Hauv lub ntiaj teb kev hloov pauv sai ntawm cov khoom siv hluav taws xob, qhov kev thov rau PCB ua haujlwm siab tsis tau ntau dua. Ntawm ntau hom PCB, 6-txheej PCB sawv tawm vim nws muaj peev xwm ua kom haum raws li kev sib tw hauv Circuit Court thaum tswj xyuas cov ntawv cog lus. Tsab ntawv xov xwm no delves rau hauv qhov intricacies ntawm 6L PCB, tshwj xeeb tshaj yog cov uas muaj qhov muag tsis pom kev, thiab tshawb txog lub luag haujlwm ntawm PCB cov tuam txhab hauv kev xa cov khoom zoo nrog cov khoom tiav zoo li EING.

Nkag siab txog 6L PCB

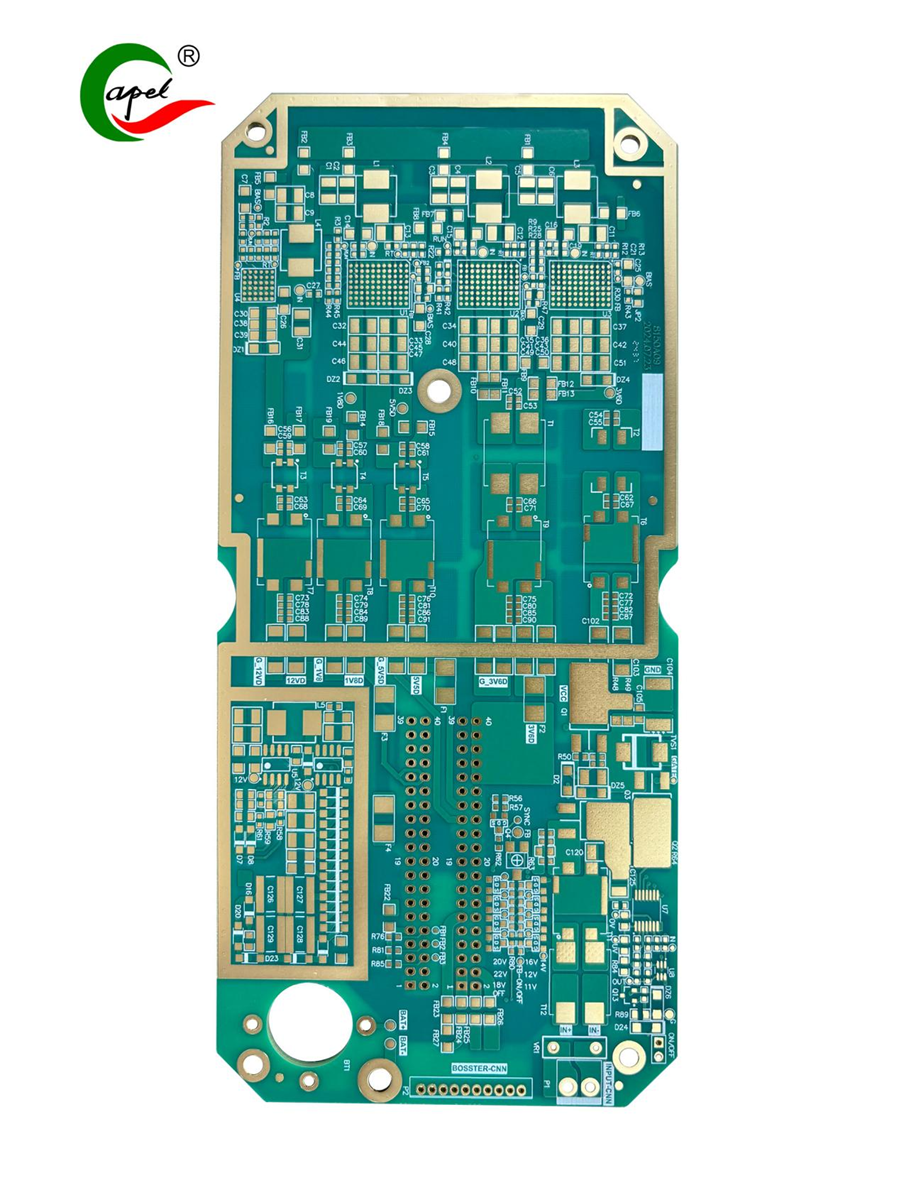

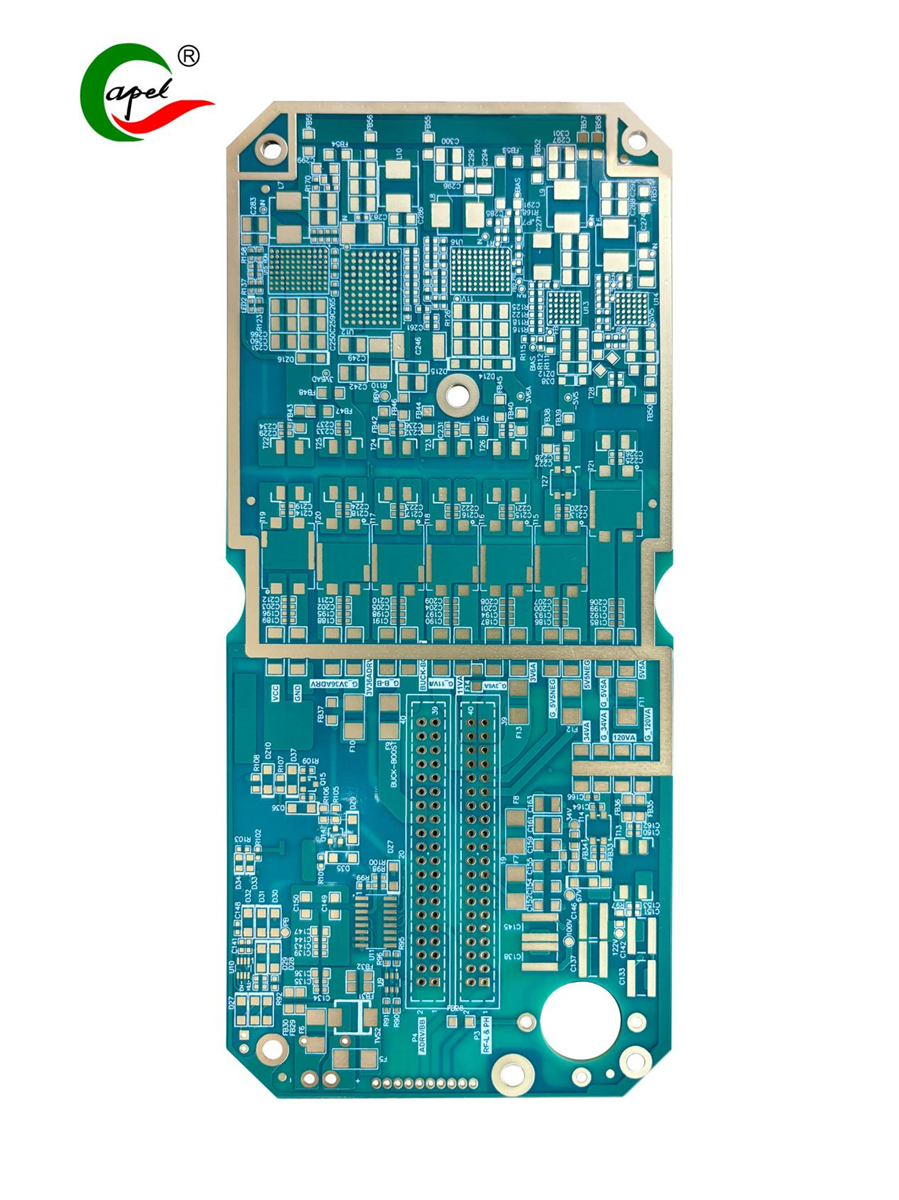

Lub 6-txheej PCB muaj 6 txheej txheej txheej sib cais los ntawm cov ntaub ntawv insulating. Qhov kev teeb tsa ntau txheej no tso cai rau kom muaj kev sib txuas ntau ntxiv, ua rau nws zoo tagnrho rau kev siv hauv kev sib txuas lus, cov neeg siv khoom siv hluav taws xob, thiab cov tshuab tsheb. Cov khaubncaws sab nraud povtseg feem ntau yog teem rau hauv ib qho kev txiav txim kom ua kom zoo dua cov teeb liab kev ncaj ncees thiab txo qis electromagnetic cuam tshuam (EMI).

Kev tsim kho ntawm 6L PCB suav nrog ntau cov txheej txheem tseem ceeb, suav nrog txheej txheej txheej, lamination, drilling, thiab etching. Txhua kauj ruam yuav tsum tau ua tiav nrog precision los xyuas kom meej cov khoom kawg ua tau raws li cov kev cai nruj ntawm cov khoom siv hluav taws xob niaj hnub no.

Qhov tseem ceeb ntawm qhov muag tsis pom qhov

Ib qho ntawm cov yam ntxwv tshiab uas tuaj yeem muab tso rau hauv 6L PCB yog kev siv cov qhov muag tsis pom kev. Lub qhov muag tsis pom kev yog lub qhov uas tsis mus tas li ntawm PCB; nws txuas ib lossis ntau txheej tab sis tsis pom los ntawm sab nraud. Cov qauv tsim no tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau kev teeb tsa thiab kev sib txuas hluav taws xob yam tsis muaj kev cuam tshuam rau pawg thawj coj saib kev ncaj ncees.

