PCB (Printed Circuit Board) yog ib qho tseem ceeb hauv cov khoom siv hluav taws xob niaj hnub, ua kom muaj kev sib txuas thiab kev ua haujlwm ntawm ntau yam khoom siv hluav taws xob. Cov txheej txheem tsim khoom PCB suav nrog ntau cov kauj ruam tseem ceeb, ib qho ntawm kev tso cov tooj liab mus rau substrate. Kab lus no peb yuav saib cov txheej txheem ntawm kev tso tooj liab ntawm PCB substrates thaum lub sijhawm tsim khoom, thiab nkag mus rau hauv cov txheej txheem sib txawv siv, xws li electroless tooj liab plating thiab electroplating.

1.Electroless tooj liab plating: piav qhia, txheej txheem tshuaj, qhov zoo, qhov tsis zoo thiab thaj chaw ntawm daim ntawv thov.

Yuav kom nkag siab tias electroless tooj liab plating yog dab tsi, nws yog ib qho tseem ceeb kom nkag siab tias nws ua haujlwm li cas. Tsis zoo li electrodeposition, uas tso siab rau hluav taws xob tam sim no rau cov hlau deposition, electroless tooj liab plating yog txheej txheem autophoretic. Nws koom nrog kev tswj cov tshuaj txo cov tooj liab ions ntawm lub substrate, uas ua rau cov txheej txheem tooj liab zoo sib xws.

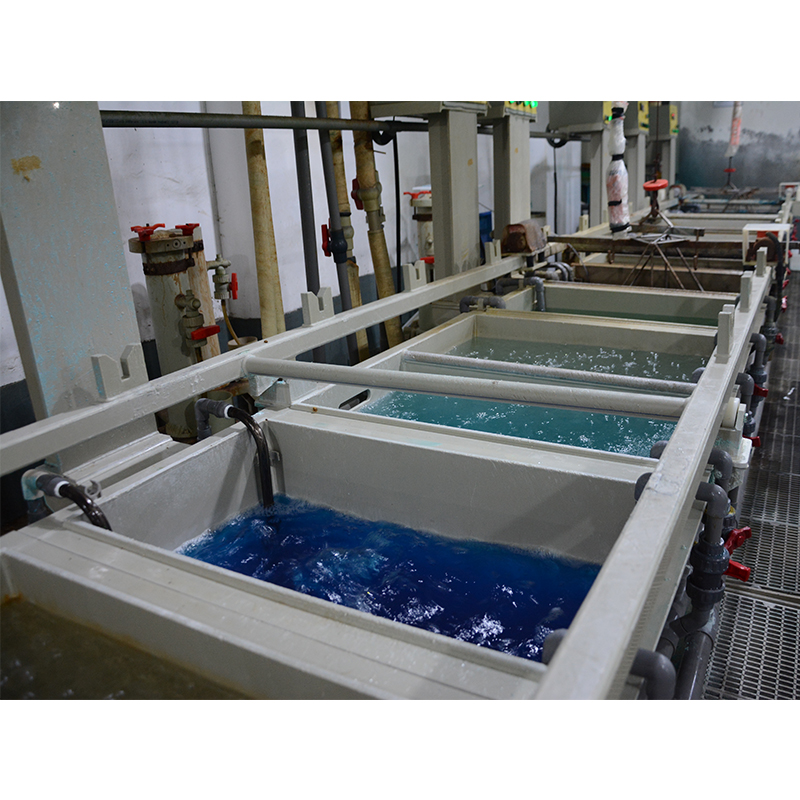

Ntxuav lub substrate:Ua tib zoo ntxuav lub substrate nto kom tshem tawm tej yam kab mob los yog oxides uas yuav tiv thaiv adhesion. Kev Ua Haujlwm: Ib qho kev ua kom muaj zog uas muaj cov khoom siv hlau zoo xws li palladium lossis platinum yog siv los pib txheej txheem electroplating. Qhov kev daws teeb meem no yooj yim tooj liab deposition mus rau lub substrate.

Nyob rau hauv lub plating tov:Raus lub activated substrate rau hauv electroless tooj liab plating tov. Lub plating tov muaj tooj liab ions, txo cov neeg ua hauj lwm thiab ntau yam additives uas tswj cov txheej txheem deposition.

Electroplating txheej txheem:Tus neeg sawv cev txo qis hauv cov tshuaj electroplating tshuaj txo cov tooj liab ions rau hauv cov hlau tooj liab atoms. Cov atoms no ces khi rau lub tshuab ua kom lub ntsej muag, tsim ib txheej nruam thiab sib xws ntawm tooj liab.

Yaug thiab qhuav:Thaum qhov xav tau tooj liab tuab tiav, lub substrate raug tshem tawm ntawm lub plating tank thiab yaug kom huv si kom tshem tawm cov tshuaj seem. Qhuav lub plated substrate ua ntej ua ntxiv. Cov txheej txheem tshuaj tooj liab plating Cov txheej txheem tshuaj ntawm electroless tooj liab plating muaj cov tshuaj tiv thaiv redox ntawm tooj liab ions thiab txo cov neeg ua haujlwm. Cov kauj ruam tseem ceeb hauv cov txheej txheem suav nrog: Ua kom muaj zog: Kev siv cov khoom siv hlau zoo xws li palladium lossis platinum los qhib lub substrate nto. Lub catalyst muab cov chaw tsim nyog rau kev sib txuas tshuaj ntawm tooj liab ions.

Tus neeg sawv cev txo qis:Tus neeg sawv cev txo qis hauv cov tshuaj plating (feem ntau yog formaldehyde lossis sodium hypophosphite) pib txo cov tshuaj tiv thaiv. Cov reagents no pub electrons rau tooj liab ions, hloov lawv mus rau hauv hlau atoms tooj liab.

Cov tshuaj tiv thaiv autocatalytic:Cov tooj liab atoms tsim los ntawm kev txo cov tshuaj tiv thaiv nrog cov catalyst ntawm lub substrate los tsim ib txheej tooj liab. Cov tshuaj tiv thaiv tshwm sim yam tsis tas yuav tsum tau siv rau sab nraud tam sim no, ua rau nws "electroless plating."

Kev tswj tus nqi deposition:Cov muaj pes tsawg leeg thiab concentration ntawm cov tshuaj plating, nrog rau cov txheej txheem tsis xws li kub thiab pH, yog ua tib zoo tswj xyuas kom meej tias cov deposition npaum li cas yog tswj thiab uniform.

