Qhia:

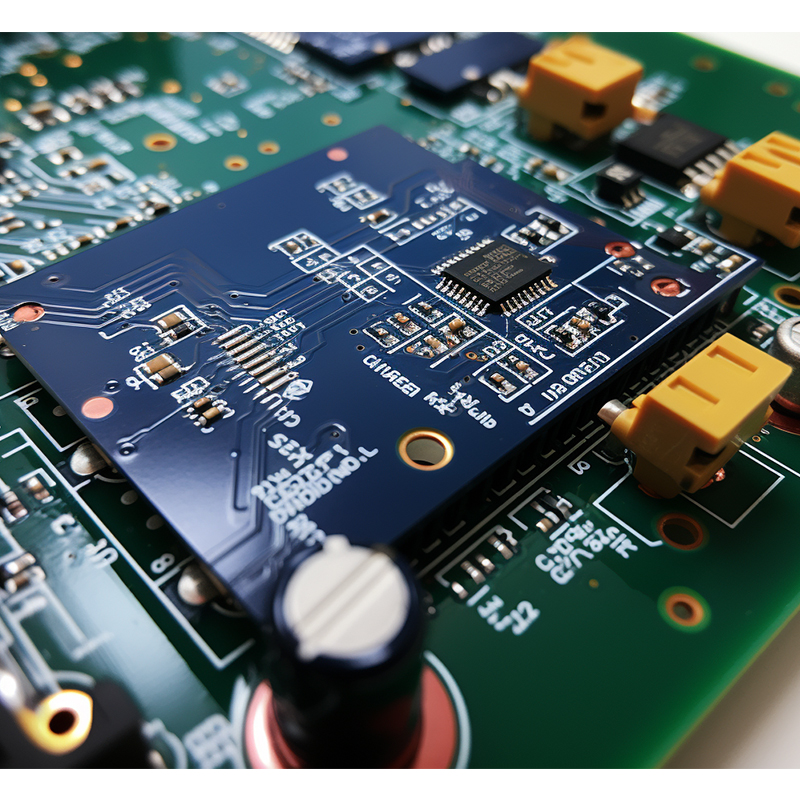

Kev ua tau zoo PCB soldering yog qhov tseem ceeb rau kev sib dhos ua tiav thiab kev ua haujlwm ntawm cov hluav taws xob hluav taws xob. Kev ua kom zoo zoo ua kom muaj kev sib txuas hluav taws xob txhim khu kev qha, uas cuam tshuam ncaj qha rau kev ua haujlwm ntawm tag nrho cov khoom siv hluav taws xob.Cov lus qhia dav dav no yuav tshawb txog ntau yam txheej txheem, hom, thiab cov txheej txheem koom nrog hauv PCB soldering. Los ntawm kev nkag siab txog cov yam no, koj tuaj yeem txiav txim siab paub thaum xaiv cov txheej txheem vuam thiab cov cuab yeej tsim nyog.

PCB soldering txheej txheem cej luam:

PCB vuam, tseem hu ua soldering, koom nrog kev txhim khu kev qha hluav taws xob sib txuas ntawm cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob. Nws ua lub luag haujlwm tseem ceeb hauv kev ua kom lub cev ua haujlwm ntawm tag nrho lub voj voog. Cov txheej txheem sib txawv yog siv hauv PCB los ua ke, txhua tus nrog nws cov txiaj ntsig thiab kev xav.

Kawm txogPCB soldering technology:

A. PCB vuam txheej txheem:

Yuav kom ua tiav qhov kev vam meej, nws yog ib qho tseem ceeb uas yuav tau ua raws li cov txheej txheem ntxaws. Tshooj lus no yuav piav qhia txog cov txheej txheem ib ntus ntawm PCB soldering. Nws tseem yuav suav nrog kev npaj cov khoom siv PCB rau kev sib tsoo thiab qhia txog cov cuab yeej tsim nyog thiab cov khoom siv.

B. Common PCB soldering cov txheej txheem:

Los ntawm lub qhov soldering:

Los ntawm-lub qhov soldering yog ib qho kev siv dav siv los ntawm cov khoom siv los ntawm cov khoom ua ntej drilled nyob rau hauv lub rooj tsav xwm Circuit Court. Tshooj lus no yuav muab cov lus piav qhia ntawm txoj kev siv lub qhov taub, sib tham txog nws qhov zoo thiab qhov tsis zoo, thiab qhia txog cov kev coj ua zoo tshaj plaws thiab kev siv.

