Nyob rau hauv ib puas-evolving toj roob hauv pes ntawm electronics, qhov kev thov rau lub tshiab thiab npaum Circuit Court board daws yeej tsis tau siab dua. Ntawm cov kev daws teeb meem no, Rigid-Flex PCBs (Printed Circuit Boards) tau tshwm sim los ua kev hloov pauv kev ua si, sib txuas cov yam ntxwv zoo tshaj plaws ntawm ob qho tib si nruj thiab hloov tau yooj yim. Kab lus no delves rau hauv cov intricacies ntawm Rigid-Flex PCB prototyping thiab sib dhos, tshawb xyuas cov txheej txheem cuam tshuam, qhov zoo uas lawv muab, thiab lub luag haujlwm ntawm SMT (Surface Mount Technology) cov nroj tsuag thiab FPC (Flexible Printed Circuit) cov chaw tsim khoom hauv lub npe no.

Nkag siab Rigid-Flex PCBs

Rigid-Flex PCBs yog hybrid circuit boards uas sib xyaw ua ke nruj thiab hloov tau yooj yim rau hauv ib chav tsev. Qhov kev tsim tshwj xeeb no tso cai rau kev hloov pauv ntau dua hauv cov ntawv thov uas qhov chaw txwv, xws li hauv smartphones, khoom siv kho mob, thiab thev naus laus zis thev naus laus zis. Cov txheej txheem FPC ntau txheej ua rau muaj kev sib txuam sib luag thaum tuav lub teeb yuag profile, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv hluav taws xob niaj hnub no.

Qhov zoo ntawm Rigid-Flex PCBs

Space Efficiency:Rigid-Flex PCBs tuaj yeem txo qhov loj thiab qhov hnyav ntawm cov khoom siv hluav taws xob. Los ntawm kev tshem tawm qhov xav tau ntawm cov khoom sib txuas thiab txo cov kev sib tshuam, cov laug cam tuaj yeem haum rau hauv qhov chaw nruj dua.

Enhanced Durability:Kev sib xyaw ua ke ntawm cov ntaub ntawv nruj thiab hloov tau yooj yim muab kev tiv thaiv zoo rau cov neeg kho tshuab kev ntxhov siab, kev co, thiab thermal expansion. Qhov kev ua haujlwm ntev no yog qhov tseem ceeb rau kev siv hauv ib puag ncig hnyav.

Txhim kho teeb liab kev ncaj ncees:Cov qauv tsim ntawm Rigid-Flex PCBs tso cai rau cov teeb liab luv luv, uas tuaj yeem txhim kho cov teeb liab kev ncaj ncees thiab txo cov hluav taws xob cuam tshuam (EMI).

Nqi-effectiveness:Thaum thawj zaug peev hauv Rigid-Flex PCB prototyping tej zaum yuav siab dua, kev txuag mus sij hawm ntev los ntawm kev txo lub sij hawm sib dhos thiab cov khoom tsawg dua tuaj yeem ua rau nws muaj txiaj ntsig zoo.

Prototyping Rigid-Flex PCBs

Prototyping yog ib kauj ruam tseem ceeb hauv kev txhim kho Rigid-Flex PCBs. Nws tso cai rau cov kws tshaj lij los sim thiab siv tau lawv cov qauv tsim ua ntej yuav tsiv mus rau qhov kev tsim tawm tag nrho. Cov txheej txheem prototyping feem ntau suav nrog cov kauj ruam hauv qab no:

Tsim thiab Simulation: Siv cov software siab tshaj CAD, engineers tsim cov ncauj lus kom ntxaws ntawm Rigid-Flex PCB. Cov cuab yeej simulation tuaj yeem pab kwv yees kev ua tau zoo thiab txheeb xyuas cov teeb meem tshwm sim thaum ntxov ntawm cov qauv tsim.

Kev xaiv khoom siv:Xaiv cov ntaub ntawv zoo yog qhov tseem ceeb rau kev ua tiav cov yam ntxwv ntawm kev ua haujlwm. Cov khoom siv feem ntau suav nrog polyimide rau cov seem hloov tau yooj yim thiab FR-4 rau cov seem nruj.