Qhov zoo ntawm electroless tooj liab plating Uniformity:Electroless tooj liab plating muaj qhov zoo sib xws, kom ntseeg tau cov tuab tuab hauv cov duab nyuaj thiab cov chaw so. Conformal Txheej: Cov txheej txheem no muab cov txheej txheem sib xws uas ua raws li cov txheej txheem geometrically irregular substrates xws li PCBs. Zoo adhesion: Electroless tooj liab plating muaj zog adhesion rau ntau yam ntaub ntawv substrate, nrog rau cov yas, ceramics thiab hlau. Selective Plating: Electroless tooj liab plating tuaj yeem xaiv cov tooj liab tso rau hauv qhov tshwj xeeb ntawm substrate siv cov txheej txheem npog. Tus nqi qis: Piv nrog rau lwm txoj hauv kev, electroless tooj liab plating yog qhov kev xaiv zoo rau kev tso tooj liab mus rau lub substrate.

Disadvantages ntawm electroless tooj liab plating Slower deposition tus nqi:Piv nrog rau txoj kev electroplating, electroless tooj liab plating feem ntau muaj qhov qis qis dua, uas tuaj yeem ua rau lub sijhawm tag nrho cov txheej txheem electroplating. Tsawg thickness: Electroless tooj liab plating feem ntau haum rau tso cov txheej tooj liab nyias thiab yog li tsis tsim nyog rau cov ntawv thov uas xav tau cov depositions tuab. Complexity: Cov txheej txheem yuav tsum tau ceev faj tswj ntawm ntau yam tsis, nrog rau qhov kub thiab txias, pH thiab tshuaj lom neeg concentration, ua rau nws nyuaj rau siv dua li lwm txoj kev electroplating. Kev Tswj Pov Hwm: Kev pov tseg cov txheej txheem pov tseg uas muaj cov hlau hnyav hnyav tuaj yeem ua rau muaj teeb meem ib puag ncig thiab yuav tsum tau ua tib zoo tuav.

Daim ntawv thov thaj chaw ntawm electroless tooj liab plating PCB Manufacturing:Electroless tooj liab plating yog siv dav hauv kev tsim cov ntawv luam tawm Circuit Board (PCBs) los tsim cov kab hluav taws xob thiab plated los ntawm qhov. Kev lag luam semiconductor: Ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv semiconductor xws li cov khoom siv nti thiab cov hlau lead. Automotive thiab aerospace industries: Electroless tooj liab plating yog siv los ua hluav taws xob connectors, keyboards thiab cov khoom siv hluav taws xob ua haujlwm siab. Kho kom zoo nkauj thiab ua haujlwm txheej: Electroless tooj liab plating tuaj yeem siv los tsim cov khoom zoo nkauj ntawm ntau yam substrates, nrog rau kev tiv thaiv corrosion thiab txhim kho hluav taws xob conductivity.

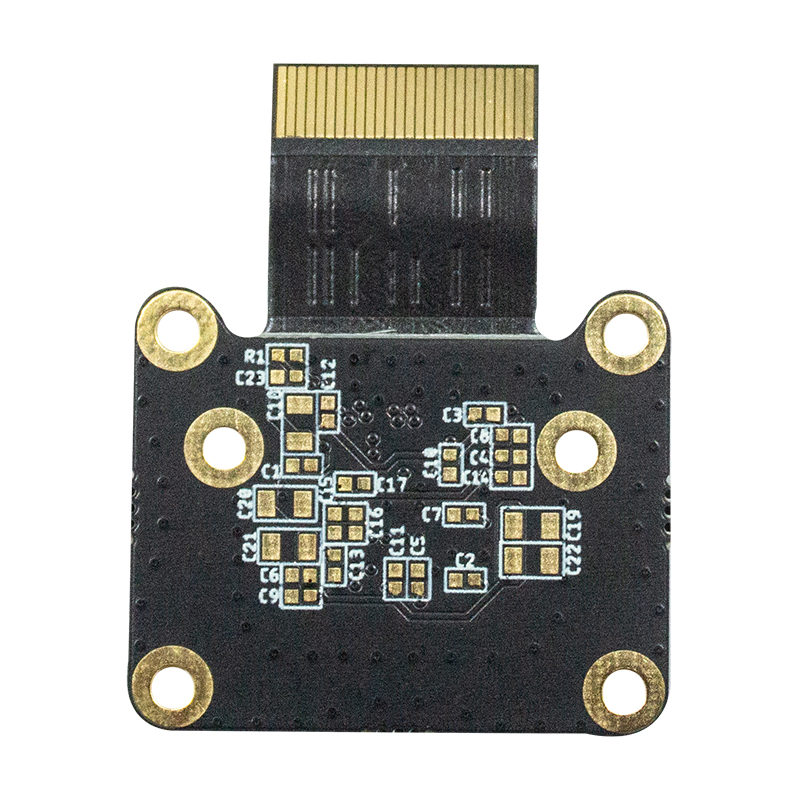

2.Copper plating ntawm PCB substrate

Copper plating ntawm PCB substrates yog ib kauj ruam tseem ceeb hauv cov txheej txheem luam tawm Circuit Board (PCB) kev tsim khoom. Tooj liab feem ntau yog siv los ua cov khoom siv electroplating vim nws cov khoom siv hluav taws xob zoo heev thiab zoo heev adhesion rau substrate. Cov txheej txheem tooj liab plating suav nrog tso cov txheej nyias ntawm tooj liab rau ntawm qhov chaw ntawm PCB los tsim cov kab hluav taws xob rau cov teeb liab hluav taws xob.

Cov txheej txheem tooj liab plating ntawm PCB substrates feem ntau suav nrog cov kauj ruam hauv qab no: Kev Npaj Nto:

Ua tib zoo ntxuav PCB substrate kom tshem tawm cov kab mob, oxides lossis impurities uas tuaj yeem cuam tshuam adhesion thiab cuam tshuam qhov zoo ntawm plating.

Electrolyte npaj:

Npaj cov tshuaj electrolyte uas muaj tooj liab sulfate ua qhov chaw ntawm tooj liab ions. Cov electrolyte kuj muaj cov tshuaj ntxiv uas tswj cov txheej txheem plating, xws li cov neeg ua haujlwm theem, cov ci ci, thiab pH adjusters.

Electrodeposition:

Dip lub PCB substrate npaj rau hauv cov tshuaj electrolyte thiab siv ncaj qha tam sim no. Lub PCB ua haujlwm raws li kev sib txuas ntawm cathode, thaum lub tooj liab anode kuj muaj nyob rau hauv cov tshuaj. Qhov tam sim no ua rau cov tooj liab ions hauv electrolyte raug txo thiab tso rau hauv PCB nto.

