tswj xyuas thermal. Kev tso cai ntawm lub zog thiab cov dav hlau hauv av, thermal vias, thiab cov khoom siv nrog cov tshuab ua kom txias (xws li cov dab dej kub) pab kom cov cua sov thiab tswj xyuas qhov kub thiab txias.

d) Mechanical ntseeg tau:Tshooj tsim yuav tsum xav txog kev ntseeg tau ntawm txhua yam, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas yuav raug thermal cycling lossis mechanical stress. Kev xaiv cov khoom tsim nyog, kev sib txuas cov txheej txheem, thiab kev teeb tsa kev teeb tsa pab ua kom muaj kev ncaj ncees thiab ua haujlwm ntev ntawm PCB.

4.Design Guidelines rau 16-Layer PCB

4.1 Txheej faib thiab faib:

Thaum tsim 16-txheej Circuit Court board, nws yog ib qho tseem ceeb uas yuav tsum tau ua tib zoo faib thiab faib cov khaubncaws sab nraud povtseg kom ua kom zoo dua qhov kev ua tau zoo thiab teeb liab kev ncaj ncees. Nov yog qee cov lus qhia rau kev faib qib

thiab kev faib tawm:

Txiav txim siab tus naj npawb ntawm cov teeb liab txheej yuav tsum tau:

Xav txog qhov nyuaj ntawm kev tsim Circuit Court thiab tus naj npawb ntawm cov teeb liab uas yuav tsum tau ua. Muab cov teeb liab txaus txaus kom haum rau txhua qhov kev xav tau, ua kom muaj chaw txaus thiab tsis txhob muaj ntau dhau.kev huam yuaj. Muab cov dav hlau hauv av thiab lub zog:

Muab tsawg kawg yog ob txheej txheej sab hauv rau hauv av thiab lub zog dav hlau. Lub dav hlau hauv av pab muab qhov kev siv ruaj khov rau cov teeb liab thiab txo qis kev cuam tshuam hluav taws xob (EMI). Lub dav hlau fais fab muab lub zog qis impedance xaim hluav taws xob uas pab txo qis qis qis.

Separate rhiab teeb liab txheej:

Nyob ntawm daim ntawv thov, nws yuav tsim nyog los cais cov teeb liab rhiab heev lossis cov teeb liab ceev ceev los ntawm cov txheej txheem nrov nrov lossis lub zog siab kom tsis txhob cuam tshuam thiab kev sib tham. Qhov no tuaj yeem ua tau los ntawm kev muab cov av tshwj xeeb lossis lub dav hlau fais fab ntawm lawv los yog siv cov txheej txheem cais.

Muab cov teeb liab sib npaug sib npaug:

Faib cov teeb liab txheej sib npaug thoob plaws hauv pawg thawj coj saib kom txo qis kev sib txuas ntawm cov teeb liab uas nyob ib sab thiab tuav cov teeb liab kev ncaj ncees. Tsis txhob tso cov teeb liab txheej ntawm ib sab ntawm ib qho chaw hauv tib qhov chaw kom txo qis interlayer crosstalk.

Xav txog high-frequency signals:

Yog tias koj tus qauv tsim muaj cov teeb liab ntau zaus, xav txog qhov tso cov teeb liab ntau zaus los ze zog rau cov txheej txheej sab nrauv kom txo tau cov kab sib kis tau zoo thiab txo qis kev nthuav tawm.

4.2 Routing thiab teeb liab routing:

Routing thiab teeb liab kab tsim tsim yog ib qho tseem ceeb los xyuas kom meej lub teeb liab kev ncaj ncees thiab txo qhov cuam tshuam. Nov yog qee cov lus qhia rau layout thiab teeb liab routing ntawm 16-txheej Circuit Court boards:

Siv cov kab dav dav rau cov teeb liab tam sim no:

Rau cov cim taw qhia uas muaj qhov siab tam sim no, xws li lub zog hluav taws xob thiab kev sib txuas hauv av, siv cov kab dav dav kom txo qis tsis kam thiab qhov hluav taws xob poob.

Sib piv impedance rau high-speed signals:

Rau cov teeb liab ceev ceev, xyuas kom meej tias cov kab impedance phim cov yam ntxwv impedance ntawm cov kab sib kis los tiv thaiv kev cuam tshuam thiab teeb liab attenuation. Siv cov txheej txheem tswj kev tsim qauv impedance thiab kho cov kab dav dav.

