Tshawb nrhiav yuav ua li cas Capel's advanced FPC-Flex PCB tsim tshuab ua tau raws li qhov kev sib tw ntawm kev tsim khoom2-txheej Flex PCBs rau lub zog tshiabroj teeb tiv thaiv Circuit Court boards. Nkag mus rau hauv kev ua tau zoo thiab kev lag luam cuam tshuam ntawm qhov kev kawm tiav no.

Qhia

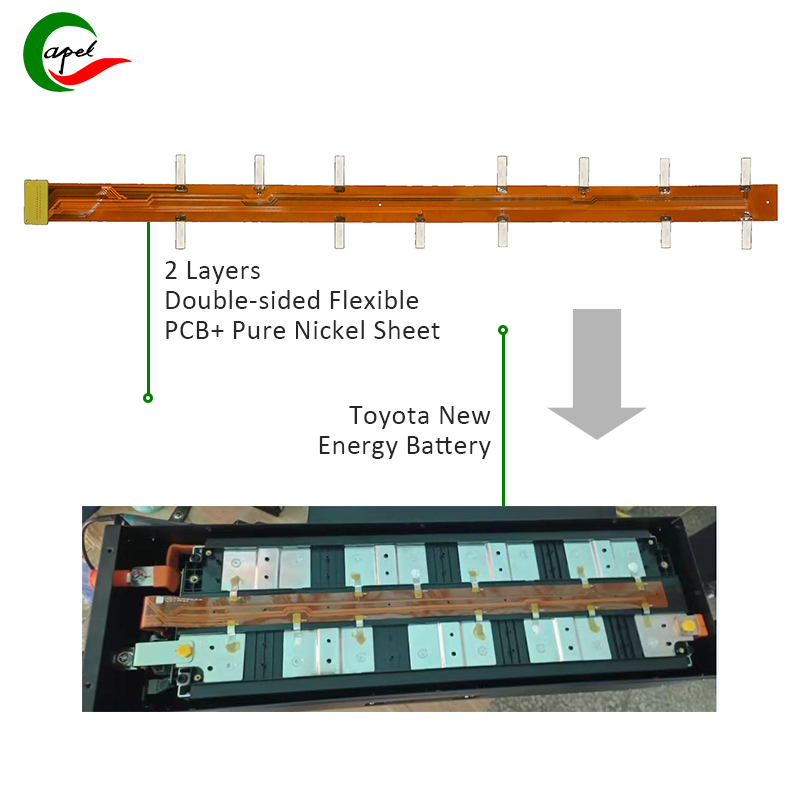

Cov tsheb tshiab lub zog xws li tsheb hluav taws xob thiab tsheb hybrid yog qhov ua ntej ntawm kev thauj mus los hauv ib puag ncig. Nrog rau kev nce qib ntawm thev naus laus zis, lub zog tshiab tsheb tau nce ntxiv rau kev ua haujlwm siab, txhim khu kev qha, thiab siv hluav taws xob zoo. Flexible PCBs (cov ntawv luam tawm yooj yim) ua lub luag haujlwm tseem ceeb hauv cov tsheb no, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov xws li roj teeb tiv thaiv Circuit Court boards. Hauv tsab xov xwm no, peb yuav ua tib zoo saib seb yuav ua li cas Capel qhov kev ua pov thawj FPC cov txheej txheem thev naus laus zis thiab cov kev daws teeb meem tshiab daws cov teeb meem kev lag luam tshwj xeeb tau ntsib los ntawm cov neeg siv khoom hauv tsheb.tshiab zog tsheb 2-txheej hloov tau PCB raug.

Cov neeg siv khoom sib tw

Cov neeg siv khoom, tus thawj coj hauv kev lag luam tsheb tshiab, tau ntsib cov teeb meem loj thaum tsim 2-txheej hloov pauv PCBs rau cov roj teeb tiv thaiv Circuit Court boards. Cov kev cai tshwj xeeb rau kev hloov pauv PCB suav nrog:

Cov ntaub ntawv: Cov PCBs yooj yim yuav tsum tau tsim los siv polyimide (PI) raws li cov substrate thiab tooj liab kab thiab nplaum raws li cov txheej txheem sib txuas.