Control ntawm plating parameter:

Ntau yam tsis tau ua tib zoo tswj thaum lub sij hawm plating, nrog rau tam sim no ceev, kub, pH, nplawm thiab plating lub sij hawm. Cov kev ntsuas no pab ua kom zoo ib yam kev tso nyiaj, adhesion, thiab xav tau thickness ntawm tooj liab txheej.

Kev kho tom qab plating:

Thaum qhov xav tau tooj liab tuab tau ncav cuag, PCB raug tshem tawm ntawm lub plating da dej thiab yaug kom tshem tawm cov tshuaj electrolyte seem. Ntxiv cov kev kho tom qab plating, xws li kev ntxuav saum npoo thiab passivation, tuaj yeem ua tau los txhim kho qhov zoo thiab ruaj khov ntawm txheej tooj liab plating.

Cov yam ntxwv cuam tshuam rau electroplating zoo:

Kev npaj nto:

Kev tu kom zoo thiab kev npaj ntawm PCB nto yog qhov tseem ceeb kom tshem tawm cov kab mob los yog oxide txheej thiab xyuas kom zoo adhesion ntawm tooj liab plating. Plating kua muaj pes tsawg leeg:

Qhov sib xyaw ntawm cov tshuaj electrolyte, nrog rau cov concentration ntawm tooj liab sulfate thiab additives, yuav cuam tshuam rau qhov zoo ntawm plating. Lub plating da dej muaj pes tsawg leeg yuav tsum tau ua tib zoo tswj kom ua tiav cov yam ntxwv xav tau plating.

Plating Parameters:

Kev tswj cov plating tsis xws li tam sim no ceev, kub, pH, nplawm thiab plating lub sij hawm yog tsim nyog los xyuas kom meej uniform deposition, adhesion thiab thickness ntawm cov tooj liab txheej.

Cov khoom siv substrate:

Hom thiab zoo ntawm PCB substrate khoom yuav cuam tshuam rau adhesion thiab zoo ntawm tooj liab plating. Cov ntaub ntawv sib txawv ntawm cov substrate yuav xav tau kev hloov kho rau txheej txheem plating kom tau txais txiaj ntsig zoo.

Nto roughness:

Qhov saum npoo roughness ntawm PCB substrate yuav cuam tshuam rau adhesion thiab zoo ntawm tooj liab plating txheej. Kev npaj saum npoo kom zoo thiab tswj cov txheej txheem plating pab txo qis cov teeb meem ntsig txog kev ntxhib

Qhov zoo ntawm PCB substrate tooj liab plating:

Zoo heev hluav taws xob conductivity:

Tooj liab paub txog nws cov hluav taws xob hluav taws xob siab, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv PCB plating. Qhov no ua kom muaj txiaj ntsig thiab txhim khu kev qha ntawm cov teeb liab hluav taws xob. Zoo heev adhesion:

Copper nthuav tawm zoo heev adhesion rau ntau yam substrates, kom ntseeg tau tias muaj zog thiab kav ntev ntawm cov txheej thiab cov substrate.

Corrosion Resistance:

Copper muaj kev tiv thaiv zoo corrosion, tiv thaiv hauv qab PCB Cheebtsam thiab ua kom muaj kev ntseeg tau ntev. Solderability: tooj liab plating muab ib tug nto haum rau soldering, ua rau nws yooj yim mus cuag cov khoom siv hluav taws xob thaum sib dhos.

Enhanced cua sov dissipation:

Tooj liab yog ib tug zoo thermal conductor, ua kom muaj cua sov dissipation ntawm PCBs. Qhov no tseem ceeb tshwj xeeb tshaj yog rau kev siv hluav taws xob siab.

Cov kev txwv thiab cov teeb meem ntawm tooj liab electroplating:

Thickness tswj:

Kev ua tiav kev tswj xyuas meej ntawm cov txheej tooj liab txheej yuav nyuaj, tshwj xeeb tshaj yog nyob rau hauv cov cheeb tsam nyuaj lossis qhov chaw nruj ntawm PCB. Uniformity: Ua kom muaj qhov sib txawv ntawm cov tooj liab tag nrho ntawm PCB, suav nrog cov chaw so thiab cov yam ntxwv zoo, tuaj yeem nyuaj.

Tus nqi:

Electroplating tooj liab tuaj yeem kim dua piv rau lwm txoj hauv kev electroplating vim tus nqi ntawm plating tank tshuaj, khoom siv, thiab kev saib xyuas.

Kev Tswj Pov Hwm:

Kev pov tseg ntawm kev siv plating kev daws teeb meem thiab kev kho cov dej khib nyiab uas muaj tooj liab ions thiab lwm yam tshuaj yuav tsum muaj kev tswj xyuas cov pov tseg kom tsim nyog kom txo tau qhov cuam tshuam ib puag ncig.

Txheej txheem complexity:

Electroplating tooj liab suav nrog ntau qhov tsis sib xws uas yuav tsum tau ua tib zoo tswj, xav tau kev paub tshwj xeeb thiab cov txheej txheem plating nyuaj.

3.Kev sib piv ntawm electroless tooj liab plating thiab electroplating

Kev ua tau zoo thiab qhov sib txawv:

Muaj ntau qhov sib txawv ntawm kev ua tau zoo thiab qhov zoo ntawm electroless tooj liab plating thiab electroplating hauv cov hauv qab no:

Electroless tooj liab plating yog cov txheej txheem chemical deposition uas tsis tas yuav muaj lub zog hluav taws xob sab nraud, thaum electroplating siv ncaj qha tam sim no los tso rau txheej tooj liab. Qhov sib txawv ntawm cov txheej txheem deposition tuaj yeem ua rau muaj kev hloov pauv hauv cov txheej txheem zoo.

Electroless tooj liab plating feem ntau muab ib qho zoo sib xws ntawm tag nrho cov substrate nto, nrog rau cov chaw so thiab cov yam ntxwv zoo. Qhov no yog vim hais tias plating tshwm sim sib npaug ntawm txhua qhov chaw tsis hais lawv txoj kev taw qhia. Electroplating, ntawm qhov tod tes, tuaj yeem muaj kev nyuaj rau kev ua tiav cov khoom tso rau hauv cov chaw nyuaj lossis nyuaj mus cuag.

Electroless tooj liab plating tuaj yeem ua tiav qhov sib piv ntau dua (qhov sib piv ntawm qhov siab rau qhov dav) dua li electroplating. Qhov no ua rau nws tsim nyog rau cov ntawv thov uas xav tau cov khoom zoo sib xws, xws li los ntawm qhov hauv PCBs.

