Automotive electronics printed circuit boards (PCBs) ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntawm cov tsheb niaj hnub no. Los ntawm kev tswj hwm lub cav tshuab thiab infotainment qhia txog kev tswj hwm kev nyab xeeb thiab kev muaj peev xwm tsav tsheb, cov PCBs yuav tsum tau ua tib zoo tsim thiab tsim cov txheej txheem los xyuas kom meej qhov ua tau zoo thiab kev ntseeg tau.Nyob rau hauv tsab xov xwm no, peb yuav delve rau hauv txoj kev taug kev nyuaj ntawm automotive electronics PCBs, tshawb txog cov kauj ruam tseem ceeb uas cuam tshuam los ntawm qhov pib tsim theem tag nrho rau kev tsim khoom.

1.Kev nkag siab ntawm tsheb hluav taws xob PCB:

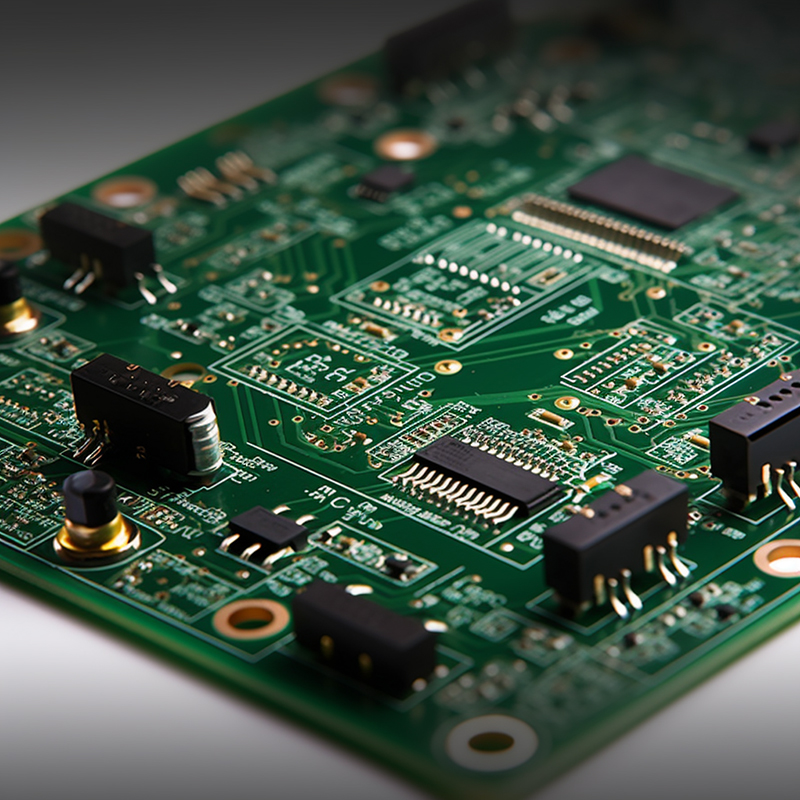

Automotive electronics PCB los yog luam tawm Circuit Board yog ib qho tseem ceeb ntawm cov tsheb niaj hnub. Lawv yog lub luag haujlwm rau kev muab kev sib txuas hluav taws xob thiab kev txhawb nqa rau ntau lub tshuab hluav taws xob hauv lub tsheb, xws li lub cav tswj lub cav, infotainment systems, sensors, thiab lwm yam.Ib qho tseem ceeb ntawm automotive electronics PCBs yog lawv lub peev xwm los tiv thaiv qhov hnyav hauv tsheb. Lub tsheb yuav raug hloov pauv kub, kev co thiab hluav taws xob nrov. Yog li, cov PCBs no yuav tsum tau ua kom ruaj khov thiab txhim khu kev qha kom ntseeg tau tias kev ua haujlwm zoo thiab kev nyab xeeb. Automotive electronics PCBs feem ntau tsim los siv cov software tshwj xeeb uas tso cai rau cov engineers los tsim cov layouts uas ua tau raws li cov kev cai tshwj xeeb ntawm kev lag luam tsheb. Cov kev cai no muaj xws li qhov loj me, qhov hnyav, kev siv hluav taws xob, thiab hluav taws xob sib raug zoo nrog lwm yam khoom. Kev tsim cov txheej txheem ntawm automotive electronics PCBs suav nrog ntau cov kauj ruam. PCB layout yog tsim ua ntej thiab ua tib zoo simulated thiab sim kom paub tseeb tias tus tsim raws li qhov yuav tsum tau specifications. Tus tsim yog ces pauv mus rau lub cev PCB siv cov tswv yim xws li etching los yog depositing conductive khoom mus rau lub PCB substrate. Muab qhov nyuaj ntawm automotive electronic PCBs, cov khoom siv ntxiv xws li cov resistors, capacitors, thiab kev sib xyaw ua ke feem ntau yog ntsia rau ntawm PCB kom ua tiav cov hluav taws xob hluav taws xob. Cov Cheebtsam no feem ntau yog nto mounted rau PCB siv automated placement machines. Kev saib xyuas tshwj xeeb yog them rau cov txheej txheem vuam kom ntseeg tau tias kev sib txuas kom raug thiab kav ntev. Muab qhov tseem ceeb ntawm automotive electronic systems, kev tswj kom zoo yog qhov tseem ceeb hauv kev lag luam tsheb. Yog li ntawd, automotive electronics PCBs raug kuaj nruj thiab tshuaj xyuas kom ntseeg tau tias lawv ua tau raws li cov qauv xav tau. Qhov no suav nrog kev ntsuam xyuas hluav taws xob, thermal cycling, kev vibration testing thiab ib puag ncig kuaj kom ntseeg tau tias PCB kev ntseeg tau thiab kav ntev nyob rau hauv ntau yam kev mob.

