Tshawb cov evolution ntawmautomotive flex PCB technology nrog Capel chaw tsim tshuaj paus, uas muaj 16 xyoo kev txawj ntse hauv kev tsim, prototyping thiab manufacturing. Kev saib tob tob ntawm 8-txheej HDI thib ob-txiav txim siab nruj-flex PCBs, cov khoom siv sib xyaw ua ke, qib siab Cov txheej txheem tsim khoom thiab lub siab tsis tu ncua yog tshwm sim hauv tsab xov xwm no.

Qhia:

Nyob rau hauv lub era ntawm advanced automotive technology, qhov kev thov rau txhim khu kev qha, high-zoo hluav taws xob tshuab tau skyrocketed. Rigid-flex printed circuit boards (PCBs) ua lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li qhov xav tau no, muab qhov tsim nyog yooj yim, ua haujlwm ntev thiab qhov chaw ua haujlwm rau kev siv tsheb. Nrog rau 16 xyoo ntawm kev txawj ntse nyob rau hauv automotive saj zawg zog PCB tsim, prototyping thiab manufacturing, Capel chaw yog nyob rau hauv lub forefront ntawm no technologies txoj kev loj hlob. Nyob rau hauv tsab xov xwm no, peb yuav delve rau hauv lub ntiaj teb complex ntawm automotive saj zawg zog PCBs, tshawb txog Capel txoj kev zoo kawg li thiab cov zoo tshaj plaws kev vam meej technology uas propelled lawv mus rau lub pinnacle ntawm saj zawg zog PCB innovation. Los ntawm kev nkag siab txog qhov nyuaj ntawm 8-txheej HDI thib ob-txiav txim siab nruj-flex PCBs, rau cov khoom siv sib xyaw ua ke, qhov ntev meej thiab cov thev naus laus zis thev naus laus zis, peb yuav nthuav tawm cov mosaic zoo kawg nkaus uas txhais Capel lub peev xwm hauv tsheb hloov pauv PCB thev naus laus zis.

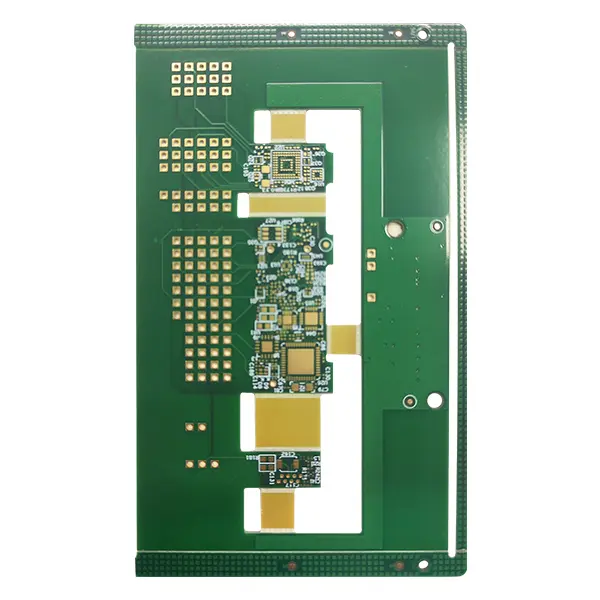

Tshooj 1: Tshawb nrhiav qhov nyuaj ntawm 8-txheej HDI thib ob-txiav txim siab-flex PCB

Flexible PCBs yog cov khoom tseem ceeb hauv cov tshuab tsheb niaj hnub rau ntau yam kev siv uas xav tau kev ntseeg siab thiab kev ua haujlwm zoo. 8-txheej HDI thib ob-theem hard-software PCB teeb tsa cov qauv tshiab hauv kev nyuaj, yuav tsum muaj kev sib haum xeeb ntawm kev siv technology thiab kev ua haujlwm zoo. Capel cov kws tshaj lij engineers tau paub txog kev kos duab ntawm kev tsim thiab tsim cov PCBs nyuaj, ua kom pom kev tsis sib xws hauv txheej txheej txheej tsim, los ntawm cov qauv thiab cov khoom xaiv. Nrog rau kev nkag siab meej txog cov thermal, mechanical thiab hluav taws xob cov kev cai ntawm kev siv tsheb, Capel xyuas kom meej tias txhua yam ntawm PCB tsim ua tau raws li cov kev cai nruj ntawm kev lag luam tsheb.