Qhov qhov muag tsis pom kev tuaj yeem pab txo qis ntawm lub rooj tsav xwm hneev taw, tso cai rau kev tsim ntau dua. Lawv kuj pab tswj kom zoo dua thermal tswj los ntawm kev muab txoj hauv kev rau cov cua kub dissipation. Txawm li cas los xij, kev tsim cov qhov muag tsis pom kev yuav tsum muaj cov txheej txheem siab heev thiab qhov tseeb, ua rau nws tseem ceeb rau kev koom tes nrog cov chaw tsim khoom muaj npe PCB.

Lub luag hauj lwm ntawm PCB manufacturers

Xaiv cov chaw tsim khoom PCB yog qhov tseem ceeb rau kev ua tiav zoo 6L PCBs nrog qhov muag tsis pom. Lub chaw tsim khoom txhim khu kev qha yuav muaj cov kws tshaj lij tsim nyog, thev naus laus zis, thiab kev tswj xyuas zoo nyob rau hauv qhov chaw kom ntseeg tau tias cov khoom kawg ua tau raws li cov qauv kev lag luam.

Thaum xaiv cov chaw tsim khoom PCB, xav txog cov hauv qab no:

Kev paub thiab kev txawj ntse: Saib rau cov tuam txhab lag luam nrog cov ntaub ntawv pov thawj hauv kev tsim cov txheej txheem PCBs, tshwj xeeb yog cov cuab yeej siv qhov muag tsis pom.

Technology thiab khoom siv:Advanced manufacturing txheej txheem, xws li laser drilling thiab automated optical inspection (AOI), yog qhov tseem ceeb rau kev tsim cov qhov muag tsis pom tseeb.

Quality Assurance:Lub chaw tsim khoom muaj koob npe yuav siv cov kev tswj xyuas zoo, suav nrog kev sim rau kev ua haujlwm hluav taws xob thiab kev ua haujlwm zoo.

Customization Options:Lub peev xwm los kho cov qauv tsim, suav nrog qhov loj thiab qhov chaw ntawm qhov muag tsis pom, yog qhov tseem ceeb rau kev ua kom tau raws li qhov project tshwj xeeb.

Resin Plug Holes: Kev daws rau qhov muag tsis pom qhov

Txhawm rau txhim kho kev ua tau zoo ntawm 6L PCBs nrog qhov muag tsis pom, cov tuam ntxhab feem ntau siv cov khoom siv ntsaws qhov. Cov txheej txheem no suav nrog kev sau cov qhov dig muag nrog cov khoom siv cob, uas ua haujlwm rau ntau lub hom phiaj:

Hluav taws xob cais:Resin plug qhov pab tiv thaiv hluav taws xob luv ntawm cov khaubncaws sab nraud povtseg, kom ntseeg tau tias kev ua tau zoo.

Mechanical Stability: Cov resin ntxiv cov qauv kev ncaj ncees rau PCB, ua rau nws tiv taus ntau yam kev ntxhov siab.

Nto tiav: EING

Kev ua tiav ntawm PCB yog qhov tseem ceeb uas cuam tshuam rau nws qhov kev ua tau zoo thiab kev ntseeg tau. EING yog qhov kev xaiv nrov ntawm cov tuam ntxhab vim nws cov khoom tshwj xeeb. Qhov kev ua tiav no suav nrog cov txheej txheem ob kauj ruam: electroless npib tsib xee plating ua raws li kev kub siab plating.

Cov txiaj ntsig ntawm EING:

Solderability:EING muab lub tiaj tus, txawm tias qhov chaw uas txhim khu kev sib txuas, ua kom yooj yim rau cov khoom sib dhos thaum sib dhos.

Corrosion Resistance:Cov txheej kub tiv thaiv lub hauv paus npib tsib xee los ntawm oxidation, ua kom muaj kev ntseeg tau ntev hauv ntau yam ib puag ncig.

Flatness:Lub npoo du ntawm EING yog qhov zoo tagnrho rau cov khoom zoo-pitch, uas muaj ntau zuj zus hauv cov khoom siv hluav taws xob niaj hnub no.

Compatibility:EING yog sib xws nrog ntau yam khoom siv PCB thiab tuaj yeem siv rau cov laug cam nrog qhov muag tsis pom kev, ua kom muaj kev sib koom ua ke ntawm cov qauv tsim.

Post lub sij hawm: Oct-14-2024

Rov qab