Taw qhia: Optimizingrigid-flexible PCB kev daws teeb meemkom ua tau raws li qhov xav tau ntawm kev lag luam sib txawv

Qhov kev thov rau lub tswv yim tshiab, ua tau zoo, thiab txhim khu kev qha cov khoom siv hluav taws xob tau nce ntau, ua rau muaj kev loj hlob sai ntawm kev lag luam rigid-flex board. Raws li tus kws tshaj lij PCB uas muaj kev paub dhau los nrog 15 xyoo ntawm kev siv tes ua haujlwm hauv kev tsim thiab tsim khoom, Kuv tau ntsib thiab ua tiav kev daws teeb meem ntau yam kev lag luam tshwj xeeb kom xa cov kev daws teeb meem zoo tshaj plaws rau peb cov neeg siv khoom.Hauv tsab xov xwm no, kuv yuav nthuav tawm cov ntaub ntawv tshawb fawb txog kev tsom mus rau yuav ua li cas 2-txheej rigid-flex PCBs tuaj yeem pab txhim kho cov txheej txheem tsim khoom, txhim kho cov khoom zoo, thiab ua tau raws li cov neeg siv khoom sib txawv.

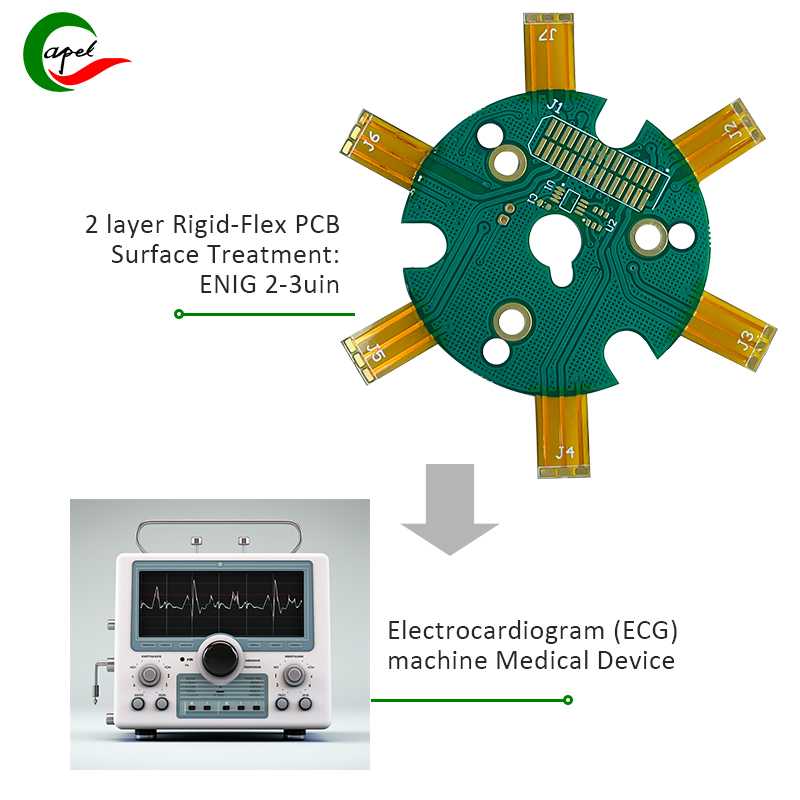

Case study 1: Simplifying the assembly process using 2-layer rigid-flex PCB

Simplifying lub Rooj Sib Tham Txheej Txheem Sib Tw:

Ib tus neeg tau txais txiaj ntsig zoo hauv kev lag luam khoom siv kho mob tau nrhiav peb cov kws tshaj lij los txhim kho cov txheej txheem sib dhos ntawm lawv cov cuab yeej saib xyuas lub cev. Lub compact xwm ntawm lub cuab yeej xav tau ib tug PCB uas muaj peev xwm integrate seamlessly nrog lub complex vaj tse tsim thaum muab qhov tsim nyog rigidity thiab yooj los tiv thaiv kev siv niaj hnub ntawm cov cuab yeej.