2.Automotive electronic PCB tsim txheej txheem:

Cov txheej txheem tsim khoom siv hluav taws xob hauv tsheb PCB suav nrog ntau cov kauj ruam tseem ceeb los xyuas kom muaj kev ntseeg siab, kev ua haujlwm, thiab kev ua haujlwm ntawm cov khoom kawg.

2.1 Scheme design: Thawj kauj ruam ntawm tus txheej txheem tsim yog schematic tsim.Nyob rau hauv cov kauj ruam no, engineers txhais cov hluav taws xob kev sib txuas ntawm ib tug neeg lub Cheebtsam raws li lub PCB qhov yuav tsum tau muaj functionality. Qhov no suav nrog kev tsim daim duab schematic uas sawv cev rau PCB Circuit Court, suav nrog kev sib txuas, cov khoom siv, thiab lawv cov kev sib raug zoo. Thaum lub sij hawm no, engineers xav txog tej yam xws li kev xav tau ntawm lub hwj chim, teeb liab txoj kev, thiab compatibility nrog rau lwm yam systems nyob rau hauv lub tsheb.

2.2 PCB layout tsim: Thaum lub schematic tiav lawm, tus tsim txav mus rau hauv lub PCB layout tsim theem.Hauv cov kauj ruam no, engineers hloov cov schematic rau hauv lub cev layout ntawm PCB. Qhov no suav nrog kev txiav txim siab qhov loj me, cov duab, thiab qhov chaw ntawm cov khoom ntawm lub rooj tsav xwm hauv Circuit Court, nrog rau kev ua haujlwm ntawm cov kab hluav taws xob. Layout tsim yuav tsum xav txog yam xws li teeb liab kev ncaj ncees, kev tswj thermal, electromagnetic cuam tshuam (EMI), thiab manufacturability. Kev saib xyuas tshwj xeeb yog them rau qhov kev tso kawm los ua kom zoo dua cov teeb liab ntws thiab txo qis suab nrov.

2.3 Cheebtsam xaiv thiab muab tso rau: Tom qab thawj zaug PCB layout tiav lawm, engineers txuas ntxiv nrog cov khoom xaiv thiab tso.Qhov no suav nrog kev xaiv cov khoom tsim nyog raws li cov kev xav tau xws li kev ua haujlwm, kev siv hluav taws xob, muaj thiab nqi. Cov yam ntxwv xws li cov khoom siv tsheb-qib, qhov kub thiab txias thiab kev vibration kam rau ua yog qhov tseem ceeb hauv kev xaiv. Cov khoom siv tom qab ntawd muab tso rau ntawm PCB raws li lawv cov hneev taw thiab cov haujlwm tau txiav txim siab thaum lub sijhawm tsim qauv tsim. Kev tso kawm kom raug thiab kev taw qhia ntawm cov khoom tseem ceeb yog qhov tseem ceeb kom ntseeg tau tias kev sib dhos ua tau zoo thiab pom cov teeb liab ntws zoo.

2.4 Kev tsom xam pom kev ncaj ncees: Kev tsom xam teeb pom kev ncaj ncees yog ib kauj ruam tseem ceeb hauv kev tsim tsheb hluav taws xob PCB.Nws suav nrog kev ntsuas qhov zoo thiab kev ntseeg siab ntawm cov teeb liab thaum lawv nthuav tawm los ntawm PCB. Qhov kev tshuaj ntsuam no pab txheeb xyuas cov teeb meem muaj peev xwm xws li teeb liab attenuation, crosstalk, reflections, thiab suab nrov cuam tshuam. Ntau yam kev simulation thiab tsom xam cov cuab yeej siv los txheeb xyuas cov qauv tsim thiab ua kom zoo tshaj plaws los xyuas kom meej lub teeb liab. Cov neeg tsim qauv tsom rau yam xws li qhov ntev ntev, qhov sib txuam impedance, lub zog ruaj khov, thiab kev tswj xyuas impedance routing kom ntseeg tau tias muaj tseeb thiab tsis muaj suab nrov kis tau tus mob.

Kev tsom xam kev ncaj ncees tseem yuav siv sij hawm rau hauv tus account lub high-speed signals thiab tseem ceeb tsheb npav interfaces tam sim no nyob rau hauv automotive electronic systems. Raws li cov thev naus laus zis zoo xws li Ethernet, CAN thiab FlexRay tau siv ntau zuj zus hauv cov tsheb, kev tswj cov teeb liab kev ncaj ncees yuav nyuaj thiab tseem ceeb.