Txo cov kab ntev thiab cov ntsiab lus crossover:

Khaws cov kab ntev kom luv li sai tau thiab txo tus naj npawb ntawm cov ntsiab lus crossover kom txo cov kab mob parasitic capacitance, inductance, thiab cuam tshuam. Ua kom zoo tshaj qhov kev tso kawm thiab siv cov txheej txheem routing kom tsis txhob muaj cov kab ntev ntev.

Sib cais high-speed thiab low-speed signals:

Sib cais high-speed thiab low-speed signals kom txo tau qhov cuam tshuam ntawm lub suab nrov ntawm high-speed signals. Muab cov teeb liab ceev ceev rau ntawm cov teeb liab tshwj xeeb thiab ua kom lawv nyob deb ntawm lub zog siab lossis cov suab nrov.

Siv cov khub sib txawv rau cov teeb liab ceev:

Txhawm rau txo qis suab nrov thiab tswj cov teeb liab kev ncaj ncees rau kev kub ceev sib txawv, siv cov txheej txheem sib txawv sib txawv. Khaws cov impedance thiab ntev ntawm qhov sib txawv ua ke kom tsis txhob muaj teeb liab skew thiab crosstalk.

4.3 Pem hauv ntej txheej thiab fais fab txheej faib:

Kev faib tawm ntawm av thiab lub dav hlau fais fab yog qhov tseem ceeb kom ua tiav lub zog zoo thiab txo qhov cuam tshuam ntawm electromagnetic. Nov yog qee cov lus qhia rau hauv av thiab lub dav hlau fais fab ntawm 16-txheej Circuit Court boards:

Faib cov av tshwj xeeb thiab lub zog dav hlau:

Faib yam tsawg kawg yog ob txheej txheej rau hauv av thiab lub dav hlau fais fab. Qhov no pab txo qis hauv av voj voog, txo EMI, thiab muab txoj hauv kev qis-impedance rov qab rau cov teeb liab siab.

Sib cais cov dav hlau digital thiab analog av:

Yog tias tus qauv tsim muaj cov ntu digital thiab analog, nws raug pom zoo kom muaj cov dav hlau sib cais rau txhua ntu. Qhov no pab txo cov suab nrov sib txuas ntawm cov ntu digital thiab analog thiab txhim kho cov teeb liab kev ncaj ncees.

Muab cov dav hlau hauv av thiab lub zog ze rau cov phiaj xwm dav hlau:

Muab cov dav hlau hauv av thiab lub zog nyob ze rau cov teeb liab dav hlau uas lawv pub kom txo qis qhov chaw voj voog thiab txo cov suab nrov.

Siv ntau lub vias rau lub dav hlau fais fab:

Siv ntau lub vias los txuas rau lub dav hlau fais fab kom sib npaug sib faib lub zog thiab txo lub zog dav hlau impedance. Qhov no pab txo cov khoom siv hluav taws xob tsawg thiab ua kom lub zog ruaj khov.

Tsis txhob nqaim caj dab hauv lub dav hlau fais fab:

Tsis txhob nqaim caj dab hauv lub dav hlau fais fab vim tias lawv tuaj yeem ua rau muaj neeg coob coob tam sim no thiab ua rau muaj kev tawm tsam, ua rau muaj hluav taws xob poob thiab lub dav hlau tsis muaj zog. Siv cov kev sib txuas muaj zog ntawm qhov sib txawv ntawm lub dav hlau fais fab.

4.4 Thermal ncoo thiab ntawm kev tso kawm:

Kev tso chaw zoo ntawm cov ntaub qhwv thermal thiab vias yog ib qho tseem ceeb kom ua tau zoo dissipating tshav kub thiab tiv thaiv cov khoom los ntawm overheating. Nov yog qee cov lus qhia rau thermal ncoo thiab ntawm kev tso rau ntawm 16-txheej Circuit Court boards:

Muab cov ntaub qhwv thermal tso rau hauv cov khoom ua kom sov:

Txheeb xyuas cov khoom siv hluav taws xob tsim hluav taws xob (xws li lub tshuab hluav taws xob lossis lub zog IC) thiab tso lub thermal ncoo ncaj qha hauv qab nws. Cov thermal pads no muab txoj hauv kev thermal ncaj qha los hloov cov cua sov mus rau sab hauv thermal txheej.

Siv ntau yam thermal vias rau cua sov dissipation:

Siv ntau lub thermal vias los txuas cov txheej txheem thermal thiab txheej txheej los muab cov cua sov kom zoo. Cov vias no tuaj yeem muab tso rau hauv ib qho qauv staggered nyob ib ncig ntawm lub thermal ncoo kom ua tiav txawm tias cua sov.

