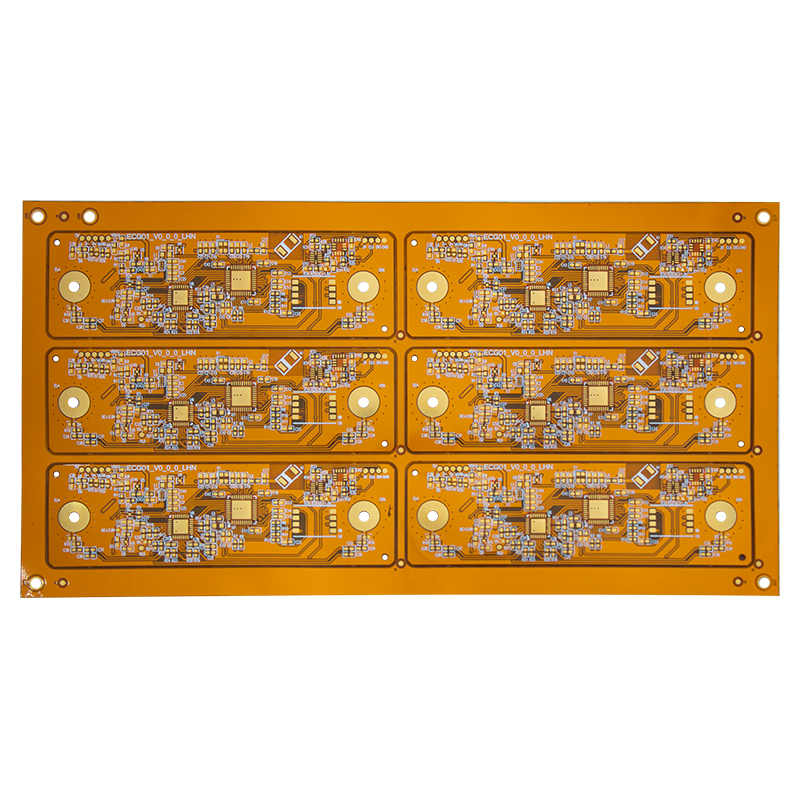

Lub ntiaj teb ntawm cov khoom siv hluav taws xob tau ua kom muaj kev vam meej nyob rau hauv kaum xyoo tsis ntev los no, thiab tom qab txhua qhov kev xav hauv hluav taws xob yog cov ntawv luam tawm Circuit Board (PCB). Cov khoom me me tab sis tseem ceeb no yog cov caj qaum ntawm yuav luag txhua yam khoom siv hluav taws xob. Ntau hom PCBs ua tau raws li qhov xav tau sib txawv, ib hom yog ENIG PCB.Hauv qhov blog no, peb yuav delve rau hauv cov ntsiab lus ntawm ENIG PCB, nthuav tawm nws cov yam ntxwv, siv thiab nws txawv li cas ntawm lwm hom PCBs.

1.Dab tsi yog immersion kub PCB?

Ntawm no peb yuav muab qhov tob saib ntawm ENIG PCBs, suav nrog lawv cov khoom, kev tsim kho, thiab cov txheej txheem electroless nickel immersion kub siv rau kev tsim khoom. Cov neeg nyeem yuav nkag siab meej txog cov yam ntxwv tshwj xeeb uas ua rau ENIG PCBs sawv tawm.

ENIG yog cov ntawv luv ntawm electroless npib tsib xee immersion kub plating, uas yog ib qho kev siv kev kho deg hauv PCB manufacturing.Nws muab cov kev daws teeb meem txhim khu kev qha thiab raug nqi los xyuas kom lub neej ntev thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. ENIG PCBs tau siv dav hauv kev lag luam xws li kev sib txuas lus, aerospace, khoom siv hluav taws xob, thiab khoom siv kho mob.

ENIG PCBs yog tsim los ntawm peb yam tseem ceeb: npib tsib xee, kub, thiab txheej thaiv.Cov txheej thaiv txheej feem ntau yog ua los ntawm ib txheej nyias ntawm electroless npib tsib xee tso rau ntawm cov kab tooj liab thiab cov ntaub qhwv ntawm PCB. Cov txheej npib tsib xee no ua raws li qhov cuam tshuam ntawm kev sib kis, tiv thaiv tooj liab los ntawm kev tsiv mus rau txheej kub thaum lub sij hawm kub deposition. Tom qab siv cov nickel txheej, nyias txheej ntawm kub yog tso rau saum. Cov txheej kub muab zoo heev conductivity, durability thiab corrosion kuj. Nws kuj tseem muab qib kev tiv thaiv oxidation, kom ntseeg tau tias PCB kev ua haujlwm ntev thiab kev ntseeg tau.