Kab dav thiab kab sib nrug: Kab dav thiab kab sib nrug yuav tsum tau ua kom raug rau 0.2mm / 0.25mm kom ntseeg tau tias kev ncaj ncees thiab kev ua haujlwm ntawm lub voj voog.

Phaj thickness: Phaj thickness yog teev raws li 0.25mm +/- 0.03mm, yuav tsum tau nruj me ntsis raws li qhov ntev kam rau ua.

Qhov tsawg kawg nkaus: PCB yuav tsum muaj qhov tsawg kawg nkaus ntawm 0.1 hli kom haum rau cov khoom tsim nyog.

Surface Treatment: Electroless Nickel Immersion Gold (ENIG) deg kev kho mob yog yuam kom nws zoo heev conductivity thiab corrosion kuj.

Tolerances: Cov neeg muas zaub yuav tsum tau nruj kam rau ua ntawm ± 0.1mm kom ua tau raws li qhov tseeb thiab qhov tseeb board qhov ntev.

Capel cov kev daws teeb meem thiab kev muaj peev xwm

Capel pab pawg paub txog FPC engineers ua tib zoo tshuaj xyuas cov neeg siv khoom xav tau thiab tsim cov kev daws teeb meem tshiab kom tau raws li qhov xav tau ntawm qhov project. Nov yog yuav ua li cas Capel qhov kev ua tau zoo thiab kev tsim kho tshiab qhia nws txoj kev vam meej hauv kev ntsib cov neeg siv khoom sib tw:

Kev Xaiv thiab Kev Ua Haujlwm Zoo: Capel qhov kev paub tob ntawm cov khoom thiab cov yam ntxwv ntawm cov khoom siv polyimide, tooj liab thiab cov nplaum ua rau muaj kev xaiv zoo thiab kev yuav khoom. Cov ntaub ntawv zoo tau raug xaiv los ua kom ntseeg tau tias muaj kev ntseeg siab, hloov tau yooj yim thiab thermal stability ntawm cov PCB hloov tau yooj yim, uas yog qhov tseem ceeb rau kev siv hluav taws xob tshiab.

Precision Manufacturing Txheej Txheem: Capel cov chaw tsim khoom siab tshaj plaws thiab kev txawj ntse hauv FPC prototyping thiab cov txheej txheem tsim khoom ua kom muaj kev ua tiav ntawm cov kab dav dav, kab sib nrug, pawg thawj coj saib thicknesses thiab qhov tsawg kawg nkaus qhov ntau thiab tsawg. Cov cuab yeej siv hluav taws xob hauv lub xeev thiab kev tswj xyuas nruj nruj yog siv los ua kom tiav qhov yuav tsum tau muaj qhov tseeb thiab sib xws rau txhua qhov hloov pauv PCB.

Superior Surface Treatment: Daim ntawv thov ntawm Electroless Nickel Immersion Gold (ENIG) nto kev kho mob yog ua tiav nrog qhov siab tshaj plaws thiab ua raws li cov qauv kev lag luam. Capel cov txheej txheem kho saum npoo muab cov conductivity, solderability thiab durability yuav tsum tau ua kom tau raws li cov kev cai nruj ntawm niaj hnub automotive electronics.

Kev Tswj Xyuas Kev Ua Haujlwm Zoo thiab Kev Ua Haujlwm Zoo: Capel txoj kev cog lus los tswj kev ua siab ntev ntawm ± 0.1mm yog pom los ntawm cov txheej txheem kev ruaj ntseg zoo. Txhua kauj ruam ntawm cov txheej txheem tsim khoom yog nruj me ntsis tshuaj xyuas kom ntseeg tau tias qhov ua tiav 2-txheej hloov pauv PCB muaj qhov tseeb qhov tseeb thiab kev ntseeg tau zoo, ua tau raws li cov qauv nruj ntawm kev lag luam tsheb tshiab.