Xav txog thermal impedance thiab txheej txheej txheej:

Thaum tsim thermal vias, xav txog cov thermal impedance ntawm lub rooj tsavxwm cov khoom thiab txheej txheej stackup.Optimize ntawm qhov loj thiab qhov sib txawv kom txo tau cov thermal tsis kam thiab ua kom kub dissipation.

4.5 Cheebtsam Qhov Chaw thiab Cov Teeb Pom Kev Zoo:

Kev muab cov khoom pov thawj zoo yog qhov tseem ceeb rau kev tswj cov teeb liab kev ncaj ncees thiab txo qis kev cuam tshuam. Nov yog qee cov lus qhia rau kev tso cov khoom ntawm 16-txheej Circuit Court board:

Pawg muaj feem cuam tshuam:

Pab pawg muaj feem xyuam nrog cov khoom uas yog ib feem ntawm tib lub subsystem los yog muaj zog hluav taws xob sib cuam tshuam. Qhov no txo cov kab ntev thiab txo cov teeb liab attenuation.

Khaws cov khoom siv ceev ceev kom ze:

Muab cov khoom siv ceev ceev, xws li cov oscillators siab lossis microcontrollers, nyob ze rau ib leeg kom txo qis qhov ntev thiab ua kom lub teeb pom kev zoo.

Txo cov kab ntev ntawm cov cim tseem ceeb:

Txo qhov ntev ntawm cov cim tseem ceeb kom txo qis kev nthuav tawm qeeb thiab teeb liab attenuation. Tso cov khoom no kom ze li sai tau.

Separate rhiab Cheebtsam:

Sib cais cov suab nrov-sensitive Cheebtsam, xws li analog Cheebtsam los yog qis-theem sensors, los ntawm high-power los yog nrov Cheebtsam kom txo kev cuam tshuam thiab tswj cov teeb liab kev ncaj ncees.

Xav txog decoupling capacitor:

Muab cov decoupling capacitors kom ze li sai tau rau lub hwj chim pins ntawm txhua yam kom muab lub zog huv si thiab txo qhov kev hloov pauv ntawm qhov hluav taws xob tsawg. Cov capacitors no pab tswj cov khoom siv hluav taws xob ruaj khov thiab txo cov suab nrov sib txuas.

5.Simulation thiab tsom xam cov cuab yeej rau Stack-Up Design

5.1 3D qauv thiab simulation software:

3D qauv thiab simulation software yog ib qho tseem ceeb rau stackup tsim vim hais tias nws tso cai rau cov neeg tsim qauv tsim virtual sawv cev ntawm PCB stackups. Lub software tuaj yeem pom cov khaubncaws sab nraud povtseg, cov khoom, thiab lawv cov kev sib cuam tshuam ntawm lub cev. Los ntawm simulating lub stackup, cov neeg tsim qauv tuaj yeem txheeb xyuas cov teeb meem muaj peev xwm xws li teeb liab crosstalk, EMI, thiab kev txwv kev siv tshuab. Nws kuj tseem pab txheeb xyuas qhov kev teeb tsa ntawm cov khoom siv thiab ua kom zoo rau tag nrho PCB tsim.

5.2 Cov cuab yeej tsom xam kev ncaj ncees:

Cov cuab yeej ntsuas kev ncaj ncees yog qhov tseem ceeb rau kev txheeb xyuas thiab ua kom zoo dua qhov kev ua haujlwm hluav taws xob ntawm PCB stackups. Cov cuab yeej no siv lej algorithms los simulate thiab txheeb xyuas tus cwj pwm ntawm cov teeb liab, suav nrog kev tswj impedance, teeb pom kev zoo, thiab suab nrov sib txuas. Los ntawm kev ua simulation thiab kev tsom xam, cov neeg tsim qauv tuaj yeem txheeb xyuas cov teeb meem kev ncaj ncees thaum ntxov hauv cov txheej txheem tsim thiab ua kom tsim nyog hloov kho kom ntseeg tau tias cov teeb liab kis tau zoo.

