HDI (High Density Interconnect) rigid-flex PCBs sawv cev rau qhov kawg ntawm kev tshaj tawm Circuit Board board thev naus laus zis, sib txuas cov txiaj ntsig ntawm high-density thaiv muaj peev xwm nrog qhov yooj yim ntawm rigid-flex boards.Tsab ntawv xov xwm no yog txhawm rau nthuav qhia cov txheej txheem tsim khoom ntawm HDI rigid-flex PCB thiab muab kev nkag siab zoo rau nws cov qauv, cov ntaub ntawv thiab cov txheej txheem tsim khoom tseem ceeb.Los ntawm kev nkag siab txog cov complexities koom nrog, engineers thiab designers yuav optimize lawv designs thiab koom tes zoo nrog manufacturers tig lawv lub tswv yim tshiab rau hauv kev muaj tiag.

1. Nkag siabHDI rigid saj zawg zog PCB:

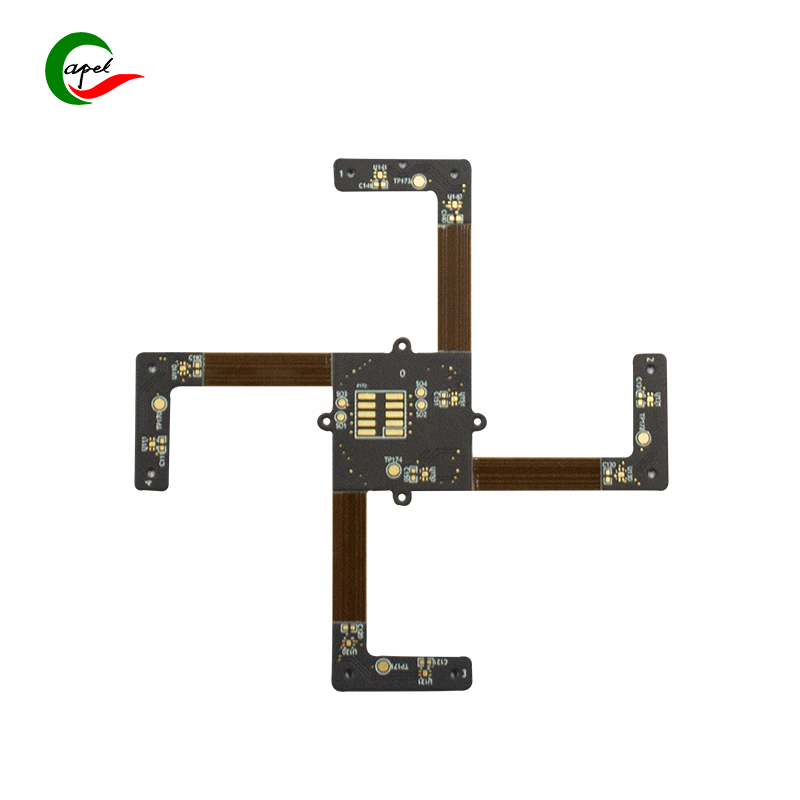

HDI (High Density Interconnect) rigid-flex PCB yog ib daim ntawv tshaj tawm ntawm cov ntawv luam tawm Circuit Board uas sib txuas cov txiaj ntsig ntawm kev sib txuas siab thiab kev ua haujlwm yooj yim.Qhov kev sib xyaw tshwj xeeb no ua rau lawv zoo tshaj plaws kom tau raws li cov khoom siv hluav taws xob niaj hnub no.

Kev kub siab tshaj plaws cuam tshuam txog kev muaj peev xwm ua kom tiav cov khoom siv siab thiab teeb liab kev nyob hauv kev txwv thaj chaw.Raws li qhov kev thov rau cov khoom me me, cov khoom siv sib txuas txuas ntxiv mus ntxiv, HDI thev naus laus zis ua rau tsim thiab tsim cov txheej txheem nyuaj hauv cov qauv me me. Kev sib txuas ntau ntxiv tso cai rau kev ua haujlwm ntau dua los ua ke rau hauv cov khoom siv me me, ua rau lawv muaj txiaj ntsig thiab muaj zog.

