Nyob rau hauv ib puas-evolving toj roob hauv pes ntawm electronics, qhov kev thov rau lub tshiab thiab npaum kev daws teeb meem yog qhov tseem ceeb. Ib qho kev daws teeb meem uas tau txais txiaj ntsig tseem ceeb yog Rigid-Flex PCB thev naus laus zis. Cov txheej txheem tsim khoom siab tshaj no ua ke nrog qhov zoo tshaj plaws ntawm ob qho tib si nruj thiab hloov tau yooj yim luam tawm Circuit Court boards, muab cov qauv tsim tsis sib xws thiab kev ntseeg tau. Hauv tsab xov xwm no, peb yuav tshawb xyuas cov txheej txheem tsim khoom Rigid-Flex PCB, cov txiaj ntsig ntawm kev pabcuam ib-nres, thiab qhov tseem ceeb ntawm kev ua haujlwm zoo thiab cov kev pabcuam sib dhos.

Nkag siab Rigid-Flex PCB Technology

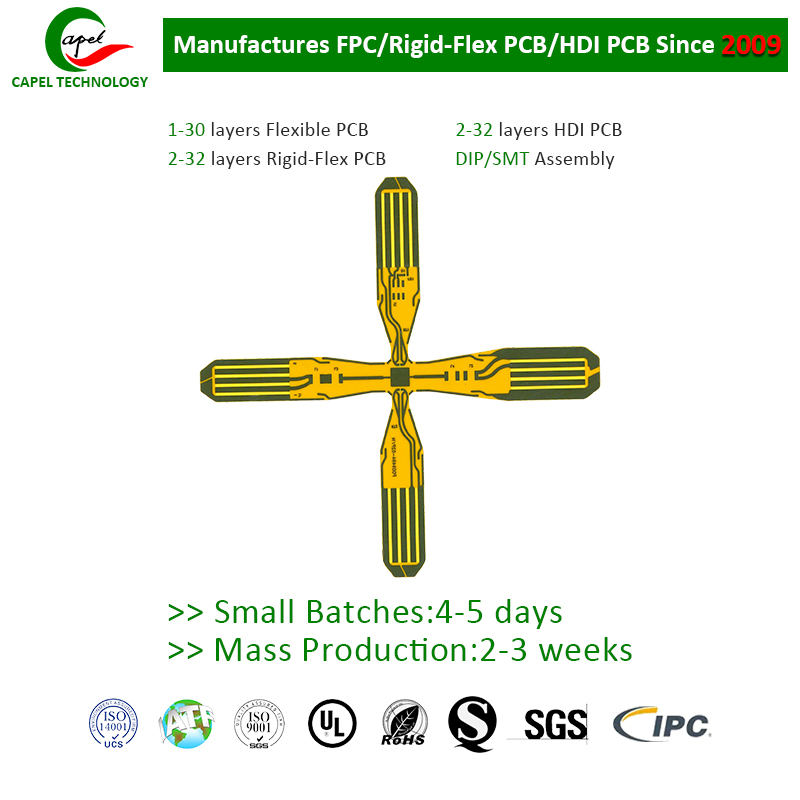

Rigid-Flex PCBs yog hybrid circuit boards uas sib xyaw ua ke nruj thiab hloov tau yooj yim rau hauv ib chav tsev. Qhov kev tsim tshwj xeeb no tso cai rau kev sib txuas hauv Circuit Court layouts thaum tuav lub compact form factor. Cov txheej txheem tsim khoom suav nrog txheej txheej hloov tau yooj yim thiab nruj, feem ntau polyimide thiab FR-4, feem. Qhov tshwm sim yog ntau yam PCB uas tuaj yeem khoov thiab flex yam tsis muaj kev cuam tshuam kev ua haujlwm.

Rigid-Flex PCB Manufacturing txheej txheem

Cov txheej txheem tsim khoom ntawm Rigid-Flex PCBs yog qhov nyuaj thiab xav tau qhov tseeb ntawm txhua theem. Ntawm no yog ib qho kev piav qhia ntawm cov kauj ruam tseem ceeb uas cuam tshuam:

Tsim thiab Layout:Cov txheej txheem pib nrog cov txheej txheem tsim kom ntxaws, qhov twg engineers siv software tshwj xeeb los tsim cov txheej txheem PCB. Cov theem no yog qhov tseem ceeb vim nws txiav txim siab ua haujlwm thiab kev ua haujlwm ntawm cov khoom kawg.

Kev xaiv khoom siv:Xaiv cov ntaub ntawv zoo yog qhov tseem ceeb rau kev ua tau zoo Rigid-Flex PCBs. Kev sib xyaw ua ke ntawm cov tawv tawv thiab hloov tau yooj yim yuav tsum tau sib xws kom ntseeg tau tias muaj zog thiab ua haujlwm tau zoo.

Txheej txheej:Cov kauj ruam tom ntej yog muab cov ntaub ntawv hloov tau yooj yim thiab nruj. Qhov no yog ua tiav siv cov txheej txheem lamination siab heev uas ua kom muaj kev sib raug zoo ntawm cov txheej txheem.