Case Study Analysis: Customer Success and Industry Impact

Capel txoj kev sib koom tes zoo nrog cov neeg siv khoom tau tsim cov khoom zoo 2-txheej hloov tau yooj yim PCBs uas tshaj qhov kev cia siab ntawm kev lag luam. Qhov kev ua tau zoo thiab kev ua tau zoo ntawm cov khoom siv tau yooj yim PCBs tau ua rau muaj txiaj ntsig zoo rau cov neeg siv khoom lub zog tshiab lub tsheb roj teeb tiv thaiv Circuit Court boards, txhim kho kev nyab xeeb thiab kev ua haujlwm ntawm lub tsheb hluav taws xob.

Lub zog kev txawj ntse thiab kev tsim kho tshiab tsim nyob rau hauv Capel txoj kev paub FPC txheej txheem thev naus laus zis yog qhov tseem ceeb hauv kev tsav txoj haujlwm no kom tau txais txiaj ntsig zoo. Capel lub peev xwm ua kom tsis tu ncua xa cov kev cai hloov pauv PCB cov kev daws teeb meem nyob rau hauv nruj kam rau ua thiab cov khoom siv tshwj xeeb qhia tau hais tias Capel lub zog hauv cheeb tsam no. Qhov cuam tshuam ntawm kev sib koom tes no txuas mus dhau qhov kev ua tiav ntawm cov neeg siv khoom ncaj qha thiab qhia txog lub luag haujlwm ntawm kev tsim FPC siab heev hauv kev txhim kho kev lag luam tsheb tshiab.

Capel txoj kev mob siab rau kev txhim kho txuas ntxiv thiab kev tsim kho tshiab hauv FPC prototyping thiab kev tsim khoom tau ua pov thawj tias yuav pab tau kom tau raws li qhov xav tau hloov pauv ntawm lub tsheb tshiab lub zog. Cov ntaub ntawv kawm no qhia tau hais tias Capel txoj kev cog lus los muab kev txhim khu kev qha, kev ua tau zoo thiab kev daws teeb meem los txhim kho lub bar rau cov khoom siv PCB hloov tau yooj yim hauv kev lag luam tsheb loj zuj zus sai.

Tshiab Zog Tsav Tsheb PCB Txheej Txheem

Hauv kev xaus

Nyob rau hauv lub dynamic toj roob hauv pes ntawm tshiab automotive zog technologies, lub luag hauj lwm ntawm FPC-Flex PCB prototyping thiab manufacturing tsis tau underestimated. Capel cov ntaub ntawv kawm tiav ua pov thawj qhia txog kev ua haujlwm zoo thiab kev tsim kho tshiab uas txhawb nqa nws cov txheej txheem FPC. Los ntawm kev daws qhov kev sib tw tshwj xeeb ntawm kev tsim 2-txheej hloov pauv PCBs rau lub zog tshiab lub tsheb roj teeb tiv thaiv Circuit Court boards, Capel tsis tsuas yog ua kom pom nws lub peev xwm xwb tab sis kuj tseem txhawb nqa kev nce qib ntawm automotive electronics.

Raws li kev lag luam txuas ntxiv mus ntxiv, kev sib koom tes tsis sib haum xeeb ntawm Capel thiab nws cov neeg siv khoom qhia txog lub peev xwm ntawm FPC cov kev daws teeb meem los tsav kev tsim kho tshiab, kev ua tau zoo thiab kev nyab xeeb hauv tsheb tshiab. Cov ntaub ntawv tshawb fawb qhia txog qhov tseem ceeb ntawm kev txawj ntse, kev tsim khoom precision thiab kev cog lus ruaj khov rau kev ua tau zoo nyob rau hauv ib qho kev hloov pauv ntawm automotive electronics toj roob hauv pes. Nrog nws cov neeg siv khoom-centric lub tswv yim thiab nrhiav kev ua tau zoo, Capel tseem tsim cov qauv tshiab rau FPC-Flex PCB kev tsim khoom hauv kev lag luam tsheb tshiab.

Tsab ntawv xov xwm no muab kev nkag siab zoo rau kev sib txuas hauv nruab nrab ntawm FPC-Flex PCB thev naus laus zis thiab lub zog tshiab lub neej yav tom ntej ntawm automotive, muab Capel ua tus thawj coj hauv kev muab cov kev daws teeb meem tshiab rau lub zog rau tiam tom ntej ntawm kev thauj mus los hauv ib puag ncig.

Post lub sij hawm: Feb-27-2024

Rov qab