Qhia:

Nyob rau hauv lub ntiaj teb no technology-tsav, qhov kev thov rau complex thiab saj zawg zog luam Circuit Court boards (PCBs) yog loj hlob sai heev. Los ntawm cov txheej txheem kev ua haujlwm siab rau cov khoom siv thiab cov khoom siv kho mob, cov PCBs siab heev tau dhau los ua ib feem tseem ceeb ntawm cov khoom siv hluav taws xob niaj hnub no. Txawm li cas los xij, raws li cov kev xav tau yooj yim thiab hloov pauv tau nce ntxiv, yog li qhov xav tau ntawm cov thev naus laus zis ntau lawm uas tuaj yeem ua tau raws li cov kev xav tau tshwj xeeb no.Hauv qhov blog no, peb yuav tshawb txog cov toj roob hauv pes hloov zuj zus ntawm PCB ntau lawm thiab sib tham seb nws puas muaj peev xwm ua tau raws li qhov yuav tsum tau muaj ntawm PCBs nyuaj thiab hloov tau.

Kawm paub txog qhov nyuaj thiab hloov pauv PCBs:

Complex PCBs yog tus cwj pwm los ntawm cov qauv tsim uas sib koom ua ke ntau yam haujlwm hauv qhov chaw txwv. Cov no muaj xws li multilayer PCBs, high-density interconnect (HDI) boards, thiab PCBs nrog dig muag thiab faus vias. Saj zawg zog PCBs, ntawm qhov tod tes, yog tsim los khoov los yog twisted yam tsis muaj kev puas tsuaj rau lub circuitry, ua rau lawv zoo tagnrho rau cov kev siv qhov yooj yim thiab qhov chaw optimization yog qhov tseem ceeb. Cov PCBs no feem ntau siv hloov pauv tau yooj yim xws li polyimide lossis polyester.

Qhov nce ntawm advanced ntau lawm technology:

Ib txwm siv PCB ntau lawm txoj kev, xws li etching, lamination, thiab lwm yam, tsis txaus los ua kom tau raws li qhov xav tau ntawm cov txheej txheem nyuaj, hloov tau yooj yim PCBs. Qhov no tau coj mus rau kev txhim kho ntawm ntau yam khoom siv thev naus laus zis uas muab ntau dua precision, yoog raws thiab ua haujlwm tau zoo.

1. Laser Direct Imaging (LDI):LDI thev naus laus zis siv lasers ncaj qha nthuav tawm PCB substrates, tshem tawm qhov xav tau rau lub sijhawm siv sijhawm thiab ua yuam kev-nrawm photomasks. Cov thev naus laus zis ua rau cov khoom siv hluav taws xob ultra-nplua, cov kab nyias nyias thiab cov vias me me, uas yog qhov tseem ceeb rau cov PCBs nyuaj.

2. Additive Manufacturing:Kev tsim khoom siv ntxiv lossis 3D luam ntawv tau hloov pauv ntawm kev tsim cov PCBs nyuaj thiab hloov tau. Nws ua rau nws yooj yim los tsim cov qauv tsim, tshwj xeeb tshaj yog rau cov qauv thiab cov khoom ntim qis. Additive manufacturing enables sai iteration thiab customization, pab designers thiab manufacturers ua tau raws li cov kev xav tau tshwj xeeb ntawm complex thiab saj zawg zog PCBs.

