Raws li qhov kev thov rau cov kev daws teeb meem yooj yim thiab cov khoom siv hluav taws xob txuas ntxiv mus ntxiv, rigid-flex PCBs tau dhau los ua kev xaiv nrov hauv PCB tsim thiab tsim khoom. Cov boards no muab cov txiaj ntsig zoo ntawm PCBs nruj thiab hloov tau yooj yim los muab kev txhim kho yooj yim yam tsis muaj kev cuam tshuam kev ua haujlwm ntev thiab kev ua haujlwm. Txhawm rau tsim txhim khu kev qha thiab ua kom zoo dua qub-flex PCBs, kev nkag siab zoo ntawm kev teeb tsa pawg yog qhov tseem ceeb. Cov txheej txheem txheej txheej txiav txim siab txog kev teeb tsa thiab txheej txheej ntawm PCB, cuam tshuam ncaj qha rau nws qhov kev ua tau zoo thiab kev tsim khoom.Cov lus qhia dav dav no yuav nkag siab txog qhov nyuaj ntawm cov txheej txheem nruj-flex PCB, muab cov kev pom zoo los pab cov neeg tsim qauv txiav txim siab paub thaum lub sijhawm tsim qauv. Nws yuav npog ntau yam nrog rau kev xaiv cov khoom, txheej txheej, kev txiav txim siab txog kev ncaj ncees, kev tswj impedance, thiab kev txwv kev tsim khoom. Los ntawm kev nkag siab txog cov complexity ntawm nruj-flex PCB stackups, cov neeg tsim qauv tuaj yeem ua kom muaj kev ncaj ncees thiab kev ntseeg siab ntawm lawv cov qauv tsim. Lawv yuav txhim kho cov teeb liab kev ncaj ncees, txo qhov cuam tshuam ntawm electromagnetic cuam tshuam (EMI) thiab pab txhawb kev tsim khoom zoo. Txawm hais tias koj yog tus tshiab rau rigid-flex PCB tsim los yog nrhiav kev txhim kho koj cov kev paub, phau ntawv qhia no yuav yog ib qho khoom muaj txiaj ntsig, ua rau koj mus rau qhov nyuaj ntawm kev teeb tsa kev teeb tsa thiab tsim cov khoom zoo, nruj hloov pauv PCB cov kev daws teeb meem rau ntau yam khoom.

1.Dab tsi yog rigid-flex board?