Flexibility yog lwm yam tseem ceeb ntawm HDI rigid-flex PCBs. Qhov kev hloov pauv no tso cai rau lub rooj tsavxwm tuaj yeem khoov, quav lossis twist yam tsis muaj kev cuam tshuam rau kev ua haujlwm lossis kev ntseeg siab.Flexibility yog tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau cov khoom siv hluav taws xob uas xav tau kev tsim lub cev tsis zoo lossis xav tau kom muaj kev vibration, poob siab, lossis qhov chaw huab cua. Nws kuj tseem ua rau muaj kev sib txuas ntawm cov khoom siv hluav taws xob los ntawm cov khoom siv hluav taws xob sib txawv, tshem tawm qhov xav tau rau cov khoom txuas ntxiv lossis cov cables.

Kev siv HDI thev naus laus zis muaj ntau qhov zoo.Ua ntej, nws zoo heev txhim kho cov teeb liab kev ncaj ncees los ntawm kev txo qhov kev ncua deb ntawm cov khoom thiab kev sib tshuam, txo cov teeb liab poob, crosstalk thiab electromagnetic cuam tshuam. Qhov no txhim kho kev ua tau zoo thiab kev ntseeg siab rau kev siv high-speed digital thiab RF. Qhov thib ob, HDI rigid-flex PCB tuaj yeem txo qhov loj thiab qhov hnyav ntawm cov khoom siv hluav taws xob. HDI thev naus laus zis tshem tawm qhov xav tau ntawm cov khoom sib txuas ntxiv, cov cables, thiab kev sib txuas ntawm pawg thawj coj saib, uas tso cai rau cov qauv tsim kom sib haum xeeb. Qhov no yog qhov tshwj xeeb tshaj yog muaj txiaj ntsig rau kev lag luam xws li aerospace thiab cov khoom siv hluav taws xob portable, uas txuag qhov hnyav thiab qhov chaw yog qhov tseem ceeb. Tsis tas li ntawd, HDI thev naus laus zis kuj tseem txhim kho kev ntseeg tau ntawm cov khoom siv hluav taws xob. Los ntawm kev txo tus naj npawb ntawm kev sib txuas, HDI rigid-flex PCBs txo qhov kev pheej hmoo ntawm kev ua tsis tiav vim kev sib txuas xoob lossis sib koom ua ke qaug zog. Qhov no txhim kho cov khoom zoo thiab ua kom muaj kev ntseeg tau ntev.

HDI rigid-flex daim ntaub ntawv muaj nyob rau hauv ntau yam kev lag luam, xws li aerospace, cov cuab yeej kho mob, kev sib txuas lus thiab cov khoom siv hluav taws xob.Hauv kev lag luam aerospace, HDI rigid-flex PCBs yog siv rau hauv kev tswj lub davhlau, avionics, thiab kev sib txuas lus vim lawv qhov loj me, lub teeb yuag, thiab muaj peev xwm tiv taus huab cua. Hauv kev kho mob, lawv tau siv rau hauv cov khoom siv xws li pacemakers, kev kho mob imaging systems, thiab implantable devices. Kev sib txuas lus thiab cov khoom siv hluav taws xob tau txais txiaj ntsig los ntawm kev txo qhov loj me thiab txhim kho kev ua tau zoo ntawm HDI rigid-flex PCBs hauv smartphones, ntsiav tshuaj, wearables, thiab lwm yam khoom siv portable.

2.HDI rigid-flexible PCB manufacturing txheej txheem: step-by-step

A. Tsim kev txwv thiab npaj cov ntaub ntawv CAD:

Thawj kauj ruam hauv HDI rigid-flex PCB manufacturing txheej txheem yog xav txog cov qauv tsim thiab npaj cov ntaub ntawv CAD. Cov kev txwv tsim ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab PCB kev ua tau zoo, kev ntseeg siab, thiab kev tsim khoom. Qee qhov kev tsim qauv tseem ceeb uas yuav tsum xav txog yog:

Kev txwv qhov loj:

Qhov loj ntawm PCB nyob ntawm qhov yuav tsum tau muaj ntawm cov cuab yeej siv uas nws siv. Nws yog ib qho tsim nyog los xyuas kom meej tias PCB haum rau hauv qhov chaw xaiv yam tsis muaj kev cuam tshuam rau kev ua haujlwm lossis kev ntseeg siab.

