Qhia:

Rapid PCB prototyping, tshwj xeeb tshaj yog kev koom ua ke ntawm cov khoom zoo-pitch, yuav tsum muaj kev txawj ntse thiab precision. Raws li thev naus laus zis txuas ntxiv mus, kev tsim hluav taws xob hluav taws xob tau dhau los ua qhov nyuaj thiab xav tau. Nrog rau ntau tshaj 15 xyoo ntawm kev paub hauv kev ua haujlwm, Capel yog lub tuam txhab ua lag luam uas sib txuas cov kev txawj ntse thiab kev tsim kho tshiab tas li kom xa cov kev daws teeb meem tsis sib xws.Hauv tsab ntawv tshaj tawm no, peb yuav dhia mus rau hauv txoj hauv kev, cov teeb meem, thiab cov kev coj ua zoo tshaj plaws rau kev ceev PCB prototyping nrog cov khoom zoo-pitch, thaum tshawb txog Capel lub peev xwm tsim khoom tsis sib xws.

Kawm paub txog qhov zoo-pitch Cheebtsam:

Fine-pitch Cheebtsam ua lub luag haujlwm tseem ceeb hauv cov khoom siv hluav taws xob niaj hnub no vim tias lawv ua kom muaj kev sib kis ceev, miniaturization, thiab txhim kho kev ua haujlwm. Qhov sib nrug ntawm tus pin ntawm cov khoom no yog tsawg dua 0.8 hli, uas ua rau lawv qhov tseeb qhov chaw ntawm PCB nyuaj dua. Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tau txais cov txheej txheem tshwj xeeb thiab cov txheej txheem los xyuas kom meej qhov kev ua tau zoo.

Advanced PCB tsim cov cuab yeej rau prototyping ceev:

Yuav kom siv tau zoo-pitch Cheebtsam rau ceev PCB prototyping, advanced PCB tsim cov cuab yeej yuav tsum tau siv. Software xws li Altium Designer, Eagle los yog KiCad muab cov yam ntxwv xws li kev tso npe ncaj qha, kev tsom xam kev ncaj ncees thiab kev ua haujlwm tsis siv neeg, uas zoo heev pab layout optimization. Capel cov kws tshaj lij pab neeg tau txais txiaj ntsig ntawm kev siv cov cuab yeej no kom ntseeg tau qib siab tshaj plaws ntawm qhov tseeb thaum tsim qauv.

Tej yam uas yuav tsum nco ntsoov thaum nteg tawm cov khoom zoo-pitch:

Thaum tsim ib qho PCB layout nrog cov khoom zoo-pitch, nws yog ib qho tseem ceeb uas yuav tau xav txog qee yam los xyuas kom meej kev ua haujlwm zoo thiab kev tsim khoom. Nov yog qee qhov kev txiav txim siab tseem ceeb:

1. Pad tsim: Cov ntaub qhwv loj thiab cov duab yog qhov tseem ceeb rau kev ua kom zoo thiab muaj hluav taws xob zoo nrog cov khoom siv.Capel cov kws tshaj lij engineers ua tib zoo tsim cov ntaub qhwv raws li cov kev xav tau tshwj xeeb ntawm cov khoom zoo-pitch, muab cov khoom zoo heev thiab kev ntseeg tau.

2. Cov kab thiab vias: Cov teeb liab ceev dhau los ntawm cov khoom siv suab zoo yuav tsum tau ua tib zoo routing kom txo qis suab nrov, teeb liab attenuation, thiab impedance mismatch.Tsim nyog los ntawm kev tso kawm thiab cov txheej txheem taug kev xws li qhov sib txuam ntev thiab qhov sib txawv ntawm qhov sib txawv pab tswj cov teeb liab kev ncaj ncees.

3. Kev tswj cov cua sov: Cov khoom zoo-pitch ua kom muaj cua sov ntau thaum ua haujlwm.Kev tswj xyuas thermal kom zoo los ntawm kev siv cov dab dej kub, cov qhov cua sov, lossis tso cov thermal pads hauv qab cov khoom yog qhov tseem ceeb rau kev tiv thaiv overheating thiab ua kom muaj kev ntseeg tau ntev.

4. Design for Manufacturing (DFM): Ua hauj lwm nrog Capel cov neeg paub txog thaum lub sij hawm tsim PCB los xyuas kom meej cov kev xaiv tsim muaj raws li lawv cov peev xwm tsim.Optimizing designs rau manufacturability pab txo cov prototyping yuam kev thiab txhim kho tag nrho cov efficiency ntawm tus txheej txheem.

Prototyping cov nyom thiab kev daws teeb meem:

Rapid PCB prototyping nrog cov khoom zoo-pitch nthuav qhia tshwj xeeb cov kev cov nyom. Txawm li cas los xij, nrog Capel qhov kev paub dav dav thiab kev txawj ntse, cov kev cov nyom no tuaj yeem txo tau yooj yim.

