Taw qhia

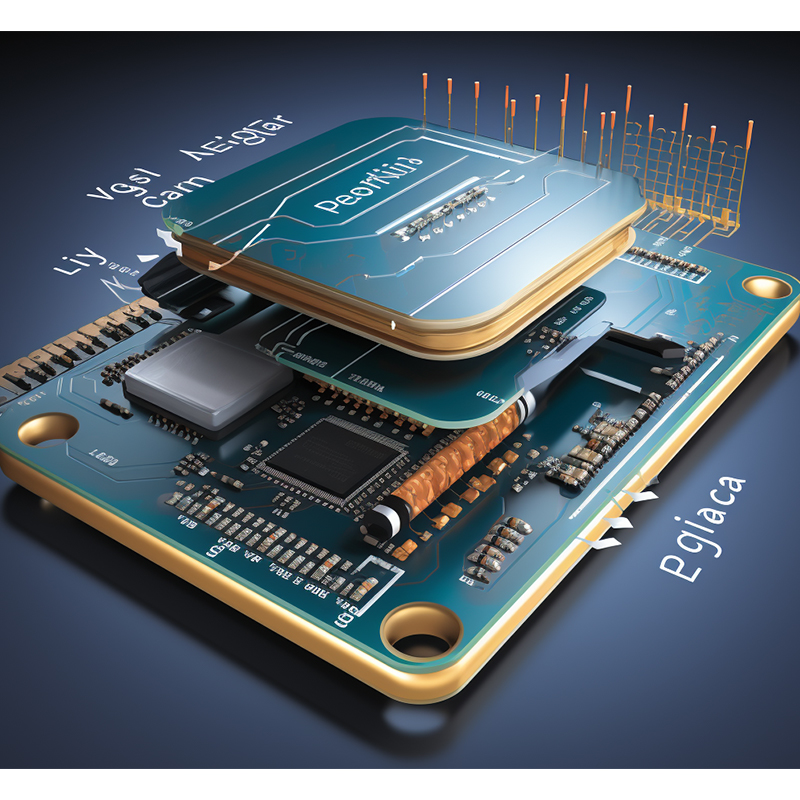

Hauv tsab ntawv tshaj tawm no, peb yuav tham txog cov tswv yim zoo thiab kev lag luam kev coj ua zoo tshaj plaws rau kev tiv thaiv nruj-flex PCB delamination, yog li tiv thaiv koj cov khoom siv hluav taws xob los ntawm kev ua tsis tiav.

Kev delamination yog ib qho teeb meem tseem ceeb uas feem ntau plagues rigid-flex printed circuit boards (PCBs) thaum lawv ua hauj lwm lub neej. Qhov tshwm sim no hais txog kev sib cais ntawm cov khaubncaws sab nraud povtseg hauv PCB, ua rau muaj kev sib txuas tsis muaj zog thiab muaj peev xwm tiv thaiv tsis ua haujlwm. Raws li cov chaw tsim khoom lossis tus tsim qauv, nws yog ib qho tseem ceeb kom nkag siab txog qhov ua rau delamination thiab ua kev tiv thaiv kev tiv thaiv kom muaj kev ruaj ntseg ntev thiab kev ntseeg siab ntawm koj lub PCB.

I. Nkag siab txog kev delamination hauv rigid-flex PCB

Kev delamination yog tshwm sim los ntawm ntau yam hauv lub sijhawm tsim khoom, sib dhos, thiab tuav cov theem ntawm rigid-flex PCBs. Thermal stress, noo noo nqus thiab xaiv cov khoom tsis zoo yog qhov ua rau delamination. Kev txheeb xyuas thiab nkag siab txog cov laj thawj no yog qhov tseem ceeb rau kev tsim cov tswv yim tiv thaiv zoo.

1. Thermal stress: Coefficient of thermal expansion (CTE) mismatch ntawm cov khoom sib txawv tuaj yeem ua rau muaj kev ntxhov siab ntau dhau thaum lub sij hawm thermal cycling, ua rau delamination.Thaum lub PCB ntsib qhov kub thiab txias hloov, cov khaubncaws sab nraud povtseg nthuav dav thiab sib cog lus ntawm tus nqi sib txawv, tsim kom muaj kev sib txhuam ntawm cov ntawv cog lus.

2. Moisture absorption: rigid saj zawg zog PCB feem ntau raug rau high humidity ib puag ncig thiab yooj yim absorbs noo noo.Cov dej molecules tuaj yeem nkag mus rau saum npoo ntawm lub rooj tsavxwm los ntawm microcracks, voids, lossis tsis zoo kaw qhov qhib, ua rau hauv zos nthuav dav, o, thiab thaum kawg delamination.

3. Kev xaiv cov khoom siv: Kev saib xyuas zoo ntawm cov khoom siv yog qhov tseem ceeb rau kev tiv thaiv delamination.Nws yog ib qho tseem ceeb uas yuav tau xaiv cov laminate tsim nyog, nplaum thiab kho qhov chaw kom muab cov dej noo tsawg thiab qhov zoo tshaj plaws thermal stability.