3.Automotive electronic PCB manufacturing txheej txheem:

3.1 Kev xaiv cov khoom siv: Automotive electronics PCB xaiv cov khoom yog qhov tseem ceeb rau kev ua kom ruaj khov, kev ntseeg siab thiab kev ua haujlwm.Cov ntaub ntawv siv yuav tsum muaj peev xwm tiv taus qhov hnyav ib puag ncig uas tau ntsib hauv kev siv tsheb, suav nrog kev hloov pauv kub, kev vibration, noo noo thiab tshuaj lom neeg raug. Cov khoom siv feem ntau siv rau hauv tsheb hluav taws xob PCBs suav nrog FR-4 (Flame Retardant-4) epoxy-raws li laminate, uas muaj cov hluav taws xob zoo, cov neeg kho tshuab lub zog thiab cov cua sov zoo heev. High-temperature laminates xws li polyimide kuj tseem siv rau hauv daim ntawv thov uas xav tau qhov kub thiab txias. Kev xaiv cov khoom siv kuj tseem yuav tsum xav txog qhov yuav tsum tau ua ntawm daim ntawv thov Circuit Court, xws li cov teeb liab ceev lossis hluav taws xob hluav taws xob.

3.2 PCB manufacturing technology: PCB manufacturing technology muaj ntau yam txheej txheem uas hloov cov qauv tsim rau hauv lub cev luam tawm Circuit Board.Cov txheej txheem tsim khoom feem ntau suav nrog cov kauj ruam hauv qab no:

a) Tsim Hloov Hloov:PCB tsim yog pauv mus rau ib qho software tshwj xeeb uas tsim cov ntaub ntawv kos duab uas xav tau rau kev tsim khoom.

b) Panelization:Kev sib txuas ntau yam PCB tsim rau hauv ib lub vaj huam sib luag los ua kom zoo dua kev tsim khoom.

c) Cov duab:Txheej txheej ntawm cov khoom siv photosensitive rau ntawm lub vaj huam sib luag, thiab siv cov ntaub ntawv kos duab kom nthuav tawm cov qauv Circuit Court uas yuav tsum tau ua ntawm lub vaj huam sib luag coated.

d) Kev sib tw:Chemically etching cov chaw raug ntawm lub vaj huam sib luag kom tshem tawm pliaj tooj liab, tawm hauv qhov xav tau cov kab hluav taws xob.

e) Drilling:Drilling qhov nyob rau hauv lub vaj huam sib luag kom haum raws li cov khoom coj thiab vias rau kev sib txuas ntawm cov txheej txheem sib txawv ntawm PCB.

f) Electroplating:Ib txheej nyias ntawm tooj liab yog electroplated rau ntawm lub vaj huam sib luag los txhim kho cov conductivity ntawm cov kab hluav taws xob thiab muab lub ntsej muag du rau cov txheej txheem tom ntej.

g) Solder Mask Daim Ntawv Thov:Siv ib txheej ntawm daim npog ntsej muag los tiv thaiv cov kab tooj liab los ntawm oxidation thiab muab rwb thaiv tsev ntawm cov kab uas nyob ib sab. Solder daim npog qhov ncauj kuj pab muab qhov pom tseeb qhov sib txawv ntawm cov khoom sib txawv thiab cov kab.

h) Screen printing:Siv cov txheej txheem luam ntawv tshuaj ntsuam los luam cov npe, lub logo thiab lwm yam ntaub ntawv tsim nyog rau PCB.

3.3 Npaj txheej tooj liab: Ua ntej tsim daim ntawv thov Circuit Court, cov txheej tooj liab ntawm PCB yuav tsum tau npaj.Qhov no suav nrog kev ntxuav cov tooj liab kom tshem tawm cov av, oxides lossis cov kab mob. Cov txheej txheem ntxuav txhim kho cov adhesion ntawm cov ntaub ntawv photosensitive siv hauv cov txheej txheem duab. Muaj ntau txoj hauv kev tu yuav siv tau, suav nrog kev siv tshuab ntxhua khaub ncaws, tshuaj ntxuav, thiab tshuaj ntxuav plasma.

3.4 Daim ntawv thov Circuit Court: Thaum cov txheej tooj liab tau npaj, daim ntawv thov Circuit Court tuaj yeem tsim rau ntawm PCB.Qhov no suav nrog kev siv cov txheej txheem duab los hloov cov qauv Circuit Court yam xav tau mus rau PCB. Cov ntaub ntawv kos duab tsim los ntawm PCB tsim yog siv los ua ib qho kev siv los nthuav tawm cov khoom siv photosensitive ntawm PCB rau UV teeb. Cov txheej txheem no hardens cov chaw raug, tsim cov kab hluav taws xob uas yuav tsum tau muaj thiab cov ntaub qhwv.

3.5 PCB etching thiab drilling: Tom qab tsim daim ntawv thov Circuit Court, siv cov tshuaj tov tshuaj kom tshem tawm cov tooj liab ntau dhau.Cov khoom siv photosensitive ua raws li daim npog ntsej muag, tiv thaiv cov kab hluav taws xob uas xav tau los ntawm etching. Tom ntej no los txog cov txheej txheem drilling ntawm kev ua lub qhov rau cov khoom coj thiab vias hauv PCB. Lub qhov yog drilled siv cov cuab yeej precision thiab lawv qhov chaw raug txiav txim raws li tus qauv PCB.