1. Cheebtsam khoom siv: Cov khoom zoo-pitch feem ntau muaj sij hawm ua cov hmoov txhuas ntev lossis muaj tsawg, ua rau lawv cov khoom muaj kev nyuaj dua.Capel tus neeg xa khoom thoob plaws lub network thiab kev sib raug zoo muaj zog ua kom muaj kev nkag mus rau cov khoom siv tau zoo, ua kom cov khoom lag luam tsis cuam tshuam.

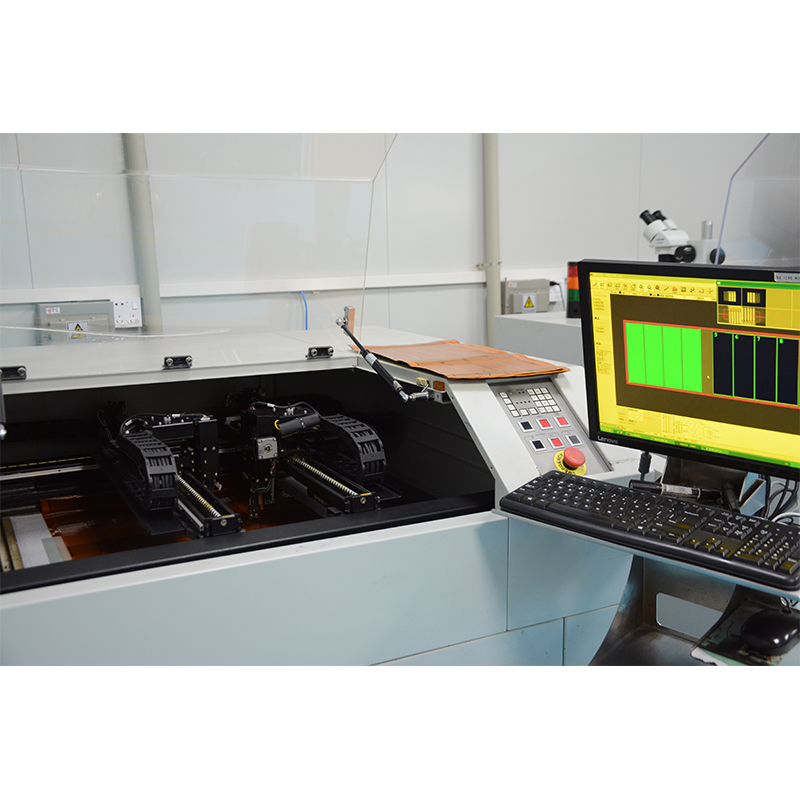

2. Vuam: Vuam zoo pitch Cheebtsam yuav tsum tau siab precision.Capel siv cov thev naus laus zis los ua ke xws li reflow ncu nrog kev tswj qhov kub thiab txias, cov tshuab muab tso rau hauv lub tshuab thiab tshuaj xyuas cov tshuaj txhuam los xyuas kom cov pob qij txha zoo meej.

3. Kev kuaj thiab tshuaj xyuas: Thaum lub sij hawm prototyping, kev ntsuam xyuas thiab kev soj ntsuam xyuas yog ib qho tseem ceeb los txheeb xyuas qhov tsis xws luag xws li cov txuas txuas, qhib, lossis tombstones.Capel ua cov kev kuaj xyuas zoo siv qhov kev tshuaj ntsuam xyuas qhov muag (AOI), kuaj X-ray thiab ciam teb kuaj xyuas kom ntseeg tau tias cov qauv tsis muaj qhov tsis zoo.

Capel's unparalleled manufacturing peev xwm:

Capel txoj kev cog lus rau kev ua tau zoo tshaj plaws thiab kev nce qib kev siv tshuab txuas ntxiv tau ua rau nws yog ib tus neeg ntseeg siab hauv kev lag luam PCB.Lub tuam txhab kev txawj ntse, ua tiav los ntawm cov chaw tsim khoom hauv lub xeev thiab ua raws li cov qauv zoo thoob ntiaj teb, ua rau nws muaj peev xwm tsim khoom tsis sib xws.

Hauv kev xaus:

Kev nrawm nrawm ntawm PCBs siv cov khoom zoo-pitch yuav tsum muaj kev paub tshwj xeeb thiab kev txawj ntse. Nrog 15 xyoo ntawm kev paub, kev txawj ntse thiab kev cog lus rau kev nruam ntej, Capel yog qhov chaw tshwj xeeb kom tau raws li cov kev cov nyom no thiab tshaj qhov kev cia siab.Ua haujlwm nrog Capel ua kom muaj qhov tsis zoo ntawm cov qauv, cov txheej txheem tsim tau zoo thiab kev txhawb nqa tsis sib xws ntawm txhua theem ntawm txoj haujlwm. Cia siab rau Capel cov kws tshaj lij coj koj tus qauv PCB rau lub neej thaum ua tau raws li qhov xav tau tshaj plaws ntawm kev lag luam hluav taws xob niaj hnub no.

Post lub sij hawm: Oct-18-2023

Rov qab