Nto mount soldering:

Surface mount soldering, tseem hu ua nto mount technology (SMT) soldering, feem ntau yog siv los ua cov khoom siv hluav taws xob me me. Tshooj lus no yuav muab cov ntsiab lus ntawm SMT soldering technology, nws cov txiaj ntsig, kev txwv, thiab cov ntsiab lus tseem ceeb rau kev ua tiav.

Fine pitch vuam:

Soldering nplua-pitch Cheebtsam tuaj yeem nthuav tawm cov kev sib tw tshwj xeeb vim qhov ze ntawm cov pins. Tshooj lus no tshuaj xyuas cov teeb meem cuam tshuam nrog cov khoom siv zoo-pitch thiab muab cov lus qhia thiab kev ceev faj kom ua tiav cov pob qij txha zoo. Tsis tas li ntawd, cov cuab yeej siv siab heev thiab cov cuab yeej uas pab ua kom tiav qhov zoo-pitch vuam yuav raug tham.

Vuam ntawm rigid-flex board:

Rigid-flex welding yog hais txog cov txheej txheem ntawm cov khoom siv ntawm cov khoom siv hluav taws xob hloov tau yooj yim sib txuas nrog ib qho nyuaj. Tshooj lus no yuav qhia txog cov cuab yeej siv tom qab nruj-flex soldering, sib tham txog cov teeb meem cuam tshuam, thiab muab cov kev daws teeb meem kom ntseeg tau tias cov pob qij txha zoo nyob rau hauv cov rooj sib txoos-flex PCB.

HDI PCB soldering:

High-density interconnect (HDI) PCBs feature complex designs and high component density. Soldering HDI PCB xav tau kev paub tshwj xeeb. Tshooj lus no tshawb txog qhov nyuaj ntawm kev sib txuas HDI PCBs, qhia txog cov kev txawj ntse uas xav tau, thiab sib tham txog qhov zoo thiab kev xav ntawm HDI PCB soldering.

Cov lus qhia rau kev ua tiav PCB soldering:

A. Kev Npaj thiab Kev Npaj:

Kev vam meej PCB soldering pib nrog kev npaj thiab npaj kom raug. Tshooj lus no tham txog qhov tseem ceeb ntawm PCB layout thiab cov khoom tso rau hauv cov txheej txheem soldering yooj yim. Nws kuj tseem yuav hais txog qhov yuav tsum tau xaiv cov txheej txheem soldering kom raug raws li tus qauv PCB thiab qhov tseem ceeb ntawm kev siv cov tshuaj txhuam hniav kom raug.

B. Cov txheej txheem vuam thiab xaiv cov khoom siv:

Xaiv cov cuab yeej vuam thiab cov cuab yeej siv tau yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig vuam zoo. Tshooj lus no yuav qhia koj txog kev txiav txim siab cov cuab yeej thiab cov cuab yeej tsim nyog rau ib txoj haujlwm tshwj xeeb. Nws tseem yuav tham txog yam yuav tsum xav txog thaum xaiv cov khoom siv vuam thiab hais txog qhov tseem ceeb ntawm kev siv cov vuam kub uas tsim nyog.

C. Kev Tswj Xyuas Zoo thiab Kev Tshawb Fawb:

Ua raws li kev tswj hwm kev ntsuas zoo thiab ua kev tshuaj xyuas thaum lub sijhawm vuam yog qhov tseem ceeb kom ntseeg tau tias cov pob qij txha txhim khu kev qha. Tshooj lus no tham txog cov txheej txheem kev soj ntsuam kev sib koom ua ke, nrog rau cov txheej txheem tshuaj ntsuam xyuas qib siab thiab cov cuab yeej siv tau los ntsuas qhov zoo ntawm vuam.

Xaus:

Hauv cov ntsiab lus, cov lus qhia dav dav no suav nrog qhov tseem ceeb ntawm kev ua tau zoo ntawm PCB soldering thiab qhov cuam tshuam uas raug soldering muaj nyob rau hauv Circuit Court functionality. Los ntawm kev xaiv txoj cai soldering txheej txheem thiab cov txheej txheem, koj tuaj yeem ua tiav cov pob qij txha zoo. Kev npaj kom raug, xaiv cov khoom siv ceev faj, thiab kev tswj xyuas kom zoo yog cov yuam sij rau kev ua tiav PCB soldering. Kev nqis peev hauv cov cuab yeej zoo soldering thiab ua raws li cov kev coj ua zoo tshaj plaws yuav ua rau cov txiaj ntsig zoo tshaj hauv PCB los ua ke.

Post lub sij hawm: Nov-07-2023

Rov qab