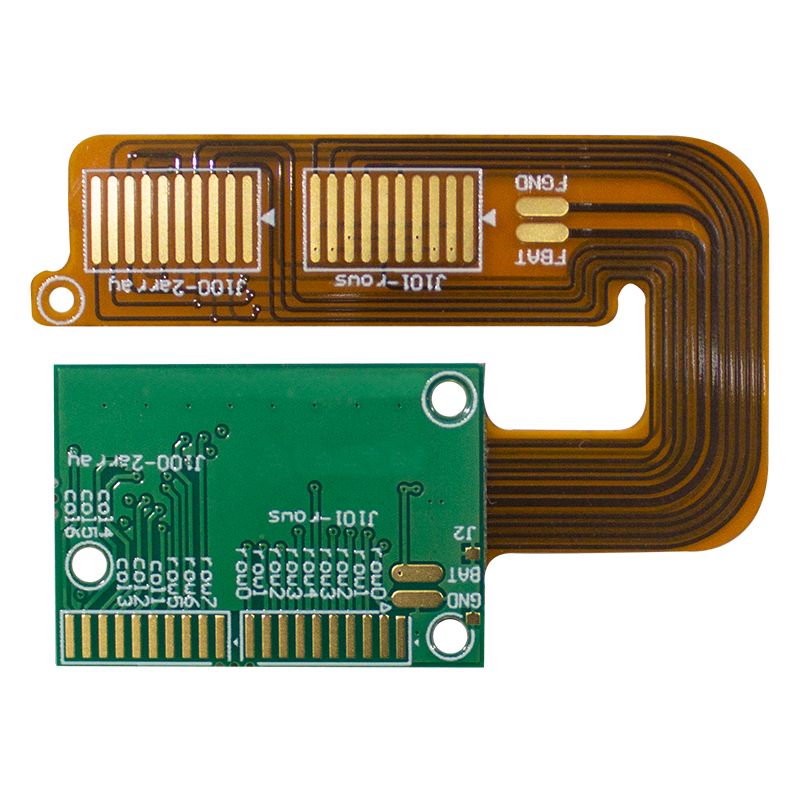

Rigid-flex board, tseem hu ua rigid-flex printed circuit board (PCB), yog ib tug PCB uas ua ke nruj thiab hloov tau yooj yim substrates ntawm ib lub rooj tsavxwm.Nws muab cov txiaj ntsig zoo ntawm cov tawv tawv thiab hloov tau yooj yim PCBs txhawm rau txhim kho kev tsim qauv yooj yim thiab ua haujlwm ntev. Nyob rau hauv lub rigid-flex board, lub rigid ib feem yog ua los ntawm cov tsoos rigid PCB cov ntaub ntawv (xws li FR4), thaum lub sij hawm hloov pauv yog ua los ntawm cov khoom siv PCB hloov tau (xws li polyimide). Cov khoom no yog sib cuam tshuam los ntawm plated los ntawm lub qhov los yog flex connectors los tsim ib tug integrated board. Cov ntu nruj muab kev txhawb nqa thiab kev ruaj ntseg rau cov khoom sib txuas, cov khoom sib txuas, thiab lwm yam khoom siv, zoo ib yam li tus qauv nruj PCB. Qhov hloov tau yooj yim, ntawm qhov tod tes, tso cai rau lub rooj tsav xwm hauv Circuit Court kom khoov thiab khoov, tso cai rau nws kom haum rau hauv cov khoom siv hluav taws xob uas muaj qhov chaw txwv lossis cov duab tsis zoo. Rigid-flex boards muaj ntau qhov zoo dua li cov tsoos nruj lossis hloov tau yooj yim PCBs. Lawv txo qhov kev xav tau ntawm cov khoom sib txuas thiab cov cables, txuag chaw, txo lub sijhawm sib dhos, thiab ua kom muaj kev ntseeg siab los ntawm kev tshem tawm cov ntsiab lus tsis ua haujlwm. Tsis tas li ntawd, rigid-flex boards ua kom yooj yim cov txheej txheem tsim los ntawm kev ua kom yooj yim ntawm kev sib txuas ntawm cov khoom nruj thiab flex, txo cov kev sib tw thiab kev txhim kho cov teeb liab kev ncaj ncees. Rigid-flex boards feem ntau yog siv rau hauv cov ntawv thov uas qhov chaw txwv lossis lub rooj tsavxwm xav tau kom ua raws li cov duab tshwj xeeb lossis qhov profile. Lawv feem ntau pom muaj nyob rau hauv aerospace, cov khoom siv kho mob, automotive electronics thiab portable electronics qhov twg qhov loj, qhov hnyav thiab kev ntseeg tau yog qhov tseem ceeb. Kev tsim thiab tsim cov rigid-flex boards yuav tsum muaj kev paub tshwj xeeb thiab kev txawj ntse vim yog kev sib xyaw ua ke ntawm cov ntaub ntawv nruj thiab yoog raws thiab kev sib tshuam. Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tau ua hauj lwm nrog ib tug paub txog PCB chaw tsim tshuaj paus uas muaj peev xwm los tuav lub complexity ntawm rigid-flex board manufacturing.

2.Vim li cas flex pcb stacking configuration tseem ceeb?

Mechanical Integrity:

Rigid-flex PCBs yog tsim los muab kev yooj yim thiab kev ntseeg tau. Cov txheej txheem stacking txiav txim siab cov txheej txheem nruj thiab hloov tau yooj yim, ua kom lub rooj tsavxwm tuaj yeem tiv taus dabtsi yog khoov, sib ntswg thiab lwm yam kev ntxhov siab yam tsis muaj kev cuam tshuam nws cov qauv kev ncaj ncees. Kev sib raug zoo txheej txheem yog qhov tseem ceeb rau kev tiv thaiv PCB qaug zog, kev ntxhov siab ntau, thiab tsis ua haujlwm dhau sijhawm.

Qhov chaw optimization:

Rigid-flex boards yog siv dav hauv cov khoom siv hluav taws xob compact nrog qhov chaw tsawg. Stacked configurations tso cai rau cov neeg tsim qauv siv qhov chaw muaj txiaj ntsig los ntawm kev teeb tsa cov txheej txheem thiab cov khoom hauv ib txoj hauv kev uas siv ntau qhov chaw 3D. Qhov no tso cai rau PCBs los nruab rau hauv cov ntaub ntawv kaw ntom nti, cov khoom siv me me thiab cov qauv txheej txheem nyuaj. Teeb liab kev ncaj ncees:

Lub teeb liab kev ncaj ncees ntawm nruj flex PCB yog qhov tseem ceeb rau nws txoj haujlwm kom raug. Stacking configuration plays lub luag haujlwm tseem ceeb hauv kev ua kom lub teeb pom kev ncaj ncees los ntawm kev coj mus rau hauv tus account yam xws li kev tswj hwm impedance, kev sib kis kab sib txuas, thiab txo qis crosstalk. Tsim nyog txheej txheej txheej tuaj yeem ua kom muaj txiaj ntsig zoo ntawm cov teeb liab ceev ceev, txo cov teeb liab attenuation, thiab xyuas kom meej cov ntaub ntawv xa mus.

Thermal Management:

Cov khoom siv hluav taws xob tsim hluav taws xob tsim hluav taws xob, thiab kev tswj xyuas kom zoo thermal yog qhov tseem ceeb rau kev tiv thaiv overheating thiab muaj peev xwm puas tsuaj rau cov khoom. Cov txheej txheem txheej txheej ntawm nruj-flex PCBs tso cai rau kev tso tawm tswv yim ntawm thermal vias, txheej tooj liab, thiab cov dab dej kub kom ua kom muaj cua sov zoo. Los ntawm kev txiav txim siab txog cov teeb meem thermal thaum lub sij hawm tsim cov txheej txheem, cov neeg tsim qauv tuaj yeem ua kom PCB ntev thiab kev ntseeg tau.

Kev txiav txim siab ntawm kev tsim khoom:

Stacking configuration cuam tshuam rau cov txheej txheem tsim khoom nruj-flex PCB. Nws txiav txim siab qhov kev txiav txim nyob rau hauv uas cov khaubncaws sab nraud povtseg yog sib koom ua ke, kev sib tw thiab kev sau npe ntawm cov txheej txheem yooj yim thiab nruj, thiab kev tso kawm ntawm cov khoom. Los ntawm kev ua tib zoo xaiv cov teeb tsa pawg, cov neeg tsim qauv tuaj yeem txhim kho cov txheej txheem tsim khoom, txo cov nqi tsim khoom, thiab txo qhov kev pheej hmoo ntawm kev tsim khoom yuam kev.