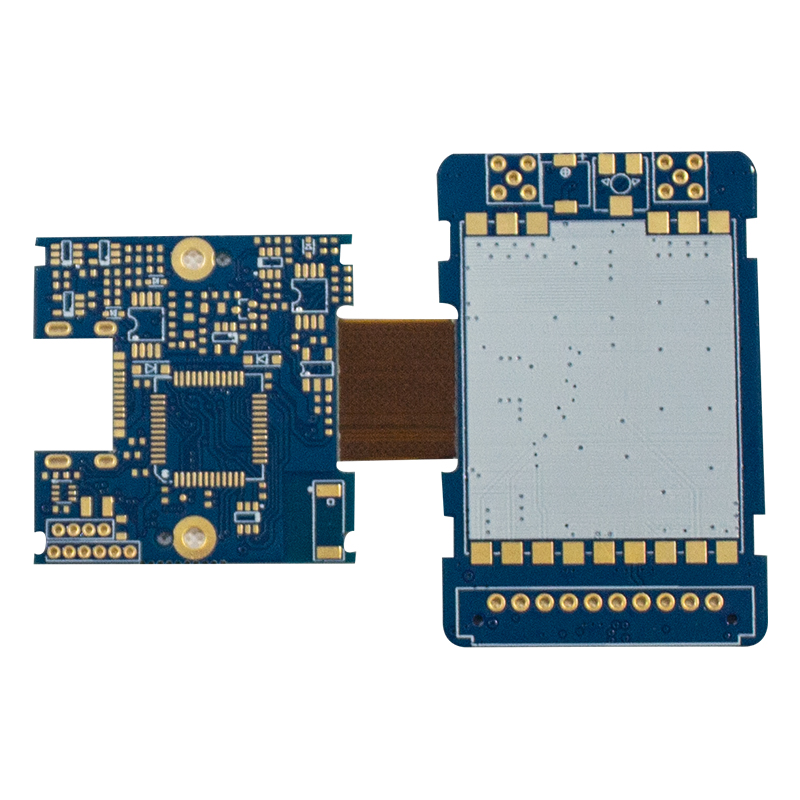

Cov txheej txheem tsim khoom ntawm ENIG PCB suav nrog ob peb kauj ruam. Ua ntej, PCB yog qhov chaw kho thiab ntxuav kom tshem tawm cov kab mob thiab oxides ntawm tooj liab. Tom qab ntawd PCB tau muab tso rau hauv lub da dej electroless npib tsib xee plating, qhov twg cov tshuaj tiv thaiv kab mob tso ib txheej npib tsib xee mus rau cov kab tooj liab thiab cov ntaub qhwv. Tom qab cov npib tsib xee tso, yaug thiab ntxuav PCB dua kom tshem tawm cov tshuaj ntxiv. Thaum kawg, PCB yog raus rau hauv ib da dej kub thiab ib txheej nyias ntawm kub yog plated rau ntawm npib tsib xee nto los ntawm ib qho kev tawm tsam. Lub thickness ntawm cov txheej kub tuaj yeem sib txawv nyob ntawm qhov kev thov tshwj xeeb thiab cov kev xav tau. ENIG PCB muaj ntau yam zoo dua lwm yam kev kho mob saum npoo. Ib qho ntawm cov txiaj ntsig tseem ceeb yog nws qhov chaw tiaj tus thiab tsis sib xws, uas ua kom zoo heev solderability thiab ua rau nws haum rau Surface Mount Technology (SMT) cov txheej txheem sib dhos. Cov chaw kub kuj tseem tiv taus oxidation, pab tswj kev sib txuas hluav taws xob txhim khu kev qha thaum lub sijhawm.

Lwm qhov txiaj ntsig ntawm ENIG PCBs yog lub peev xwm los muab cov pob qij txha ruaj khov thiab zoo ib yam.Lub tiaj thiab du nto ntawm txheej kub txhawb nqa zoo wetting thiab adhesion thaum lub sij hawm soldering txheej txheem, ua rau muaj zog thiab txhim khu kev qha solder sib koom.

