Dab tsi yog cov rigid-flex boards, thiab lawv puas tuaj yeem siv rau hauv cov ntawv siv hluav taws xob siab? Hauv phau ntawv qhia dav dav no, peb yuav tshawb nrhiav cov lus nug no thiab ua kom pom lub ntsiab lus ntawm lub ncauj lus.

Nyob rau hauv niaj hnub no qhov chaw ceev-paced thev naus laus zis, engineers thiab designers niaj hnub nrhiav cov kev daws teeb meem tshiab kom tau raws li qhov kev thov loj hlob ntxiv rau cov khoom siv hluav taws xob muaj zog thiab compact. Ib qho chaw uas qhov no tseem ceeb tshwj xeeb yog hauv kev siv hluav taws xob siab. Txhawm rau ua kom tau raws li cov teeb meem tshwm sim los ntawm cov kev xav tau no, ntau tus kws tshaj lij tau tig mus rau nruj-flex printed circuit boards (PCBs).

I. Nkag siab Rigid Flex PCBs:

A. Kev txhais ntawm rigid flex PCBs

Rigid-flex PCB yog hybrid ntawm ib txwm nruj PCB thiab hloov tau yooj yim PCB. Lawv muaj ntau txheej ntawm nruj thiab hloov tau yooj yim substrates interconnected los ntawm saj zawg zog conductive cov ntaub ntawv. Qhov kev tsim no tso cai rau PCB khoov thiab khoov yam tsis muaj kev cuam tshuam rau kev ncaj ncees ntawm kev sib txuas hauv hluav taws xob, muab kev ywj pheej tsim tshiab thiab ntau yam.

B. Qhov zoo thiab qhov tsis zoo ntawm flex flex PCBs

Qhov zoo ntawm rigid-flex board:

Qhov Chaw Ua Haujlwm Zoo: Rigid-flex PCBs ua rau cov neeg tsim qauv siv qhov chaw peb sab zoo vim tias lawv tuaj yeem khoov, quav lossis twist kom haum rau thaj chaw muaj. Txhim khu kev ntseeg tau zoo: Tsis tas yuav tsum muaj cov khoom sib txuas thiab cov kab sib txuas sib txuas, txo qhov muaj peev xwm ntawm cov tshuab tsis ua haujlwm thiab cov teeb liab poob. Rigid-flex PCBs kuj tseem tiv taus kev co, kev poob siab, thiab kub hloov pauv. Txhim kho cov teeb liab kev ncaj ncees: Los ntawm kev txo cov kev sib tshuam thiab kev sib kis txoj kev luv luv, nruj-flex PCBs txo cov teeb liab distortion, ua kom muaj kev ua tau zoo dua thiab kev ntseeg tau ntawm lub cev. Kev sib dhos yooj yim: Rigid-flex PCBs tshem tawm qhov xav tau ntawm cov txheej txheem sib dhos nyuaj los ntawm kev tshem tawm qhov xav tau ntawm cov khoom sib txuas thiab cov pob qij txha, txo qhov kev pheej hmoo ntawm tib neeg kev ua yuam kev thiab txuag lub sijhawm thaum lub sijhawm tsim khoom. Tus Nqi-Kev Ua Tau Zoo: Txawm hais tias kim dua li cov PCBs ib txwm muaj, cov PCB nruj-flex tuaj yeem txuag tau cov nqi los ntawm kev txo cov khoom suav thiab tshem tawm qhov xav tau rau cov cables ntxiv thiab cov khoom sib txuas.

Disadvantages ntawm rigid-flex board:

Cov qauv tsim tsis yooj yim: Kev tsim qauv nruj-flex PCBs yuav tsum muaj kev paub tshwj xeeb thiab kev txawj ntse vim yog kev sib xyaw ntawm cov ntaub ntawv nruj thiab hloov tau yooj yim. Qhov kev nyuaj no tuaj yeem ua rau lub sijhawm txhim kho ntxiv thiab tus nqi tsim qauv ntau dua. Tus nqi pib: Tus nqi pib ntawm kev txhim kho PCB rigid-flex tuaj yeem siab dua li ib txwm siv PCB, ua rau nws tsis tsim nyog rau cov khoom ntim qis lossis cov haujlwm uas muaj peev nyiaj tsawg. Reworkability txwv tsis pub dhau: Thaum lub rigid-flex PCB tau sib sau ua ke, nws yog qhov nyuaj rau kev hloov kho lossis kho vim tias qhov hloov pauv tau yooj yim heev thiab nkag siab rau cov kev hloov pauv.

