Txoj kev loj hlob sai ntawm kev lag luam hluav taws xob tau ua rau muaj kev siv dav dav ntawm rigid-flex board. Txawm li cas los xij, vim qhov sib txawv ntawm lub zog, thev naus laus zis, kev paub dhau los, cov txheej txheem tsim khoom, cov txheej txheem muaj peev xwm thiab cov khoom siv sib txawv ntawm cov tuam txhab sib txawv, cov teeb meem zoo ntawm cov rigid-flex boards hauv cov txheej txheem ntau lawm kuj txawv.Cov nram qab no Capel yuav piav qhia meej txog ob qho teeb meem thiab cov kev daws teeb meem uas yuav tshwm sim hauv kev tsim khoom loj ntawm cov rooj tog zaum yooj yim.

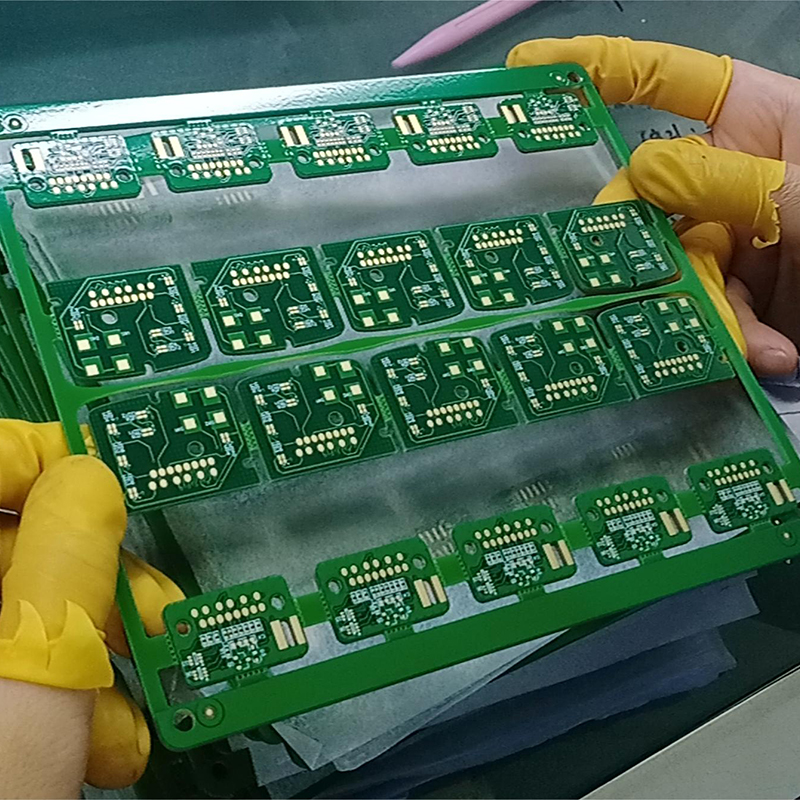

Nyob rau hauv cov txheej txheem ntau lawm ntawm rigid-flex boards, pluag tinning yog ib qho teeb meem tshwm sim. Cov tinning tsis zoo yuav ua rau tsis ruaj khov

solder pob qij txha thiab cuam tshuam cov khoom ntseeg tau.

Nov yog qee qhov ua rau ua rau tsis zoo tinning:

1. Tu qhov teeb meem:Yog hais tias lub Circuit Court board nto tsis huv huv ua ntej tinning, nws yuav ua rau tsis zoo soldering;

2. Qhov kub thiab txias tsis haum:Yog hais tias qhov kub ntawm soldering yog siab dhau los yog tsawg dhau, nws yuav ua rau tsis zoo tinning;

3. Solder paste teeb meem zoo:low-zoo solder paste yuav ua rau tsis zoo tinning;

4. Cov teeb meem zoo ntawm SMD Cheebtsam:Yog hais tias lub ncoo zoo ntawm SMD Cheebtsam tsis zoo tagnrho, nws tseem yuav ua rau tsis zoo tinning;

5. Kev siv vuam tsis raug:Kev ua haujlwm vuam tsis raug kuj tseem tuaj yeem ua rau tsis zoo tinning.

Yuav kom zam dhau los yog daws cov teeb meem tsis zoo no, thov ua tib zoo mloog cov ntsiab lus hauv qab no:

1. Xyuas kom meej tias lub rooj tsavxwm nto yog huv si kom tshem tau cov roj, plua plav thiab lwm yam impurities ua ntej tinning;