3.6 Plating thiab solder daim npog qhov ncauj: Tom qab cov txheej txheem etching thiab drilling tiav, PCB yog plated los txhim kho cov conductivity ntawm cov kab hluav taws xob.Phaj ib txheej nyias ntawm tooj liab rau ntawm qhov chaw tooj liab. Cov txheej txheem plating no pab ua kom muaj kev sib txuas hluav taws xob txhim khu kev qha thiab nce PCB kav ntev. Tom qab plating, ib txheej ntawm daim npog ntsej muag yog siv rau PCB. Lub npog ntsej muag muab cov rwb thaiv tsev thiab tiv thaiv cov kab tooj liab los ntawm oxidation. Nws feem ntau yog siv los ntawm kev tshuaj ntsuam luam ntawv, thiab thaj chaw uas cov khoom tau muab tso rau yog sab laug qhib rau soldering.

3.7 PCB kuaj thiab tshuaj xyuas: Cov kauj ruam kawg hauv kev tsim khoom yog PCB kuaj thiab tshuaj xyuas.Qhov no suav nrog kev txheeb xyuas qhov ua haujlwm thiab qhov zoo ntawm PCB. Ntau yam kev ntsuam xyuas xws li kev soj ntsuam txuas ntxiv, kev ntsuas kev tiv thaiv hluav taws xob, thiab kev ntsuas hluav taws xob tau ua los xyuas kom meej tias PCB ua tau raws li qhov yuav tsum tau ua. Kev tshuaj xyuas qhov muag kuj tau ua los xyuas seb muaj qhov tsis xws luag xws li luv luv, opens, misalignments, los yog cov khoom siv qhov chaw tsis raug.

Cov txheej txheem kev tsim khoom ntawm automotive electronics PCB suav nrog ntau cov kauj ruam los ntawm kev xaiv cov khoom siv rau kev kuaj thiab tshuaj xyuas. Txhua kauj ruam ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev ntseeg siab, kev ua haujlwm thiab kev ua haujlwm ntawm PCB kawg. Cov neeg tsim khoom yuav tsum ua raws li cov qauv kev lag luam thiab cov kev coj ua zoo tshaj plaws kom ntseeg tau tias PCBs ua tau raws li cov kev cai nruj ntawm kev siv tsheb.

4.Kev txiav txim siab tshwj xeeb ntawm lub tsheb: muaj qee yam ntawm cov tsheb tshwj xeeb uas yuav tsum tau txiav txim siab thaum tsim thiab

manufacturing automotive PCBs.

4.1 Thaum tshav kub kub dissipation thiab thermal tswj: Hauv tsheb, PCBs raug cuam tshuam los ntawm qhov kub thiab txias vim lub cav cua sov thiab ib puag ncig ib puag ncig.Yog li ntawd, thermal dissipation thiab thermal tswj yog qhov tseem ceeb hauv kev tsim tsheb PCB. Cov khoom tsim hluav taws xob xws li hluav taws xob hluav taws xob, microcontrollers, thiab sensors yuav tsum tau muab tso rau hauv PCB kom txo cov cua sov kom tsawg. Thaum tshav kub kub dab dej thiab vents muaj nyob rau kom ua tau zoo tshav kub dissipation. Tsis tas li ntawd, cov tshuab cua kom zoo thiab cua txias yuav tsum tau muab tso rau hauv cov qauv tsim tsheb kom tsis txhob muaj cua sov ntau dhau thiab ua kom muaj kev ntseeg siab ntawm PCB thiab kev ua haujlwm ntev.

4.2 Kev vibration thiab poob siab tsis kam: Lub tsheb ua haujlwm nyob rau hauv ntau txoj kev thiab raug kev vibrations thiab shocks tshwm sim los ntawm pob, pob qhov thiab cov av ntxhib.Cov kev vibrations thiab shocks tuaj yeem cuam tshuam rau PCB durability thiab kev ntseeg siab. Txhawm rau kom muaj kev tiv thaiv kev vibration thiab poob siab, PCBs siv hauv tsheb yuav tsum muaj zog thiab ruaj khov. Cov txheej txheem tsim xws li siv cov pob qij txha ntxiv, txhawb nqa PCB nrog epoxy lossis cov khoom siv ntxiv, thiab ua tib zoo xaiv cov khoom tiv thaiv kev co thiab cov khoom sib txuas tuaj yeem pab txo qis qhov tsis zoo ntawm kev co thiab kev poob siab.

4.3 Electromagnetic compatibility (EMC): Electromagnetic cuam tshuam (EMI) thiab xov tooj cua zaus cuam tshuam (RFI) tuaj yeem cuam tshuam rau kev ua haujlwm ntawm cov khoom siv hluav taws xob hauv tsheb.Kev sib raug zoo ntawm ntau yam khoom nyob rau hauv lub tsheb yuav tsim electromagnetic teb uas cuam tshuam rau ib leeg. Txhawm rau kom paub meej EMC, PCB tsim yuav tsum suav nrog kev tiv thaiv tsim nyog, hauv av, thiab cov txheej txheem lim kom txo qis emissions thiab cuam tshuam rau cov teeb liab electromagnetic. Tiv thaiv cov kaus poom, cov khoom siv hluav taws xob, thiab cov txheej txheem PCB tsim nyog (xws li kev sib cais rhiab analog thiab cov cim digital) tuaj yeem pab txo qhov cuam tshuam ntawm EMI thiab RFI thiab ua kom muaj kev ua haujlwm zoo ntawm cov khoom siv hluav taws xob hauv tsheb.