C. Daim ntawv thov ntawm rigid flex PCBs

Rigid-flex boards yog dav siv nyob rau hauv ntau yam lag luam, xws li: Aerospace thiab Defense: Rigid-flex PCBs yog qhov zoo tagnrho rau kev siv dav hlau thiab kev tiv thaiv vim lawv muaj peev xwm tiv taus huab cua thiab muaj kev ntseeg siab. Lawv siv nyob rau hauv avionics systems, radars, satellites thiab cov khoom siv tub rog. Cov Khoom Siv Kho Mob: Rigid-flex PCBs tau siv ntau dua hauv cov khoom siv kho mob vim lawv qhov yooj yim thiab cov qauv sib txuam. Lawv yog siv nyob rau hauv pacemakers, implants, kho mob imaging systems thiab wearable Health saib xyuas cov cuab yeej. Consumer Electronics: Cov neeg siv khoom siv hluav taws xob ua lag luam tau txais txiaj ntsig los ntawm nruj-flex PCBs hauv cov khoom siv xws li smartphones, ntsiav tshuaj, game consoles, thiab wearables. Cov PCBs no pab tsim cov qauv me me thiab txhim kho kev ua haujlwm. Automotive kev lag luam: Rigid-flex PCB yog tsim rau automotive electronics, nrog rau advanced driver help systems (ADAS), infotainment systems, powertrains thiab teeb pom kev zoo systems. Lawv muab kev cia siab rau thiab qhov chaw optimization nyob rau hauv hnyav automotive ib puag ncig.

2.Maximizing lub peev xwm ntawm rigid-flex PCBs nyob rau hauv high-power applications: Cov ntsiab lus tseem ceeb:

2.1.Power yuav tsum tau thiab txwv:

A. Nkag siab txog cov kev xav tau ntawm lub hwj chim: Ua ntej tsim lub rigid-flex PCB rau kev siv hluav taws xob siab, lub zog yuav tsum tau txhais kom meej. Txiav txim siab qhov voltage, tam sim no thiab lub hwj chim theem ntawm PCB yuav tsum tau ua, coj mus rau hauv tus account ncov thiab ua haujlwm tas mus li.

B. Xav txog kev txwv lub zog: Rigid-flex PCBs muaj qhov tshwj xeeb lub zog siab tshaj plaws uas yuav tsum tau xav txog thaum lub sijhawm tsim. PCB overloading tuaj yeem ua rau overheating, voltage poob, thiab muaj peev xwm puas tsuaj rau cov khoom. Tshawb xyuas cov kev txwv fais fab uas muab los ntawm cov chaw tsim khoom thiab xyuas kom tus qauv tsim muaj raws li cov lus qhia no.

2.2.Heat dissipation considerations:

A. Txheeb xyuas cov khoom siv cua sov: Hauv kev siv hluav taws xob siab, qee yam khoom tuaj yeem tsim kom muaj cua sov ntau. Txheeb xyuas cov khoom no thiab txiav txim siab lawv qhov chaw nyob ntawm qhov nruj-flex PCB. Ua ke lawv los tsom rau kev ua kom txias thiab ua kom muaj kev ua kom zoo tshaj plaws.

B. Ua raws li cov txheej txheem kev tswj xyuas thermal zoo: Thermal dissipation yog qhov tseem ceeb rau kev tswj xyuas kev ua tau zoo thiab kev ntseeg siab hauv kev siv hluav taws xob siab. Muab cov thermal vias, cov dab dej kub, thiab cov thermal pads rau hauv PCB tsim los txhim kho cov cua sov. Tsis tas li ntawd, yog tias tsim nyog, xav txog kev siv cov txheej txheem txias txias, xws li kev ua kom txias nrog cov kiv cua lossis ua kua txias. peb.

2.3.Kev xaiv thiab muab tso rau hauv:

A. Xaiv cov khoom tsim nyog: Xaiv cov khoom siv nrog lub peev xwm tuav lub zog tsim nyog yog qhov tseem ceeb rau kev ua tiav ntawm kev siv hluav taws xob siab. Xaiv cov khoom tsim thiab ntsuas rau kev siv lub zog siab. Xav txog lawv qhov ntsuas kub, qhov muaj peev xwm nqa tau tam sim no, thiab qhov txwv tsis pub muaj hluav taws xob kom ntseeg tau tias lawv tuaj yeem tswj tau qhov yuav tsum tau muaj zog.

