Hauv kev tsim khoom siv hluav taws xob, kev sib dhos tshuab saum npoo av (SMT) yog ib qho ntawm cov txheej txheem tseem ceeb rau kev ua tiav cov khoom siv hluav taws xob.SMT sib dhos ua lub luag haujlwm tseem ceeb hauv tag nrho qhov zoo, kev ntseeg tau thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. Txhawm rau pab koj nkag siab zoo dua thiab paub txog PCB sib dhos, Capel yuav coj koj los tshawb txog cov hauv paus ntawm SMT refactoring. thiab sib tham txog vim li cas nws tseem ceeb heev hauv kev tsim khoom siv hluav taws xob.

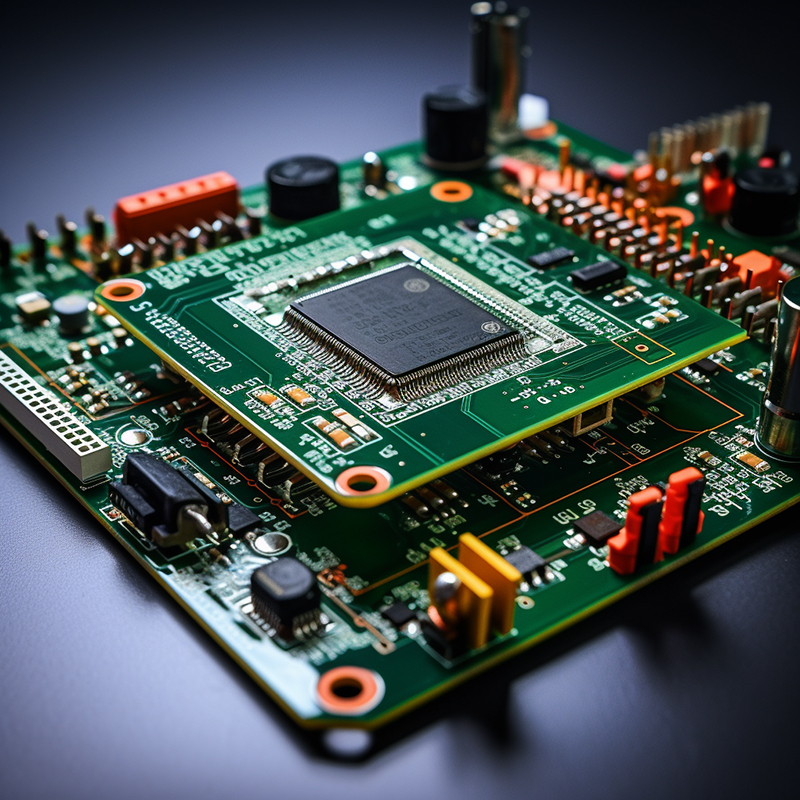

SMT sib dhos, tseem hu ua nto mount los ua ke, yog ib txoj kev ntawm mounting hluav taws xob Cheebtsam nyob rau saum npoo ntawm ib tug luam Circuit Court board (PCB).Tsis zoo li ib txwm siv los ntawm lub qhov (THT), uas ntxig cov khoom los ntawm qhov hauv PCB, SMT sib dhos yuav tsum muab cov khoom ncaj qha rau ntawm lub rooj tsavxwm. Nyob rau hauv xyoo tas los no, cov thev naus laus zis no tau txais txiaj ntsig thoob plaws vim nws qhov txiaj ntsig ntau ntawm THT, xws li cov khoom siv ntau dua, lub rooj tsav xwm me me, txhim kho teeb liab kev ncaj ncees, thiab kev tsim khoom nrawm dua.

Tam sim no, cia peb delve rau hauv lub hauv paus ntawm SMT sib dhos.

1. Kev tso kawm ntawm cov khoom siv:Thawj kauj ruam hauv kev sib dhos SMT suav nrog kev tso npe ntawm cov khoom siv hluav taws xob ntawm PCB. Qhov no feem ntau yog ua tiav siv lub tshuab nqa-thiab-qhov chaw uas cia li xaiv cov khoom los ntawm lub feeder thiab muab lawv tso rau ntawm lub rooj tsavxwm. Kev tso chaw kom raug ntawm cov khoom tseem ceeb yog qhov tseem ceeb rau kev ua haujlwm kom zoo thiab kev ntseeg siab ntawm cov khoom siv hluav taws xob.

