Hauv tsab ntawv tshaj tawm no, peb yuav tshawb xyuas cov xwm txheej los txiav txim siab thaum xaiv cov ntaub ntawv ua yeeb yaj kiab rau PCBs hloov tau yooj yim thiab muab cov lus pom muaj txiaj ntsig los pab koj txiav txim siab paub.

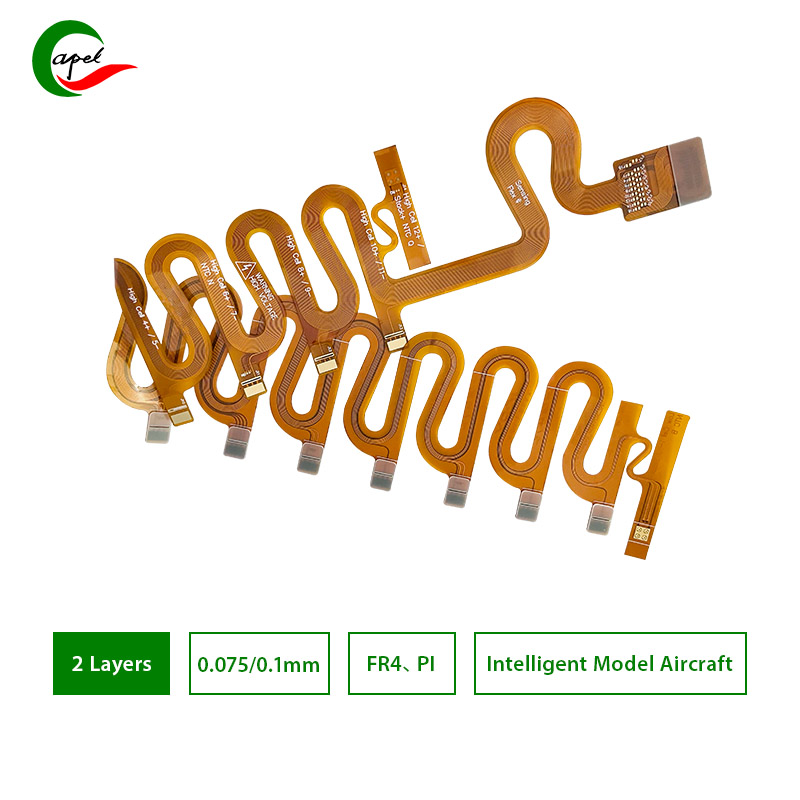

Nyob rau xyoo tas los no,flexible PCBs(cov ntaub ntawv hloov pauv hloov tau yooj yim) tau txais txiaj ntsig vim lawv muaj peev xwm ua tau raws li cov duab nyuaj, txhim kho hluav taws xob ua haujlwm, thiab txo qhov hnyav thiab qhov chaw yuav tsum tau ua. Cov kab hluav taws xob hloov tau yooj yim no tau siv dav hauv ntau lub lag luam, suav nrog tsheb, khoom siv hluav taws xob, khoom siv kho mob thiab aerospace. Ib qho tseem ceeb ntawm kev tsim cov PCB hloov tau yooj yim yog xaiv cov khoom siv zaj duab xis tsim nyog los xyuas kom meej qhov kev ua tau zoo thiab kev ntseeg tau.

1. Flexibility thiab dabtsi yog khoov:

Flexible PCBs paub txog lawv qhov yooj yim thiab muaj peev xwm khoov. Yog li ntawd, cov ntaub ntawv nyias-zaj duab xis siv los tsim cov circuits yuav tsum muaj qhov yooj yim thiab khoov tau zoo. Ib qho khoom siv feem ntau yog polyimide zaj duab xis (PI). Polyimide muaj cov cuab yeej zoo heev xws li lub zog tensile siab, zoo thermal stability thiab tshuaj lom neeg zoo heev, ua rau nws zoo tagnrho rau cov ntawv siv PCB hloov tau. Tsis tas li ntawd, cov yeeb yaj kiab ua kua siv lead ua polymer (LCP) kuj tseem nrov rau lawv qhov kev hloov pauv tau zoo thiab qhov zoo ntawm qhov ntev.

