Taw qhia

Flexible printed circuit boards (FPCs) yog kev hloov pauv ntawm kev lag luam hluav taws xob, muab qhov tsis muaj qhov sib piv thiab kev tsim muaj peev xwm. Raws li qhov kev thov ntau dua thiab cov khoom siv hluav taws xob sib sib zog txuas ntxiv zuj zus, FPCs ua lub luag haujlwm tseem ceeb hauv kev tsim cov kev daws teeb meem tshiab thiab hloov tau yooj yim. Ntawm ntau hom FPCs, 2-txheej flexible PCBs sawv tawm rau lawv cov kev siv ntau yam thiab siv tau hauv ntau qhov kev lag luam. Hauv phau ntawv qhia no, peb yuav tshawb nrhiav cov qauv tsim thiab kev tsim qauv ntawm 2-txheej hloov pauv PCBs, tsom mus rau lawv cov ntawv thov, cov khoom siv, cov lus qhia tshwj xeeb, thiab cov khoom tiav.

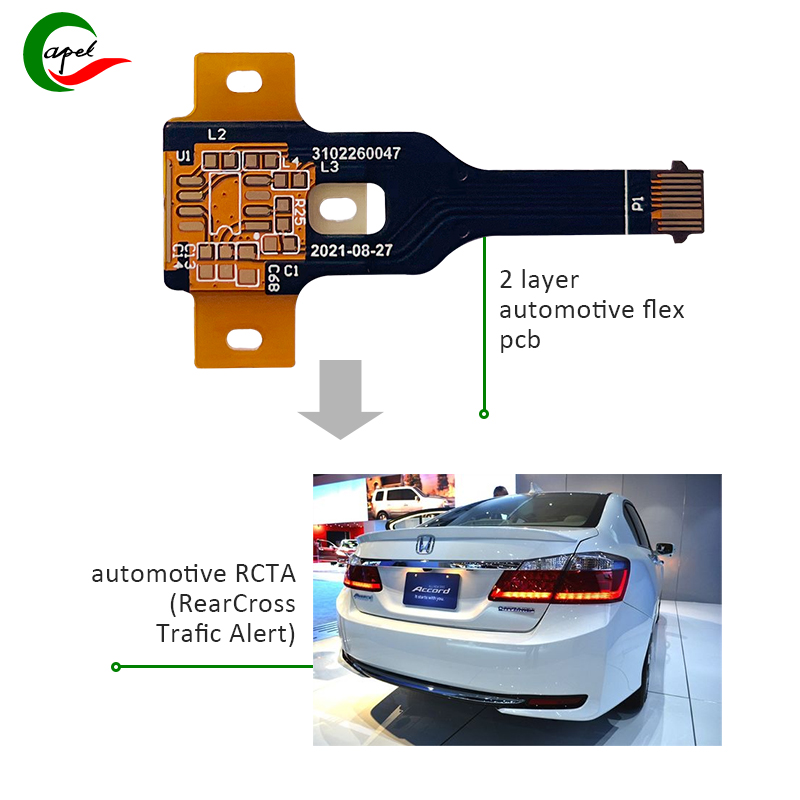

Yam khoom:2-Txheej Flexible PCB

Lub 2-txheej flex PCB, tseem hu ua ob-sided flex Circuit Court, yog ib qho yooj yim luam tawm Circuit Board uas muaj ob txheej txheej txheej sib cais los ntawm cov txheej txheem dielectric. Qhov kev teeb tsa no muab cov neeg tsim qauv nrog kev yooj yim rau txoj kab ntawm ob sab ntawm lub substrate, tso cai rau kev tsim ntau dua thiab kev ua haujlwm. Lub peev xwm los txhim kho cov khoom ntawm ob sab ntawm lub rooj tsavxwm ua rau 2-txheej flex PCBs zoo tagnrho rau cov ntawv thov uas xav tau cov khoom siv siab thiab qhov chaw txwv.