Kev daws:

Los ntawm kev siv cov txiaj ntsig ntawm 2-txheej rigid-flex PCB thev naus laus zis, peb tuaj yeem ua kom yooj yim ntawm cov txheej txheem sib dhos los ntawm kev tshem tawm qhov xav tau ntxiv kev sib txuas, txuas, thiab xaim. Cov qauv nruj-flex ua rau muaj kev sib koom ua ke ntawm cov khoom siv qhov ntev, txo cov hneev taw tag nrho thaum txhim kho cov qauv kev ntseeg siab.

Cov txiaj ntsig:

Kev siv ntawm 2-txheej rigid-flex PCB tsis yog tsuas yog ua kom cov cuab yeej sib dhos tab sis kuj pab txhim kho kev ntseeg tau thiab kav ntev. Kev txo cov khoom suav thiab kev sib txuas yooj yim muaj qhov cuam tshuam zoo rau tag nrho cov nqi-zoo ntawm cov khoom thaum ua tau raws li cov qauv kev cai nruj.

Case Study 2: Txhim kho Durability thiab Reliability hauv Aerospace Applications nrog 2-Layer Rigid-Flex PCB

Txhim kho Durability hauv Aerospace Applications Challenge:

Lub tuam txhab ua haujlwm aerospace tau sib tw peb los tsim cov kev daws teeb meem ruaj khov thiab ruaj khov rau nws cov tshuab avionics siab heev. Rigid-flex PCBs yuav tsum muaj peev xwm tiv taus qhov kub hloov pauv thiab kev ntxhov siab ntawm cov tshuab thiab muab kev ua haujlwm tsis muaj kev cuam tshuam hauv cov huab cua hnyav.

Kev daws:

Kev siv peb cov kev paub dhau los hauv kev xaiv cov khoom siv thiab kev tsim kho kom zoo, peb tsim 2-txheej rigid-flex luam tawm Circuit Board siv cov laminates ua haujlwm siab thiab hloov tau yooj yim substrates nrog thermal stability thiab mechanical resilience. Tus tsim ua tau raws li qhov chaw nruj nruj nyob rau hauv avionics systems, kom ntseeg tau tias cov teeb liab ruaj khov thiab tsis muaj teeb meem ua haujlwm.

Qhov tshwm sim:

Siv 2-txheej rigid-flex PCB pawg thawj coj saib tsis yog tsuas yog txhim kho cov kav ntev thiab kev ua haujlwm ntawm avionics system, tab sis kuj tseem txo qhov hnyav ntawm tag nrho cov kab ke. Kev txhim kho kev ntseeg siab thiab kev ua tau zoo ntawm rigid-flex PCBs pab txuas ntxiv lub neej kev pab cuam ntawm avionics systems, ua rau cov neeg siv khoom ntseeg siab hauv peb cov kev daws teeb meem.

Case Study 3: Powering Wearable Technology with Custom Designed 2-Layer Rigid-Flex PCB

Kev Sib Tw ntawm Txhim Kho Wearable Technology:

Hauv lub ntiaj teb tshiab ntawm kev siv thev naus laus zis thev naus laus zis, cov neeg siv khoom nrhiav cov kev daws teeb meem hloov tau yooj yim thiab ruaj khov rau lawv cov khoom siv zog tom ntej thiab kev saib xyuas kev noj qab haus huv. Qhov kev sib tw yog los tsim cov PCBs uas tuaj yeem ua tau raws li qhov sib txawv ntawm cov khoom siv hnav, tiv taus kev txav mus los, thiab tiv taus hws thiab ya raws.

Kev daws:

Leveraging qhov yooj yim hauv paus ntawm 2-txheej rigid-flex PCBs, peb tsim ib tug kev cai daws teeb meem uas integrates seamlessly nrog lub wearable ntaus ntawv daim ntawv tseem ceeb thaum ua kom ruggedness thiab kev ntseeg tau. Tus txheej txheem tsim yuav tsum tau ua tib zoo xav txog cov ntaub ntawv hloov tau yooj yim, khoov lub vojvoog, thiab miniaturization kom haum rau qhov loj me ntawm cov khoom siv hnav.