4.4 Cov qauv kev nyab xeeb thiab kev ntseeg tau: Automotive electronics yuav tsum ua raws li cov qauv kev nyab xeeb thiab kev ntseeg siab kom ntseeg tau tias muaj kev nyab xeeb ntawm cov neeg caij tsheb thiab kev ua haujlwm tag nrho ntawm lub tsheb.Cov qauv no suav nrog ISO 26262 rau kev nyab xeeb kev ua haujlwm, uas txhais tau hais tias yuav tsum muaj kev nyab xeeb rau kev tsheb, thiab ntau lub teb chaws thiab thoob ntiaj teb cov qauv rau kev nyab xeeb hluav taws xob thiab kev txiav txim siab ib puag ncig (xws li IEC 60068 rau kev kuaj ib puag ncig). PCB manufacturers yuav tsum nkag siab thiab ua raws li cov qauv no thaum tsim thiab tsim tsheb PCBs. Tsis tas li ntawd, kev ntsuam xyuas kev ntseeg tau xws li kev ntsuas kub, ntsuas kev vibration, thiab kev laus nrawm yuav tsum tau ua kom ntseeg tau tias PCB ua tau raws li qhov yuav tsum tau muaj kev ntseeg siab rau kev siv tsheb.

Vim yog qhov kub thiab txias ntawm lub tsheb ib puag ncig, cua kub dissipation thiab thermal tswj yog qhov tseem ceeb. Kev co thiab kev poob siab yog qhov tseem ceeb los xyuas kom meej tias PCB tuaj yeem tiv taus txoj kev hnyav. Electromagnetic compatibility yog qhov tseem ceeb rau kev txo qis kev cuam tshuam ntawm ntau yam khoom siv hluav taws xob hauv tsheb. Tsis tas li ntawd, ua raws li cov qauv kev nyab xeeb thiab kev ntseeg siab yog qhov tseem ceeb los ua kom muaj kev nyab xeeb thiab ua haujlwm zoo ntawm koj lub tsheb. Los ntawm kev daws cov teeb meem no, PCB cov tuam txhab tuaj yeem tsim cov PCBs zoo uas ua tau raws li cov kev cai tshwj xeeb ntawm kev lag luam tsheb.

5.Automotive electronic PCB los ua ke thiab kev koom ua ke:

Automotive electronics PCB sib dhos thiab kev koom ua ke koom nrog ntau theem nrog rau kev tsim khoom, kev sib dhos tshuab saum npoo av, kev siv tshuab thiab phau ntawv sib dhos, thiab kev tswj xyuas zoo thiab kev sim. Txhua theem pab tsim cov khoom zoo, txhim khu kev qha PCBs uas ua tau raws li cov kev cai nruj ntawm kev siv tsheb. Cov neeg tsim khoom yuav tsum ua raws li cov txheej txheem nruj thiab cov qauv zoo kom ntseeg tau tias kev ua haujlwm thiab kev ua haujlwm ntev ntawm cov khoom siv hluav taws xob hauv tsheb.

5.1 Cov khoom siv: Kev yuav khoom yog ib kauj ruam tseem ceeb hauv cov txheej txheem kev sib dhos hauv tsheb hauv PCB.Pab neeg muag khoom ua haujlwm ze nrog cov neeg muag khoom kom tau txais thiab yuav cov khoom tsim nyog. Cov khoom xaiv yuav tsum ua kom tau raws li qhov yuav tsum tau ua rau kev ua tau zoo, kev ntseeg tau, thiab kev sib raug zoo nrog cov ntawv thov tsheb. Cov txheej txheem kev yuav khoom suav nrog kev txheeb xyuas cov neeg muab kev ntseeg siab, sib piv cov nqi thiab lub sijhawm xa khoom, thiab xyuas kom meej cov khoom muaj tseeb thiab ua tau raws li cov qauv tsim nyog. Cov pab pawg neeg yuav khoom tseem xav txog yam xws li kev tswj xyuas kev tsis txaus ntseeg kom ntseeg tau tias muaj cov khoom muaj nyob hauv lub neej ntawm cov khoom.

5.2 Nto Mount Technology (SMT): Surface mount technology (SMT) yog txoj kev nyiam rau kev sib sau ua ke hauv tsheb hluav taws xob PCBs vim nws qhov ua tau zoo, qhov tseeb, thiab kev sib raug zoo nrog cov khoom me me. SMT suav nrog kev tso cov khoom ncaj qha rau ntawm PCB nto, tshem tawm qhov xav tau ntawm cov hlau lead lossis pins.SMT Cheebtsam suav nrog cov khoom siv me me, lub teeb yuag xws li resistors, capacitors, integrated circuits, thiab microcontrollers. Cov khoom no tau muab tso rau hauv PCB siv lub tshuab tso rau hauv lub tshuab. Lub tshuab precisely positions Cheebtsam ntawm lub solder muab tshuaj txhuam rau ntawm PCB, kom ntseeg tau meej kev sib raug zoo thiab txo lub sij hawm ntawm kev ua yuam kev. Cov txheej txheem SMT muaj ntau yam txiaj ntsig, suav nrog kev ua kom muaj zog ntxiv, txhim kho kev tsim khoom, thiab txhim kho hluav taws xob ua haujlwm. Tsis tas li ntawd, SMT tso cai rau kev soj ntsuam thiab kev sim, ua kom ceev thiab txhim khu kev qha ntau lawm.