3.Key Cheebtsam ntawm nruj-flex PCB stackup

Thaum tsim ib qho nyuaj-flex PCB stackup, muaj ntau yam tseem ceeb los xav txog. Cov khoom no ua lub luag haujlwm tseem ceeb hauv kev muab kev txhawb nqa tsim nyog, kev sib txuas hluav taws xob, thiab kev yooj yim rau tag nrho PCB tsim. Cov hauv qab no yog cov khoom tseem ceeb ntawm kev sib tw-flex PCB stackup:

Rigid txheej:

Cov txheej txheem nruj feem ntau yog tsim los ntawm cov khoom siv nruj xws li FR-4 lossis cov khoom zoo sib xws. Cov txheej no muab txhua yam muaj zog thiab ruaj khov rau PCB. Nws tseem muaj cov khoom siv hauv tsev thiab tso cai rau kev teeb tsa ntawm cov khoom siv saum npoo av (SMD) thiab cov khoom siv los ntawm lub qhov. Cov txheej txheem nruj muab lub hauv paus ruaj khov rau cov txheej txheem yooj yim thiab ua kom muaj kev sib raug zoo thiab nruj ntawm tag nrho PCB.

Flexible txheej:

Cov txheej txheem yooj yim muaj cov khoom siv yooj yim xws li polyimide lossis cov khoom zoo sib xws. Cov txheej no tso cai rau PCB khoov, quav, thiab flex. Lub flex txheej yog qhov chaw feem ntau ntawm cov khoom siv hluav taws xob thiab hluav taws xob sib txuas. Nws muab qhov tsim nyog yooj yim rau cov ntawv thov uas xav kom PCB khoov lossis ua raws li cov duab sib txawv lossis qhov chaw. Kev hloov pauv ntawm cov txheej txheem no yuav tsum tau ua tib zoo xav kom nws ua tau raws li qhov yuav tsum tau ua ntawm daim ntawv thov.

Adhesive txheej:

Ib txheej nplaum yog ib txheej nyias ntawm cov ntaub nplaum uas siv los ntawm cov txheej txheem nruj thiab cov txheej txheem yooj yim. Nws lub hom phiaj tseem ceeb yog ua kom cov txheej txheem nruj thiab hloov tau yooj yim ua ke, muab cov qauv kev ncaj ncees rau lub laminate. Nws xyuas kom meej tias cov khaubncaws sab nraud povtseg ruaj khov rau ib leeg txawm tias thaum khoov lossis khoov txav. Cov nplaum txheej kuj ua raws li cov khoom siv dielectric, muab rwb thaiv tsev ntawm cov khaubncaws sab nraud povtseg. Kev xaiv ntawm cov khoom siv nplaum yog qhov tseem ceeb vim nws yuav tsum muaj cov khoom sib txuas zoo, lub zog dielectric siab, thiab kev sib raug zoo nrog cov khoom siv hauv paus.

Reinforcement thiab npog:

Kev txhawb zog thiab npog yog cov txheej txheem ntxiv feem ntau ntxiv rau PCB stackup los txhim kho nws lub zog, kev tiv thaiv, thiab kev ntseeg siab. Cov kev txhawb zog tuaj yeem suav nrog cov ntaub ntawv xws li FR-4 lossis polyimide-raws li cov nplaum nplaum uas tsis muaj cov ntaub ntawv uas tau laminated rau cov chaw tshwj xeeb ntawm cov txheej txheem nruj los yog hloov tau yooj yim los muab kev nruj thiab kev txhawb nqa ntxiv. PCB nto yog coated nrog npog xws li solder lub qhov ncauj qhov ntswg thiab tiv thaiv txheej los tiv thaiv lawv los ntawm ib puag ncig yam xws li ya raws, plua plav, thiab mechanical stress.

Cov khoom tseem ceeb no ua hauj lwm ua ke los tsim kom zoo zoo tsim rigid-flex PCB stackup uas ua tau raws li daim ntawv thov. Cov txheej txheem kev ncaj ncees thiab kev hloov pauv tau muab los ntawm cov txheej txheem nruj thiab hloov tau yooj yim, nrog rau cov txheej nplaum nplaum, xyuas kom meej tias PCB tuaj yeem tiv taus kev khoov lossis flexing txav yam tsis muaj kev cuam tshuam rau kev ncaj ncees ntawm Circuit Court. Tsis tas li ntawd, kev siv cov kev txhawb zog thiab cov ntaub npog ua kom muaj kev ntseeg tau zoo thiab kev tiv thaiv ntawm PCB. Los ntawm kev ua tib zoo xaiv thiab tsim cov khoom siv no, cov kws tsim khoom tuaj yeem tsim cov khoom siv zoo thiab txhim khu kev qha rigid-flex PCB stackups.