2. Tswj qhov kub thiab lub sij hawm ntawm tinning: Nyob rau hauv tus txheej txheem ntawm tinning, nws yog ib qho tseem ceeb heev rau kev tswj qhov kub thiab lub sij hawm ntawm tinning. Nco ntsoov siv qhov ntsuas kub kom raug thiab ua kom haum raws li cov khoom siv thiab kev xav tau. Qhov kub thiab txias ntev heev Lub sij hawm yuav ua rau cov pob qij txha ua kom sov los yog yaj, thiab tseem ua rau lub rigid-flex board puas. Ntawm qhov tsis sib xws, qhov kub thiab lub sij hawm qis dhau yuav ua rau cov khoom siv tsis tuaj yeem ntub tag nrho thiab diffuse mus rau qhov sib koom ua ke, yog li ua kom tsis muaj zog solder;

3. Xaiv cov khoom siv soldering uas tsim nyog: xaiv tus neeg muag khoom muag muag muag, xyuas kom meej tias nws phim cov khoom siv ntawm lub rooj tsavxwm rigid-flex, thiab xyuas kom meej tias cov xwm txheej ntawm kev khaws cia thiab siv cov tshuaj txhuam hniav zoo.

Xaiv cov ntaub ntawv zoo tshaj plaws los xyuas kom meej tias cov ntaub ntawv soldering muaj qhov ntub dej zoo thiab cov ntsiab lus melting kom zoo, yog li ntawd lawv tuaj yeem muab sib npaug sib npaug thiab tsim cov pob qij txha ruaj khov thaum lub sij hawm tinning;

4. Nco ntsoov siv cov khoom ua kom zoo zoo, thiab xyuas qhov flatness thiab txheej ntawm lub ncoo;

5. Kev cob qhia thiab txhim kho vuam kev ua haujlwm kom paub meej cov txheej txheem soldering raug thiab sijhawm;

6. Tswj lub thickness thiab uniformity ntawm lub tin: xyuas kom meej tias cov tin yog sib npaug zos rau ntawm soldering point kom tsis txhob muaj cov concentration hauv zos thiab unevenness. Cov cuab yeej tsim nyog thiab cov txheej txheem, xws li cov tshuab tinning lossis cov khoom siv tinning tsis siv neeg, tuaj yeem siv los xyuas kom meej tias kev faib tawm thiab cov tuab tuab ntawm cov khoom siv;

7. Kev tshuaj xyuas thiab kev sim tsis tu ncua: Kev tshuaj xyuas thiab kev sim tsis tu ncua yog ua los xyuas kom meej qhov zoo ntawm cov pob qij txha ntawm lub rooj tsavxwm nruj-flex. Qhov zoo thiab kev ntseeg siab ntawm cov pob qij txha tuaj yeem raug soj ntsuam los ntawm kev tshuaj xyuas qhov muag, rub kev sim, thiab lwm yam. Nrhiav thiab daws cov teeb meem ntawm cov tinning tsis zoo nyob rau lub sijhawm kom tsis txhob muaj teeb meem zoo thiab tsis ua haujlwm hauv kev tsim khoom tom ntej.

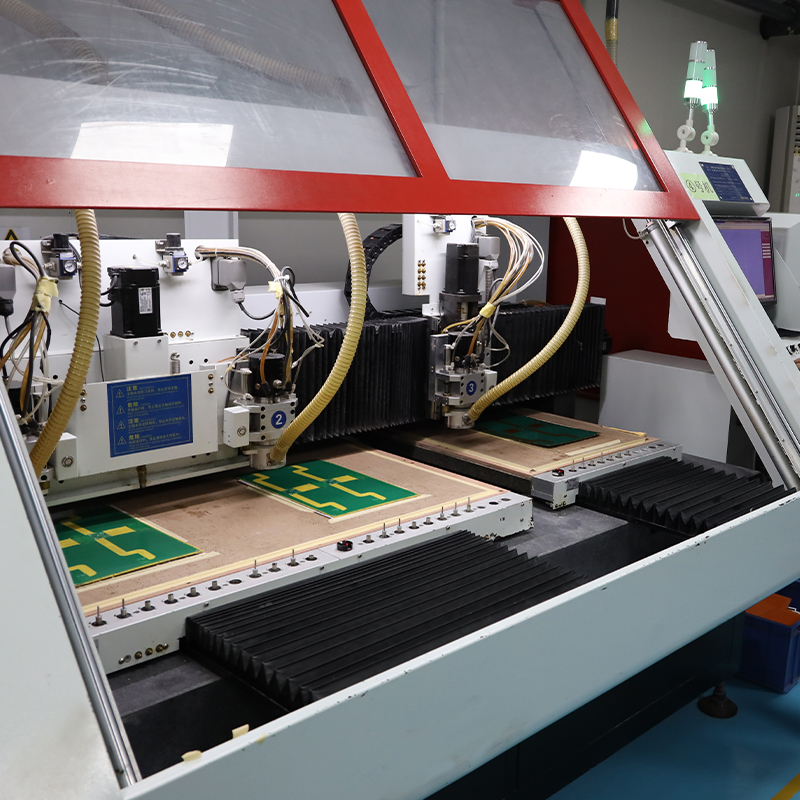

Tsis txaus qhov tooj liab thickness thiab tsis sib xws qhov tooj liab plating kuj yog teeb meem uas yuav tshwm sim nyob rau hauv loj ntau lawm.