Cov txiaj ntsig:

Kev sib koom ua ke ntawm 2-txheej rigid-flex Circuit Court board ua pov thawj hauv kev ua tiav cov neeg siv khoom lub hom phiaj ntawm kev xa cov khoom siv ergonomic thiab ruaj khov. Custom-designed rigid-flex PCBs muab kev hloov pauv tsis sib xws yam tsis muaj kev cuam tshuam hluav taws xob ua haujlwm, paving txoj hauv kev rau kev txhim kho cov neeg siv khoom thiab txuas ntxiv lub neej ntawm cov khoom.

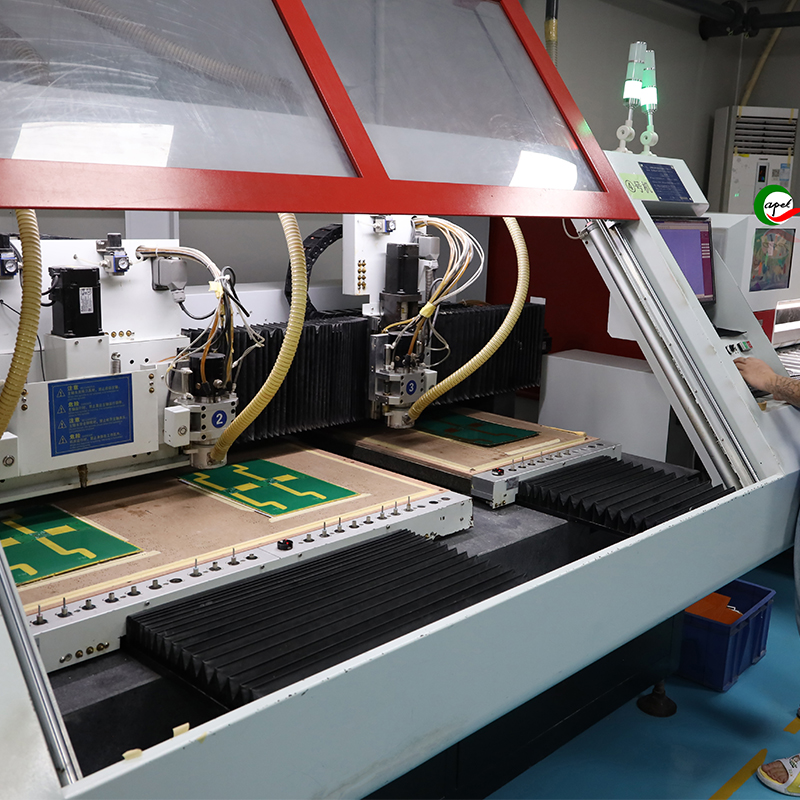

2 Txheej Rigid Flex PCB Fabrication txheej txheem

Xaus: Txhawb kev tsim kho tshiab thiab ua tau zoo hauv kev lag luam rigid-flex board

Nyob rau hauv lub dynamic toj roob hauv pes ntawm rigid-flex PCB tsim thiab tsim, daim ntawv thov ntawm 2-txheej rigid-flex PCBs tau tshwm sim raws li ib tug transformative kev daws teeb meem rau countless kev lag luam-kev sib tw. Los ntawm cov ntaub ntawv kev tshawb fawb tau nthuav tawm, nws yog qhov tseeb tias ntau yam, kev ntseeg siab thiab kev hloov pauv ntawm 2-txheej rigid-flex PCB thev naus laus zis ua rau cov txheej txheem tsim khoom thiab txhim kho txhua yam los ntawm cov cuab yeej kho mob mus rau kev siv dav hlau thiab siv thev naus laus zis. khoom zoo. Raws li tus kws tshaj lij engineers, nws yog ib qho tseem ceeb kom nyob twj ywm nyob rau hauv lub forefront ntawm technologies kev nce qib thiab leverage no kev txawj ntse kom xa customized, cuam tshuam kev daws teeb meem uas tsav innovation thiab zoo tshaj plaws nyob rau hauv lub nruj-flex kev lag luam.

Post lub sij hawm: Jan-23-2024

Rov qab