Kev delamination hauv PCB tuaj yeem ua rau muaj teeb meem kev ua haujlwm tseem ceeb, tshwj xeeb tshaj yog nyob rau hauv cov qauv nruj-flex uas ob qho tib si nruj thiab cov ntaub ntawv hloov tau ua ke. Kev nkag siab yuav ua li cas tiv thaiv delamination yog qhov tseem ceeb rau kev ua kom lub neej ntev thiab kev ntseeg siab ntawm cov rooj sib txoos nyuaj no. Tsab ntawv xov xwm no yuav tshawb txog cov lus qhia tswv yim rau kev tiv thaiv PCB delamination, tsom rau PCB lamination, cov khoom siv sib raug zoo, thiab kev ua kom zoo dua qub.

Nkag siab txog PCB Delamination

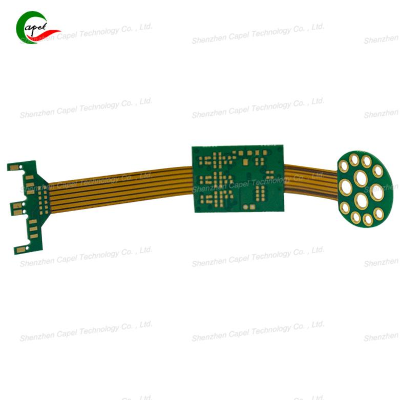

Delamination tshwm sim thaum txheej txheej ntawm PCB sib cais vim muaj ntau yam, nrog rau kev ntxhov siab thermal, kev nqus dej, thiab kev siv tshuab. Nyob rau hauv nruj-flex PCBs, qhov kev sib tw tau nce siab vim muaj qhov sib txawv ntawm cov khoom nruj thiab hloov tau yooj yim. Yog li ntawd, ua kom muaj kev sib raug zoo ntawm cov ntaub ntawv no yog thawj kauj ruam hauv kev tiv thaiv delamination.

Xyuas kom cov khoom siv PCB Compatibility

Kev xaiv cov ntaub ntawv tseem ceeb hauv kev tiv thaiv delamination. Thaum tsim ib qho nyuaj-flex PCB, nws yog ib qho tseem ceeb los xaiv cov ntaub ntawv uas muaj cov thermal expansion coefficients zoo sib xws. Qhov kev sib raug zoo no txo qis kev ntxhov siab thaum caij tsheb kauj vab, uas tuaj yeem ua rau delamination. Tsis tas li ntawd, xav txog cov nplaum uas siv hauv txheej txheem lamination. Cov nplaum nplaum zoo uas tau tsim tshwj xeeb rau kev siv tawv-flex tuaj yeem txhim kho kev sib raug zoo ntawm cov khaubncaws sab nraud povtseg.

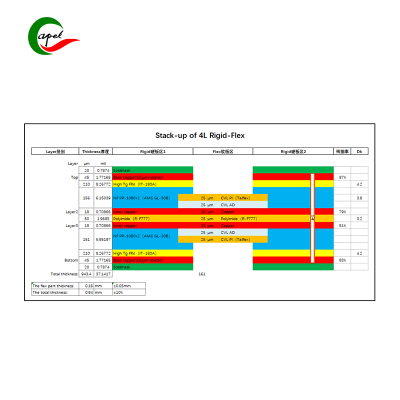

PCB Lamination txheej txheem

Cov txheej txheem lamination yog ib theem tseem ceeb hauv kev tsim PCB. Kev lamination zoo ua kom ntseeg tau tias cov khaubncaws sab nraud povtseg zoo rau ib leeg, txo qhov kev pheej hmoo ntawm delamination. Nov yog qee cov lus qhia tswv yim rau kev ua haujlwm zoo PCB lamination:

Kub thiab siab tswj: Xyuas kom meej tias cov txheej txheem lamination yog ua los ntawm qhov tseeb qhov kub thiab txias. Qhov kub thiab txias dhau tuaj yeem ua rau cov ntaub ntawv tsis zoo, thaum lub siab tsis txaus tuaj yeem ua rau tsis zoo adhesion.

Nqus Lamination: Siv lub tshuab nqus tsev thaum lub sij hawm lamination tuaj yeem pab tshem tawm cov pa npuas uas yuav ua rau muaj qhov tsis muaj zog hauv daim ntawv cog lus. Cov txheej txheem no ua kom muaj kev sib txuam ntau dua thoob plaws PCB txheej.

Kho lub sij hawm: Cia lub sij hawm kho kom txaus rau cov nplaum kom zoo. Rushing txheej txheem no tuaj yeem ua rau tsis tiav adhesion, ua rau muaj kev pheej hmoo ntawm delamination.

Optimized Rigid-Flex PCB Machining Parameters

Machining parameters ua lub luag haujlwm tseem ceeb hauv kev ncaj ncees ntawm rigid-flex PCBs. Nov yog qee cov tswv yim zoo machining los tiv thaiv delamination:

Cov txheej txheem Drilling: Siv cov cuab yeej laum tsim nyog thiab nrawm kom txo qis kev tsim hluav taws xob thaum lub sijhawm drilling. Kev kub ntau dhau tuaj yeem ua rau cov nplaum nplaum tsis muaj zog thiab ua rau delamination.

Routing thiab Txiav: Thaum routing los yog txiav PCB, xyuas kom meej tias cov cuab yeej ntse thiab zoo. Cov cuab yeej npub tuaj yeem ua rau siab dhau thiab kub, ua rau muaj kev ncaj ncees ntawm cov khaubncaws sab nraud povtseg.

Kev kho ntug: Kho cov npoo ntawm PCB kom zoo tom qab machining. Qhov no tuaj yeem koom nrog kev sib tw los yog sib khi cov npoo kom tiv thaiv kom tsis txhob ya raws, uas tuaj yeem ua rau delamination dhau sijhawm.

Tswv yim tswv yim los tiv thaiv PCB delamination

Ntxiv nrog rau cov tswv yim saum toj no, xav txog cov lus qhia hauv qab no:

Environmental Control: Khaws PCBs nyob rau hauv ib puag ncig tswj kom tiv thaiv kom tsis txhob ya raws. Cov av noo tuaj yeem ua rau cov nplaum nplaum tsis muaj zog thiab ua rau delamination.

Kev kuaj tsis tu ncua: Siv cov kev ntsuam xyuas tsis tu ncua ntawm PCBs rau cov cim qhia ntawm delamination thaum lub sijhawm tsim khoom. Kev tshawb pom ntxov tuaj yeem pab txo cov teeb meem ua ntej lawv nce ntxiv.

Kev cob qhia thiab kev paub: Xyuas kom meej tias txhua tus neeg ua haujlwm koom nrog hauv cov txheej txheem tsim khoom PCB raug cob qhia hauv kev coj ua zoo tshaj plaws rau lamination thiab machining. Kev paub txog yam uas ua rau kev txiav txim siab tuaj yeem ua rau kev txiav txim siab zoo dua.

Post lub sij hawm: Oct-31-2024

Rov qab