Daim ntawv thov

Lub versatility ntawm 2-txheej flex PCBs ua rau lawv haum rau ntau yam kev siv hauv kev lag luam sib txawv. Ib qho ntawm cov ntawv thov tseem ceeb ntawm 2-txheej hloov pauv PCB yog nyob rau hauv kev lag luam tsheb hluav taws xob. Hauv kev lag luam tsheb, qhov chaw thiab qhov hnyav yog qhov tseem ceeb, thiab 2-txheej flex PCBs muab qhov yooj yim kom ua tau raws li cov kev cai no. Lawv yog siv nyob rau hauv automotive tswj systems, sensors, teeb pom kev zoo, infotainment systems, thiab lwm yam. Kev lag luam automotive cia siab rau cov kav ntev thiab kev ntseeg siab ntawm 2-txheej hloov pauv PCBs kom ntseeg tau tias kev ua tau zoo ib yam hauv cov chaw nyuaj.

Ntxiv nrog rau kev siv tsheb, 2-txheej hloov pauv PCBs tau siv dav hauv cov khoom siv hluav taws xob, khoom siv kho mob, aerospace thiab cov cuab yeej siv khoom lag luam. Lawv muaj peev xwm hloov mus rau cov duab tsis sib xws, txo qhov hnyav thiab nce kev ntseeg tau ua rau lawv tsis muaj peev xwm nyob hauv ntau yam khoom siv hluav taws xob.

Khoom siv

2-Layer Flexible PCB xaiv cov khoom tseem ceeb hauv kev txiav txim siab ntawm pawg thawj coj saib kev ua haujlwm, kev ntseeg siab, thiab kev tsim khoom. Cov ntaub ntawv tseem ceeb siv los tsim 2-txheej PCB hloov tau muaj xws li polyimide (PI) zaj duab xis, tooj liab, thiab nplaum. Polyimide yog cov khoom siv substrate ntawm kev xaiv vim nws zoo heev thermal stability, yooj thiab kub tsis kam. Copper foil yog siv los ua cov khoom siv hluav taws xob, uas muaj qhov zoo tshaj plaws conductivity thiab solderability. Adhesive cov ntaub ntawv yog siv los khi cov txheej txheem PCB ua ke, ua kom cov neeg kho tshuab ruaj khov thiab tswj xyuas kev ncaj ncees.

Kab dav, kab sib nrug thiab board thickness

Thaum tsim 2-txheej PCB hloov tau yooj yim, kab dav, kab sib nrug thiab board thickness yog qhov tseem ceeb, uas cuam tshuam ncaj qha rau kev ua haujlwm thiab kev tsim khoom ntawm lub rooj tsavxwm. Cov kab dav dav thiab kab sib nrug rau 2-txheej hloov pauv PCBs tau teev tseg raws li 0.2mm / 0.2mm, qhia qhov tsawg kawg nkaus ntawm cov kab hluav taws xob thiab qhov sib txawv ntawm lawv. Cov qhov ntev no yog ib qho tseem ceeb los xyuas kom meej lub teeb pom kev ncaj ncees, kev tswj xyuas impedance, thiab kev txhim khu kev qha thaum sib dhos. Tsis tas li ntawd, board thickness ntawm 0.2mm +/- 0.03mm plays lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov yooj yim, khoov lub vojvoog thiab tag nrho cov khoom siv kho tshuab ntawm 2-txheej flex PCB.

Yam tsawg kawg nkaus qhov loj thiab qhov chaw kho mob

Kev ua tiav qhov tseeb thiab zoo ib yam ntawm qhov ntau thiab tsawg yog qhov tseem ceeb rau 2-txheej hloov pauv PCB tsim, tshwj xeeb tshaj yog muab cov qauv me me ntawm cov khoom siv hluav taws xob. Qhov tshwj xeeb qhov tsawg kawg nkaus qhov loj ntawm 0.1 hli qhia lub peev xwm ntawm 2-txheej flex PCBs kom haum rau cov khoom me me thiab ntom ntom. Tsis tas li ntawd, kev kho saum npoo ua lub luag haujlwm tseem ceeb hauv kev txhim kho hluav taws xob kev ua haujlwm thiab kev ua haujlwm ntawm PCBs. Electroless Nickel Immersion Kub (ENIG) nrog lub thickness ntawm 2-3uin yog ib qho kev xaiv rau 2-txheej flexible PCBs thiab muaj zoo corrosion kuj, flatness, thiab solderability. ENIG kev kho mob saum npoo yog qhov tshwj xeeb rau kev ua kom zoo-pitch Cheebtsam thiab ua kom ntseeg tau cov pob qij txha txhim khu kev qha.