Etching thiab Drilling:Thaum cov khaubncaws sab nraud povtseg, cov qauv Circuit Court yog etched rau saum npoo. Qhov no yog ua raws li qhov drilling qhov rau vias thiab cov khoom tso rau hauv.

Nto Finishing:Cov kauj ruam kawg hauv cov txheej txheem tsim khoom yog txheej txheej, uas txhim kho PCB qhov kev ua tau zoo thiab kev ua haujlwm ntev. Cov kev xaiv ua tiav suav nrog ENIG (Electroless Nickel Immersion Gold) thiab HASL (Hot Air Solder Leveling).

Qhov tseem ceeb ntawm Prototyping Services

Prototyping yog ib theem tseem ceeb hauv Rigid-Flex PCB manufacturing txheej txheem. Nws tso cai rau cov neeg tsim qauv thiab cov kws tsim qauv sim lawv cov tswv yim ua ntej kev tsim tawm tag nrho. Ib tug txhim khu kev qha Rigid-Flex PCB tsum yuav muab cov kev pab cuam prototyping uas muaj xws li:

Rapid Prototyping:Lub sijhawm hloov pauv sai yog qhov tseem ceeb rau kev nyob sib tw. Ib tus neeg muab kev pabcuam ib-nres tuaj yeem xa cov qauv qauv hauv ib hnub, tso cai rau kev rov ua dua sai dua thiab tsim kev txhim kho.

Kev xeem thiab kev lees paub: Prototyping kuj tseem muaj kev sim nruj kom ntseeg tau tias tus qauv tsim tau raws li txhua qhov tshwj xeeb. Qhov no suav nrog kev ntsuas hluav taws xob, ntsuas thermal, thiab ntsuas kev ntsuas kev ntxhov siab.

Kev Hloov Kho Tsim:Raws li cov txiaj ntsig kev sim, kev hloov kho tuaj yeem ua rau tus qauv tsim. Cov txheej txheem rov ua dua no yog qhov tseem ceeb rau kev ua tiav cov khoom zoo kawg nkaus.

Kev Pabcuam Sibtham: Nqa Cov Qauv rau Lub Neej

Thaum cov theem prototyping tiav, cov kauj ruam tom ntej yog kev sib dhos. Cov kev pabcuam zoo sib dhos yog qhov tseem ceeb rau kev ua kom ntseeg tau tias Rigid-Flex PCBs ua haujlwm raws li qhov xav tau. Ib lub chaw muab kev pabcuam ib-nres feem ntau yuav muab cov kev pabcuam sib dhos hauv qab no:

Component Sourcing: Ib tus neeg muag khoom txhim khu kev qha yuav tsim kev sib raug zoo nrog cov tuam txhab tsim khoom, xyuas kom nkag mus rau cov khoom zoo ntawm cov nqi sib tw.

Automated Assembly: Cov txheej txheem sib dhos ua tau zoo, xws li cov tshuab tuaj tos thiab chaw, xyuas kom meej thiab ua haujlwm tau zoo hauv cov txheej txheem sib dhos. Qhov no txo qhov kev pheej hmoo ntawm kev ua yuam kev thiab txhim kho tag nrho qhov zoo ntawm cov khoom kawg.

Kev Tswj Xyuas Zoo:Kev ntsuas nruj nruj yog qhov tseem ceeb hauv cov txheej txheem sib dhos. Qhov no suav nrog kev tshuaj xyuas qhov muag, automated optical inspections (AOI), thiab kev sim ua haujlwm kom ntseeg tau tias txhua PCB ua tau raws li cov qauv xav tau.

Cov txiaj ntsig ntawm One-Stop Service

Xaiv qhov chaw muab kev pabcuam ib-nres rau Rigid-Flex PCB prototyping thiab sib dhos muaj ntau yam zoo:

Kev sib txuas lus yooj yim: Ua hauj lwm nrog ib tus neeg muag khoom yooj yim ua rau kev sib txuas lus yooj yim, txo qhov kev nkag siab thiab yuam kev.

Nqi Efficiency:Ib qho kev pabcuam ib-nres feem ntau tuaj yeem muab tus nqi zoo dua vim txo cov nqi nyiaj siv ua haujlwm thiab kev yuav khoom ntau.

Faster Turnaround Sijhawm:Nrog rau tag nrho cov kev pab cuam nyob rau hauv ib lub ru tsev, lub sij hawm los ntawm kev tsim mus rau ntau lawm yog luv luv, uas tso cai rau kom nkag mus rau lub lag luam sai.

Kev Ua Tau Zoo:Ib tus neeg muag khoom muaj peev xwm tswj tau qhov zoo ib yam thoob plaws txhua theem ntawm cov txheej txheem tsim khoom, los ntawm prototyping mus rau kev sib dhos.

Post lub sij hawm: Oct-22-2024

Rov qab