Electroless tooj liab plating feem ntau ua rau smoother, flatter nto dua electroplating.

Electroplating tej zaum yuav ua rau tsis sib xws, ntxhib los yog void deposits vim muaj kev hloov nyob rau hauv tam sim no ceev thiab da dej tej yam kev mob. Qhov zoo ntawm daim ntawv cog lus ntawm tooj liab plating txheej thiab lub substrate yuav txawv ntawm electroless tooj liab plating thiab electroplating.

Electroless tooj liab plating feem ntau muab adhesion zoo dua vim cov tshuaj sib txuas ntawm electroless tooj liab rau lub substrate. Plating cia siab rau kev sib txuas ntawm cov tshuab thiab electrochemical, uas tuaj yeem ua rau cov nyiaj tsis muaj zog nyob rau qee kis.

Tus nqi sib piv:

Chemical Deposition vs. Electroplating: Thaum muab piv cov nqi ntawm electroless tooj liab plating thiab electroplating, ntau yam yuav tsum tau xav txog:

Cov nqi tshuaj:

Electroless tooj liab plating feem ntau xav tau cov tshuaj kim dua piv rau electroplating. Cov tshuaj siv hauv electroless plating, xws li txo cov neeg ua hauj lwm thiab cov stabilizers, feem ntau yog tshwj xeeb thiab kim.

Khoom siv:

Plating units xav tau cov cuab yeej siv ntau dua thiab kim, suav nrog cov khoom siv hluav taws xob, cov khoom siv hluav taws xob thiab cov anodes. Electroless tooj liab plating tshuab yog qhov yooj yim dua thiab xav tau cov khoom tsawg dua.

Cov nqi kho mob:

Cov khoom siv plating yuav xav tau kev saib xyuas ib ntus, calibration, thiab hloov cov anodes lossis lwm yam khoom. Electroless tooj liab plating tshuab feem ntau xav tau kev saib xyuas tsis tu ncua thiab muaj cov nqi kho mob qis dua.

Kev siv cov tshuaj plating:

Plating systems siv cov tshuaj plating ntawm tus nqi siab dua vim yog siv cov hluav taws xob tam sim no. Kev siv tshuaj lom neeg ntawm electroless tooj liab plating tshuab yog qis dua vim tias cov tshuaj tiv thaiv electroplating tshwm sim los ntawm cov tshuaj tiv thaiv tshuaj.

Kev tswj cov khoom pov tseg:

Electroplating tsim cov khoom pov tseg ntxiv, suav nrog kev siv plating da dej thiab yaug cov dej uas muaj hlau ions, uas yuav tsum tau kho thiab pov tseg kom tsim nyog. Qhov no nce tus nqi tag nrho ntawm plating. Electroless tooj liab plating tsim cov khoom pov tseg tsawg dua vim tias nws tsis cia siab rau cov khoom siv txuas ntxiv ntawm cov hlau ions hauv plating da dej.

Complexities thiab cov nyom ntawm Electroplating thiab Chemical Deposition:

Electroplating yuav tsum tau ceev faj tswj ntawm ntau yam tsis xws li tam sim no ceev, kub, pH, plating lub sij hawm thiab stirring. Kev ua tiav cov txheej txheem zoo ib yam thiab cov yam ntxwv ntawm cov plating xav tau tuaj yeem nyuaj, tshwj xeeb tshaj yog nyob rau hauv cov geometry nyuaj lossis cov cheeb tsam tam sim no. Kev ua kom zoo ntawm plating da dej muaj pes tsawg leeg thiab cov ntsuas yuav xav tau kev sim thiab kev txawj ntse.

Electroless tooj liab plating kuj yuav tsum tau tswj cov tsis xws li txo tus neeg sawv cev concentration, kub, pH thiab plating lub sij hawm. Txawm li cas los xij, kev tswj hwm ntawm cov kev txwv no feem ntau tsis tshua tseem ceeb hauv electroless plating dua li hauv electroplating. Ua kom tiav cov khoom plating xav tau, xws li kev tso nyiaj, thickness, thiab adhesion, tseem yuav xav tau kev ua kom zoo thiab saib xyuas cov txheej txheem plating.

Hauv electroplating thiab electroless tooj liab plating, adhesion rau ntau yam ntaub ntawv substrate tuaj yeem yog ib qho kev sib tw. Kev kho ua ntej ntawm substrate nto kom tshem tawm cov kab mob thiab txhawb nqa adhesion yog qhov tseem ceeb rau ob qho tib si txheej txheem.

Kev daws teeb meem thiab kev daws teeb meem hauv electroplating lossis electroless tooj liab plating yuav tsum muaj kev paub tshwj xeeb thiab kev paub dhau los. Cov teeb meem xws li roughness, uneven deposition, voids, bubbling, los yog adhesion tsis zoo yuav tshwm sim thaum lub sij hawm ob txheej txheem, thiab txheeb xyuas cov hauv paus ntsiab lus thiab kev kho yuav ua tau nyuaj.

Scope ntawm kev siv ntawm txhua lub tshuab:

Electroplating feem ntau yog siv nyob rau hauv ntau yam kev lag luam xws li electronics, automotive, aerospace thiab hniav nyiaj hniav kub uas yuav tsum tau cov tuab tuab tswj, high-zoo tag thiab lub cev xav tau. Nws yog dav siv nyob rau hauv kev kho kom zoo nkauj finishes, hlau coatings, tiv thaiv corrosion thiab hluav taws xob tivthaiv manufacturing.

Electroless tooj liab plating feem ntau yog siv hauv kev lag luam hluav taws xob, tshwj xeeb tshaj yog nyob rau hauv kev tsim cov ntawv luam tawm Circuit Board (PCBs). Nws yog siv los tsim cov kab hluav taws xob, cov khoom siv hluav taws xob thiab cov khoom tiav ntawm PCBs. Electroless tooj liab plating kuj yog siv los metallize plastics, tsim tooj liab interconnects nyob rau hauv semiconductor tej pob khoom, thiab lwm yam kev siv uas yuav tsum tau uniform thiab conformal tooj liab deposition.

