Nyob rau hauv lub ntiaj teb ntawm cov ntawv luam tawm Circuit Boards (PCBs), kev xaiv qhov chaw tiav yog qhov tseem ceeb rau kev ua haujlwm tag nrho thiab kev ua haujlwm ntev ntawm cov khoom siv hluav taws xob. Kev kho saum npoo muab cov txheej tiv thaiv tiv thaiv oxidation, txhim kho solderability, thiab txhim khu kev ntseeg hluav taws xob ntawm PCB. Ib hom PCB nrov yog cov tuab tooj liab PCB, paub txog nws lub peev xwm los tuav cov khoom hnyav tam sim no thiab muab kev tswj xyuas thermal zoo dua. Txawm li cas los xij,Cov lus nug uas feem ntau tshwm sim yog: Puas yog tooj liab PCBs tuaj yeem tsim nrog cov khoom sib txawv? Nyob rau hauv tsab xov xwm no, peb yuav tshawb txog ntau yam kev xaiv tiav saum npoo muaj rau tuab tooj liab PCBs thiab cov kev txiav txim siab koom nrog hauv kev xaiv qhov tsim nyog tiav.

1. Kawm txog Heavy Copper PCBs

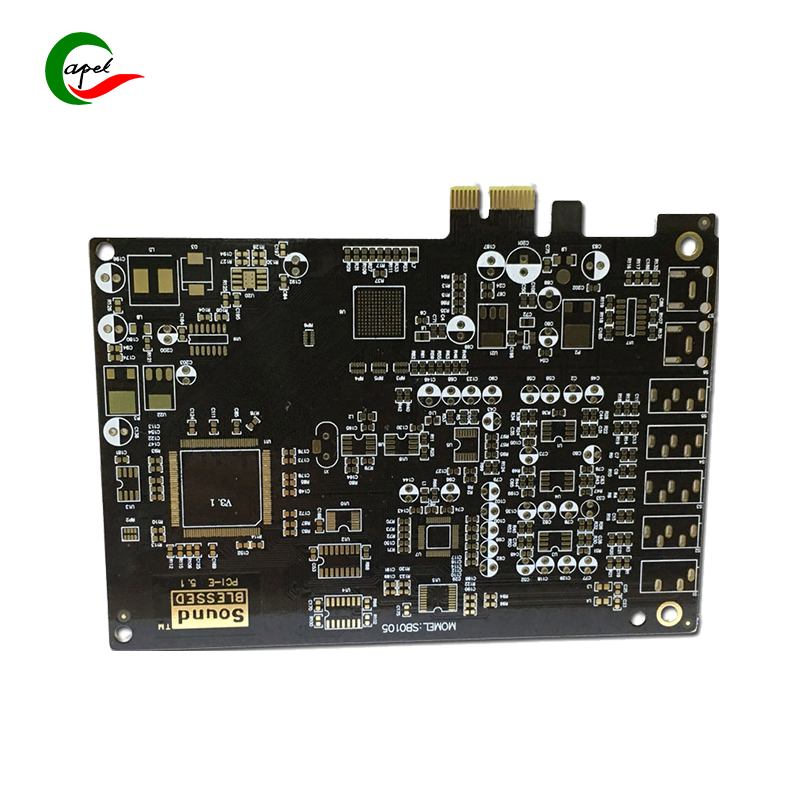

Ua ntej delving rau saum npoo tiav cov kev xaiv, nws yog ib qho tsim nyog yuav tsum nkag siab tias qhov tuab tooj liab PCB yog dab tsi thiab nws cov yam ntxwv tshwj xeeb. Feem ntau, PCBs nrog tooj liab thickness ntau dua 3 ooj (105 µm) yog suav tias yog tooj liab PCBs. Cov laug cam no yog tsim los nqa cov dej ntws siab thiab cov cua sov kom zoo, uas ua rau lawv tsim nyog rau lub zog hluav taws xob, tsheb, kev siv dav hlau thiab lwm yam khoom siv uas muaj lub zog siab. Thick tooj liab PCBs muab cov thermal conductivity zoo, muaj zog dua txhua yam thiab qis qis dua li cov qauv PCBs.