ENIG PCBs kuj tseem paub txog lawv cov kev ua tau zoo ntawm hluav taws xob thiab teeb liab kev ncaj ncees.Cov nickel txheej ua raws li qhov thaiv, tiv thaiv tooj liab los ntawm diffusing rau hauv cov txheej kub thiab tswj cov khoom hluav taws xob ntawm lub voj voog. Ntawm qhov tod tes, cov txheej kub muaj kev sib cuag tsis zoo thiab cov khoom siv hluav taws xob zoo heev, kom ntseeg tau tias cov teeb liab kis tau zoo.

2.Cov txiaj ntsig ntawm ENIG PCB

Ntawm no peb delve rau hauv cov txiaj ntsig ntawm ENIG PCBs xws li superior solderability, durability, corrosion kuj thiab hluav taws xob conductivity. Cov txiaj ntsig no ua rau ENIG PCB haum rau ntau yam kev siv

ENIG PCB lossis Electroless Nickel Immersion Kub PCB muaj ntau qhov zoo dua lwm yam kev kho saum npoo, ua rau nws tsim nyog rau ntau yam kev siv hauv kev lag luam hluav taws xob. Cia peb tshawb txog qee qhov txiaj ntsig zoo hauv kev nthuav dav ntxiv.

Zoo heev solderability:

ENIG PCBs muaj qhov zoo tshaj plaws solderability, ua rau lawv zoo tagnrho rau Surface Mount Technology (SMT) cov txheej txheem sib dhos. Cov txheej kub nyob rau sab saum toj ntawm cov npib tsib xee barrier muab lub tiaj tiaj thiab zoo ib yam, txhawb kev ntub dej zoo thiab adhesion thaum lub sij hawm soldering. Qhov no ua rau muaj zog, txhim khu kev qha kev sib koom ua ke, ua kom muaj kev ncaj ncees thiab kev ua tau zoo ntawm PCB sib dhos.

Durability:

ENIG PCBs paub txog lawv cov kav ntev thiab ntev. Cov txheej kub ua raws li cov txheej txheem tiv thaiv, muab qib kev tiv thaiv oxidation thiab corrosion. Qhov no ua kom ntseeg tau tias PCB tuaj yeem tiv taus ib puag ncig hnyav, suav nrog cov av noo siab, hloov pauv kub thiab raug tshuaj lom neeg. Lub durability ntawm ENIG PCBs txhais tau tias muaj kev ntseeg siab dua thiab lub neej ntev dua, ua rau lawv tsim nyog rau cov ntawv thov uas xav tau kev ua haujlwm ntev.

Corrosion Resistance:

Electroless npib tsib xee txheej hauv ENIG PCB tsim ib qho kev thaiv ntawm cov kab tooj liab thiab txheej kub. Qhov kev thaiv no tiv thaiv tooj liab los ntawm kev tsiv mus rau hauv kub thaum lub sij hawm kub deposition. Yog li ntawd, ENIG PCB nthuav tawm zoo heev corrosion kuj txawm nyob rau hauv ib puag ncig corrosive. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov uas PCBs tuaj yeem raug ya raws, tshuaj lom neeg lossis lwm yam corrosive agents.

conductivity:

ENIG PCB yog qhov ua tau zoo ua tsaug rau nws cov txheej kub. Kub yog ib qho zoo heev tus neeg xyuas pib ntawm hluav taws xob thiab tuaj yeem xa cov teeb liab zoo ntawm PCBs. Lub ntsej muag kub zoo ib yam kuj ua kom tsis muaj kev sib cuag, txo qis cov teeb liab poob lossis degradation. Qhov no ua rau ENIG PCB haum rau cov ntawv thov uas yuav tsum tau muaj kev kub ceev thiab cov teeb liab kis tau zoo, xws li kev sib txuas lus, aerospace thiab cov khoom siv hluav taws xob.

Nto Flatness:

ENIG PCBs muaj lub tiaj tiaj thiab tsis sib xws, uas yog qhov tseem ceeb rau kev sib dhos zoo ib yam thiab txhim khu kev qha. Lub tiaj tiaj ua kom muaj kev sib faib ntawm cov tshuaj txhuam hniav thaum lub sij hawm luam ntawv stencil, yog li txhim kho kev sib koom tes zoo. Nws kuj ua kom yooj yim tso rau qhov chaw ntawm qhov chaw mounting, txo qhov kev pheej hmoo ntawm kev tsis ncaj ncees los yog luv luv circuits. Qhov chaw tiaj tus ntawm ENIG PCBs nce kev tsim khoom tag nrho thiab ua rau cov khoom siv PCB zoo dua.