B. Optimize tivthaiv kev npaj: Cov kev npaj ntawm cov khoom nyob rau hauv ib tug nruj-flex PCB muaj peev xwm ho cuam tshuam nws cov kev ua tau zoo thiab kub dissipation peev xwm. Sib sau cov khoom siv hluav taws xob siab ua ke kom muaj chaw txaus rau cov cua sov dissipation. Tsis tas li ntawd, xav txog qhov sib thooj sib thooj kom txo cov teeb liab cuam tshuam thiab txhim kho hluav taws xob ua haujlwm zoo.

2.4.Mechanical durability thiab kev ntseeg siab:

A. Xaiv cov ntaub ntawv Rugged: Cov ntawv siv hluav taws xob muaj zog feem ntau cuam tshuam nrog ib puag ncig hnyav, kev vibrations, thiab cov neeg kho tshuab kev nyuaj siab. Xaiv cov ntaub ntawv nruj thiab hloov tau yooj yim nrog cov cuab yeej tsim nyog kom ntseeg tau tias PCB kav ntev thiab kev ntseeg tau. Xav txog cov khoom siv ruaj khov, yoog raws thiab ua haujlwm rau cov dej noo, tshuaj lom neeg thiab kub hloov pauv.

B. Txhim kho qhov chaw hloov tau yooj yim: Hauv qhov nruj-flex PCB, qhov hloov pauv tau yooj yim rau cov neeg kho tshuab kev ntxhov siab thiab qaug zog. Txhim kho cov cheeb tsam no nrog cov txheej tooj liab ntxiv lossis polyimide npog kom lawv lub zog muaj zog thiab txuas ntxiv lub neej ntawm PCB.

3.Cov txiaj ntsig ntawm Kev Siv Rigid Flex PCBs rau Kev Siv Hluav Taws Xob

A. Txhim kho teeb liab kev ncaj ncees

Rigid-flex PCBs ho txhim kho cov teeb liab kev ncaj ncees, yog li txhim kho kev ua tau zoo ntawm kev siv hluav taws xob siab. Los ntawm kev tswj hwm impedance zoo dua, cov teeb liab poob tuaj yeem txo qis, ua rau muaj kev ntseeg siab, muaj txiaj ntsig teeb liab kis tau tus mob. Kev siv cov ntu tsis sib xws yuav pab txo qhov tshwm sim ntawm cov teeb liab cuam tshuam los ntawm kev vibration thiab mechanical stress, kom ntseeg tau tias kev ua haujlwm zoo ib yam.

B. Txhim kho thermal tswj

Thermal dissipation yog qhov tseem ceeb hauv kev siv hluav taws xob siab, vim tias cov cua sov ntau dhau tuaj yeem ua rau kev ua haujlwm tsis zoo thiab txawm tias ua rau cov khoom tsis zoo rov qab los. Rigid-flex PCBs muaj peev xwm tswj tau thermal zoo, muab txoj hauv kev ua kom sov tau zoo thiab txo qis kev ntxhov siab. Los ntawm kev siv cov ntaub ntawv zoo thermal conductivity thiab ua tib zoo muab tso rau hauv thermal vias thiab cov dab dej kub, cov PCBs ua kom pom cov cua sov dissipation, ua kom muaj kev ntseeg siab thiab txuas ntxiv nws txoj sia.

C. Muaj peev xwm txuag chaw

Raws li qhov kev thov rau kev sib cog lus, kev siv hluav taws xob zoo txuas ntxiv mus, kev muaj peev xwm txuag tau qhov chaw tau dhau los ua ib qho tseem ceeb ntawm PCB tsim. Rigid-flex PCBs ua tau zoo hauv cheeb tsam no, txhawb kev tsim qauv peb sab thiab ua kom muaj txiaj ntsig zoo ntawm qhov chaw muaj. Tshem tawm cov khoom sib txuas thiab kev sib txuas sib txuas txo qhov loj thiab qhov hnyav, uas yog qhov tshwj xeeb tshaj yog muaj txiaj ntsig hauv kev siv hluav taws xob siab uas qhov chaw txwv.