4.Copper deposition cov txheej txheem rau ntau hom PCB

Ib sab PCB:

Hauv ib sab PCBs, tooj liab deposition feem ntau yog ua los ntawm cov txheej txheem rho tawm. Lub substrate feem ntau yog ua los ntawm cov khoom siv tsis zoo xws li FR-4 lossis phenolic resin, coated nrog nyias txheej ntawm tooj liab ntawm ib sab. Cov txheej tooj liab ua haujlwm raws li txoj hauv kev rau lub voj voog. Cov txheej txheem pib nrog kev tu thiab kev npaj ntawm substrate nto kom ntseeg tau zoo adhesion. Tom ntej no yog daim ntawv thov txheej nyias ntawm cov khoom siv photoresist, uas raug UV teeb los ntawm photomask los txhais cov qauv Circuit Court. Cov cheeb tsam raug tawm tsam ua rau soluble thiab tom qab ntawd ntxuav tawm, nthuav tawm cov txheej tooj liab hauv qab. Tom qab ntawd cov tooj liab raug etched siv cov etchant xws li ferric chloride lossis ammonium persulfate. Lub etchant xaiv tshem tawm cov tooj liab, tawm hauv cov qauv uas xav tau. Tom qab ntawd qhov seem tiv thaiv yog stripped, tawm hauv cov kab tooj liab. Tom qab cov txheej txheem etching, PCB tuaj yeem dhau los ua cov txheej txheem kev npaj saum npoo av ntxiv xws li daim npog ntsej muag, kev tshuaj ntsuam luam ntawv, thiab kev siv cov txheej tiv thaiv kom ntseeg tau tias muaj kev ruaj ntseg thiab kev tiv thaiv ib puag ncig.

Ob chav sided PCB:

Ib ob sab PCB muaj tooj liab txheej ntawm ob sab ntawm substrate. Cov txheej txheem ntawm kev tso cov tooj liab ntawm ob sab muaj cov kauj ruam ntxiv piv rau PCBs ib leeg. Cov txheej txheem zoo ib yam li PCB ib leeg, pib nrog kev tu thiab kev npaj ntawm substrate nto. Ib txheej ntawm tooj liab yog muab tso rau ntawm ob sab ntawm lub substrate siv electroless tooj liab plating los yog electroplating. Electroplating feem ntau yog siv rau cov kauj ruam no vim nws tso cai rau kev tswj kom zoo dua ntawm cov tuab thiab zoo ntawm cov txheej tooj liab. Tom qab cov txheej tooj liab tau muab tso rau, ob sab yog coated nrog photoresist thiab cov qauv Circuit Court yog txhais los ntawm kev raug thiab kev txhim kho cov kauj ruam zoo ib yam li cov PCBs ib leeg. Tom qab ntawd cov tooj liab raug etched los tsim cov kab hluav taws xob uas yuav tsum tau muaj. Tom qab etching, qhov kev tawm tsam raug tshem tawm thiab PCB dhau los ua cov kauj ruam ntxiv xws li daim ntawv thov daim npog ntsej muag thiab kev kho saum npoo kom tiav cov khoom ntawm ob sab PCB.

Multilayer PCB:

Multilayer PCBs yog ua los ntawm ntau txheej ntawm tooj liab thiab insulating cov ntaub ntawv sib dhos rau saum ib leeg. Copper deposition nyob rau hauv multilayer PCBs muaj ntau yam kauj ruam los tsim conductive txoj kev ntawm txheej. Cov txheej txheem pib nrog kev tsim cov txheej txheem PCB ib leeg, zoo ib yam li ib sab lossis ob sab PCBs. Txhua txheej yog npaj thiab ib tug photoresist yog siv los txhais cov qauv Circuit Court, ua raws li tooj liab deposition ntawm electroplating los yog electroless tooj liab plating. Tom qab deposition, txhua txheej yog coated nrog ib tug insulating khoom (feem ntau epoxy-raws li prepreg los yog cob) thiab ces stacked ua ke. Cov khaubncaws sab nraud povtseg yog ua raws siv precision drilling thiab cov txheej txheem kev sau npe tshuab kom ntseeg tau tias muaj kev sib raug zoo ntawm cov khaubncaws sab nraud povtseg. Thaum cov khaubncaws sab nraud povtseg, vias yog tsim los ntawm qhov drilling qhov los ntawm cov khaubncaws sab nraud povtseg ntawm cov ntsiab lus tshwj xeeb uas yuav tsum muaj kev sib tshuam. Cov vias ces plated nrog tooj liab siv electroplating los yog electroless tooj liab plating los tsim hluav taws xob sib txuas ntawm cov khaubncaws sab nraud povtseg. Cov txheej txheem txuas ntxiv los ntawm kev rov ua txheej txheej txheej txheej, drilling, thiab tooj liab plating cov kauj ruam kom txog rau thaum tag nrho cov txheej txheem tsim nyog thiab kev sib tshuam raug tsim. Cov kauj ruam kawg suav nrog kev kho saum npoo, daim ntawv thov daim npog ntsej muag thiab lwm cov txheej txheem ua tiav kom tiav kev tsim khoom ntawm ntau txheej PCB.

High Density Interconnect (HDI) PCB:

HDI PCB yog ntau txheej PCB tsim los ua kom haum rau cov khoom siv hluav taws xob siab thiab cov ntawv me me. Copper deposition hauv HDI PCBs koom nrog cov txheej txheem siab heev los pab kom muaj cov yam ntxwv zoo thiab cov qauv tsim nruj. Cov txheej txheem pib los ntawm kev tsim ntau txheej txheej ultra-nyias, feem ntau hu ua cov khoom tseem ceeb. Cov cores no muaj cov ntawv ci tooj liab nyias nyias ntawm txhua sab thiab yog tsim los ntawm cov khoom siv ua haujlwm siab xws li BT (Bismaleimide Triazine) lossis PTFE (Polytetrafluoroethylene). Cov ntaub ntawv tseem ceeb yog stacked thiab laminated ua ke los tsim ntau txheej txheej. Laser drilling yog siv los tsim microvias, uas yog qhov me me uas txuas cov txheej. Microvias feem ntau muaj cov khoom siv hluav taws xob xws li tooj liab lossis conductive epoxy. Tom qab tsim cov microvias, cov khaubncaws sab nraud povtseg ntxiv yog stacked thiab laminated. Cov txheej txheem lamination ua ntu zus thiab cov txheej txheem laser drilling yog rov ua dua los tsim ntau txheej txheej nrog microvia interconnects. Thaum kawg, tooj liab tau muab tso rau saum npoo ntawm HDI PCB siv cov txheej txheem xws li electroplating lossis electroless tooj liab plating. Muab cov yam ntxwv zoo thiab cov khoom siv hluav taws xob siab ntawm HDI PCBs, kev tso nyiaj yog ua tib zoo tswj kom ua tiav cov txheej txheej tooj liab uas yuav tsum tau ua thiab zoo. Cov txheej txheem xaus nrog kev kho deg ntxiv thiab ua tiav cov txheej txheem kom tiav HDI PCB kev tsim khoom, uas yuav suav nrog daim ntawv thov daim npog ntsej muag, daim ntawv thov nto thiab kev sim.