Hlau Bonding Compatibility:

ENIG PCBs kuj tau sib xws nrog cov txheej txheem kev sib txuas ntawm cov xov hlau, qhov uas cov xov hlau me me tau txuas nrog PCB los ua kev sib txuas hluav taws xob. Cov txheej kub muab qhov chaw tsim nyog rau kev sib txuas ntawm cov hlau, ua kom muaj zog thiab txhim khu kev qha xaim. Qhov no ua rau ENIG PCBs yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau kev sib txuas ntawm cov xov hlau, xws li microelectronics, automotive electronics thiab cov khoom siv kho mob.

RoHS Ua raws:

ENIG PCBs yog ib puag ncig tus phooj ywg thiab ua raws li Txoj Cai Lij Choj Ntawm Cov Tshuaj Tiv Thaiv Kab Mob (RoHS) cov lus qhia. Cov txheej txheem ENIG tso tawm tsis cuam tshuam nrog cov khoom tsis zoo, ua rau nws muaj kev nyab xeeb dua thiab muaj kev nyab xeeb dua rau lwm yam kev kho mob saum npoo uas yuav muaj cov tshuaj lom.

3.ENIG PCB vs. lwm hom PCB

Kev sib piv nrog rau lwm hom PCB xws li FR-4, OSP, HASL thiab Immersion Silver PCB yuav qhia txog cov yam ntxwv tshwj xeeb, qhov zoo thiab qhov tsis zoo ntawm txhua PCB.

FR-4 PCB:FR-4 (Flame Retardant 4) yog cov khoom siv dav hauv PCB substrate. Nws yog ib qho epoxy resin reinforced nrog woven iav fibers thiab paub txog nws zoo hluav taws xob insulating zog. FR-4 PCB muaj cov yam ntxwv hauv qab no:

qhov zoo:

Zoo mechanical zog thiab rigidity

Hluav taws xob rwb thaiv tsev zoo heev

Tus nqi siv tau thiab dav siv

tsis txaus:

Tsis haum rau cov ntawv thov ntau zaus vim qhov poob siab dielectric

Tsawg thermal conductivity

Yooj yim absorbs ya raws lub sij hawm, ua rau impedance hloov thiab teeb liab attenuation

Hauv cov ntawv thov uas xav tau kev xa xov hluav taws xob ntau zaus, ENIG PCB nyiam dua FR-4 PCB vim ENIG muaj cov khoom siv hluav taws xob zoo dua thiab qis dua teeb liab.

OSP PCB:OSP (Organic Solderability Preservative) yog kev kho saum npoo siv rau PCBs los tiv thaiv cov kab tooj liab los ntawm oxidation. OSP PCB muaj cov yam ntxwv hauv qab no:

qhov zoo:

Ib puag ncig tus phooj ywg thiab RoHS raws

Tus nqi qis dua piv rau lwm yam kev kho saum npoo

Zoo rau smoothness thiab flatness

tsis txaus:

Tsawg txee lub neej; txheej tiv thaiv degrades lub sij hawm

Txwv tsis pub muaj dej noo thiab hnyav ib puag ncig

Tsawg thermal kuj

Thaum corrosion kuj, durability thiab ncua kev pab cuam lub neej yog ib qho tseem ceeb, ENIG PCB yog nyiam dua OSP PCB vim ENIG lub superior oxidation thiab corrosion tiv thaiv.

Spray tin PCB:HASL (Hot Air Solder Leveling) yog ib txoj kev kho saum npoo uas cov

PCB yog immersed nyob rau hauv molten solder thiab ces leveled nrog cua kub. HASL PCB muaj cov yam ntxwv hauv qab no:

qhov zoo:Tus nqi siv tau thiab dav siv

Zoo solderability thiab coplanarity

Haum rau los ntawm qhov sib txuas

tsis txaus:

Qhov saum npoo yog qhov tsis sib xws thiab muaj peev xwm ua rau muaj teeb meem coplanarity

Cov txheej txheej tuab yuav tsis sib haum nrog cov khoom zoo

Ua rau thermal shock thiab oxidation thaum reflow soldering

ENIG PCBs nyiam dua HASL PCBs rau cov ntawv thov uas yuav tsum tau ua kom zoo tshaj plaws, ua kom lub ntsej muag zoo dua, kev sib koom ua ke zoo dua, thiab kev sib raug zoo nrog cov khoom zoo.