Impedance thiab kam rau ua

Hauv kev siv high-speed digital thiab analog, impedance tswj yog qhov tseem ceeb rau kev tswj cov teeb liab kev ncaj ncees thiab txo cov teeb liab distortion. Txawm hais tias tsis muaj qhov tshwj xeeb impedance qhov tseem ceeb, muaj peev xwm tswj tau qhov impedance ntawm 2-txheej flex PCB yog qhov tseem ceeb rau kev ua tau zoo ntawm cov khoom siv hluav taws xob. Tsis tas li ntawd, qhov kam rau ua tau teev tseg raws li ± 0.1mm, uas yog hais txog qhov tso cai sib txawv thaum lub sijhawm tsim khoom. Kev tswj nruj nruj yog qhov tseem ceeb rau kev ua kom raug thiab sib xws hauv cov khoom kawg, tshwj xeeb tshaj yog thaum cuam tshuam nrog micro-features thiab complex designs.

2 Txheej Flexible PCB Prototyping txheej txheem

Prototyping yog ib theem tseem ceeb nyob rau hauv 2-txheej flex PCB txoj kev loj hlob, tso cai rau cov neeg tsim qauv los xyuas qhov tsim, kev ua haujlwm, thiab kev ua haujlwm ua ntej ua tiav kev tsim khoom. Cov txheej txheem prototyping suav nrog ntau cov kauj ruam tseem ceeb, suav nrog kev tsim qauv, kev xaiv cov khoom, kev tsim khoom, thiab kev sim. Kev txheeb xyuas tus qauv tsim kom ntseeg tau tias lub rooj tsavxwm ua tau raws li qhov yuav tsum tau ua thiab kev ua haujlwm, thaum xaiv cov khoom siv suav nrog xaiv cov substrate uas tsim nyog, cov khoom siv hluav taws xob thiab kev kho saum npoo raws li daim ntawv thov thiab kev ua haujlwm.

Lub fabrication ntawm 2-txheej hloov tau PCB prototypes koom nrog kev siv cov cuab yeej tshwj xeeb thiab cov txheej txheem los tsim cov txheej txheem hloov tau yooj yim, siv cov qauv siv hluav taws xob, thiab sib sau ua ke. Advanced manufacturing txuj ci xws li laser drilling, xaiv plating thiab tswj impedance routing yog siv los ua kom tiav qhov yuav tsum tau muaj functionality thiab kev ua tau zoo cwj pwm. Thaum cov qauv tsim, kev sim nruj thiab kev siv tau zoo yog ua los ntsuas kev ua haujlwm ntawm hluav taws xob, kev ua haujlwm yooj yim thiab kev ntseeg siab nyob rau hauv ntau yam ib puag ncig. Kev tawm tswv yim los ntawm qib prototyping pab tsim kev txhim kho thiab txhim kho, thaum kawg ua rau muaj zog thiab txhim khu kev qha 2-txheej hloov pauv PCB tsim npaj rau ntau lawm.

2 Txheej Flexible PCB - FPC Tsim thiab Prototyping txheej txheem

Xaus

Hauv cov ntsiab lus, 2-txheej flex PCBs sawv cev rau cov kev daws teeb meem rau cov khoom siv hluav taws xob niaj hnub no, muab kev hloov pauv tsis sib xws, kev ntseeg siab thiab kev ua haujlwm. Nws ntau yam kev siv, cov ntaub ntawv siab heev, cov lus qhia meej meej thiab cov txheej txheem prototyping ua rau nws yog ib qho tseem ceeb hauv kev lag luam hluav taws xob. Raws li kev siv thev naus laus zis txuas ntxiv mus, 2-txheej hloov pauv PCBs yuav tsis ua rau muaj lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv hluav taws xob tshiab uas ua tau raws li cov kev xav tau ntawm lub ntiaj teb niaj hnub no. Txawm hais tias nyob rau hauv tsheb, cov neeg siv khoom siv hluav taws xob, khoom siv kho mob lossis aerospace, kev tsim thiab kev tsim qauv ntawm 2-txheej hloov pauv PCBs yog qhov tseem ceeb rau kev tsav lub nthwv dej tom ntej ntawm kev tsim kho hluav taws xob.

Post lub sij hawm: Feb-23-2024

Rov qab