2. Cov tswv yim los tiv thaiv delamination

Tam sim no peb nkag siab tias yog vim li cas, cia peb tshawb nrhiav cov tswv yim tseem ceeb los tiv thaiv kev nruj-flex PCB delamination:

1. Kev txiav txim siab tsim nyog:

a) Tsawg tooj liab thickness:Copper thickness ntau dhau ua rau muaj kev ntxhov siab ntau dua thaum caij tsheb kauj vab. Yog li ntawd, siv qhov tsawg kawg nkaus yuav tsum tau tooj liab thickness nce PCB yooj thiab txo qhov kev pheej hmoo ntawm delamination.

b) Balanced txheej txheej:Siv zog rau kev sib faib ntawm cov txheej tooj liab nyob rau hauv qhov nruj thiab hloov tau yooj yim ntawm PCB. Kev sib npaug zoo pab tswj kom muaj qhov sib npaug ntawm thermal expansion thiab contraction, txo qhov peev xwm rau delamination.

c) Tswj kev kam rau siab:Ua raws li kev tswj hwm qhov ntev ntawm qhov loj, ntawm txoj kab uas hla thiab kab dav kom ntseeg tau tias kev ntxhov siab thaum lub sij hawm hloov thermal yog sib npaug faib thoob plaws hauv PCB.

d) Nqaij qaib fillets:Cov fillets txo cov ntsiab lus kev ntxhov siab, pab ua kom zoo dua khoov hloov pauv thiab txo cov peev xwm rau delamination.

2. Kev xaiv cov khoom siv:

a) High Tg Laminates:Xaiv cov laminates nrog cov iav hloov pauv siab dua (Tg) vim tias lawv muaj qhov kub thiab txias zoo dua, txo CTE tsis sib haum ntawm cov ntaub ntawv, thiab txo qis thermal cycling txheej txheem stratified txaus ntshai.

b) Cov ntaub ntawv CTE tsawg:Xaiv cov ntaub ntawv uas tsis tshua muaj CTE qhov tseem ceeb kom txo qis thermal expansion mismatch ntawm cov khaubncaws sab nraud povtseg sib txawv, yog li txo kev ntxhov siab thiab txhim kho tag nrho cov kev ntseeg siab ntawm rigid-flex PCBs.

c) Cov ntaub ntawv tsis muaj dej noo:Xaiv cov ntaub ntawv uas muaj qhov nqus dej tsawg kom txo tau qhov kev pheej hmoo ntawm delamination vim qhov nqus dej noo. Xav txog kev siv cov coatings tshwj xeeb lossis cov sealants los tiv thaiv thaj chaw tsis zoo ntawm PCB los ntawm kev nkag mus rau cov dej noo.

3. Cov kev coj ua muaj zog:

a) Tswj impedance:Ua raws li cov txheej txheem kev tswj hwm impedance tsim kom txo qis kev ntxhov siab ntawm PCB thaum ua haujlwm, yog li txo qhov kev pheej hmoo ntawm delamination.

b) Cia thiab tuav kom zoo:Khaws thiab tuav PCBs nyob rau hauv ib puag ncig tswj nrog tswj cov av noo kom tiv thaiv kom tsis txhob ya raws thiab cuam tshuam cov teeb meem delamination.

c) Kev kuaj thiab tshuaj xyuas:Kev soj ntsuam nruj thiab tshuaj xyuas cov txheej txheem yog ua los txheeb xyuas cov kev tsim khoom muaj peev xwm uas tuaj yeem ua rau delamination. Ua raws li cov txheej txheem kuaj tsis muaj kev puas tsuaj xws li thermal cycling, microsectioning, thiab scanning acoustic microscopy tuaj yeem pab txheeb xyuas qhov zais zais thaum ntxov.

Xaus

Kev tiv thaiv delamination ntawm nruj-flex PCBs yog qhov tseem ceeb los xyuas kom meej lawv lub neej ntev thiab txhim khu kev qha. Koj tuaj yeem txo qhov kev pheej hmoo ntawm delamination los ntawm kev nkag siab txog cov laj thawj thiab kev ceev faj tsim nyog thaum tsim, xaiv cov khoom siv, thiab kev tsim khoom.Ua raws li kev tswj xyuas thermal kom zoo, siv cov khoom siv nrog cov khoom zoo tagnrho, siv cov kev tsim khoom zoo, thiab kev sim ua kom zoo tuaj yeem txhim kho qhov zoo thiab kev ntseeg siab ntawm cov PCB rigid-flex. Los ntawm kev ua raws li cov tswv yim no thiab ua raws li cov kev hloov tshiab tshiab hauv cov ntaub ntawv thiab kev tsim cov thev naus laus zis, koj tuaj yeem ua kom muaj kev vam meej ntawm PCBs ruaj khov thiab txhim khu kev qha uas ua rau muaj kev ruaj ntseg thiab kev ncaj ncees ntawm koj cov khoom siv hluav taws xob.

Post lub sij hawm: Sep-20-2023

Rov qab