Kev ntseeg tau:

PCB tsim yuav tsum txhim khu kev qha thiab muaj peev xwm tiv taus kev ua haujlwm siab. Yam xws li kub, av noo, kev vibration thiab mechanical stress yuav tsum tau xav txog thaum lub sij hawm tsim qauv.

Teeb liab kev ncaj ncees:

Cov qauv tsim yuav tsum xav txog qhov teeb meem kev ncaj ncees kom txo tau qhov kev pheej hmoo ntawm cov teeb liab attenuation, suab nrov, los yog cuam tshuam. High-speed digital thiab RF signals yuav tsum tau ceev faj routing thiab impedance tswj.

Thermal Management:

Thermal tswj yog ib qho tseem ceeb rau kev tiv thaiv overheating thiab ua kom pom kev ua tau zoo ntawm cov khoom siv hluav taws xob. Thaum tshav kub kub dissipation tuaj yeem ua tiav los ntawm kev tso cov thermal vias, cov dab dej kub, thiab cov ntaub qhwv thermal. CAD software yog siv los tsim cov ntaub ntawv PCB layout. Nws tso cai rau cov neeg tsim qauv los txhais cov txheej txheem stacking, cov khoom tso rau hauv thiab tooj liab kab routing. CAD software muab cov cuab yeej thiab lub peev xwm los sawv cev kom raug thiab pom cov qauv tsim, ua kom yooj yim los txheeb xyuas thiab kho txhua yam teeb meem ua ntej tsim khoom.

B. Kev Xaiv thiab Layup Design:

Tom qab npaj cov ntaub ntawv CAD, cov kauj ruam tom ntej yog xaiv cov khoom siv thiab layup tsim. Kev xaiv cov ntaub ntawv raug yog qhov tseem ceeb los xyuas kom meej tias HDI rigid-flex PCBs ua tiav cov khoom siv hluav taws xob xav tau, kev tswj xyuas thermal, thiab kev ua haujlwm zoo. Rigid txheej cov ntaub ntawv, xws li FR-4 los yog high-kev ua tau zoo laminates, muab txhua yam kev txhawb nqa thiab stability. Cov txheej txheem yoog raws feem ntau yog ua los ntawm polyimide lossis polyester zaj duab xis kom yooj yim thiab ua haujlwm ntev. Cov txheej txheem tsim txheej txheem suav nrog kev txiav txim siab ntawm cov txheej txheem sib txawv, suav nrog cov txheej txheem nruj thiab hloov tau yooj yim, tooj liab tuab, thiab cov khoom siv dielectric. Lub stackup tsim yuav tsum xav txog tej yam xws li teeb liab kev ncaj ncees, impedance tswj, thiab hluav taws xob faib. Kev muab cov txheej txheem tsim nyog thiab xaiv cov khoom siv pab ua kom cov teeb liab kis tau zoo, txo qis kev sib tham thiab muab qhov tsim nyog tau yooj yim.

C. Laser drilling thiab microhole tsim:

Laser drilling yog ib kauj ruam tseem ceeb hauv kev tsim high-density routing microvias hauv HDI PCBs. Microvias yog qhov me me uas siv los txuas cov txheej txheem sib txawv ntawm PCB, tso cai rau kev sib txuas ntau dua. Laser drilling muaj ntau qhov zoo dua li cov txheej txheem kho tshuab drilling. Nws tso cai rau me me apertures, tso cai rau ntau dua routing ceev thiab ntau compact designs. Laser drilling kuj muab ntau dua precision thiab tswj, txo qhov kev pheej hmoo ntawm misalignment los yog puas tsuaj rau cov khoom nyob ib puag ncig. Nyob rau hauv cov txheej txheem laser drilling, lub teeb tsom laser yog siv los ua cov khoom siv, tsim cov qhov me me. Tom qab ntawd lub qhov yog metallized los muab conductivity ntawm cov khaubncaws sab nraud povtseg, tso cai kis tau tus mob ntawm cov teeb liab.