4.Rigid-flex PCB stackup configuration hom

Thaum tsim rigid-flex PCB stackups, ntau hom kev teeb tsa tuaj yeem siv nyob ntawm qhov tshwj xeeb ntawm daim ntawv thov. Cov txheej txheem txheej txheej txiav txim siab cov txheej txheem suav nrog hauv kev tsim thiab kev npaj ntawm cov txheej txheem nruj thiab hloov tau. Cov nram qab no yog peb hom kev nruj-flex PCB stackup configurations:

1 txheej ntawm nruj thiab mos lamination:

Hauv qhov kev teeb tsa no, PCB muaj ib txheej ntawm cov khoom nruj thiab ib txheej ntawm cov khoom siv tau yooj yim. Cov txheej txheem nruj muab qhov tsim nyog ruaj khov thiab kev txhawb nqa, thaum cov txheej txheem yooj yim tso cai rau PCB hloov pauv thiab khoov. Qhov kev teeb tsa no tsim nyog rau cov ntawv thov uas xav tau kev hloov pauv yooj yim thiab tsim qauv yooj yim.

2 txheej ntawm nruj thiab mos superposition:

Hauv qhov kev teeb tsa no, PCB muaj ob txheej txheej - txheej nruj thiab txheej hloov tau yooj yim. Ib txheej nruj yog sandwiched ntawm ob txheej hloov tau yooj yim, tsim kom muaj "phau ntawv" kev npaj. Qhov kev teeb tsa no muab kev yooj yim dua thiab tso cai rau ntau qhov kev tsim qauv siv cov khoom ntawm ob sab ntawm PCB. Nws muab kev yooj yim dua hauv kev khoov thiab khoov dua li ib txheej txheej txheej.

Multi-layer nruj thiab mos superposition:

Hauv qhov kev teeb tsa no, PCB muaj ntau txheej txheej - ua ke ntawm cov txheej txheem nruj thiab hloov tau yooj yim. Cov khaubncaws sab nraud povtseg yog stacked nyob rau sab saum toj ntawm txhua lwm yam, alternating ntawm nruj thiab saj zawg zog txheej. Qhov kev teeb tsa no muab cov qib siab tshaj plaws ntawm kev hloov pauv thiab tso cai rau cov qauv siv ntau tshaj plaws siv ntau yam khoom siv thiab cov khoom siv hluav taws xob. Nws yog tsim rau cov ntawv thov uas yuav tsum tau ua kom yooj yim thiab compact tsim.

Qhov kev xaiv ntawm nruj-flex stackup configuration nyob ntawm tej yam xws li cov theem ntawm kev yooj yim yuav tsum tau, Circuit Court tsim complexity, thiab qhov chaw txwv. Engineers yuav tsum tau ua tib zoo soj ntsuam daim ntawv thov cov cai thiab cov kev txwv los txiav txim qhov tsim nyog tshaj plaws stacking configuration.

Ntxiv nrog rau kev tsim kho-flex laminate, lwm yam xws li xaiv cov khoom siv, thickness ntawm txhua txheej, thiab ntawm kev sib txuas tsim kuj tseem ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab tag nrho cov kev ua tau zoo thiab kev ntseeg siab ntawm rigid-flex PCBs. Nws yog ib qho tseem ceeb uas yuav tau ua hauj lwm zoo nrog PCB cov chaw tsim khoom thiab cov kws tshaj lij tsim los xyuas kom meej tias qhov kev xaiv stackup configuration ua tau raws li cov kev cai tshwj xeeb thiab cov qauv ntawm daim ntawv thov.

Los ntawm kev xaiv qhov tsim nyog rigid-flex stackup configuration thiab optimizing lwm yam tsis tsim, engineers muaj peev xwm siv txhim khu kev qha, high-performance rigid-flex PCBs uas ua tau raws li cov kev xav tau tshwj xeeb ntawm lawv daim ntawv thov.

5.Qhov tseem ceeb los xav txog thaum xaiv Rigid-Flex PCB Stacking Configuration

Thaum xaiv ib qho nyuaj-flex PCB stackup configuration, muaj ntau yam los xav txog kom ua tau zoo thiab kev ntseeg tau. Nov yog tsib yam tseem ceeb uas yuav tsum nco ntsoov:

Teeb liab kev ncaj ncees:

Kev xaiv ntawm stackup configuration tuaj yeem cuam tshuam rau lub teeb liab kev ncaj ncees ntawm PCB. Cov cim qhia ntawm cov khaubncaws sab nraud povtseg yuav muaj cov yam ntxwv impedance sib txawv piv rau cov khaubncaws sab nraud povtseg. Nws yog ib qho tseem ceeb los xaiv ib qho kev teeb tsa stackup uas txo qis cov teeb liab poob, crosstalk, thiab impedance mismatch. Cov txheej txheem tswj kom zoo impedance yuav tsum tau siv los tswj cov teeb liab kev ncaj ncees thoob plaws hauv PCB.

Flexibility Requirements:

Cov theem ntawm kev hloov pauv ntawm PCB yog qhov tseem ceeb rau kev txiav txim siab. Cov ntawv thov sib txawv tuaj yeem muaj qhov sib txawv ntawm kev khoov thiab khoov. Lub stackup configuration yuav tsum tau xaiv kom haum raws li qhov yuav tsum tau yooj yim thaum xyuas kom meej tias lub PCB ua tau raws li tag nrho cov mechanical thiab hluav taws xob kev ua tau zoo. Tus naj npawb thiab cov txheej txheem hloov pauv yuav tsum tau ua tib zoo txiav txim siab raws li cov kev xav tau tshwj xeeb.