D. Txhim kho txhua yam yooj

Txhim kho cov neeg kho tshuab hloov tau yooj yim: Lwm qhov zoo ntawm cov tawv-flex PCBs yog lawv cov kev hloov kho zoo heev. Kev sib xyaw ua ke ntawm cov khoom nruj thiab hloov tau yooj yim tso cai rau lawv hloov mus rau cov duab tsis sib xws, khoov thiab nkhaus, ua rau lawv zoo tagnrho rau cov ntawv thov uas xav tau cov qauv tsim thiab cov qauv tsim. Qhov kev hloov pauv no tseem ua rau lawv ua rau lawv tsis kam rau cov neeg kho tshuab kev ntxhov siab, kev co thiab kev poob siab, ua kom ntseeg tau tias muaj kev ua haujlwm zoo hauv qhov chaw hnyav.

E. Muaj peev xwm tsim tau

Rigid-flex PCBs qhib lub ntiaj teb ntawm kev muaj peev xwm ntawm kev tsim qauv yooj yim. Cov neeg tsim khoom muaj kev ywj pheej los koom ua ke ntau yam khoom siv thiab ua kom zoo dua lawv cov txheej txheem los txhim kho kev ua haujlwm hluav taws xob. Lub peev xwm los hloov kho PCB layout raws li cov ntawv thov tshwj xeeb yuav ua rau muaj kev ua haujlwm zoo thiab ua haujlwm ntawm tag nrho. Qhov kev hloov pauv no ua rau muaj txiaj ntsig tshwj xeeb hauv kev siv hluav taws xob siab, qhov twg qhov chaw txwv thiab kev tsim qauv tsis yooj yim feem ntau ua rau muaj teeb meem loj.

4.A Guide to Mastering High-Power Rigid-Flex PCB Design: Txoj Kev Ua Kom Zoo Qhia:

A. Tsim nyog kab dav thiab qhov sib nrug:

Ib qho kev txiav txim siab tseem ceeb hauv kev tsim lub zog siab-rigid-flex PCBs yog ua kom muaj qhov dav txaus thiab qhov sib txawv. Cov kab dav dav ua kom muaj txiaj ntsig zoo tam sim no thiab txo qis kev tiv thaiv, txo qhov kev pheej hmoo ntawm overheating thiab ua kom pom kev ua haujlwm zoo. Kev sib nrug kom zoo ntawm cov cim yuav pab tiv thaiv kev sib tham sib tham thiab cuam tshuam thiab tswj cov teeb liab kev ncaj ncees. Ua raws li cov qauv kev lag luam rau cov kab dav dav thiab qhov sib txawv yog qhov tseem ceeb rau kev ua kom muaj kev nyab xeeb, kev cia siab, thiab kev ruaj ntseg ntawm kev siv hluav taws xob siab.

B. Txheej txheej txheej txheej thiab xaiv cov khoom siv:

Txheej txheej txheej thiab xaiv cov khoom muaj feem cuam tshuam rau kev ua tau zoo thiab ua haujlwm ntev ntawm lub zog siab-rigid-flex PCBs. Cov txheej txheej txaus txaus ua rau muaj kev faib hluav taws xob zoo thiab cov teeb liab kis tau tus mob thaum txo cov suab nrov cuam tshuam. Ua tib zoo xaiv cov ntaub ntawv zoo, xws li cov laminates zoo thiab cov ntawv ci tooj liab nrog cov thermal conductivity zoo, tuaj yeem pab txhim kho cov cua sov thiab kev ntseeg tau tag nrho.

C. Cheebtsam muab tso rau thiab routing xav txog:

Kev ua haujlwm tau zoo ntawm kev tso kawm thiab kev ua haujlwm yog qhov tseem ceeb rau kev ua haujlwm zoo ntawm lub zog siab nruj-flex PCBs. Qhov kev tso kawm zoo tshaj plaws txo cov teeb liab txoj kev ntev, txo qis voltage thiab txhim kho cov teeb liab zoo. Thaum tsim PCBs rau kev siv hluav taws xob siab, nws yog ib qho tseem ceeb kom nkag siab txog cov yam ntxwv thermal ntawm cov khoom. Cov txheej txheem routing kom raug, xws li zam kev khoov ntse thiab siv cov khub sib txawv thaum tsim nyog, tuaj yeem pab tswj cov suab nrov thiab ua kom muaj kev ncaj ncees.

D. Thermal tswj cov txheej txheem:

Thermal tswj yog qhov tseem ceeb rau kev tiv thaiv overheating thiab tswj kev ruaj ntseg ntawm high-power rigid-flex PCBs. Kev koom ua ke nrog cov thev naus laus zis xws li thermal vias, cov dab dej kub thiab siv cov khoom siv tooj liab zoo pab kom cov cua sov thiab tiv thaiv cov khoom kom tsis txhob ncav cuag qhov kub thiab txias. Nws yog ib qho tseem ceeb uas yuav tsum xav txog cov yam ntxwv ntawm cov khoom siv thermal thiab cov khoom siv thaum lub sij hawm tsim qauv kom muaj qhov cua kom zoo thiab ua kom muaj cua sov kom zoo, yog li txuas lub neej ntawm PCB.