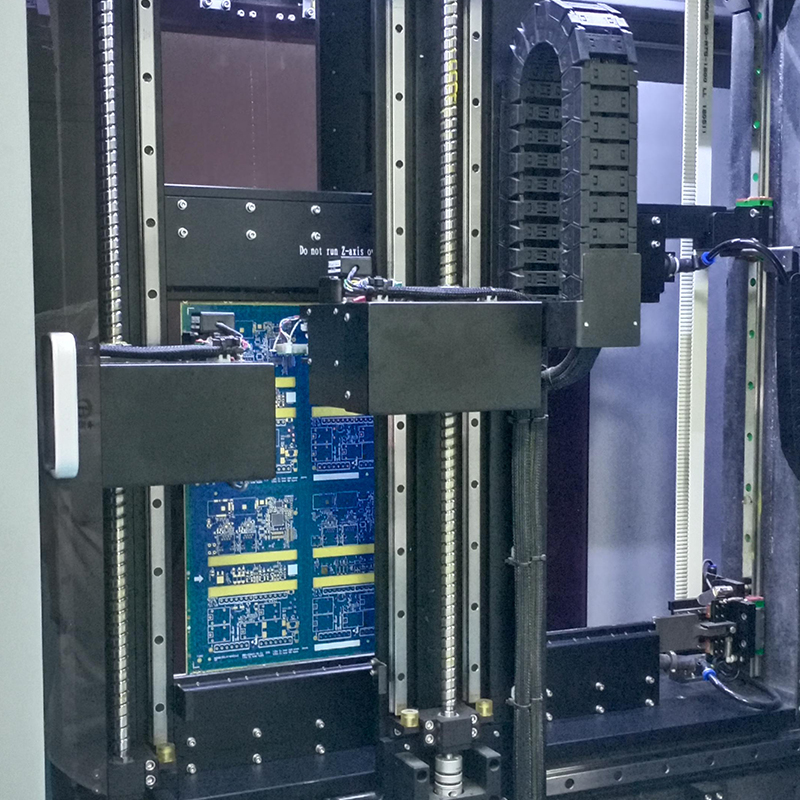

3. Saj zawg zog substrate tuav:Kev lig kev cai, nruj PCBs yog tus qauv, txwv kev tsim muaj peev xwm thiab txo qhov hloov pauv ntawm cov tshuab hluav taws xob. Txawm li cas los xij, kev nce qib hauv cov ntaub ntawv substrate thiab kev siv thev naus laus zis tau qhib txoj hauv kev tshiab rau kev tsim cov ntawv luam tawm yooj yim. Cov neeg tsim khoom tam sim no tau nruab nrog cov tshuab tshwj xeeb uas ua kom muaj qhov raug tuav thiab ua kom zoo ntawm cov substrates hloov tau, txo qhov kev pheej hmoo ntawm kev puas tsuaj thaum lub sijhawm tsim khoom.

Cov kev sib tw thiab kev daws teeb meem:

Txawm hais tias kev tsim khoom siv thev naus laus zis txuas ntxiv mus, cov kev cov nyom tseem yuav tsum tau kov yeej kom ua tau raws li cov kev xav tau ntawm cov khoom siv nyuaj, hloov tau yooj yim PCBs.

1. Nqi:Kev siv cov thev naus laus zis ntau lawm feem ntau xav tau cov nqi siab dua. Qhov no tuaj yeem raug ntaus nqi rau thawj zaug peev uas yuav tsum tau ua hauv cov khoom siv, kev cob qhia thiab cov ntaub ntawv tshwj xeeb. Txawm li cas los xij, raws li cov thev naus laus zis no nthuav dav thiab xav tau nce ntxiv, kev lag luam ntawm cov nplai yuav tsum txo cov nqi.

2. Kev txawj thiab kev cob qhia:Kev siv cov thev naus laus zis tshiab yuav tsum muaj cov kws tshaj lij hauv kev ua haujlwm thiab tswj xyuas cov tshuab siab heev. Cov tuam txhab yuav tsum tau nqis peev pab rau cov kev kawm tsis tu ncua thiab nyiam cov txuj ci los xyuas kom muaj kev hloov pauv mus rau cov thev naus laus zis tshiab no.

3. Cov qauv thiab kev tswj xyuas zoo:Raws li PCB thev naus laus zis txuas ntxiv txhim kho, nws tau dhau los ua qhov tseem ceeb los tsim cov qauv kev lag luam thiab siv cov kev tswj xyuas nruj. Cov neeg tsim khoom, cov tswj hwm thiab cov koom haum kev lag luam yuav tsum ua haujlwm ua ke kom ntseeg tau tias muaj kev ntseeg siab thiab kev nyab xeeb ntawm cov PCBs nyuaj thiab hloov tau yooj yim.

Hauv cov ntsiab lus:

Tsav los ntawm kev xav tau ntawm cov tshuab hluav taws xob niaj hnub no, cov kev xav tau ntawm cov PCBs nyuaj thiab hloov tau hloov tas li.Thaum cov thev naus laus zis ntau lawm xws li laser direct imaging thiab additive manufacturing muaj peev xwm txhim kho PCB ntau lawm, tseem muaj kev cov nyom kom kov yeej cov nqi, kev txawj ntse thiab kev tswj kom zoo. Txawm li cas los xij, nrog rau kev siv zog txuas ntxiv thiab kev koom tes ua haujlwm, thaj chaw tsim khoom tau npaj kom tau raws thiab tshaj qhov xav tau ntawm cov PCBs nyuaj thiab hloov tau. Raws li kev siv thev naus laus zis txuas ntxiv mus, peb tuaj yeem cia siab txuas ntxiv kev tsim kho tshiab hauv cov txheej txheem tsim khoom kom ntseeg tau tias kev sib koom ua ke ntawm PCBs mus rau hauv cov ntawv siv hluav taws xob feem ntau.

Post lub sij hawm: Oct-30-2023

Rov qab