Qhov chaw txwv:

Qhov chaw muaj nyob rau hauv ib yam khoom lossis khoom siv tuaj yeem cuam tshuam qhov kev xaiv ntawm pawg-up configuration. Compact designs nrog tsawg PCB qhov chaw yuav xav tau ntau txheej rigid-flex configurations kom siv tau qhov chaw ntau tshaj. Ntawm qhov tod tes, cov qauv loj dua tso cai rau kev hloov pauv ntau dua thaum xaiv cov teeb tsa pawg. Optimizing stacking kom haum rau qhov chaw muaj yam tsis muaj kev cuam tshuam kev ua haujlwm lossis kev ntseeg siab yog qhov tseem ceeb.

Thermal Management:

Kev tswj xyuas thermal zoo yog qhov tseem ceeb rau kev tiv thaiv kev tsim hluav taws xob, uas tuaj yeem cuam tshuam kev ua haujlwm thiab kev ntseeg siab ntawm cov circuits thiab cov khoom. Qhov kev xaiv ntawm stackup configuration yuav tsum coj cov cua kub dissipation rau hauv kev xav. Piv txwv li, yog tias PCB tsim hluav taws xob ntau, nws yuav xav tau ib qho layup uas pab dissipate lub tshav kub, xws li koom nrog hlau cores los yog siv thermal vias. Cov khoom siv cua sov kuj tseem yuav tsum tau muab tso rau hauv cov pawg kom dissipate tshav kub zoo.

Fabrication thiab Assembly Considerations:

Kev teeb tsa pawg-up xaiv yuav tsum yooj yim rau fabricate thiab sib sau ua ke. Cov yam ntxwv xws li kev yooj yim ntawm kev tsim khoom, kev sib raug zoo nrog cov txheej txheem tsim khoom thiab kev sib dhos thev naus laus zis, thiab muaj cov khoom tsim nyog yuav tsum tau txiav txim siab. Piv txwv li, qee qhov kev teeb tsa pawg yuav xav tau cov txheej txheem tsim tshwj xeeb lossis tej zaum yuav muaj kev txwv ntawm cov khoom siv uas tuaj yeem siv tau. Ua haujlwm nrog PCB cov chaw tsim khoom thaum ntxov hauv cov txheej txheem tsim qauv yog qhov tseem ceeb los xyuas kom meej tias cov kev xaiv xaiv tuaj yeem tsim thiab sib sau ua haujlwm tau zoo.

Los ntawm ua tib zoo tshuaj xyuas tsib yam no, cov kws tsim khoom tuaj yeem txiav txim siab txog kev xaiv ib qho nyuaj-flex PCB stacking configuration. Nws raug nquahu kom ua haujlwm nrog tus kws tshaj lij kev tsim khoom thiab sib dhos kom ntseeg tau tias qhov kev xaiv tsim tau ua tau raws li txhua qhov kev tsim qauv thiab ua tau raws li cov txheej txheem tsim khoom. Customizing lub stackup los daws teeb meem kev ncaj ncees, yooj, qhov chaw txwv, thermal tswj thiab kev txiav txim siab ntawm kev tsim khoom yuav ua rau muaj zog thiab txhim khu kev qha rigid-flex PCB.

6.Tsim kev txiav txim siab rau kev sib tw-txheej txheem PCB pawg-up

Thaum tsim ib qho nyuaj-flex PCB stackup, muaj ntau yam tseem ceeb uas yuav tsum tau xav txog kom ua tau zoo thiab kev ntseeg tau. Nov yog tsib qhov kev txiav txim siab tsim qauv tseem ceeb:

Layer Distribution thiab Symmetry:

Kev faib tawm txheej hauv stackup yog qhov tseem ceeb rau kev ua tiav qhov sib npaug thiab sib luag hauv kev tsim. Qhov no pab tiv thaiv warping los yog buckling teeb meem thaum lub sij hawm khoov txheej txheem. Nws raug nquahu kom muaj cov txheej txheem tib yam ntawm txhua sab ntawm flex board thiab muab cov txheej txheem flex rau hauv nruab nrab ntawm pawg. Qhov no ua kom muaj kev sib npaug ntawm kev ntxhov siab thiab txo qis kev pheej hmoo ntawm kev ua tsis tiav.

Cable thiab Trace Layout:

Qhov kev teeb tsa ntawm cov cables thiab cov cim ntawm PCB yuav tsum tau ua tib zoo xav. Txoj kev khiav ntawm cov cables thiab cov cim yuav tsum tau npaj kom txo qis kev ntxhov siab thiab tiv thaiv kev puas tsuaj thaum khoov. Nws raug nquahu kom siv cov cables hloov tau yooj yim thiab cov kab khiav deb ntawm thaj chaw uas muaj kev ntxhov siab heev, xws li nyob ze ntawm khoov lossis quav cov ntsiab lus. Tsis tas li ntawd, siv cov ces kaum sib npaug siv cov kaum ntse ntse tuaj yeem txo cov kev ntxhov siab thiab txhim kho PCB yooj.

Hauv av thiab lub dav hlau fais fab:

Hauv av thiab lub dav hlau fais fab kev faib tawm yog qhov tseem ceeb heev los tswj cov teeb liab kom raug thiab kev faib hluav taws xob. Nws raug nquahu kom faib cov av tshwj xeeb thiab lub dav hlau fais fab los muab kev faib hluav taws xob sib npaug thiab ruaj khov thoob plaws hauv PCB. Cov khaubncaws sab nraud povtseg no kuj ua raws li electromagnetic cuam tshuam (EMI) shields. Qhov chaw zoo ntawm av vias thiab stitched vias yog qhov tseem ceeb los txo cov impedance hauv av thiab txhim kho EMI kev ua tau zoo.