E. Ua raws li cov qauv kev nyab xeeb:

Hauv kev siv hluav taws xob siab, kev nyab xeeb yog qhov tseem ceeb thiab ua kom ua raws li cov qauv kev nyab xeeb tseem ceeb yog qhov tseem ceeb. Ua raws li cov qauv xws li UL, IEC, thiab IPC ua kom ntseeg tau tias PCB tsim tau raws li kev lag luam uas yuav tsum tau muaj rau hluav taws xob rwb thaiv tsev, nplaim taws, thiab tiv thaiv kev phom sij. Ua raws li cov qauv kev nyab xeeb ua kom muaj kev ntseeg siab thiab kev ncaj ncees ntawm lub zog siab-rigid-flex PCBs, ua kom muaj kev nyab xeeb rau cov neeg siv kawg.

5.Yuav ua li cas nruj-flex PCBs yog revolutionizing high-power applications:

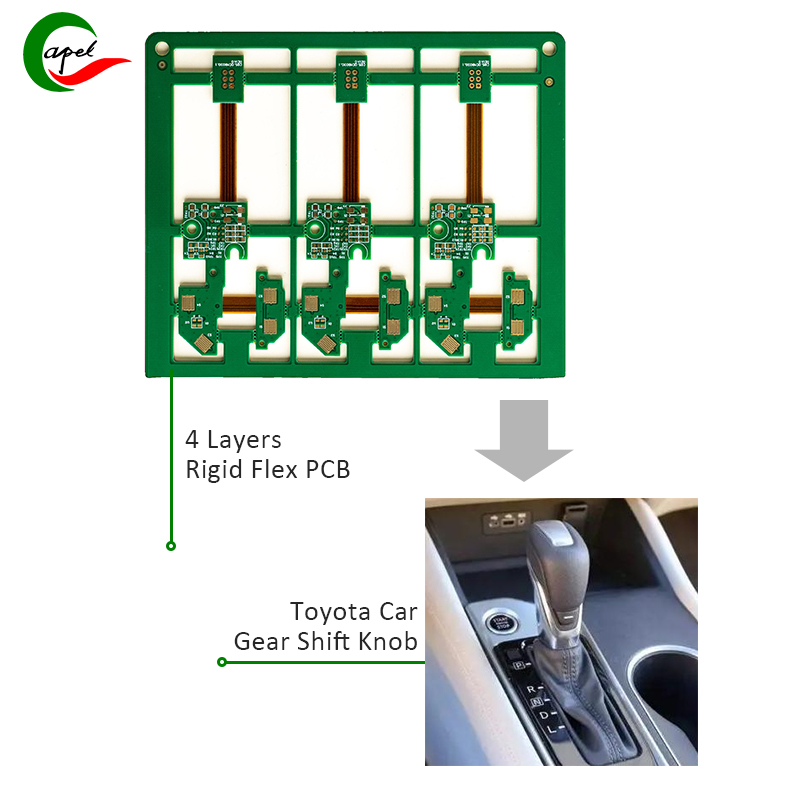

A. Piv txwv 1: Automotive kev lag luam:

Kev lag luam automotive yog nyob rau hauv pem hauv ntej ntawm innovation, tas li thawb ciam teb los txhim kho tsheb kev ua tau zoo, kev nyab xeeb thiab kev ua haujlwm zoo. Rigid-flex PCBs tau ua lub luag haujlwm tseem ceeb hauv kev hloov pauv ntawm daim teb no, txhawb kev txhim kho cov tshuab hluav taws xob siab heev. Hauv kev siv hluav taws xob hluav taws xob loj xws li tsheb hluav taws xob (EVs), rigid-flex PCBs ua rau txoj hauv kev rau kev txhim kho lub zog, kev tsim qauv tsim thiab kev ntseeg siab tsis sib xws. Lawv qhov yooj yooj yim ua rau muaj kev sib txuam tsis sib haum rau hauv qhov chaw txwv, tshem tawm qhov xav tau ntawm cov hlua hlau loj thiab txo qhov hnyav. Rigid-flex PCBs revolutionize roj teeb tswj systems, lub cev muaj zog tswj units thiab lwm yam tseem ceeb Cheebtsam, xyuas kom meej lub hwj chim faib, ua kom ntev kev tsav tsheb ntau thiab txhim kho tag nrho cov tsheb ua tau zoo - teeb tsa cov qauv tshiab rau kev lag luam tsheb.