Immersion nyiaj PCB:Immersion silver yog ib txoj kev kho saum npoo uas lub PCB tau muab tso rau hauv cov nyiaj da dej, tsim ib txheej nyias ntawm cov nyiaj hla cov kab tooj liab. Immersion Silver PCB muaj cov yam ntxwv hauv qab no:

qhov zoo:

Zoo heev hluav taws xob conductivity thiab solderability

Zoo flatness thiab coplanarity

Haum rau cov khoom siv suab zoo

tsis txaus:

Tsawg lub neej txee vim tarnishing dhau sijhawm

rhiab heev rau kev tuav thiab kis kab mob thaum sib dhos

Tsis haum rau cov ntawv thov kub

Thaum lub sijhawm ua haujlwm ntev, kev tiv thaiv corrosion thiab lub neej ntev ntev yuav tsum tau ua, ENIG PCB yog qhov zoo dua rau immersion nyiaj PCB vim ENIG muaj kev tiv thaiv ntau dua rau tarnishing thiab zoo sib xws nrog cov ntawv thov kub.

4.Kev thov ntawm ENIG PCB

ENIG PCB (ie Electroless Nickel Immersion Gold PCB) yog dav siv nyob rau hauv ntau yam lag luam vim nws muaj ntau yam zoo dua lwm hom PCB.Cov lus no tshawb txog ntau yam kev lag luam siv ENIG PCBs, hais txog lawv qhov tseem ceeb hauv cov khoom siv hluav taws xob, aerospace thiab kev tiv thaiv, cov khoom siv kho mob. , thiab industrial automation.

Cov khoom siv hluav taws xob siv hluav taws xob:

ENIG PCBs ua lub luag haujlwm tseem ceeb hauv cov neeg siv khoom siv hluav taws xob uas qhov loj me, kev ua haujlwm siab thiab kev ntseeg siab yog qhov tseem ceeb. Lawv siv hauv smartphones, ntsiav tshuaj, laptops, game consoles, thiab lwm yam khoom siv hluav taws xob. ENIG qhov kev ua tau zoo tshaj plaws thiab tsis tshua muaj qhov tsis zoo ua rau nws zoo tagnrho rau cov ntawv thov siv zaus, ua kom cov ntaub ntawv hloov pauv sai, teeb liab kev ncaj ncees, thiab txo cov hluav taws xob cuam tshuam. Tsis tas li ntawd, ENIG PCBs muab cov khoom zoo, uas yog qhov tseem ceeb thaum lub sij hawm sib dhos ntawm cov khoom siv hluav taws xob.

Aerospace thiab Defense:

Kev lag luam aerospace thiab kev tiv thaiv muaj kev nruj me ntsis rau cov tshuab hluav taws xob vim muaj kev ua haujlwm hnyav, huab cua txias thiab cov qauv kev ntseeg siab. ENIG PCBs yog dav siv hauv avionics, satellite systems, radar khoom thiab tub rog qib electronics. ENIG qhov tshwj xeeb corrosion kuj thiab kav ntev ua rau nws haum rau kev pab cuam lub neej ntev hauv qhov chaw nyuaj. Tsis tas li ntawd, nws cov tuab tuab thiab flatness ua kom muaj kev ua tau zoo thiab kev ntseeg tau.

Cov cuab yeej kho mob:

Hauv kev kho mob, ENIG PCBs tau siv ntau yam kev siv, suav nrog cov neeg mob saib xyuas cov kab mob, cov cuab yeej kuaj mob, cov cuab yeej siv tshuaj ntsuam xyuas, cov cuab yeej phais thiab cov khoom siv cog qoob loo. ENIG's biocompatibility thiab corrosion kuj ua rau nws tsim nyog rau cov khoom siv kho mob uas nkag mus rau hauv cov kua hauv lub cev los yog ua kom tsis muaj menyuam. Tsis tas li ntawd, ENIG tus du nto thiab solderability tso cai rau kev sib txuas thiab sib dhos ntawm cov khoom siv hluav taws xob nyuaj hauv cov khoom siv kho mob. automated kev lag luam:

ENIG PCBs tau siv dav hauv kev lag luam automation, suav nrog cov txheej txheem tswj hwm, neeg hlau, lub cev muaj zog, khoom siv hluav taws xob, thiab sensors. ENIG qhov kev ntseeg siab thiab kev sib raug zoo ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov kev lag luam uas yuav tsum tau ua haujlwm tas mus li thiab tsis kam mus rau qhov chaw hnyav. ENIG qhov zoo tshaj plaws solderability ua kom ntseeg tau kev sib txuas hauv kev siv hluav taws xob siab thiab kub kub, muab qhov tsim nyog ruaj khov thiab ruaj khov rau kev lag luam automation systems.