Kev ntsuam xyuas kev ncaj ncees:

Lub teeb liab kev ncaj ncees yog qhov tseem ceeb rau kev ua haujlwm ntawm PCB. Cov cim cim yuav tsum tau ua tib zoo tsim los txo qis impedance discontinuities, crosstalk, thiab teeb liab reflections. Cov neeg tsim qauv PCB yuav tsum siv cov cuab yeej software los ua cov teeb meem kev ntseeg siab kom ua kom zoo dua qhov dav thiab qhov sib txawv, tswj xyuas qhov cuam tshuam, thiab xyuas kom meej cov teeb liab kev ncaj ncees thoob plaws tag nrho cov nruj-flex PCB.

Flexible thiab Khoov Cheeb Tsam:

Ib qho yooj yim thiab nruj ntawm PCB muaj cov kev xav tau sib txawv ntawm kev hloov pauv thiab khoov. Nws yog ib qho tsim nyog los txheeb xyuas thiab xaiv cov chaw tshwj xeeb rau cov ntu hloov tau yooj yim thiab nruj. Qhov chaw flex yuav tsum hloov pauv kom haum raws li qhov yuav tsum tau khoov vojvoog yam tsis muaj kev ntxhov siab rau cov kab lossis cov khoom. Cov txheej txheem kev txhawb zog xws li cov tav lossis cov txheej txheem polymer tuaj yeem siv los ua kom cov khoom siv dag zog thiab kev ntseeg siab ntawm cov chaw hloov tau yooj yim.

Los ntawm kev xav txog cov qauv tsim, cov engineers tuaj yeem tsim kho kom zoo tshaj plaws-flex PCB stackups. Nws yog ib qho tseem ceeb rau kev ua hauj lwm nrog PCB cov tuam txhab kom nkag siab txog lawv cov peev xwm, cov khoom siv, thiab kev txwv kev tsim khoom. Tsis tas li ntawd, koom nrog pab pawg tsim khoom thaum ntxov hauv cov txheej txheem tsim tuaj yeem pab daws cov teeb meem kev tsim khoom thiab ua kom muaj kev hloov pauv ntawm kev tsim mus rau ntau lawm. Los ntawm kev them nyiaj rau cov txheej txheem kev faib tawm, kev xa mus thiab kev tso chaw, hauv av thiab lub dav hlau fais fab, teeb liab kev ncaj ncees thiab qhov chaw flex tau yooj yim, cov neeg tsim qauv tuaj yeem tsim kev txhim khu kev qha thiab ua haujlwm zoo nruj-flex PCBs.

7.Layer tsim tshuab rau rigid saj zawg zog pcb

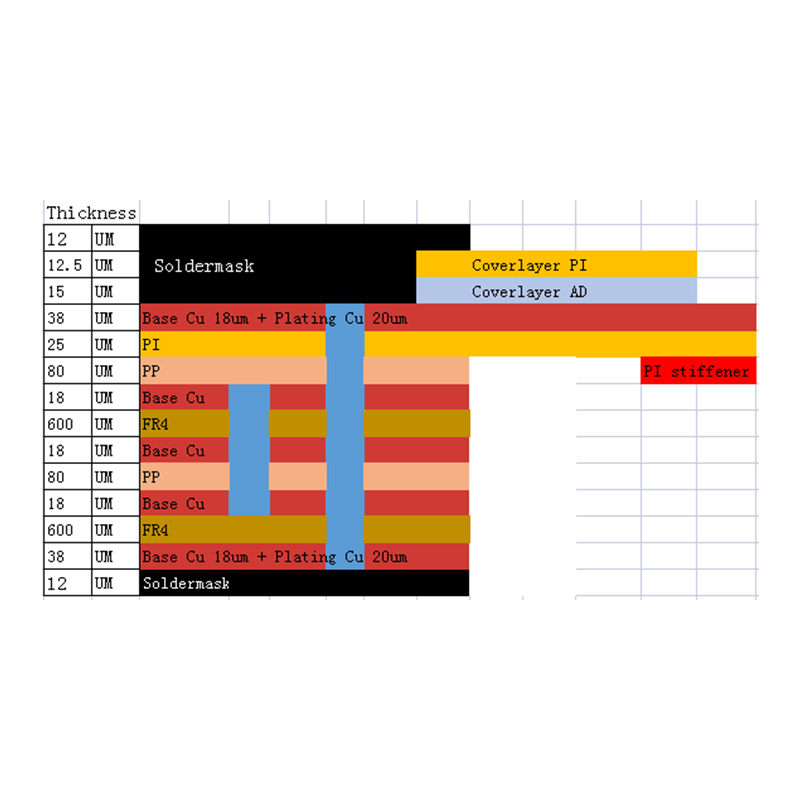

Thaum tsim cov rigid-flex boards, txheej txheej txheem tsim ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm kom raug thiab kev ntseeg tau. Nov yog plaub txheej txheem tsim txheej txheem tseem ceeb:

Sequential lamination:

Sequential lamination yog ib qho kev siv thev naus laus zis hauv kev tsim khoom nruj-flex board. Nyob rau hauv txoj kev no, cais cov txheej nruj thiab hloov tau yooj yim yog tsim nyias thiab tom qab ntawd laminated ua ke. Cov khaubncaws sab nraud povtseg feem ntau yog ua los ntawm FR4 los yog cov ntaub ntawv zoo sib xws, thaum cov khaubncaws sab nraud povtseg yog ua los ntawm polyimide los yog zoo sib xws substrates. Sequential lamination muab kev hloov pauv ntau dua hauv kev xaiv txheej thiab tuab, tso cai rau kev tswj xyuas ntau dua ntawm cov khoom siv hluav taws xob thiab cov khoom siv ntawm PCB. Dual Access Lamination:

Nyob rau hauv dual access lamination, vias yog drilled nyob rau hauv nruj thiab saj zawg zog khaubncaws sab nraud povtseg tso cai rau nkag mus rau ob sab ntawm PCB. Cov cuab yeej no muab kev yooj yim dua rau hauv qhov chaw tso khoom thiab cov kab khiav tawm. Nws kuj txhawb kev siv qhov muag tsis pom thiab faus vias, uas pab txo cov txheej txheem suav thiab txhim kho cov teeb liab kev ncaj ncees. Dual-channel lamination yog tshwj xeeb tshaj yog pab tau thaum tsim complex rigid-flex PCBs nrog ntau txheej thiab nruj qhov chaw txwv.

Z-axis conductive nplaum:

Z-axis conductive nplaum yog siv los tsim kev sib txuas hluav taws xob ntawm cov txheej txheem nruj thiab cov txheej txheem yooj yim hauv cov txheej txheem nruj-flex. Nws yog siv los ntawm cov ntaub qhwv cov ntaub qhwv rau ntawm cov txheej txheem hloov tau thiab cov ntaub qhwv zoo sib xws ntawm cov txheej nruj. Cov nplaum muaj cov khoom siv hluav taws xob uas tsim cov kab hluav taws xob thaum compressed ntawm cov khaubncaws sab nraud povtseg thaum lamination. Z-axis conductive nplaum muab ib qho kev sib txuas hluav taws xob txhim khu kev qha thaum tswj PCB yooj yooj yim thiab txhua yam kev ncaj ncees.

Hybrid stacking configuration:

Nyob rau hauv ib tug hybrid stacking configuration, ib tug ua ke ntawm nruj thiab saj zawg zog txheej yog siv los tsim ib tug customized txheej pawg. Qhov no ua rau cov neeg tsim qauv ua kom zoo dua PCB layout raws li cov kev cai tshwj xeeb ntawm tus tsim. Piv txwv li, cov khaubncaws sab nraud povtseg tuaj yeem siv los txhim kho cov khoom siv thiab muab cov khoom siv rigidity, thaum cov khaubncaws sab nraud povtseg tuaj yeem siv los ua cov cim qhia hauv thaj chaw uas yuav tsum tau hloov pauv. Hybrid stacking configurations muab cov neeg tsim qauv nrog cov qib siab ntawm kev yoog raws thiab kev kho kom haum rau cov qauv nruj-flex PCB.

Los ntawm kev siv cov txheej txheem tsim txheej txheem no, cov neeg tsim qauv tuaj yeem tsim cov PCB nruj-flex uas muaj zog thiab ua haujlwm zoo. Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum tau ua haujlwm ze nrog PCB cov chaw tsim khoom kom ntseeg tau tias cov cuab yeej xaiv tau sib xws nrog lawv cov peev txheej tsim khoom. Kev sib txuas lus ntawm pab pawg tsim thiab tsim khoom yog qhov tseem ceeb los daws cov teeb meem uas muaj peev xwm thiab ua kom muaj kev hloov pauv ntawm kev tsim mus rau ntau lawm. Nrog cov txheej txheem tsim txheej txheem tsim nyog, cov neeg tsim qauv tuaj yeem ua tiav qhov kev ua haujlwm hluav taws xob uas xav tau, kev ua haujlwm yooj yim thiab kev ntseeg siab hauv kev nruj-flex PCBs.

8.Rigid-flexible PCB lamination tshuab kev nce qib

Kev nce qib hauv kev nruj-flex PCB lamination tshuab tau ua kom muaj kev vam meej hauv ntau yam. Nov yog plaub qhov kev kawm tseem ceeb:

Material Innovation:

Kev nce qib hauv cov ntaub ntawv kev tshawb fawb tau ua kom yooj yim rau kev txhim kho cov khoom siv substrate tshiab tsim tshwj xeeb rau cov rooj zaum nruj-flex. Cov ntaub ntawv no muab kev yooj yim dua, durability, thiab tsis kam mus rau qhov kub thiab txias. Rau cov khaubncaws sab nraud povtseg, cov ntaub ntawv xws li polyimide thiab kua siv lead ua polymer (LCP) muab kev yooj yim heev thaum tswj cov khoom hluav taws xob. Rau cov khaubncaws sab nraud povtseg, cov ntaub ntawv xws li FR4 thiab high-temperature laminates tuaj yeem muab qhov tsim nyog rigidity thiab kev ntseeg tau. 3D luam tawm Circuits:

3D tshuab luam ntawv tau hloov pauv ntau qhov kev lag luam, suav nrog kev tsim PCB. Lub peev xwm los 3D luam tawm cov kab hluav taws xob ncaj qha mus rau qhov hloov pauv tau yooj yim tso cai rau kev tsim ntau yam thiab nyuaj PCB. Cov thev naus laus zis ua kom yooj yim prototyping sai thiab kho kom haum, tso cai rau cov neeg tsim qauv tsim cov qauv tsim tshwj xeeb thiab sib koom ua ke ncaj qha rau hauv cov txheej txheem yooj yim. Kev siv 3D luam tawm circuits hauv rigid-flex PCBs tsub kom tsim tau yooj yim thiab shortens txoj kev loj hlob.