B. Piv txwv 2: Aerospace thiab tiv thaiv kev lag luam:

Hauv kev lag luam aerospace thiab kev tiv thaiv, precision, durability thiab kev ntseeg siab yog qhov tseem ceeb. Rigid-flex PCBs tau ua pov thawj los ua ib qho kev hloov pauv hauv kev ua kom tau raws li qhov yuav tsum tau muaj zog ntawm kev siv hluav taws xob siab hauv daim teb no. Aerospace systems, xws li davhlau tswj systems, avionics thiab kev sib txuas lus systems, yuav tsum tau rugged thiab resilient hluav taws xob Cheebtsam tiv thaiv huab cua. Rigid-flex PCBs muab cov khoom siv tsis sib xws vim yog kev sib xyaw ua ke ntawm cov txheej txheem nruj thiab hloov tau yooj yim, tso cai rau lawv tiv taus kev co, poob siab, thiab kub hloov yam tsis muaj kev cuam tshuam kev ua haujlwm. Tsis tas li ntawd, nws daim ntawv compact thiab txo qhov hnyav pab txhawb kev txhim kho roj efficiency thiab muaj peev xwm ntxiv load. Los ntawm kev txais yuav nruj-flex PCBs, kev lag luam aerospace thiab kev tiv thaiv kev lag luam tau ua rau muaj kev nce qib tseem ceeb hauv kev siv lub luag haujlwm tseem ceeb, txhim kho kev ua tau zoo thiab ua kom muaj kev ntseeg siab tsis tu ncua.

C. Piv txwv 3: Kev siv hluav taws xob tauj dua tshiab:

Kev lag luam hluav taws xob tauj dua tshiab tau ntsib txoj kev sib tw ntawm kev siv hluav taws xob thiab xa hluav taws xob zoo los ntawm cov khoom siv txuas ntxiv xws li hnub ci thiab cua. Rigid-flex PCBs tau dhau los ua ib feem tseem ceeb ntawm kev lag luam, tsav kev tsim kho tshiab thiab ua kom muaj kev sib txuam ntawm cov khoom siv hluav taws xob nyuaj. Hnub ci inverters, ntse kab sib chaws thiab cua turbine tswj tag nrho cia siab rau lub zog muaj peev xwm thiab kav ntev ntawm rigid-flex PCBs. Lawv muaj peev xwm tiv taus ib puag ncig hnyav, ua ke nrog cov khoom siv thermal zoo, ua kom ntseeg tau kev ua haujlwm thiab ua haujlwm ntev dua. Rigid-flexible PCBs pab txhim kho tag nrho cov kev ua tau zoo ntawm cov tshuab hluav taws xob tauj dua tshiab, ua kom lub zog hloov pauv hloov pauv, ntse saib xyuas thiab siv tau zoo ntawm lub zog ruaj khov.

6.Overcoming cov kev cov nyom thiab txo cov kev pheej hmoo nyob rau hauv high-power applications nrog rigid-flex PCBs:

A. Cov nqe lus them nqi:

Tus nqi yog ib qho tseem ceeb uas cov neeg txiav txim siab yuav tsum tau ntsuas thaum txiav txim siab nruj-flex PCBs rau kev siv hluav taws xob siab. Piv nrog rau cov tsoos PCBs nruj, rigid-flex PCBs zoo li yuav kim dua vim yog cov qauv tsim ntxiv, cov khoom siv, thiab kev tsim khoom nyuaj. Kev sib xyaw ua ke nruj thiab yoog raws cov khoom yuav tsum tau ua tiav engineering thiab cov txheej txheem nyuaj, ua rau cov nqi tsim khoom ntau dua. Txawm li cas los xij, nws yuav tsum raug saib raws li kev nqis peev ntau dua li qhov kev txwv. Tus nqi ntawm kev siv rigid-flex PCBs tuaj yeem tsim nyog los ntawm ntau cov txiaj ntsig uas nws coj, xws li kev txhim kho kev ntseeg tau, txo qhov hnyav, qhov chaw txuag, thiab txhim khu kev ruaj ntseg. Los ntawm kev nkag siab txog cov txiaj ntsig mus sij hawm ntev thiab ua qhov kev ntsuam xyuas tus nqi-cov txiaj ntsig zoo, cov tuam txhab tuaj yeem txiav txim siab paub thiab ua kom rov qab los ntawm kev nqis peev thaum sib koom ua ke nruj-flex PCBs rau hauv kev siv hluav taws xob siab.