5.3 Thermal tsom xam cov cuab yeej:

Cov cuab yeej ntsuas cua sov ua lub luag haujlwm tseem ceeb hauv kev tsim qauv tsim los ntawm kev txheeb xyuas thiab ua kom zoo dua thermal tswj ntawm PCBs. Cov cuab yeej no simulate tshav kub dissipation thiab kub faib nyob rau hauv txhua txheej ntawm pawg. Los ntawm kev ua qauv zoo ntawm lub zog dissipation thiab cua sov txoj hauv kev, cov neeg tsim qauv tuaj yeem txheeb xyuas qhov kub thiab txias, ua kom zoo dua qhov tso ntawm cov txheej tooj liab thiab thermal vias, thiab xyuas kom meej qhov txias ntawm cov khoom tseem ceeb.

5.4 Tsim rau manufacturability:

Kev tsim qauv rau kev tsim khoom yog ib qho tseem ceeb ntawm kev tsim stackup. Muaj ntau yam khoom siv software muaj uas tuaj yeem pab xyuas kom meej tias cov pawg xaiv tau tsim tau zoo. Cov cuab yeej no muab cov lus tawm tswv yim txog qhov ua tau raws li qhov xav tau stackup, suav nrog cov khoom muaj xws li cov khoom muaj, txheej thickness, txheej txheem tsim khoom, thiab cov nqi tsim khoom. Lawv pab cov neeg tsim qauv txiav txim siab paub txog kev txhim kho stacking kom yooj yim rau kev tsim khoom, txo qhov kev pheej hmoo ntawm kev ncua, thiab nce yields.

6.Step-by-Step Design Process rau 16-Layer PCBs

6.1 Cov kev xav tau pib sau:

Hauv cov kauj ruam no, sau tag nrho cov kev cai tsim nyog rau 16-txheej PCB tsim. Nkag siab txog PCB qhov kev ua haujlwm, xav tau kev ua haujlwm hluav taws xob, kev txwv tsis pub siv tshuab, thiab cov qauv tsim tshwj xeeb lossis cov qauv uas yuav tsum tau ua raws.

6.2 Kev faib khoom thiab kev teeb tsa:

Raws li qhov yuav tsum tau ua, faib cov khoom ntawm PCB thiab txiav txim siab lawv cov kev npaj. Xav txog yam xws li teeb liab kev ncaj ncees, kev xav txog thermal, thiab kev txwv kev siv tshuab. Pawg pawg raws li cov yam ntxwv ntawm hluav taws xob thiab muab tso rau hauv lub rooj tsavxwm kom txo qis kev cuam tshuam thiab ua kom zoo dua cov teeb liab ntws.

6.3 Stack-up tsim thiab txheej txheej:

Txiav txim siab cov txheej txheem tsim rau 16-txheej PCB. Xav txog yam xws li dielectric tas li, thermal conductivity, thiab tus nqi los xaiv cov khoom tsim nyog. Muab cov teeb liab, lub zog, thiab cov dav hlau hauv av raws li qhov xav tau ntawm hluav taws xob. Muab cov dav hlau hauv av thiab lub zog sib npaug kom ntseeg tau tias muaj kev sib npaug thiab txhim kho cov teeb liab kev ncaj ncees.

6.4 Teeb liab routing thiab routing optimization:

Nyob rau hauv cov kauj ruam no, cov teeb liab kab yog hla ntawm cov khoom los xyuas kom meej impedance tswj, teeb liab kev ncaj ncees, thiab txo cov teeb liab crosstalk. Ua kom zoo tshaj plaws kom txo tau qhov ntev ntawm cov cim tseem ceeb, tsis txhob hla cov kab rhiab, thiab tswj kev sib cais ntawm cov teeb liab siab ceev thiab qis. Siv cov khub sib txawv thiab cov txheej txheem tswj impedance routing thaum xav tau.

6.5 Interlayer kev sib txuas thiab ntawm kev tso kawm:

Npaj qhov kev tso kawm ntawm kev sib txuas vias ntawm cov khaubncaws sab nraud povtseg. Txiav txim siab qhov tsim nyog ntawm hom, xws li los ntawm lub qhov lossis qhov qhov muag tsis pom, raws li cov txheej txheem hloov pauv thiab cov khoom sib txuas. Optimize ntawm layout kom txo cov teeb liab kev xav, impedance discontinuities, thiab tswj txawm tis ntawm PCB.

6.6 Qhov kawg tsim pov thawj thiab simulation:

Ua ntej kev tsim khoom, qhov kawg tsim kev txheeb xyuas thiab simulation yog ua. Siv cov cuab yeej simulation los txheeb xyuas PCB cov qauv tsim rau cov teeb liab kev ncaj ncees, lub zog ncaj ncees, kev coj tus cwj pwm thermal, thiab kev tsim khoom. Txheeb xyuas tus qauv tsim tawm tsam thawj qhov yuav tsum tau ua thiab ua qhov tsim nyog hloov kho kom ua tau zoo thiab ua kom muaj kev tsim khoom.