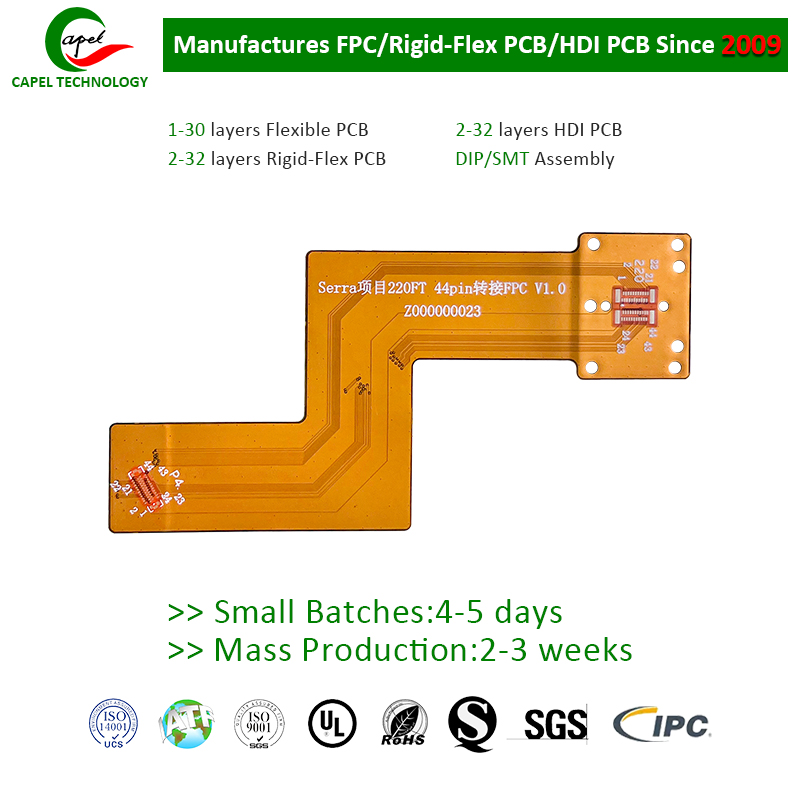

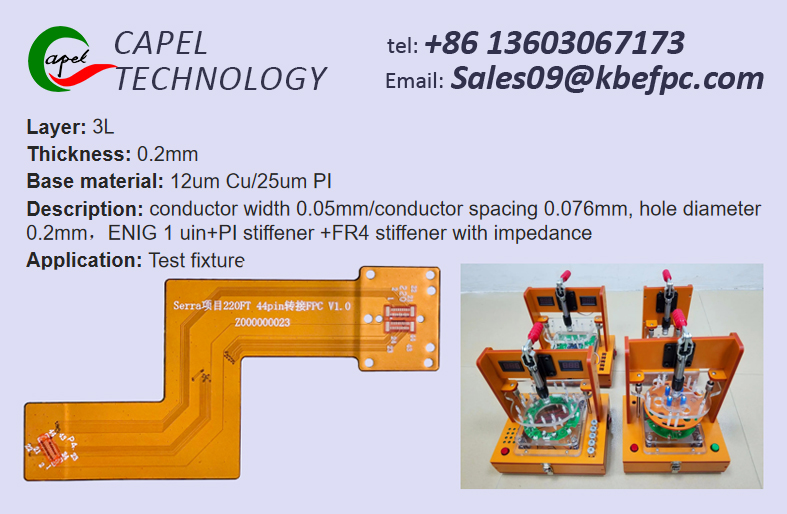

Fabrication:Thaum tsim tau tiav lawm, PCB yog tsim nyob rau hauv lub Hoobkas tshwj xeeb FPC. Cov txheej txheem no suav nrog etching cov qauv hauv Circuit Court rau ntawm lub substrate, siv daim npog ntsej muag, thiab ntxiv cov khoom tiav.

Kev kuaj:Tom qab kev tsim khoom, tus qauv ua tiav kev sim nruj kom paub tseeb tias nws ua tau raws li qhov xav tau tshwj xeeb. Qhov no yuav suav nrog kev sim hluav taws xob, thermal cycling, thiab kev ntsuam xyuas kev ntxhov siab.

Kev sib dhos ntawm Rigid-Flex PCBs

Kev sib dhos ntawm Rigid-Flex PCBs yog cov txheej txheem nyuaj uas yuav tsum tau muaj qhov tseeb thiab kev txawj ntse. Nws feem ntau suav nrog SMT thiab kev sib dhos los ntawm lub qhov. Ntawm no yog saib ze dua ntawm txhua txoj kev:

SMT sib dhos

Surface Mount Technology (SMT) yog siv dav hauv kev sib dhos ntawm Rigid-Flex PCBs vim nws qhov ua tau zoo thiab muaj peev xwm ua kom haum rau cov khoom siv siab. SMT cov nroj tsuag siv cov tshuab tuaj tos-thiab-qhov chaw rau cov khoom siv hauv lub rooj tsavxwm, ua raws li cov reflow soldering kom ruaj ntseg rau hauv qhov chaw. Txoj kev no yog qhov zoo tshwj xeeb rau ntau txheej FPC tsim, qhov chaw nyob ntawm tus nqi.

Los ntawm-Hole Assembly

Thaum SMT yog txoj kev nyiam rau ntau daim ntawv thov, los ntawm lub qhov sib dhos tseem cuam tshuam, tshwj xeeb tshaj yog rau cov khoom loj lossis cov uas xav tau kev siv tshuab ntxiv. Nyob rau hauv cov txheej txheem no, cov khoom yog muab tso rau hauv pre-drilled qhov thiab soldered rau lub rooj tsavxwm. Cov txheej txheem no feem ntau siv ua ke nrog SMT los tsim kom muaj kev sib koom ua ke.

Lub luag haujlwm ntawm FPC Factories

FPC factories ua lub luag haujlwm tseem ceeb hauv kev tsim cov Rigid-Flex PCBs. Cov chaw tshwj xeeb no tau nruab nrog cov tshuab siab heev thiab thev naus laus zis los daws cov teeb meem tshwj xeeb cuam tshuam nrog kev tsim hluav taws xob hloov tau yooj yim. Qhov tseem ceeb ntawm FPC factories suav nrog:

Khoom siv Advanced:FPC cov chaw tsim khoom siv lub xeev-ntawm-tus-kos duab khoom siv rau laser txiav, etching, thiab lamination, kom ntseeg tau siab precision thiab zoo nyob rau hauv cov khoom kawg.

Kev Tswj Xyuas Zoo:Cov kev tswj xyuas nruj nruj tau siv thoob plaws hauv cov txheej txheem tsim khoom kom ntseeg tau tias txhua Rigid-Flex PCB ua tau raws li cov qauv kev lag luam thiab cov neeg siv khoom tshwj xeeb.

Scalability: FPC cov chaw tsim khoom yog tsim los ntsuas kev tsim khoom raws li qhov xav tau, tso cai rau kev hloov pauv tau zoo los ntawm kev tsim qauv mus rau kev tsim khoom tag nrho.

Post lub sij hawm: Oct-22-2024

Rov qab