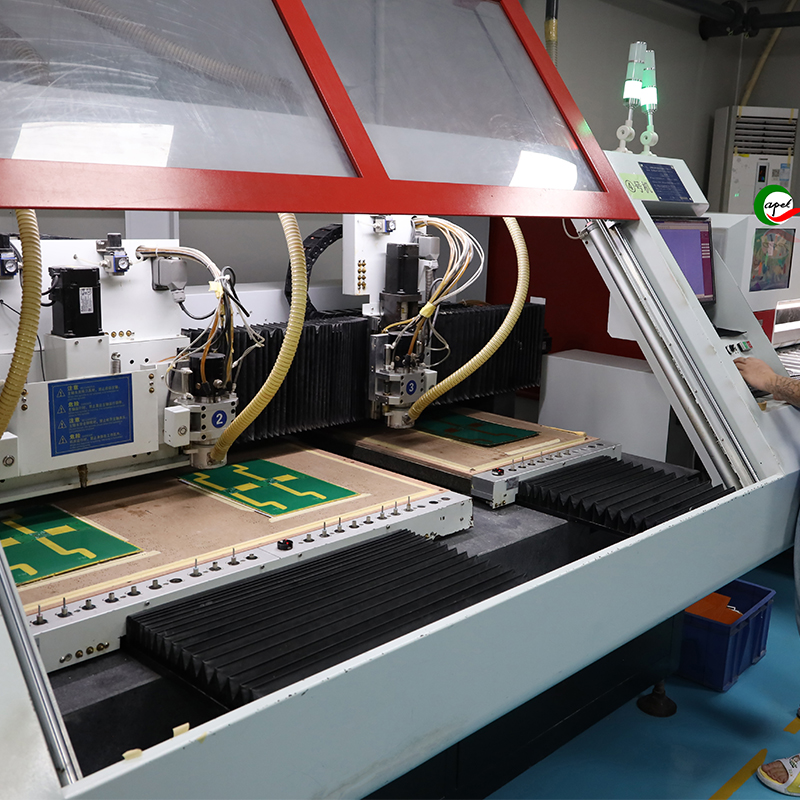

B. Manufacturing complexities:

Kev tsim cov rigid-flex PCBsrau cov ntawv siv hluav taws xob siab nthuav qhia cov kev sib tw tshwj xeeb vim lawv cov qauv tsim thiab xav tau tshwj xeeb. Kev sib koom ua ke ntawm cov khoom tsis sib xws thiab hloov tau yooj yim yuav tsum muaj cov txheej txheem tsim khoom thiab cov cuab yeej tshwj xeeb. Kev sib raug zoo ntawm cov khaubncaws sab nraud povtseg, kom ntseeg tau tias muaj kev sib txuas ntawm hluav taws xob, thiab kev tswj xyuas lub zog ntawm lub tshuab hluav taws xob thoob plaws hauv lub neej ntawm lub rooj tsavxwm Circuit Court yuav tsum tau ua tib zoo saib xyuas kom meej. Cov neeg tsim khoom yuav tsum tau nqis peev rau hauv cov tshuab siab heev, ntiav cov kws tshaj lij thiab siv cov kev tswj xyuas nruj kom txo tau cov kev pheej hmoo hauv cov txheej txheem tsim khoom. Ua haujlwm nrog kev paub dhau los thiab muaj npe nrov rigid-flex PCB cov chaw tsim khoom yog qhov tseem ceeb los ua kom muaj kev ua tiav ntawm kev siv hluav taws xob siab. Los ntawm kev siv cov kev txawj ntse ntawm cov tuam txhab tsim khoom no, cov tuam txhab tuaj yeem txo qis kev tsim khoom thiab ua kom cov khoom xa khoom zoo thiab cov khoom zoo.