2.Qhov tseem ceeb ntawm kev kho deg hauv Heavy Copper Pcb Manufacturing:

Kev npaj nto ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv cov kab tooj liab thiab cov ntaub qhwv los ntawm oxidation thiab ua kom cov pob qij txha txhim khu kev qha. Lawv ua raws li kev thaiv ntawm cov tooj liab thiab cov khoom siv sab nraud, tiv thaiv corrosion thiab tswj kev ua haujlwm. Tsis tas li ntawd, qhov chaw ua kom tiav pab muab qhov chaw tiaj tus rau kev tso kawm thiab kev sib txuas ntawm cov hlau. Xaiv qhov raug qhov chaw tiav rau tuab tooj liab PCBs yog qhov tseem ceeb rau kev ua kom zoo dua lawv cov kev ua tau zoo thiab kev ntseeg tau.

3.Ntoo kho kev xaiv rau Heavy Copper PCB:

Cua kub solder leveling (HASL):

HASL yog ib qho tseem ceeb tshaj plaws thiab muaj txiaj ntsig zoo PCB kev kho mob. Nyob rau hauv cov txheej txheem no, PCB yog raus rau hauv ib da dej ntawm molten solder thiab cov tshaj solder yog tshem tawm siv ib tug kub cua riam. Qhov seem solder tsim ib txheej tuab ntawm tooj liab, tiv thaiv nws los ntawm corrosion. Txawm hais tias HASL yog ib txoj kev kho saum npoo uas siv dav, nws tsis yog qhov kev xaiv zoo tshaj plaws rau cov tuab tooj liab PCBs vim muaj ntau yam. Kev ua haujlwm siab kub koom nrog hauv cov txheej txheem no tuaj yeem ua rau thermal stress ntawm cov txheej tooj liab tuab, ua rau warping lossis delamination.

Electroless nickel immersion kub plating (ENIG):

ENIG yog qhov kev xaiv nrov rau kev kho mob saum npoo thiab paub txog nws qhov zoo tshaj plaws weldability thiab corrosion kuj. Nws koom nrog tso ib txheej nyias ntawm electroless npib tsib xee thiab tom qab ntawd tso ib txheej ntawm immersion kub rau ntawm tooj liab. ENIG muaj lub tiaj tus, du nto tiav, ua rau nws tsim nyog rau cov khoom zoo-pitch thiab kub hlau sib txuas. Thaum ENIG tuaj yeem siv rau ntawm cov tooj liab PCBs tuab, nws yog ib qho tseem ceeb uas yuav tsum xav txog cov tuab ntawm txheej kub kom muaj kev tiv thaiv txaus tiv thaiv cov dej ntws thiab thermal.

Electroless Nickel Plating Electroless Palladium Immersion Kub (ENEPIG):

ENEPIG yog ib qho kev kho saum npoo av uas muab zoo heev solderability, corrosion kuj thiab hlau bondability. Nws suav nrog tso ib txheej ntawm electroless npib tsib xee, ces ib txheej ntawm electroless palladium, thiab thaum kawg ib txheej ntawm immersion kub. ENEPIG muaj qhov ua tau zoo heev thiab tuaj yeem siv rau tuab tooj liab PCBs. Nws muab cov rugged nto tiav, ua rau nws tsim nyog rau kev siv hluav taws xob siab thiab cov khoom zoo-pitch.

Immersion Tin (ISn):

Immersion tin yog lwm txoj kev kho mob saum npoo rau tuab tooj liab PCBs. Nws immerses PCB nyob rau hauv ib tug tin-raws li tov, tsim ib tug nyias txheej ntawm tin rau ntawm tooj liab nto. Immersion tin muab zoo heev solderability, ib tug tiaj tus nto, thiab yog tus phooj ywg environmentally. Txawm li cas los xij, ib qho kev txiav txim siab thaum siv cov immersion tin ntawm tuab tooj liab PCBs yog tias cov tuab ntawm cov tin txheej yuav tsum tau ua tib zoo tswj kom muaj kev tiv thaiv txaus tiv thaiv oxidation thiab siab tam sim no ntws.