rigid-flex boards. Qhov tshwm sim ntawm cov teeb meem no yuav cuam tshuam rau cov khoom zoo. Cov nram qab no tsom xam cov laj thawj thiab

cov kev daws teeb meem uas yuav ua rau muaj teeb meem no:

Yog vim li cas:

1. Cov teeb meem ua ntej:Ua ntej electroplating, pretreatment ntawm lub qhov phab ntsa yog ib qho tseem ceeb heev. Yog hais tias muaj teeb meem xws li corrosion, paug los yog tsis sib xws nyob rau hauv lub qhov phab ntsa, nws yuav cuam tshuam rau cov uniformity thiab adhesion ntawm cov txheej txheem plating. Xyuas kom cov phab ntsa ntawm lub qhov yog ntxuav kom huv si kom tshem tawm cov kab mob thiab oxide txheej.

2. Plating tov formulation teeb meem:Cov txheej txheem plating tsis raug kuj tuaj yeem ua rau plating tsis sib xws. Cov muaj pes tsawg leeg thiab concentration ntawm cov tshuaj plating yuav tsum nruj me ntsis tswj thiab kho kom zoo ib yam thiab stability thaum lub sij hawm plating txheej txheem.

3. Qhov teeb meem ntawm electroplating tsis:electroplating tsis muaj xws li tam sim no ceev, electroplating lub sij hawm thiab kub, thiab lwm yam. Tsis yog plating parameter tej zaum yuav ua rau muaj teeb meem ntawm tsis sib xws plating thiab tsis txaus thickness. Xyuas kom tseeb tias cov plating tsis raug teeb tsa raws li cov khoom yuav tsum tau ua thiab ua kom tsim nyog kho thiab saib xyuas.

4. Txheej txheem teeb meem:Cov txheej txheem cov kauj ruam thiab kev ua haujlwm hauv cov txheej txheem electroplating tseem yuav cuam tshuam rau qhov sib xws thiab qhov zoo ntawm electroplating. Xyuas kom cov neeg ua haujlwm nruj me ntsis ua raws li cov txheej txheem ntws thiab siv cov cuab yeej tsim nyog thiab cov cuab yeej siv.

Kev daws:

1. Txhim kho cov txheej txheem pretreatment kom huv si thiab flatness ntawm lub qhov phab ntsa.

2. Tsis tu ncua xyuas thiab kho cov formulation ntawm cov tshuaj electroplating kom nws stability thiab uniformity.

3. Teem kom raug plating tsis raws li cov khoom xav tau, thiab saib xyuas thiab kho kom zoo.

4. Kev cob qhia cov neeg ua haujlwm los txhim kho cov txheej txheem kev ua haujlwm thiab kev paub txog.

5. Qhia txog kev tswj xyuas kom zoo los xyuas kom meej tias txhua qhov txuas tau dhau los ua kev tswj hwm thiab kev sim zoo.

6. Txhim khu kev tswj cov ntaub ntawv thiab cov ntaub ntawv kaw: tsim kom muaj kev tswj xyuas cov ntaub ntawv tiav thiab cov ntaub ntawv kaw lus los sau cov txiaj ntsig ntawm qhov ntsuas ntawm qhov tooj liab thickness thiab plating uniformity. Los ntawm kev txheeb cais thiab kev txheeb xyuas ntawm cov ntaub ntawv, qhov xwm txheej txawv txav ntawm lub qhov tooj liab tuab thiab electroplating uniformity tuaj yeem pom nyob rau lub sijhawm, thiab cov kev ntsuas sib xws yuav tsum tau coj los kho thiab txhim kho.

Cov saum toj no yog ob qho teeb meem loj ntawm cov tinning tsis zoo, qhov tsis txaus ntawm lub qhov tooj liab tuab, thiab qhov tsis sib xws ntawm qhov tooj liab plating uas feem ntau tshwm sim hauv rigid-flex board.Kuv vam tias qhov kev tshuaj xyuas thiab cov txheej txheem muab los ntawm Capel yuav pab tau rau txhua tus. Yog xav paub ntxiv txog lwm cov lus nug hauv pawg thawj coj saib xyuas, thov sab laj nrog pab pawg kws tshaj lij Capel, 15 xyoo ntawm pawg kws tshaj lij thiab kev paub dhau los yuav coj koj qhov project.

Post lub sij hawm: Aug-21-2023

Rov qab