Tshooj 2: Cov khoom sib xyaw kom raug thiab qhov ntev ntawm kev ncaj ncees

Cov ntaub ntawv siv hauv tsheb hloov pauv PCBs ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab lawv cov kev ua tau zoo, kev ntseeg siab thiab kev ua haujlwm ntev. Capel txoj kev siv polyimide (PI), tooj liab, nplaum thiab FR4 embodies lub ntsiab ntawm durability thiab functionality. Txhua yam khoom siv tau ua tib zoo xaiv los tiv thaiv cov kev ua haujlwm hnyav uas muaj nyob rau hauv ib puag ncig hauv tsheb, kom ntseeg tau tias PCB hloov tau muab kev ua tau zoo tshaj plaws hauv txhua qhov xwm txheej. Tsis tas li ntawd, cov kab dav dav dav, kab sib nrug thiab lub rooj tsav xwm tuab tshwj xeeb qhia txog Capel txoj kev cog lus muaj zog rau qhov raug thiab qhov sib xws, uas yog cov yam ntxwv tseem ceeb los xyuas kom muaj kev ua haujlwm zoo thiab kev sib raug zoo hauv lub tshuab tsheb.

Tshooj 3:Complexities ntawm Qhov Tsim thiab Kev Npaj Nto

Cov qauv tsim qhov nyuaj hauv PCBs hloov tau yooj yim yog qhov tseem ceeb los xyuas kom muaj kev sib tshuam thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. Capel qhov kev txawj ntse hauv kev tsim thiab siv qhov muag tsis pom, faus, thiab plated los ntawm kev sau underscores lawv txoj kev cog lus kom ua tiav cov teeb pom kev zoo thiab kev ua haujlwm hluav taws xob. Tsis tas li ntawd, electroless npib tsib xee immersion kub (ENIG) nto kho tshuab nrog 2-3uin ultra-thin txheej qhia Capel txoj kev mob siab rau kev txhim kho kev ntseeg siab, solderability thiab tag nrho cov zoo ntawm cov PCBs hloov tau yooj yim rau kev siv tsheb.

Tshooj 4:Pioneering Advanced Manufacturing Processes thiab Tolerance Control

Kev tsim kho tsheb hloov pauv PCBs yuav tsum muaj kev sib koom ua ke ntawm cov txheej txheem siab heev thiab kev tswj xyuas nruj. Capel's 16 xyoo dhau los tau ua rau muaj peev xwm tsim tau los ntawm qhov tseeb, kev ntseeg tau thiab ua haujlwm tau zoo. Lub tuam txhab ua raws li kev ua siab ntev, nrog rau qib siab ntawm ± 0.1mm, uas qhia txog lawv qhov kev cog lus tsis sib haum xeeb rau kev tsis sib haum xeeb thiab zoo nrog txhua qhov hloov pauv PCB lawv tsim. Los ntawm drilling mus rau plating, imaging rau lamination thiab zaum kawg sib dhos, Capel cov txheej txheem tsim embodies thev naus laus zis innovation thiab kev ua haujlwm zoo.