Sib koom tes thiab sib txuas lus nrog lwm tus neeg muaj feem xws li hluav taws xob engineers, mechanical engineers, thiab manufacturing teams thoob plaws hauv cov txheej txheem tsim los xyuas kom meej tias txhua yam yuav tsum tau ua thiab cov teeb meem yuav daws tau. Tsis tu ncua tshuaj xyuas thiab rov ua cov qauv tsim los koom nrog kev tawm tswv yim thiab kev txhim kho.

7.Industry Cov Kev Cai Zoo Tshaj Plaws thiab Kev Tshawb Fawb Txog Kev Tshawb Fawb

7.1 Cov teeb meem ua tau zoo ntawm 16-txheej PCB tsim:

Case Study 1:Shenzhen Capel Technology Co., Ltd. ntse tsim ib 16-txheej PCB rau high-ceev network khoom. Los ntawm kev ua tib zoo xav txog kev ncaj ncees thiab kev faib hluav taws xob, lawv ua tiav kev ua tau zoo dua thiab txo qhov cuam tshuam ntawm electromagnetic. Tus yuam sij rau lawv txoj kev vam meej yog qhov ua kom zoo tshaj plaws ntawm pawg tsim siv kev tswj hwm impedance routing thev naus laus zis.

Case Study 2:Shenzhen Capel Technology Co., Ltd. tsim 16-txheej PCB rau cov khoom siv kho mob nyuaj. Los ntawm kev siv kev sib xyaw ua ke ntawm nto mount thiab los ntawm lub qhov, lawv tau ua tiav ib qho kev sib cog lus tsis tau muaj zog. Ua tib zoo muab tso rau hauv qhov chaw thiab ua haujlwm tau zoo kom ntseeg tau cov teeb liab zoo thiab kev ntseeg siab.

7.2 Kawm los ntawm kev ua tsis tiav thiab zam qhov kev poob siab:

Case Study 1:Qee cov tuam txhab pcb tau ntsib teeb meem teeb meem kev ncaj ncees hauv 16-txheej PCB tsim khoom siv sib txuas lus. Cov laj thawj rau kev ua tsis tiav yog qhov tsis txaus ntawm kev tswj hwm impedance thiab tsis muaj kev faib dav hlau hauv av. Cov lus qhia tau kawm yog ua tib zoo txheeb xyuas cov teeb meem kev ncaj ncees thiab ua raws li cov txheej txheem tswj kev tswj xyuas nruj.

Case Study 2:Qee tus neeg tsim khoom pcb tau ntsib cov teeb meem kev tsim khoom nrog nws 16-txheej PCB vim qhov tsim qauv tsis yooj yim. Kev siv ntau dhau ntawm qhov muag tsis pom kev thiab cov khoom ntim ntom ntom ua rau kev tsim khoom thiab kev sib dhos nyuaj. Cov lus qhia tau kawm yog txhawm rau txhawm rau sib npaug ntawm kev tsim qauv tsis yooj yim thiab kev tsim khoom tau muab lub peev xwm ntawm cov chaw tsim khoom PCB xaiv.

Txhawm rau kom tsis txhob muaj qhov pitfalls thiab pitfalls hauv 16-txheej PCB tsim, nws yog ib qho tseem ceeb rau:

a. Ua tib zoo nkag siab txog qhov yuav tsum tau ua thiab kev txwv ntawm tus qauv tsim.

b.Stacked configurations uas optimize teeb liab kev ncaj ncees thiab lub hwj chim faib. c. Ua tib zoo faib thiab npaj cov khoom kom ua tau zoo thiab ua kom yooj yim rau kev tsim khoom.

d. Ua kom muaj cov txheej txheem routing kom raug, xws li tswj cov impedance thiab tsis txhob siv ntau dhau ntawm qhov muag tsis pom.

e. Sib koom tes thiab sib txuas lus zoo nrog txhua tus neeg muaj feem cuam tshuam nrog cov txheej txheem tsim, suav nrog cov kws tsim hluav taws xob thiab tshuab tshuab thiab pab pawg tsim khoom.

f.Ua tiav kev tsim qauv pov thawj thiab simulation txhawm rau txheeb xyuas thiab kho cov teeb meem muaj peev xwm ua ntej tsim khoom.

Post lub sij hawm: Sep-26-2023

Rov qab