2. Daim ntawv thov solder paste:Tom qab mounting Cheebtsam, siv solder paste (ib tug sib tov ntawm solder hais thiab flux) rau lub ncoo ntawm lub PCB. Solder paste ua raws li cov nplaum ib ntus, tuav cov khoom hauv qhov chaw ua ntej soldering. Nws kuj tseem pab tsim kev sib txuas hluav taws xob ntawm cov khoom siv thiab PCB.

3. Reflow soldering:Cov kauj ruam tom ntej hauv SMT sib dhos yog reflow soldering. Qhov no suav nrog cua sov PCB hauv kev tswj hwm kom yaj cov tshuaj txhuam hniav thiab tsim ib qho kev sib koom ua ke mus tas li. Reflow soldering tuaj yeem ua tiav siv ntau txoj hauv kev xws li convection, infrared tawg lossis theem vapor. Thaum lub sij hawm tus txheej txheem no, lub solder paste hloov mus rau hauv lub molten lub xeev, ntws mus rau cov khoom coj thiab PCB pads, thiab solidifies los tsim ib tug muaj zog solder kev twb kev txuas.

4. Kev tshuaj xyuas thiab kev tswj xyuas zoo:Tom qab cov txheej txheem soldering tiav, PCB yuav dhau los ntawm kev tshuaj xyuas nruj thiab kev tswj xyuas kom zoo kom ntseeg tau tias tag nrho cov khoom raug muab tso rau kom raug thiab cov pob qij txha yog cov khoom zoo. Kev tshuaj xyuas qhov muag pom tau zoo (AOI) thiab X-ray tshuaj xyuas cov txheej txheem feem ntau yog siv los txheeb xyuas cov teeb meem lossis kev tsis sib haum xeeb hauv kev sib dhos. Txhua qhov tsis sib xws uas pom thaum kuaj tau raug kho ua ntej PCB mus rau theem tom ntej ntawm kev tsim khoom.

Yog li, vim li cas SMT sib dhos tseem ceeb hauv kev tsim hluav taws xob?

1. Tus nqi efficiency:SMT sib dhos muaj tus nqi zoo dua THT vim nws txo tag nrho lub sijhawm tsim khoom thiab ua kom yooj yim rau kev tsim khoom. Kev siv cov cuab yeej siv hluav taws xob rau kev tso kawm thiab kev sib txuas ua kom muaj txiaj ntsig ntau dua thiab cov nqi zog qis dua, ua rau nws muaj txiaj ntsig zoo rau kev tsim khoom loj.

2. Miniaturization:Txoj kev loj hlob ntawm cov khoom siv hluav taws xob yog cov khoom siv me me thiab cov khoom siv compact. SMT sib dhos ua rau lub miniaturization ntawm electronics los ntawm mounting Cheebtsam nrog ib tug me me hneev taw. Qhov no tsis yog tsuas yog txhim kho kev txav mus los, tab sis kuj tseem qhib cov qauv tsim tshiab rau cov neeg tsim khoom lag luam.

3. Kev ua tau zoo dua:Txij li thaum SMT Cheebtsam yog mounted ncaj qha rau ntawm PCB nto, luv luv hluav taws xob txoj kev tso cai rau kom zoo teeb liab kev ncaj ncees thiab txhim khu kev ua tau zoo ntawm cov khoom siv hluav taws xob. Qhov txo qis hauv parasitic capacitance thiab inductance minimizes teeb liab poob, crosstalk thiab suab nrov, txhim kho kev ua haujlwm tag nrho.

4. Cov khoom siv ntau dua:Piv nrog THT, SMT sib dhos tuaj yeem ua tiav cov khoom siv ntau dua ntawm PCB. Qhov no txhais tau hais tias ntau lub zog tuaj yeem muab tso rau hauv qhov chaw me me, ua kom muaj kev txhim kho ntawm cov khoom siv hluav taws xob uas muaj zog thiab muaj txiaj ntsig zoo. Qhov no tseem ceeb tshwj xeeb tshaj yog nyob rau hauv kev lag luam uas qhov chaw feem ntau txwv, xws li xov tooj ntawm tes, khoom siv hluav taws xob, thiab khoom siv kho mob.