D. Tshuaj tooj liab plating:

Electroless tooj liab plating yog ib kauj ruam tseem ceeb hauv kev tsim cov txheej txheem HDI rigid-flex boards. Cov txheej txheem yuav tso ib txheej nyias ntawm tooj liab nyob rau hauv lub micropores thiab ntawm qhov chaw ntawm PCB. Qhov tseem ceeb ntawm electroless tooj liab plating yog nyob rau hauv nws lub peev xwm los xyuas kom meej kev ruaj ntseg hluav taws xob kev twb kev txuas thiab zoo teeb liab kis tau tus mob. Cov txheej tooj liab sau cov microvias thiab txuas cov txheej txheem sib txawv ntawm PCB, tsim txoj hauv kev rau cov teeb liab. Nws kuj muab ib tug solderable nto rau cov khoom txuas. Cov txheej txheem electroless tooj liab plating muaj ob peb kauj ruam, nrog rau kev npaj nto, ua kom thiab tso tawm. PCB yog thawj zaug ntxuav thiab qhib kom txhawb nqa adhesion. Tom qab ntawd cov tshuaj tiv thaiv yog siv los siv cov tshuaj uas muaj tooj liab ions rau PCB nto, tso ib txheej nyias ntawm tooj liab.

E. Duab Hloov thiab Lithography:

Cov duab kis tau tus mob thiab photolithography yog cov khoom ntawm HDI rigid-flex PCB manufacturing txheej txheem. Cov kauj ruam no suav nrog kev siv cov khoom siv photoresist los tsim cov qauv hauv Circuit Court ntawm PCB nto thiab nthuav tawm nws rau UV teeb los ntawm cov qauv photomask. Thaum lub sijhawm hloov cov duab, cov khoom siv photoresist yog siv rau ntawm PCB nto. Photoresist cov ntaub ntawv yog rhiab heev rau UV teeb thiab tuaj yeem xaiv raug. Lub PCB yog tom qab ntawd ua raws li cov qauv photomask thiab UV lub teeb tau dhau los ntawm cov chaw ntshiab ntawm lub photomask kom nthuav tawm cov photoresist. Tom qab kis tau, PCB yog tsim los tshem tawm cov photoresist tsis pom, tawm hauv cov qauv Circuit Court uas xav tau. Cov qauv no ua raws li cov txheej txheem tiv thaiv hauv cov txheej txheem tom ntej. Txhawm rau tsim cov kab hluav taws xob, cov tshuaj etching yog siv los tshem tawm cov tooj liab uas tsis xav tau. Cov cheeb tsam uas tsis tau them los ntawm photoresist yog raug rau cov etchant, uas xaiv tshem tawm cov tooj liab, tawm hauv cov kab uas xav tau.

F. Etching thiab electroplating txheej txheem:

Lub hom phiaj ntawm cov txheej txheem etching yog tshem tawm cov tooj liab ntau dhau thiab tsim cov kab hluav taws xob ntawm HDI rigid-flex PCB. Etching suav nrog kev siv cov etchant, feem ntau yog cov kua qaub lossis tshuaj lom neeg, los xaiv tshem tawm cov tsis xav tau tooj liab. Lub etching yog tswj los ntawm cov txheej txheem tiv thaiv photoresist uas tiv thaiv cov etchant los ntawm kev tawm tsam cov kab hluav taws xob uas yuav tsum tau ua. Ua tib zoo tswj lub sijhawm thiab concentration ntawm etchant kom ua tiav qhov xav tau kab dav thiab qhov tob. Tom qab etching, qhov seem photoresist yog stripped tawm kom nthuav tawm cov kab hluav taws xob. Cov txheej txheem stripping yog siv cov kuab tshuaj kom yaj thiab tshem tawm cov photoresist, tawm hauv qhov chaw huv thiab zoo-txhais kab mob. Txhawm rau txhim kho cov kab hluav taws xob thiab xyuas kom muaj kev ua tau zoo, yuav tsum muaj txheej txheem plating. Qhov no suav nrog tso ib txheej tooj liab ntxiv rau ntawm cov kab hluav taws xob los ntawm kev siv electroplating lossis electroless plating txheej txheem. Lub thickness thiab uniformity ntawm tooj liab plating yog ib qho tseem ceeb rau kev ua tiav cov khoom siv hluav taws xob txhim khu kev qha.