Flexible Circuit Board:

Flexible PCBs, tseem hu ua flex circuits, yog tsim los ua kom yoog raws thiab tuaj yeem hloov mus rau cov duab sib txawv lossis khoov thaum ua haujlwm. Copper deposition nyob rau hauv saj zawg zog PCBs yuav tsum tau tshwj xeeb cov tswv yim uas ua tau raws li qhov yuav tsum tau yooj thiab durability. Plexible PCBs tuaj yeem ua ib sab, ob sab, lossis ntau txheej, thiab cov txheej txheem tooj liab sib txawv raws li kev tsim qauv. Feem ntau hais lus, hloov pauv PCBs siv cov ntawv ci tooj liab zoo dua piv rau cov PCB nruj kom ua tiav qhov yooj yim. Rau ib leeg-txhim kho PCBs, cov txheej txheem zoo ib yam li ib leeg-ib tog nruj PCBs, uas yog, ib txheej nyias ntawm tooj liab yog tso rau ntawm qhov hloov pauv tau yooj yim siv electroless tooj liab plating, electroplating, lossis ob qho tib si. Rau ob sab lossis ntau txheej hloov pauv tau PCBs, cov txheej txheem yuav tso cov tooj liab rau ntawm ob sab ntawm lub substrate hloov tau siv electroless tooj liab plating lossis electroplating. Muab rau hauv tus account lub cim txhua yam khoom ntawm cov ntaub ntawv hloov tau yooj yim, deposition yog ua tib zoo tswj kom zoo adhesion thiab yooj. Tom qab tooj liab deposition, lub saj zawg zog PCB mus los ntawm cov txheej txheem ntxiv xws li drilling, circuit patterning, thiab deg kho cov kauj ruam los tsim kom tau qhov yuav tsum tau circuitry thiab ua kom tiav cov khoom ntawm lub saj zawg zog PCB.

5. Ua ntej thiab Innovations hauv Copper Deposition ntawm PCBs

Kev Tsim Kho Tshuab Tseeb: Ntau xyoo dhau los, cov tshuab tooj liab tso rau ntawm PCBs tau txuas ntxiv txhim kho thiab txhim kho, ua rau muaj kev ua tau zoo thiab kev ntseeg tau. Qee qhov kev tsim kho tshiab tshaj plaws hauv PCB tooj liab deposition suav nrog:

Advanced plating technology:

Cov thev naus laus zis tshiab plating, xws li pulse plating thiab thim rov qab pulse plating, tau raug tsim los ua kom tau zoo dua thiab zoo dua tooj liab deposition. Cov thev naus laus zis no pab kov yeej cov teeb meem xws li qhov chaw roughness, grain loj thiab thickness faib los txhim kho hluav taws xob kev ua tau zoo.

Direct metallization:

Traditional PCB manufacturing koom nrog ntau cov kauj ruam los tsim cov kev coj ua, suav nrog kev tso cov noob txheej ua ntej tooj liab plating. Txoj kev loj hlob ntawm cov txheej txheem metallization ncaj qha tshem tawm qhov xav tau ntawm cov noob txheej cais, yog li ua kom yooj yim rau kev tsim khoom, txo cov nqi thiab txhim kho kev ntseeg tau.

Microvia technology:

Microvias yog qhov me me uas txuas cov txheej txheem sib txawv hauv ntau txheej PCB. Kev nce qib hauv microvia technology xws li cov ntshav drilling thiab ntshav etching enreable kev tsim me me, ntau dua cov cim siab dua thiab txhim kho cov cim kev ncaj ncees. Surface Finish Innovation: Nto tiav yog ib qho tseem ceeb rau kev tiv thaiv tooj liab kab los ntawm oxidation thiab muab solderability. Kev txhim kho hauv cov thev naus laus zis kho saum npoo av, xws li Immersion Silver (ImAg), Organic Solderability Preservative (OSP), thiab Electroless Nickel Immersion Gold (ENIG), muab kev tiv thaiv corrosion zoo dua, txhim kho solderability, thiab nce kev ntseeg tau tag nrho.

Nanotechnology thiab Copper Deposition: Nanotechnology plays lub luag haujlwm tseem ceeb hauv kev nce qib ntawm PCB tooj liab deposition. Qee qhov kev siv ntawm nanotechnology hauv tooj liab deposition muaj xws li:

Nanoparticle-based plating:

Copper nanoparticles tuaj yeem muab tso rau hauv cov tshuaj plating los txhim kho cov txheej txheem deposition. Cov nanoparticles no pab txhim kho tooj liab adhesion, grain loj thiab kev faib tawm, yog li txo cov resistivity thiab txhim kho hluav taws xob kev ua tau zoo.

Nanostructured Conductive Materials:

Cov ntaub ntawv nanostructured, xws li cov pa roj carbon nanotubes thiab graphene, tuaj yeem ua ke rau hauv PCB substrates lossis ua haujlwm ua cov khoom siv thaum lub sijhawm tso tawm. Cov ntaub ntawv no muaj ntau dua hluav taws xob conductivity, mechanical zog thiab thermal zog, yog li txhim kho tag nrho cov kev ua tau zoo ntawm PCB.

Nanocoating:

Nanocoating tuaj yeem siv rau PCB nto los txhim kho nto smoothness, solderability thiab corrosion tiv thaiv. Cov txheej txheej no feem ntau yog tsim los ntawm nanocomposites uas muab kev tiv thaiv zoo dua tiv thaiv ib puag ncig thiab ua rau lub neej ntev ntawm PCB.

Nanoscale interconnects:Nanoscale interconnects, xws li nanowires thiab nanorods, tab tom tshawb nrhiav los ua kom muaj kev sib txuas ntau dua hauv PCBs. Cov qauv no pab txhawb kev sib koom ua ke ntawm ntau lub voj voog mus rau hauv ib cheeb tsam me me, tso cai rau kev tsim cov khoom siv hluav taws xob me me, compact dua.