Tsis tas li ntawd, ENIG PCBs yog siv rau hauv lwm cov lag luam xws li tsheb, kev sib txuas lus, lub zog, thiab IoT (Internet of Things) li.Kev lag luam tsheb siv ENIG PCBs hauv tsheb hluav taws xob, lub cav tswj cov tshuab, kev nyab xeeb thiab kev lom zem tshuab. Telecom networks cia siab rau ENIG PCBs los tsim cov chaw nres tsheb hauv paus, routers, keyboards thiab khoom siv sib txuas lus. Hauv kev lag luam hluav taws xob, ENIG PCBs tau siv rau hauv kev tsim hluav taws xob, kev faib hluav taws xob thiab cov tshuab hluav taws xob tauj dua tshiab. Tsis tas li ntawd, ENIG PCBs yog ib feem tseem ceeb ntawm IoT cov khoom siv, txuas ntau yam khoom siv thiab ua kom muaj kev sib pauv ntaub ntawv thiab kev siv lub tshuab ua haujlwm.

5.ENIG PCB Manufacturing thiab Design Considerations

Thaum tsim thiab tsim ENIG PCBs, muaj ntau yam tseem ceeb uas yuav tsum tau xav txog txhawm rau ua kom pom kev ua tau zoo thiab kev ntseeg tau. Nov yog qee cov qauv tsim qauv thiab cov txheej txheem tsim khoom tshwj xeeb rau ENIG PCBs:

Pad tsim:

Lub ncoo tsim ntawm ENIG PCB yog ib qho tseem ceeb kom ntseeg tau tias kev sib txuas thiab kev ntseeg tau zoo. Cov ntaub qhwv yuav tsum tau tsim nrog qhov tseeb qhov ntev, suav nrog qhov dav, qhov ntev, thiab qhov sib txawv, kom haum rau cov khoom siv lead ua thiab cov tshuaj txhuam. Cov ntaub qhwv ntsej muag yuav tsum du thiab huv si kom tso cai rau ntub dej kom zoo thaum lub sijhawm ua haujlwm.

Khiav qhov dav thiab qhov sib txawv:

Cov kab dav dav thiab qhov sib nrug yuav tsum ua raws li cov qauv kev lag luam thiab cov kev cai tshwj xeeb ntawm PCB. Xyuas kom qhov tseeb qhov ntev tuaj yeem tiv thaiv cov teeb meem xws li teeb liab cuam tshuam, luv Circuit Court, thiab hluav taws xob tsis ruaj khov.

Board thickness thiab uniformity:

ENIG PCB muaj ib txheej ntawm electroless npib tsib xee thiab ib txheej kub immersed. Plating thickness yuav tsum tau tswj nyob rau hauv tshwj xeeb tolerances los xyuas kom meej ib yam kev pab them nqi ntawm tag nrho cov PCB nto. Uniform plating thickness yog qhov tseem ceeb rau kev ua haujlwm hluav taws xob zoo ib yam thiab txhim khu kev qha cov pob qij txha.

Daim ntawv thov Solder Mask:

Kev siv lub npog ntsej muag kom zoo yog qhov tseem ceeb rau kev tiv thaiv PCB kab thiab tiv thaiv cov txuas hniav. Lub npog ntsej muag yuav tsum tau siv sib npaug thiab raug kom ntseeg tau tias cov ntaub qhwv ntsej muag muaj qhov yuav tsum tau siv lub npog ntsej muag qhib rau cov khoom siv.

Solder Paste Template Tsim:

Thaum siv tshuab nto mount (SMT) yog siv rau kev sib dhos, cov nplaum nplaum nplaum yog siv los ua kom raug tso rau hauv cov khoom siv PCB. Tus qauv tsim stencil yuav tsum ua kom raug nrog cov ntaub qhwv ntsej muag thiab tso cai rau kev tso tawm ntawm cov tshuaj txhuam hniav kom ntseeg tau tias muaj kev sib koom ua ke zoo thaum lub sijhawm rov ua haujlwm.