G. Daim ntawv thov daim npog ntsej muag thiab cov khoom sib dhos:

Daim ntawv thov daim npog ntsej muag thiab cov khoom sib dhos yog cov kauj ruam tseem ceeb hauv HDI nruj-flex PCB txheej txheem tsim khoom. Siv daim npog ntsej muag los tiv thaiv cov kab tooj liab thiab muab rwb thaiv tsev ntawm lawv. Solder mask tsim ib txheej tiv thaiv tag nrho PCB nto, tsis suav nrog cov cheeb tsam uas yuav tsum tau soldering, xws li cov ntaub qhwv thiab vias. Qhov no pab tiv thaiv solder bridging thiab luv luv thaum sib dhos. Cov khoom sib dhos yog muab cov khoom siv hluav taws xob tso rau hauv PCB thiab muab lawv tso rau hauv qhov chaw. Cheebtsam tau ua tib zoo muab tso rau hauv thiab ua raws li qhov chaw tsaws kom ntseeg tau tias muaj kev sib txuas hluav taws xob zoo. Siv cov txheej txheem soldering xws li reflow lossis yoj soldering nyob ntawm seb hom khoom thiab cov kev xav tau sib dhos. Cov txheej txheem reflow soldering suav nrog cua sov PCB mus rau qhov kub thiab txias uas ua rau cov solder yaj thiab tsim ib qho kev sib txuas mus tas li ntawm cov khoom ua thiab cov PCB pads. Wave soldering feem ntau yog siv rau hauv cov khoom hauv lub qhov, qhov twg PCB tau dhau los ntawm nthwv dej ntawm molten solder los tsim kev sib txuas.

H. Kev Ntsuas thiab Kev Tswj Xyuas Zoo:

Cov kauj ruam kawg hauv HDI rigid-flex PCB manufacturing txheej txheem yog kev sim thiab kev tswj kom zoo. Kev ntsuam xyuas nruj yog qhov tseem ceeb los xyuas kom meej PCB kev ua tau zoo, kev ntseeg tau thiab kev ua haujlwm. Ua kev ntsuam xyuas hluav taws xob los xyuas qhov luv, qhib, thiab txuas ntxiv. Qhov no suav nrog kev siv cov hluav taws xob tshwj xeeb thiab cov tam sim no rau PCB thiab ntsuas cov lus teb uas siv cov khoom siv ntsuas hluav taws xob. Kev tshuaj xyuas qhov muag kuj tau ua los xyuas kom meej qhov zoo ntawm cov khoom sib koom ua ke, qhov chaw tso khoom, thiab kev huv tag nrho ntawm PCB. Nws pab txheeb xyuas tej yam tsis xws luag xws li misaligned Cheebtsam, solder txuas hniav, los yog cov kab mob. Tsis tas li ntawd, kev ntsuam xyuas kev ntxhov siab thermal tuaj yeem ua tau los ntsuas PCB lub peev xwm los tiv thaiv qhov kub thiab txias los yog thermal shock. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas PCB raug hloov pauv kub heev. Thaum lub sij hawm thiab tom qab txhua kauj ruam ntawm kev tsim cov txheej txheem, kev tswj xyuas kev ua tau zoo yog siv los xyuas kom meej tias PCB ua tau raws li qhov xav tau tshwj xeeb thiab cov qauv. Qhov no suav nrog kev saib xyuas cov txheej txheem tsis tu ncua, kev tswj xyuas cov txheej txheem txheeb cais (SPC), thiab ua cov kev tshuaj xyuas ib ntus txhawm rau txheeb xyuas thiab kho txhua qhov sib txawv lossis qhov tsis sib xws.

3. Cov kev sib tw ntsib hauv kev tsim HDI rigid-flex boards:

Kev tsim HDI rigid-flex boards nthuav tawm qee qhov nyuaj thiab cov nyom uas yuav tsum tau ua tib zoo tswj xyuas kom muaj cov khoom zoo kawg.Cov kev cov nyom no muaj nyob ib ncig ntawm peb qhov tseem ceeb: kev sib dhos meej, qhov tsis xws luag, thiab kev hloov pauv impedance thaum lamination.