Cov kev sib tw thiab cov lus qhia yav tom ntej: Txawm hais tias muaj kev vam meej, ntau qhov kev sib tw thiab cov cib fim tseem nyob ntxiv los txhim kho tooj liab deposition ntawm PCBs. Qee qhov teeb meem tseem ceeb thiab cov lus qhia yav tom ntej muaj xws li:

Copper Fill hauv High Aspect Ratio Structures:

High nam piv qauv xws li vias los yog microvias tam sim no cov kev cov nyom nyob rau hauv kev ua tau zoo sib xws thiab txhim khu kev qha tooj liab sau. Kev tshawb fawb ntxiv yog xav tau los tsim cov txheej txheem plating siab lossis lwm txoj hauv kev los daws cov teeb meem no thiab xyuas kom meej cov tooj liab tso rau hauv cov qauv sib piv siab.

Txo Copper Trace Dav:

Raws li cov khoom siv hluav taws xob ua me me thiab ntau dua, qhov kev xav tau ntawm cov kab tooj liab nqaim txuas ntxiv mus ntxiv. Qhov kev sib tw yog kom ua tau raws li qhov sib xws thiab txhim khu kev qha tooj liab tso rau hauv cov kab nqaim no, ua kom muaj hluav taws xob zoo ib yam thiab kev ntseeg tau.

Lwm yam khoom siv conductor:

Thaum tooj liab yog cov khoom siv feem ntau siv, lwm cov ntaub ntawv xws li nyiaj, txhuas, thiab carbon nanotubes tau tshawb nrhiav rau lawv cov khoom tshwj xeeb thiab kev ua tau zoo. Kev tshawb fawb yav tom ntej yuav tsom mus rau kev tsim cov txheej txheem kev tso nyiaj rau cov khoom siv hloov pauv no kom kov yeej cov teeb meem xws li adhesion, resistivity, thiab compatibility nrog PCB manufacturing txheej txheem. Ib puag ncigCov txheej txheem phooj ywg:

PCB kev lag luam yog tas li ua hauj lwm rau ib puag ncig tus phooj ywg txheej txheem. Cov kev txhim kho yav tom ntej yuav tsom mus rau kev txo lossis tshem tawm kev siv tshuaj lom neeg thaum lub sij hawm tooj liab deposition, optimizing zog noj, thiab txo cov khoom pov tseg kom txo tau cov kev cuam tshuam ib puag ncig ntawm PCB manufacturing.

Advanced Simulation thiab Modeling:

Kev simulation thiab kev ua qauv ua qauv pab txhim kho cov txheej txheem tooj liab deposition, kwv yees tus cwj pwm ntawm kev tso nyiaj, thiab txhim kho qhov tseeb thiab kev ua haujlwm ntawm PCB kev tsim khoom. Kev nce qib yav tom ntej yuav suav nrog kev sib koom ua ke ntawm kev simulation siab heev thiab cov cuab yeej ua qauv rau hauv kev tsim thiab tsim cov txheej txheem kom tswj tau zoo dua thiab ua kom zoo dua.

6.Quality Assurance and Control of Copper Deposition for PCB Substrates

Qhov tseem ceeb ntawm kev ruaj ntseg zoo: Kev ruaj ntseg zoo yog qhov tseem ceeb hauv cov txheej txheem tooj liab tso rau hauv qab no:

Product Reliability:

Cov tooj liab tso rau ntawm PCB tsim lub hauv paus rau kev sib txuas hluav taws xob. Kev ua kom zoo ntawm tooj liab deposition yog ib qho tseem ceeb rau kev txhim khu kev qha thiab kav ntev ntawm cov khoom siv hluav taws xob. Tsis zoo tooj liab deposition tuaj yeem ua rau kev sib txuas tsis raug, teeb liab attenuation, thiab tag nrho txo PCB kev ntseeg tau.

Kev ua haujlwm hluav taws xob:

Qhov zoo ntawm tooj liab plating ncaj qha cuam tshuam rau kev ua haujlwm hluav taws xob ntawm PCB. Uniform tooj liab thickness thiab tis, du nto tiav, thiab kom zoo adhesion yog ib qho tseem ceeb kom ua tau raws li qhov tsis muaj kev tiv thaiv, zoo teeb liab kis tau tus mob, thiab tsawg heev teeb liab poob.

Txo cov nqi:

Kev ruaj ntseg zoo pab txheeb xyuas thiab tiv thaiv cov teeb meem thaum ntxov ntawm cov txheej txheem, txo qhov yuav tsum tau rov ua haujlwm dua lossis tshem tawm cov PCBs. Qhov no tuaj yeem txuag nqi thiab txhim kho kev tsim khoom tag nrho.

Cov neeg siv khoom txaus siab:

Muab cov khoom lag luam zoo yog qhov tseem ceeb rau cov neeg siv khoom txaus siab thiab tsim lub koob npe zoo hauv kev lag luam. Cov neeg siv khoom xav tau cov khoom lag luam txhim khu kev qha thiab ruaj khov, thiab kev ruaj ntseg zoo ua kom cov tooj liab deposition ua tau raws li lossis tshaj qhov kev cia siab.

Kev kuaj thiab tshuaj xyuas txoj hauv kev rau kev tso nyiaj tooj liab: Ntau yam kev sim thiab tshuaj xyuas yog siv los xyuas kom meej qhov zoo ntawm tooj liab deposition ntawm PCBs. Qee txoj hauv kev muaj xws li:

Kev tshuaj xyuas qhov muag:

Kev kuaj pom pom yog ib txoj hauv kev yooj yim thiab tseem ceeb ntawm kev txheeb xyuas qhov pom tseeb ntawm qhov tsis xws li khawb, dents lossis roughness. Qhov kev tshuaj xyuas no tuaj yeem ua tiav manually lossis nrog kev pab los ntawm kev tshuaj ntsuam xyuas qhov muag (AOI).

Microscopy:

Microscopy siv cov tswv yim xws li scanning electron microscopy (SEM) tuaj yeem muab cov ncauj lus kom ntxaws tsom xam ntawm tooj liab deposition. Nws tuaj yeem ua tib zoo xyuas qhov chaw tiav, adhesion thiab uniformity ntawm txheej tooj liab.

X-ray tsom xam:

X-ray tsom cov txuj ci, xws li X-ray fluorescence (XRF) thiab X-ray diffraction (XRD), yog siv los ntsuas qhov muaj pes tsawg leeg, tuab thiab kev faib tawm ntawm tooj liab deposits. Cov tswv yim no tuaj yeem txheeb xyuas cov impurities, cov ntsiab lus muaj pes tsawg leeg, thiab tshawb xyuas qhov tsis sib xws hauv cov tooj liab deposition.