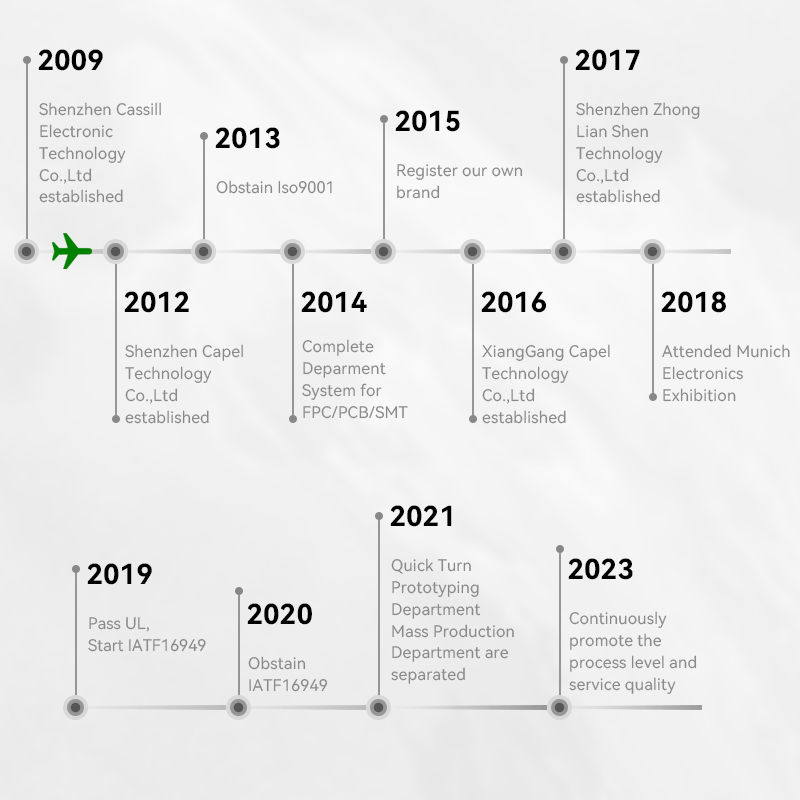

Tshooj 5 Lub ntsiab lus ntawm 16 xyoo: kev txawj ntse, kev tshaj lij thiab kev tsim kho tshiab

Lub Hoobkas Capel 16-xyoo keeb kwm raws li lub tsheb hloov pauv PCB cov chaw tsim khoom yog ib qho pov thawj rau lawv qhov kev cog lus tsis txaus ntseeg rau kev ua tau zoo, kev tsim kho tshiab thiab cov neeg siv khoom txaus siab. Cov kws tshaj lij hauv tsheb hloov pauv PCB tsim, tsim qauv thiab tsim khoom ua haujlwm ua lub teeb pom kev ntawm kev tshaj lij thiab kev muaj peev xwm, txhim kho lawv txoj haujlwm ua tus thawj coj hauv kev lag luam. Kev sib koom ua ke ntawm Capel cov txheej txheem ua tau zoo tshaj plaws, kev siv thev naus laus zis thiab kev cog lus rau kev txhim kho txuas ntxiv tau ua rau lub tuam txhab muaj kev ntseeg siab rau automotive OEMs thiab cov chaw muag khoom thoob ntiaj teb.

Automotive Flex PCB Design & Prototyping thiab Fabrication Process

Tshooj 6: Xaus: Lub neej yav tom ntej ntawm automotive saj zawg zog PCBs thiab Capel lub siab indomitable

Raws li kev siv tshuab thev naus laus zis txuas ntxiv mus ntawm qhov tsis tau pom dua, lub luag haujlwm ntawm PCB hloov pauv tau dhau los ua qhov tseem ceeb. Nrog 16 xyoo ntawm kev txawj ntse, lub Hoobkas Capel yog nyob rau hauv lub forefront ntawm no technologies kev loj hlob, tsav los ntawm ib tug relentless lub siab ntawm innovation, precision thiab adaptability. Tag nrho cov txheej txheem los ntawm kev tsim tswv yim rau kev tsim qauv thiab kev tsim khoom zaum kawg qhia txog Capel txoj kev cog lus ruaj khov rau kev txhim kho thev naus laus zis thiab cov neeg siv khoom txaus siab. Raws li kev lag luam tsheb txav mus rau lub neej yav tom ntej uas muaj kev ywj pheej, kev sib txuas, thiab kev siv hluav taws xob, Capel qhov kev txawj ntse yuav tsis xav tias yuav txuas ntxiv mus rau qhov zoo li qub thiab kho dua tshiab ntawm automotive saj zawg zog PCB thev naus laus zis.

Txhua tus hais

Capel's 16 xyoo ntawm kev paub hauv tsheb hloov pauv PCB tsim, kev tsim qauv thiab kev tsim khoom tau crystallized rau hauv kev coj noj coj ua ntawm kev ua tau zoo, kev tsim kho tshiab thiab kev txawj ntse. Lawv paub txog qhov nyuaj ntawm 8-txheej HDI thib ob-theem rigid-flex PCB, cov khoom siv muaj pes tsawg leeg, cov txheej txheem tsim khoom siab heev thiab kev cog lus tsis txaus ntseeg rau cov neeg siv khoom txaus siab tau ua rau lawv ua tus thawj coj tsis sib xws hauv tsheb hloov pauv PCB thev naus laus zis. Raws li kev lag luam tsheb leaps mus rau qhov tshiab frontiers ntawm innovation, Capel cov kev txawj ntse yuav txuas ntxiv mus ua lub hauv paus txhim khu kev qha rau yav tom ntej technologies.

Post lub sij hawm: Mar-04-2024

Rov qab