Flexible Embedded Cheebtsam:

Lwm qhov kev nce qib loj hauv kev siv tshuab lamination yog kev sib koom ua ke ncaj qha ntawm cov khoom siv rau hauv cov txheej txheem hloov tau yooj yim ntawm ib qho nyuaj-flex PCB. Los ntawm embedding Cheebtsam xws li resistors, capacitors thiab txawm microcontrollers mus rau hauv hloov tau yooj yim substrates, designers yuav txo tau tag nrho cov PCB loj thiab txhim kho teeb liab kev ncaj ncees. Cov cuab yeej no ua rau muaj kev sib txuam ntau dua thiab hnav, ua rau nws zoo tagnrho rau kev siv nrog qhov chaw nruj.

High-speed teeb liab thaiv:

Raws li qhov kev thov rau kev sib txuas lus ceev txuas ntxiv mus ntxiv, kev nce qib hauv kev siv tshuab lamination ua kom muaj txiaj ntsig zoo ntawm cov teeb liab xaim hluav taws xob hauv PCBs nruj-hloov. Siv cov tswv yim zoo xws li kev tswj xyuas impedance routing, sib txawv khub routing, thiab microstrip lossis stripline tsim los tswj cov teeb liab kev ncaj ncees thiab txo cov teeb liab poob. Kev txiav txim siab tsim qauv kuj tseem xav txog qhov cuam tshuam ntawm kev sib txuas, kev sib tham sib tham, thiab cov teeb liab cuam tshuam. Kev siv cov khoom siv tshwj xeeb thiab cov txheej txheem tsim khoom pab ua kom tiav qhov kev ua tau zoo ntawm cov PCBs nruj-flex.

Kev nce qib ntxiv hauv kev siv tshuab tsis yooj yim-flex lamination ua rau muaj kev txhim kho ntau dua, hloov tau yooj yim, thiab cov khoom siv hluav taws xob puv. Kev nce qib hauv cov khoom siv tshiab, 3D luam tawm circuits, cov khoom siv tau yooj yim kos thiab cov teeb liab ceev ceev muab cov neeg tsim qauv nrog kev yooj yim dua thiab muaj peev xwm los tsim cov qauv tshiab thiab txhim khu kev qha rigid-flex PCB. Raws li kev siv thev naus laus zis txuas ntxiv mus, cov neeg tsim qauv thiab cov tuam txhab tsim khoom yuav tsum nyob twj ywm tshiab thiab ua haujlwm zoo ua ke kom tau txais txiaj ntsig zoo ntawm qhov kev nce qib tshiab thiab ua tiav qhov kev ua tau zoo ntawm PCB qhov kev ua tau zoo.

Hauv cov ntsiab lus,tsim thiab xaiv qhov raug nruj-flex PCB stackup configuration yog ib qho tseem ceeb rau kev ua tiav kev ua tau zoo, kev ntseeg tau, thiab yooj. Los ntawm kev txiav txim siab txog yam xws li teeb liab kev ncaj ncees, qhov yuav tsum tau ua kom yooj yim thiab kev txwv kev tsim khoom, cov neeg tsim khoom tuaj yeem hloov kho cov stackup kom tau raws li lawv cov kev xav tau tshwj xeeb. Kev nce qib tsis tu ncua hauv cov khoom siv thev naus laus zis muab kev cia siab dav rau kev tsim kho hluav taws xob zoo dua. Cov ntaub ntawv substrate tshiab tau tsim los rau cov PCBs nruj-flex txhim kho kev yooj yim, ua haujlwm ntev, thiab kub thiab noo noo tsis kam. Tsis tas li ntawd, kev sib koom ua ke ncaj qha rau hauv cov txheej txheem flex ntxiv txo qhov loj thiab qhov hnyav ntawm PCB, ua rau nws tsim nyog rau kev siv nrog qhov chaw nruj. Tsis tas li ntawd, kev nce qib hauv tshuab lamination muab cov sijhawm zoo siab. Kev siv 3D luam ntawv thev naus laus zis tuaj yeem ua kom muaj kev tsim ntau dua thiab ua kom yooj yim prototyping sai thiab kho kom haum.

Tsis tas li ntawd, kev nce qib hauv high-ceev teeb liab routing thev naus laus zis ua rau cov PCBs ruaj khov kom ua tiav kev sib txuas lus zoo thiab txhim khu kev qha.

Raws li thev naus laus zis txuas ntxiv mus, cov neeg tsim qauv yuav tsum nyob twj ywm ntawm qhov kev nce qib tshiab thiab ua haujlwm ze nrog cov tuam txhab tsim khoom. Los ntawm kev nce qib hauv cov khoom siv thiab kev tsim thev naus laus zis, cov neeg tsim qauv tuaj yeem tsim cov qauv tshiab thiab txhim khu kev qha rigid-flex PCB tsim kom tau raws li cov kev xav tau ntawm kev lag luam hluav taws xob niaj hnub hloov. Nrog cov lus cog tseg ntawm kev txhim kho cov khoom siv hluav taws xob, lub neej yav tom ntej ntawm rigid-flex PCB stackups zoo li cog lus.

Post lub sij hawm: Sep-12-2023

Rov qab