C. Txwv tsis pub muaj cov neeg muab khoom tshwj xeeb:

Lwm qhov kev sib tw thaum siv rigid-flex PCBs rau kev siv hluav taws xob siab yog qhov txwv ntawm cov neeg muag khoom tshwj xeeb. Cov txheej txheem nyuaj thiab cov txheej txheem tsim khoom nyuaj tau tiv thaiv ntau lub tuam txhab PCB los ntawm kev nkag mus rau hauv lub lag luam niche. Yog li ntawd, nrhiav kev ntseeg siab thiab paub cov neeg xa khoom tuaj yeem nyuaj. Ua hauj lwm nrog tus neeg muag khoom uas muaj peev xwm ua tau zoo hauv kev siv tshuab nruj-flex PCB yog qhov tseem ceeb rau kev nkag mus rau cov ntaub ntawv zoo, kev txawj ntse hauv kev lag luam thiab kev txhawb nqa. Ua haujlwm ze nrog cov neeg muab khoom tshwj xeeb no pab txo cov kev pheej hmoo, ua kom cov khoom zoo thiab cov ntaub ntawv tau txais, thiab ua kom tag nrho cov txheej txheem tsim khoom. Kev tsim kom muaj kev sib raug zoo mus ntev nrog cov neeg muab kev ntseeg siab yog ib lub tswv yim zoo uas tsis yog tsuas yog txo cov kev txwv tsis pub muaj, tab sis kuj txhawb kev sib koom tes thiab kev tsim kho tshiab hauv kev lag luam siab zog.

Hauv Summary:

Rigid-flex PCBs yog qhov kev xaiv zoo tshaj plaws rau kev siv hluav taws xob siab. Lawv lub peev xwm los daws cov kev ntxhov siab thermal, compact loj thiab txhim khu kev ntseeg siab ua rau lawv txhim khu kev qha, muaj txiaj ntsig zoo.Txawm li cas los xij, kev txiav txim siab tsim nyog thiab xaiv cov khoom siv yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo. Kev sab laj nrog cov kws tshaj lij PCB yog ib feem tseem ceeb ntawm cov txheej txheem.

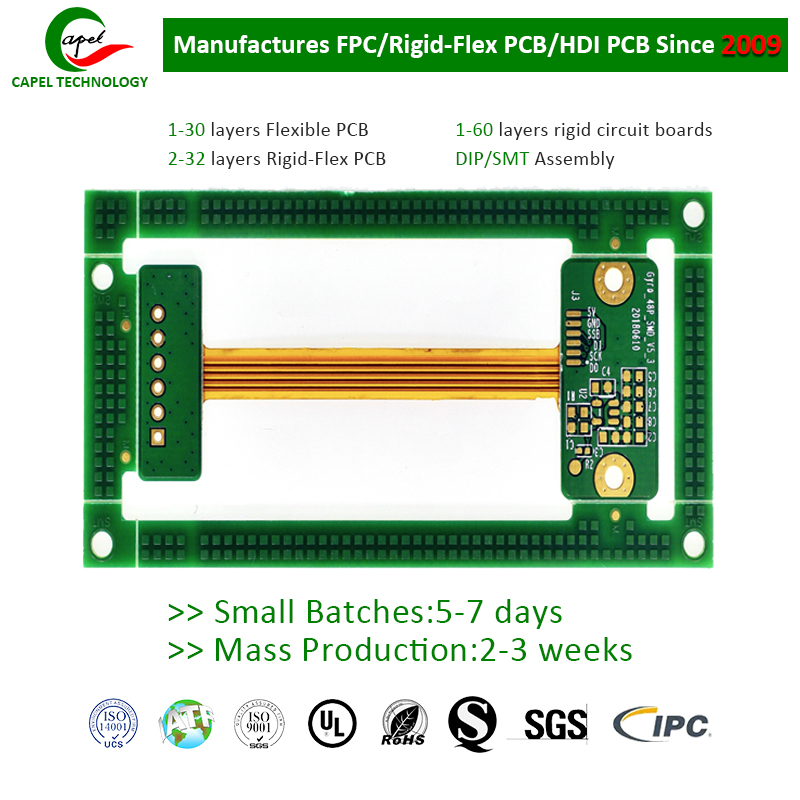

Yog tias koj tab tom nrhiav kev daws teeb meem rau koj cov kev xav tau ntawm lub zog siab, xav txog kev tshawb nrhiav cov txiaj ntsig ntawm rigid-flex PCB thev naus laus zis. Nrog lawv cov kev tsim tshwj xeeb thiab kev ua haujlwm, cov laug cam no tuaj yeem pab koj ua tau raws li cov kev xav tau ntawm lub ntiaj teb kev hloov pauv hluav taws xob puas tau.-Capel nrog 15 xyoo ntawm kev tshaj lij kev paub dhau los hauv Rigid Flexible PCB kev lag luam.

Post lub sij hawm: Sep-16-2023

Rov qab