Kev sib raug zoo yog qhov tseem ceeb rau HDI rigid-flex boards vim tias lawv koom nrog ntau txheej thiab cov ntaub ntawv uas yuav tsum tau muab tso rau qhov tseeb. Ua kom tiav qhov kev sib raug zoo yuav tsum tau ua tib zoo tuav thiab muab cov txheej txheem sib txawv kom ntseeg tau tias cov vias thiab lwm yam khoom ua kom zoo. Ib qho misalignment tuaj yeem ua rau muaj teeb meem loj xws li teeb liab poob, luv luv, lossis so. Cov neeg tsim khoom yuav tsum nqis peev rau hauv cov cuab yeej siv siab thiab thev naus laus zis kom ntseeg tau tias muaj kev sib raug zoo thoob plaws hauv cov txheej txheem tsim khoom.

Kev zam qhov tsis xws luag yog lwm qhov nyuaj. Thaum lub sij hawm tsim cov txheej txheem, tej yam tsis xws li khawb, dents, los yog cov kab mob yuav tshwm sim, cuam tshuam rau kev ua tau zoo thiab kev ntseeg siab ntawm HDI rigid-flex boards.Cov teeb meem no tuaj yeem cuam tshuam nrog kev sib txuas hluav taws xob, cuam tshuam rau lub teeb liab kev ncaj ncees, lossis txawm tias ua rau lub rooj tsavxwm ua tsis tiav. Txhawm rau tiv thaiv qhov tsis xws luag, yuav tsum muaj kev tswj xyuas nruj, suav nrog kev ua tib zoo tuav, kev tshuaj xyuas tsis tu ncua, thiab siv qhov chaw huv si thaum lub sijhawm tsim khoom.

Kev txo qis impedance hloov thaum lub sij hawm lamination yog qhov tseem ceeb rau kev tswj xyuas hluav taws xob ua haujlwm ntawm HDI rigid-flex boards.Lamination suav nrog kev siv cua sov thiab siab los khi cov txheej txheem sib txawv ua ke. Txawm li cas los xij, cov txheej txheem no yuav ua rau muaj kev hloov pauv ntawm qhov dielectric tas li thiab tus neeg xyuas pib dav, uas ua rau muaj kev hloov pauv impedance tsis zoo. Kev tswj cov txheej txheem lamination kom txo qis cov kev hloov pauv no yuav tsum tau tswj xyuas qhov kub thiab txias, siab, thiab lub sijhawm, nrog rau kev ua raws li cov qauv tsim tshwj xeeb. Tsis tas li ntawd, cov kev sim siab thiab kev txheeb xyuas cov txheej txheem tuaj yeem ua haujlwm kom ntseeg tau tias qhov yuav tsum tau muaj kev tiv thaiv impedance.

Kev kov yeej cov kev cov nyom no hauv kev tsim HDI flex boards xav kom cov neeg tsim qauv thiab cov chaw tsim khoom ua haujlwm zoo ua ke thoob plaws hauv cov txheej txheem.Cov neeg tsim qauv yuav tsum ua tib zoo xav txog cov kev txwv tsim khoom thiab sib txuas lus zoo rau cov neeg tsim khoom. Ntawm qhov tod tes, cov neeg tsim khoom yuav tsum nkag siab txog cov qauv tsim thiab kev txwv txhawm rau txhawm rau ua raws li cov txheej txheem tsim khoom tsim nyog. Kev sib koom tes pab daws cov teeb meem tshwm sim thaum ntxov ntawm cov qauv tsim thiab ua kom cov txheej txheem tsim tau zoo rau cov khoom zoo HDI rigid-flex boards.

Xaus:

Kev tsim cov txheej txheem ntawm HDI rigid-flex PCB yog cov txheej txheem nyuaj tab sis tseem ceeb uas yuav tsum muaj kev txawj ntse, meej thiab txhim khu kev qha.Kev nkag siab txog txhua theem ntawm cov txheej txheem ua rau Capel txhim kho lawv lub peev xwm los xa cov txiaj ntsig zoo nyob rau hauv lub sijhawm nruj. Los ntawm qhov tseem ceeb ntawm kev sib koom tes tsim kev sib koom tes, automation thiab kev txhim kho cov txheej txheem tas mus li, Capel tuaj yeem nyob rau hauv pem hauv ntej ntawm HDI rigid-flex PCB manufacturing thiab ua tau raws li qhov kev thov loj hlob rau ntau qhov kev ua haujlwm thiab kev ua haujlwm siab thoob plaws hauv kev lag luam.

Post lub sij hawm: Sep-15-2023

Rov qab