2. Dielectric qhov tsis tu ncua thiab poob yam:

Lub dielectric tas li thiab dissipation yam ntawm cov khoom siv zaj duab xis ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov ua tau zoo ntawm PCBs hloov tau. Cov khoom no muab kev nkag siab txog cov khoom muaj peev xwm xa hluav taws xob tsis muaj kev poob qis. Tsawg dielectric tsis tu ncua thiab dissipation qhov tseem ceeb yog qhov zoo tagnrho rau cov ntawv thov ntau zaus vim tias lawv txo cov teeb liab poob thiab ua kom ntseeg tau tias kev ua tau zoo. Qee cov khoom siv uas tsis tshua muaj dielectric tas li yog polyimide thiab LCP.

3. Thermal stability thiab kub tsis kam:

Flexible PCBs feem ntau raug hloov pauv qhov kub thiab txias, tshwj xeeb tshaj yog hauv kev siv tsheb thiab aerospace. Yog li ntawd, xaiv cov ntaub ntawv zaj duab xis nrog zoo thermal stability thiab kuj yog ib qho tseem ceeb los xyuas kom meej kev ua tau zoo thiab kev ntseeg tau. High-temperature polyimide films, xws li Kapton®, yog dav siv nyob rau hauv saj zawg zog PCB manufacturing vim lawv muaj peev xwm tiv taus qhov kub thiab txias thaum tswj kev ua haujlwm zoo. LCP films, ntawm qhov tod tes, muaj cov thermal stability zoo sib xws thiab tuaj yeem suav tias yog lwm txoj hauv kev.

4. Tshuaj compatibility:

Nyias zaj duab xis cov ntaub ntawv siv nyob rau hauv saj zawg zog PCBs yuav tsum tau chemically haum nrog rau tej thaj chaw uas lawv deployed. Thaum lub sij hawm PCB sib dhos thiab tuav, raug rau cov khoom xws li cov kuab tshuaj, tshuaj ntxuav, thiab cov fluxes yuav tsum raug txiav txim siab. Polyimide muaj cov tshuaj tiv thaiv zoo heev thiab yog thawj qhov kev xaiv rau feem ntau hloov pauv PCB daim ntaub ntawv.

5. Adhesive compatibility:

Cov ntaub ntawv nyias nyias feem ntau laminated nrog cov nplaum nplaum los tsim cov qauv muaj zog hauv PCBs hloov tau. Yog li ntawd, nws yog ib qho tseem ceeb heev uas yuav tau xaiv cov khoom siv ua yeeb yaj kiab uas sib haum nrog cov nplaum uas tau xaiv. Cov khoom siv yuav tsum sib raug zoo nrog cov nplaum kom ntseeg tau tias muaj kev sib raug zoo thiab ua kom muaj kev ncaj ncees ntawm PCB hloov tau. Ua ntej ua tiav cov khoom siv zaj duab xis, nws raug nquahu kom cov txheej txheem nplaum tshwj xeeb raug sim rau kev sib raug zoo kom ntseeg tau tias muaj kev sib raug zoo.

6. Muaj thiab Nqi:

Thaum kawg, cov khoom siv zaj duab xis muaj thiab tus nqi yuav tsum tau txiav txim siab hauv cov txheej txheem xaiv. Thaum polyimide muaj dav thiab muaj txiaj ntsig zoo, lwm cov ntaub ntawv xws li LCP tuaj yeem raug nqi kim dua. Kev ntsuas qhov project xav tau, kev txwv nyiaj txiag, thiab kev muaj nyob hauv khw yuav pab txiav txim siab cov khoom siv yeeb yaj kiab zoo tshaj plaws rau koj tus qauv PCB hloov tau.

Hauv cov ntsiab lus, xaiv cov khoom siv zaj duab xis zoo rau koj lub PCB hloov tau yog qhov tseem ceeb rau kev ua kom pom kev ua tau zoo, kev ntseeg tau thiab kev ua haujlwm ntev.Cov yam ntxwv xws li yoog raws thiab khoov tau, dielectric qhov tsis tu ncua thiab tsis zoo, thermal stability thiab tsis kam, tshuaj lom neeg sib raug zoo, nplaum sib raug zoo, thiab muaj thiab cov nqi yuav tsum tau ua tib zoo soj ntsuam thaum lub sijhawm xaiv. Los ntawm kev txiav txim siab txog cov yam no thiab ua qhov kev tshawb fawb tob, koj tuaj yeem ua qhov kev txiav txim siab uas yuav ua rau muaj kev tsim qauv zoo, zoo siab hloov pauv PCB rau koj daim ntawv thov tshwj xeeb.

Post lub sij hawm: Sep-21-2023

Rov qab