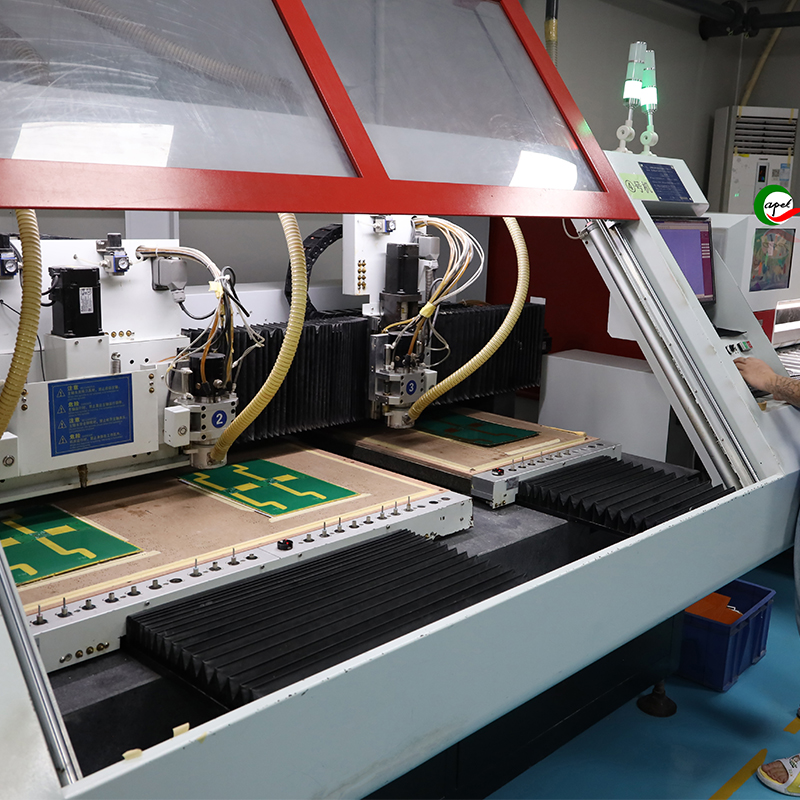

5.3 Kev sib dhos tsis siv neeg thiab phau ntawv: Kev sib dhos ntawm cov khoom siv hluav taws xob hauv tsheb PCB tuaj yeem ua tiav los ntawm kev siv tshuab thiab phau ntawv, nyob ntawm qhov nyuaj ntawm lub rooj tsavxwm thiab cov kev cai tshwj xeeb ntawm daim ntawv thov.Kev sib dhos tsis siv neeg suav nrog kev siv cov tshuab siab heev los sib sau PCBs sai thiab raug. Cov tshuab tsis siv neeg, xws li chip mounters, solder paste printers, thiab reflow ncu, yog siv rau kev muab tso rau hauv cov khoom siv, cov ntaub ntawv siv tshuaj pleev xim, thiab rov ua dua. Automated los ua ke yog qhov ua tau zoo, txo lub sijhawm tsim khoom thiab txo qhov yuam kev. Los ntawm txhais tes sib dhos, ntawm qhov tod tes, feem ntau yog siv rau cov khoom ntim qis lossis thaum qee yam khoom siv tsis haum rau kev sib dhos. Cov kws tshaj lij siv cov cuab yeej tshwj xeeb thiab cov cuab yeej siv los ua tib zoo tso cov khoom ntawm PCB. Kev sib dhos ntawm phau ntawv tso cai rau kev hloov pauv ntau dua thiab kev hloov kho dua li kev sib dhos ua ke, tab sis qeeb dua thiab ua rau tib neeg yuam kev.

5.4 Kev Tswj Xyuas Zoo thiab Kev Ntsuas Zoo: Kev Tswj Xyuas Zoo thiab Kev Ntsuas Zoo yog cov kauj ruam tseem ceeb hauv kev tsim khoom siv hluav taws xob hauv tsheb PCB thiab kev sib koom ua ke. Cov txheej txheem no pab xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv tsim nyog thiab kev ua haujlwm zoo.Kev tswj xyuas kev ua tau zoo pib nrog kev tshuaj xyuas cov khoom nkag los xyuas lawv qhov tseeb thiab qhov zoo. Thaum lub sij hawm sib dhos txheej txheem, kev tshuaj xyuas yog ua nyob rau hauv ntau theem los txheeb xyuas thiab kho tej yam tsis xws luag lossis teeb meem. Kev tshuaj xyuas qhov muag, kev tshuaj xyuas qhov muag tsis pom kev (AOI) thiab kev kuaj X-ray feem ntau yog siv los txheeb xyuas qhov tsis xws luag xws li cov txuas txuas, cov khoom siv misalignment lossis qhib kev sib txuas.

Tom qab kev sib sau ua ke, PCB yuav tsum tau sim ua haujlwm kom paub tseeb tias nws qhov kev ua tau zoo. TCov txheej txheem kev ntsuas yuav suav nrog kev ntsuas hluav taws xob, kev sim ua haujlwm, kev ntsuas hauv Circuit Court, thiab kev ntsuas ib puag ncig los xyuas qhov ua haujlwm, cov yam ntxwv hluav taws xob, thiab kev ntseeg siab ntawm PCB.