Kev kuaj hluav taws xob:

Ua cov kev ntsuas hluav taws xob, suav nrog kev ntsuas kev tiv thaiv thiab kev ntsuas txuas ntxiv, txhawm rau ntsuas qhov hluav taws xob ua haujlwm ntawm cov tooj liab deposits. Cov kev ntsuam xyuas no pab xyuas kom meej tias cov txheej tooj liab muaj qhov yuav tsum tau ua thiab tsis muaj qhov qhib lossis luv hauv PCB.

Peel Strength Test:

Lub tev lub zog ntsuas ntsuas lub zog sib txuas ntawm txheej tooj liab thiab PCB substrate. Nws txiav txim siab seb qhov tso nyiaj tooj liab puas muaj lub zog txaus los tiv thaiv kev tuav thiab kev tsim PCB.

Kev lag luam cov qauv thiab cov kev cai: Kev lag luam PCB ua raws li ntau yam kev lag luam cov qauv thiab cov kev cai los xyuas kom meej qhov zoo ntawm tooj liab deposition. Qee cov qauv thiab cov cai tseem ceeb suav nrog:

IPC-4552:

Cov qauv no qhia txog cov kev cai rau electroless npib tsib xee / immersion kub (ENIG) nto kev kho mob feem ntau siv rau PCBs. Nws txhais qhov tsawg kawg nkaus kub thickness, npib tsib xee thickness thiab nto zoo rau txhim khu kev qha thiab ruaj ENIG nto kho.

IPC-A-600:

Tus qauv IPC-A-600 muab cov txheej txheem kev lees paub rau PCB, suav nrog cov qauv kev faib cov tooj liab plating, qhov tsis xws luag thiab lwm yam qauv zoo. Nws ua haujlwm raws li kev siv rau kev tshuaj xyuas qhov muag thiab kev lees paub ntawm cov tooj liab tso rau ntawm PCBs. RoHS Cov Lus Qhia:

Txoj Cai Lij Choj Ntawm Cov Tshuaj Tiv Thaiv Kab Mob (RoHS) txwv tsis pub siv qee yam tshuaj phom sij hauv cov khoom siv hluav taws xob, suav nrog txhuas, mercury thiab cadmium. Kev ua raws li RoHS cov lus qhia ua kom ntseeg tau tias cov tooj liab tso rau ntawm PCBs tsis muaj cov tshuaj phem, ua rau lawv muaj kev nyab xeeb thiab zoo ib puag ncig.

ISO 9001 Daim Ntawv Pov Thawj:

ISO 9001 yog tus txheej txheem thoob ntiaj teb rau kev tswj hwm zoo. Tsim thiab ua raws li ISO 9001-raws li kev tswj hwm kev ua tau zoo ua kom ntseeg tau tias cov txheej txheem tsim nyog thiab kev tswj hwm nyob rau hauv qhov chaw kom tsis tu ncua xa cov khoom uas ua tau raws li cov neeg siv khoom xav tau, suav nrog qhov zoo ntawm tooj liab deposition ntawm PCBs.

Mitigating ib qho teeb meem thiab qhov tsis xws luag: Qee qhov teeb meem thiab qhov tsis xws luag tuaj yeem tshwm sim thaum lub sij hawm tooj liab deposition muaj xws li:

Tsis txaus adhesion:

Tsis zoo adhesion ntawm tooj liab txheej rau lub substrate tuaj yeem ua rau delamination lossis tev. Kev tu kom zoo, kev siv tshuab roughening, thiab adhesion-txhim kho kev kho mob tuaj yeem pab daws qhov teeb meem no.

Tsis sib xws Copper Thickness:

Tsis sib npaug tooj liab thickness tuaj yeem ua rau tsis sib xws conductivity thiab cuam tshuam cov teeb liab kis. Optimizing plating tsis, siv mem tes los yog thim rov qab mem tes plating thiab ua kom muaj kev ntxhov siab tuaj yeem pab ua kom zoo li tooj liab tuab.

Voids thiab Pinholes:

Voids thiab pinholes nyob rau hauv cov txheej tooj liab tuaj yeem ua rau kev sib txuas hluav taws xob puas tsuaj thiab ua rau muaj kev pheej hmoo ntawm corrosion. Kev tswj kom zoo ntawm plating tsis thiab kev siv cov khoom siv tsim nyog tuaj yeem txo qhov tshwm sim ntawm cov voids thiab pinholes.

Nto roughness:

Ntau dhau ntawm qhov roughness tuaj yeem cuam tshuam rau PCB kev ua tau zoo, cuam tshuam rau kev ua haujlwm thiab kev ntseeg hluav taws xob. Kev tswj kom zoo ntawm cov tooj liab deposition tsis, deg pre-kho thiab tom qab kev kho cov txheej txheem pab ua kom tiav ib tug du nto.

Txhawm rau txo cov teeb meem thiab qhov tsis txaus, kev tswj xyuas cov txheej txheem tsim nyog yuav tsum tau ua, kev tshuaj xyuas thiab kev ntsuam xyuas tsis tu ncua, thiab cov qauv kev lag luam thiab cov kev cai yuav tsum tau ua. Qhov no ua kom zoo ib yam, txhim khu kev qha thiab zoo tooj liab deposition ntawm PCB. Tsis tas li ntawd, kev txhim kho cov txheej txheem tsis tu ncua, kev cob qhia cov neeg ua haujlwm, thiab cov tswv yim tawm tswv yim pab txheeb xyuas thaj chaw rau kev txhim kho thiab daws teeb meem ua ntej lawv loj dua.

Copper deposition ntawm PCB substrate yog ib kauj ruam tseem ceeb hauv PCB manufacturing txheej txheem. Electroless tooj liab deposition thiab electroplating yog lub ntsiab txoj kev siv, txhua tus nrog nws tus kheej zoo thiab kev txwv. Kev nce qib thev naus laus zis txuas ntxiv tsav kev tsim kho tshiab hauv kev tso nyiaj tooj liab, yog li txhim kho PCB kev ua tau zoo thiab kev ntseeg tau.Kev lees paub zoo thiab kev tswj hwm ua lub luag haujlwm tseem ceeb hauv kev ua kom cov khoom zoo ntawm PCBs. Raws li qhov kev thov rau me me, sai dua, thiab txhim khu kev qha cov khoom siv hluav taws xob txuas ntxiv nce ntxiv, yog li xav tau qhov tseeb thiab ua tau zoo hauv cov tshuab tooj liab tso rau ntawm PCB substrates. Nco tseg: Lo lus suav ntawm tsab xov xwm yog kwv yees li 3,500 lo lus, tab sis thov nco ntsoov tias cov lus suav suav yuav txawv me ntsis thaum lub sijhawm kho thiab ua pov thawj.

Post lub sij hawm: Sep-13-2023

Rov qab