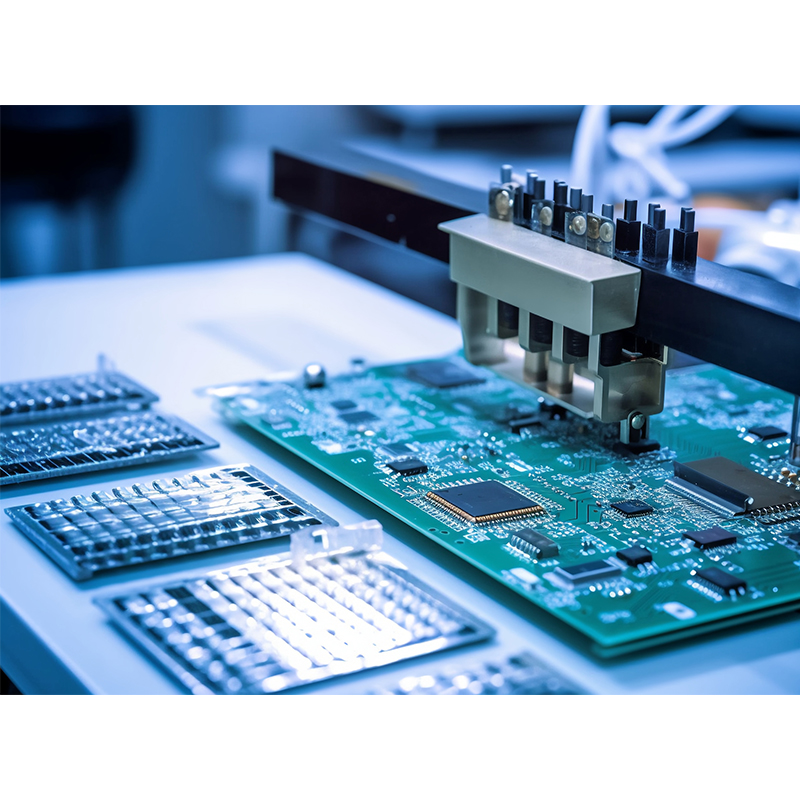

Kev Tswj Xyuas Zoo:

Thaum lub sij hawm tsim cov txheej txheem, nws yog ib qho tseem ceeb uas yuav tau ua kom zoo tswj xyuas kom paub tseeb tias ENIG PCB ua tau raws li qhov yuav tsum tau specifications. Cov kev tshuaj xyuas no yuav suav nrog kev tshuaj xyuas qhov muag, kuaj hluav taws xob thiab kev txheeb xyuas kev sib koom ua ke. Kev tswj xyuas zoo pab txheeb xyuas cov teeb meem thaum lub sij hawm tsim khoom thiab xyuas kom meej tias cov PCB tiav ua tau raws li cov qauv xav tau.

Compatibility sib dhos:

Nws yog ib qho tseem ceeb uas yuav tau xav txog qhov sib xws ntawm ENIG nto tiav nrog cov txheej txheem sib dhos sib txawv. Lub solderability thiab reflow yam ntxwv ntawm ENIG yuav tsum tau sib xws nrog cov txheej txheem sib dhos tshwj xeeb siv. Qhov no suav nrog kev txiav txim siab xws li kev xaiv solder paste, reflow profile optimization, thiab kev sib raug zoo nrog cov txheej txheem tsis muaj hlau lead (yog tias tsim nyog).

Los ntawm kev ua raws li cov txheej txheem tsim qauv no thiab cov txheej txheem tsim khoom rau ENIG PCBs, cov tuam ntxhab tuaj yeem xyuas kom meej tias cov khoom kawg ua tau raws li qhov yuav tsum tau ua thiab cov qauv kev ntseeg tau. Nws yog ib qho tseem ceeb uas yuav tsum tau ua haujlwm ze nrog PCB cov tuam txhab thiab cov koom tes sib koom ua ke kom tau raws li cov kev cai tshwj xeeb thiab ua kom muaj kev vam meej ntawm kev tsim khoom thiab kev sib dhos.

6.ENIG PCB FAQ

ENIG PCB yog dab tsi? Nws sawv rau dab tsi?