Kev tswj xyuas kev ua tau zoo thiab kev ntsuam xyuas kuj tseem cuam tshuam txog kev taug qab, qhov twg txhua PCB tau cim lossis cim nrog tus cim tshwj xeeb los taug qab nws cov keeb kwm tsim khoom thiab ua kom lub luag haujlwm.Qhov no ua rau cov tuam txhab lag luam txheeb xyuas thiab kho txhua qhov teeb meem thiab muab cov ntaub ntawv tseem ceeb rau kev txhim kho txuas ntxiv.

6.Automotive electronics PCB Yav tom ntej tiam sis thiab cov kev cov nyom: Lub neej yav tom ntej ntawm automotive electronics PCBs yuav raug cuam tshuam los ntawm

tiam sis xws li miniaturization, nce complexity, kev koom ua ke ntawm advanced technologies, thiab xav tau kev txhim kho

cov txheej txheem tsim khoom.

6.1 Miniaturization thiab nce complexity: Ib qho tseem ceeb tiam sis nyob rau hauv automotive electronics PCBs yog lub nruam thawb rau miniaturization thiab complexity.Raws li cov tsheb tau dhau los ua ntau dua thiab nruab nrog ntau lub tshuab hluav taws xob, qhov kev thov rau PCBs me thiab ntom ntom txuas ntxiv nce ntxiv. Qhov no miniaturization ua rau muaj teeb meem nyob rau hauv kev tso kawm, routing, thermal dissipation, thiab kev ntseeg tau. PCB tus tsim thiab cov tuam txhab tsim khoom yuav tsum nrhiav cov kev daws teeb meem tshiab kom haum raws li cov qauv ntawm cov ntaub ntawv shrinking thaum tswj PCB kev ua tau zoo thiab kav ntev.

6.2 Kev koom ua ke ntawm cov thev naus laus zis siab tshaj: Kev lag luam tsheb tau pom kev nce qib sai hauv kev siv thev naus laus zis, suav nrog kev sib koom ua ke ntawm cov thev naus laus zis tshiab rau hauv tsheb.PCBs ua lub luag haujlwm tseem ceeb hauv kev ua kom cov thev naus laus zis no, xws li kev pabcuam tsav tsheb siab tshaj (ADAS), lub tshuab hluav taws xob tsheb, kev sib txuas kev daws teeb meem thiab kev tsav tsheb tsis muaj zog. Cov thev naus laus zis siab tshaj no xav tau PCBs uas tuaj yeem txhawb kev nrawm dua, tswj cov ntaub ntawv ua haujlwm nyuaj, thiab ua kom muaj kev sib txuas lus zoo ntawm ntau yam khoom thiab cov tshuab. Tsim thiab tsim cov PCBs uas ua tau raws li cov kev cai no yog qhov nyuaj rau kev lag luam.

6.3 Cov txheej txheem tsim khoom yuav tsum tau ua kom muaj zog: Raws li qhov kev thov rau automotive electronics PCBs txuas ntxiv mus, cov tuam ntxhab tau ntsib nrog cov kev sib tw ntawm kev txhim kho cov txheej txheem tsim khoom kom tau raws li cov khoom siv ntau dua thaum tswj cov qauv zoo.Streamlining ntau lawm txheej txheem, txhim kho efficiency, shortening lub voj voog lub sij hawm thiab txo qhov tsis xws luag yog qhov chaw uas manufacturers yuav tsum tsom rau lawv cov dag zog. Kev siv cov thev naus laus zis ntawm kev tsim khoom, xws li kev sib sau ua ke, neeg hlau thiab cov tshuab soj ntsuam siab heev, pab txhim kho kev ua tau zoo thiab raug ntawm cov txheej txheem ntau lawm. Txais Kev Lag Luam 4.0 lub tswv yim xws li Internet ntawm Yam (IoT) thiab cov ntaub ntawv tshuaj ntsuam xyuas tuaj yeem muab cov kev nkag siab zoo rau cov txheej txheem kev ua kom zoo dua qub thiab kev saib xyuas kwv yees, yog li ua kom cov khoom tsim tau thiab tso tawm.

7.Well-known automotive circuit board chaw tsim tshuaj paus:

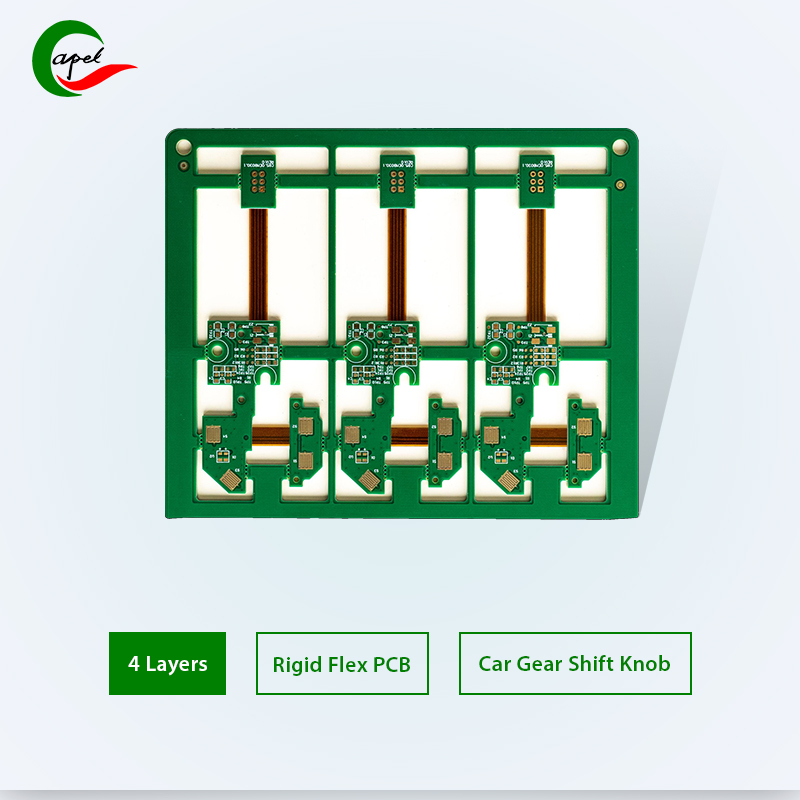

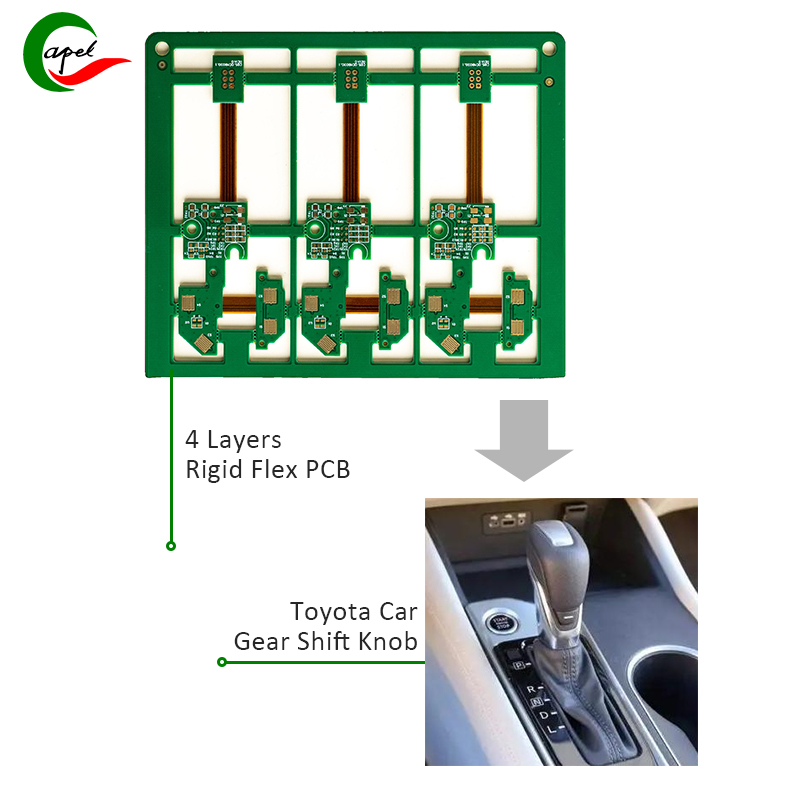

Shenzhen Capel Technology Co., Ltd. tau tsim ib lub koom haum Circuit Court board nyob rau hauv 2009 thiab pib tsim thiab tsim tau yooj yim Circuit Court boards, hybrid boards, thiab rigid boards. Tshaj li 15 xyoo dhau los, peb tau ua tiav kaum tawm txhiab tus automotive circuit board project rau cov neeg siv khoom, tau txais kev nplua nuj nyob hauv kev lag luam tsheb, thiab muab cov neeg siv khoom muaj kev nyab xeeb thiab txhim khu kev qha. Capel cov kws tshaj lij engineering thiab R & D pab pawg yog cov kws tshaj lij uas koj tuaj yeem ntseeg tau!

Hauv cov ntsiab lus,automotive electronics PCB manufacturing txheej txheem yog ib txoj hauj lwm nyuaj thiab ceev faj uas yuav tsum tau muaj kev sib raug zoo ntawm engineers, designers, thiab manufacturers. Cov kev cai nruj ntawm kev lag luam tsheb yuav tsum muaj cov khoom zoo, txhim khu kev qha thiab nyab xeeb PCBs. Raws li kev siv thev naus laus zis txuas ntxiv mus, automotive electronics PCBs yuav tsum tau ua kom tau raws li qhov kev thov loj zuj zus ntxiv rau kev ua haujlwm nyuaj thiab ntse. Txhawm rau ua ntej ntawm qhov kev hloov pauv sai sai no, PCB cov tuam txhab yuav tsum ua raws li cov qauv tshiab. Lawv yuav tsum tau nqis peev rau hauv cov txheej txheem tsim khoom thiab cov cuab yeej siv los xyuas kom meej tias cov khoom lag luam zoo tshaj plaws PCBs. Kev siv cov kev coj ua tau zoo tsis yog tsuas yog txhim kho kev tsav tsheb, tab sis kuj tseem ceeb rau kev nyab xeeb thiab kev ua kom raug.

Post lub sij hawm: Sep-11-2023

Rov qab