Organic solderability preservative (OSP):

OSP yog ib qho kev kho saum npoo uas tsim cov txheej txheem tiv thaiv kab mob ntawm cov tooj liab uas raug. Nws muaj zoo solderability thiab yog tus nqi zoo. OSP yog qhov tsim nyog rau cov ntawv thov hluav taws xob qis mus rau nruab nrab thiab tuaj yeem siv rau ntawm cov tooj liab PCBs ntev npaum li qhov muaj peev xwm nqa tam sim no thiab thermal dissipation yuav tsum tau ua. Ib qho ntawm cov laj thawj uas yuav tsum tau xav txog thaum siv OSP ntawm tuab tooj liab PCBs yog cov thickness ntxiv ntawm cov organic txheej, uas yuav cuam tshuam rau tag nrho cov hluav taws xob thiab thermal ua haujlwm.

4. Tej yam uas yuav tsum tau xav txog thaum xaiv qhov chaw tiav rau Heavy Copper PCBs: Thaum xaiv qhov chaw tiav rau Hnyav

Copper PCB, muaj ntau yam los xav txog:

Tam sim no Carrying Peev Xwm:

Thick tooj liab PCBs feem ntau yog siv rau hauv kev siv hluav taws xob siab, yog li nws yog ib qho tseem ceeb uas yuav tsum xaiv qhov chaw tiav uas tuaj yeem ua haujlwm siab tam sim no yam tsis muaj qhov tseem ceeb los yog overheating. Cov kev xaiv xws li ENIG, ENEPIG, thiab immersion tin feem ntau haum rau cov ntawv thov tam sim no.

Thermal Management:

Thick tooj liab PCB paub txog nws zoo heev thermal conductivity thiab kub dissipation peev xwm. Kev ua tiav saum npoo yuav tsum tsis txhob cuam tshuam kev hloov pauv cua sov lossis ua rau muaj kev ntxhov siab ntau dhau ntawm cov txheej tooj liab. Kev kho deg xws li ENIG thiab ENEPIG muaj cov txheej nyias nyias uas feem ntau tau txais txiaj ntsig zoo rau kev tswj xyuas thermal.

Solderability:

Nto tiav yuav tsum muab zoo heev solderability kom ntseeg tau tias cov pob qij txha txhim khu kev qha thiab kev ua haujlwm zoo ntawm cov khoom. Cov kev xaiv xws li ENIG, ENEPIG thiab HASL muab kev txhim khu kev qha.

Khoom Compatibility:

Xav txog qhov sib haum xeeb ntawm qhov xaiv qhov chaw tiav nrog cov khoom tshwj xeeb uas yuav tsum tau muab tso rau ntawm PCB. Cov khoom siv suab zoo thiab kev sib txuas kub hlau yuav xav tau kev kho saum npoo xws li ENIG lossis ENEPIG.

Tus nqi:

Tus nqi ib txwm yog qhov tseem ceeb hauv kev tsim khoom PCB. Tus nqi ntawm cov kev kho deg sib txawv txawv ntawm cov khoom xws li tus nqi ntawm cov khoom siv, cov txheej txheem nyuaj thiab cov khoom siv yuav tsum tau ua. Ntsuam xyuas tus nqi cuam tshuam ntawm qhov kev xaiv nto tiav yam tsis muaj kev cuam tshuam kev ua haujlwm thiab kev ntseeg tau.

Thick tooj liab PCBs muab cov txiaj ntsig tshwj xeeb rau cov ntawv siv hluav taws xob siab, thiab xaiv qhov zoo saum npoo yog qhov tseem ceeb rau kev txhim kho lawv cov kev ua tau zoo thiab kev ntseeg tau.Thaum cov kev xaiv ib txwm muaj xws li HASL yuav tsis tsim nyog vim muaj teeb meem thermal, kev kho saum npoo xws li ENIG, ENEPIG, immersion tin thiab OSP tuaj yeem txiav txim siab nyob ntawm qhov yuav tsum tau ua. Cov yam ntxwv xws li kev muaj peev xwm nqa tam sim no, kev tswj xyuas thermal, solderability, tivthaiv kev sib raug zoo thiab tus nqi yuav tsum tau ua tib zoo soj ntsuam thaum xaiv ib qho tiav rau tuab tooj liab PCBs. Los ntawm kev xaiv ntse, cov tuam txhab tsim khoom tuaj yeem ua kom tiav kev tsim khoom thiab ua haujlwm ntev ntev ntawm cov tooj liab PCBs hauv ntau yam kev siv hluav taws xob thiab hluav taws xob.

Post lub sij hawm: Sep-13-2023

Rov qab