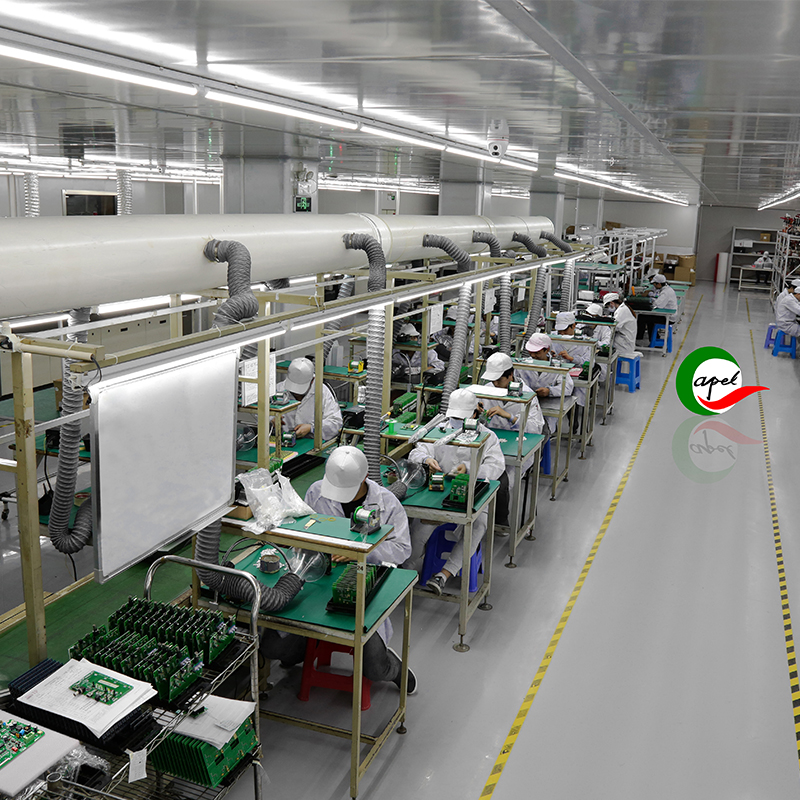

Raws li kev txheeb xyuas saum toj no,nkag siab txog cov hauv paus ntawm SMT sib dhos yog qhov tseem ceeb rau txhua tus neeg koom nrog hauv kev tsim khoom siv hluav taws xob. SMT sib dhos muaj ntau qhov zoo dua li cov cuab yeej siv los ntawm lub qhov, suav nrog cov nqi ua haujlwm, muaj peev xwm ua haujlwm me me, txhim kho kev ua haujlwm, thiab cov khoom siv ntau dua. Raws li qhov kev thov rau cov khoom siv hluav taws xob me me, nrawm dua, thiab txhim khu kev ntseeg tau txuas ntxiv zuj zus, SMT sib dhos yuav ua lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li cov kev xav tau no.Shenzhen Capel Technology Co., Ltd. muaj nws tus kheej PCB los ua ke Hoobkas thiab tau muab cov kev pabcuam no txij li xyoo 2009. Nrog rau 15 xyoo ntawm kev ua haujlwm nplua nuj, cov txheej txheem nruj heev, muaj peev xwm ua tau zoo heev, cov cuab yeej siv hluav taws xob siab heev, kev tswj xyuas zoo, thiab Capel muaj pab pawg kws tshaj lij los muab cov neeg siv khoom thoob ntiaj teb nrog kev ua haujlwm siab, zoo nrawm tig PCB Sib dhos ua qauv. Cov khoom no suav nrog kev sib dhos yooj yim PCB, sib dhos PCB nruj, nruj-flex PCB sib dhos, HDI PCB sib dhos, sib dhos PCB siab thiab cov txheej txheem tshwj xeeb PCB sib dhos. Peb cov lus teb ua ntej muag thiab tom qab muag kev pabcuam thiab xa khoom raws sijhawm ua rau peb cov neeg siv khoom sai sai rau kev lag luam rau lawv cov haujlwm.

Post lub sij hawm: Aug-24-2023

Rov qab