ENIG PCB stands rau Electroless Nickel Immersion Kub Printed Circuit Board. Nws yog ib qho kev kho deg uas siv los ntawm PCBs thiab muab kev tiv thaiv corrosion, flatness thiab zoo solderability.

Dab tsi yog cov txiaj ntsig ntawm kev siv ENIG PCB?

ENIG PCBs muaj ntau yam txiaj ntsig, suav nrog kev ua haujlwm zoo heev, kev siv hluav taws xob siab thiab kev tiv thaiv corrosion. Cov kub tiav muab cov txheej txheem tiv thaiv, ua rau nws tsim nyog rau cov ntawv thov uas muaj kev ntseeg siab yog qhov tseem ceeb.

Puas yog ENIG PCB kim?

ENIG PCBs zoo li yuav kim dua me ntsis piv rau lwm cov kev kho saum npoo. Tus nqi ntxiv yog vim cov kub siv hauv cov txheej txheem soaking. Txawm li cas los xij, qhov zoo thiab kev ntseeg tau muab los ntawm ENIG ua rau nws xaiv thawj zaug rau ntau daim ntawv thov, ua pov thawj nws tus nqi siab dua me ntsis.

Puas muaj kev txwv rau kev siv ENIG PCB?

Thaum ENIG PCBs muaj ntau qhov zoo, lawv kuj muaj qee qhov kev txwv. Piv txwv li, cov chaw kub yuav hnav tau yooj yim yog tias muaj kev ntxhov siab ntau dhau los yog hnav. Tsis tas li ntawd, ENIG tej zaum yuav tsis haum rau cov ntawv thov uas muaj qhov kub thiab txias lossis qhov twg qee cov tshuaj hnyav siv.

Puas yog ENIG PCB yooj yim mus yuav?

Yog lawm, ENIG PCBs yog dav siv los ntawm ntau yam PCB tuam ntxhab thiab cov muag khoom. Lawv yog cov kev xaiv ua tiav thiab tuaj yeem muab tau yooj yim kom haum raws li qhov xav tau sib txawv. Nws raug nquahu kom kuaj xyuas qhov muaj thiab lub sijhawm xa khoom nrog rau cov chaw tsim khoom lossis cov chaw muag khoom tshwj xeeb.

Kuv puas tuaj yeem rov ua haujlwm lossis kho ENIG PCB?

Yog lawm, ENIG PCBs tuaj yeem rov ua haujlwm lossis kho dua. Txawm li cas los xij, cov txheej txheem rov ua dua thiab kho dua tshiab rau ENIG yuav xav tau kev txiav txim siab tshwj xeeb thiab cov txheej txheem piv rau lwm yam kev kho saum npoo. Nws raug nquahu kom sab laj nrog tus kws tshaj lij PCB rov ua haujlwm kom ntseeg tau tias kev tuav tau zoo thiab tsis txhob cuam tshuam qhov kev ncaj ncees ntawm qhov chaw kub.

ENIG puas tuaj yeem siv rau cov hlau lead thiab tsis muaj hlau lead?

Yog lawm, ENIG tuaj yeem siv nrog cov txheej txheem ua cov hlau lead thiab tsis muaj hlau lead. Txawm li cas los xij, nws yog ib qho tseem ceeb kom ntseeg tau tias kev sib raug zoo nrog cov khoom siv tshwj xeeb thiab cov khoom siv reflow. Yuav kom ua tiav cov pob qij txha txhim khu kev qha thaum lub sij hawm sib dhos, vuam tsis yuav tsum tau kho kom zoo.

ENIG txheej txheem yog ib qho kev txhim khu kev qha thiab raug nqi zoo rau cov tuam ntxhab thiab cov neeg nyiam siv hluav taws xob. Kev sib xyaw ua ke ntawm nyias, sib npaug sib npaug ntawm cov npib tsib xee barrier thiab cov txheej kub saum toj kawg nkaus muab qhov pom kev ua tiav kom ntseeg tau tias lub neej ntev thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. Txawm hais tias nyob rau hauv kev sib txuas lus, aerospace lossis cov khoom siv hluav taws xob, ENIG PCBs tseem ua lub luag haujlwm tseem ceeb hauv kev ua kom thev naus laus zis thiab tsim lub neej yav tom ntej ntawm hluav taws xob.

Post lub sij hawm: Sep-13-2023

Rov qab