Thaum FPC lub rooj tsav xwm hloov tau yooj yim yog khoov, hom kev ntxhov siab ntawm ob sab ntawm cov tub ntxhais kab sib txawv.

Qhov no yog vim muaj zog sib txawv ua rau sab hauv thiab sab nraud ntawm qhov nkhaus.

Nyob rau sab hauv ntawm lub ntsej muag nkhaus, FPC raug kev nyuaj siab. Qhov no yog vim hais tias cov khoom yog compressed thiab squeezed raws li nws khoov rau sab hauv. Qhov compression no tuaj yeem ua rau cov khaubncaws sab nraud povtseg hauv FPC yuav raug compressed, uas yuav ua rau delamination lossis tawg ntawm cov khoom.

Nyob rau sab nraud ntawm qhov nkhaus, FPC raug rau kev ntxhov siab tensile. Qhov no yog vim hais tias cov khoom yog stretched thaum nws yog khoov sab nraud. Cov kab tooj liab thiab cov khoom siv hluav taws xob ntawm cov chaw sab nraud tuaj yeem raug kev nruj nreem uas tuaj yeem cuam tshuam qhov kev ncaj ncees ntawm Circuit Court. Txhawm rau txo qhov kev ntxhov siab ntawm FPC thaum khoov, nws yog ib qho tseem ceeb uas yuav tsum tau tsim lub flex Circuit Court siv cov ntaub ntawv tsim nyog thiab cov txheej txheem tsim. Qhov no suav nrog kev siv cov ntaub ntawv uas tsim nyog hloov tau, tsim nyog thickness, thiab xav txog qhov tsawg kawg nkaus khoov vojvoog ntawm FPC. Kev txhawb nqa txaus lossis cov qauv txhawb nqa kuj tuaj yeem siv los faib kev ntxhov siab ntau sib npaug thoob plaws hauv Circuit Court.

Los ntawm kev nkag siab txog hom kev ntxhov siab thiab kev txiav txim siab tsim nyog, kev ntseeg tau thiab ua haujlwm ntev ntawm FPC hloov tau yooj yim Circuit Court boards thaum khoov lossis flexed tuaj yeem txhim kho.

Cov hauv qab no yog qee qhov kev txiav txim siab tsim tshwj xeeb uas tuaj yeem pab txhim kho qhov kev ntseeg tau thiab ua haujlwm ntev ntawm FPC hloov tau yooj yim Circuit Court boards thaum lawv khoov lossis flexed:

Kev xaiv khoom siv:Xaiv cov khoom tsim nyog yog qhov tseem ceeb. Ib qho yooj yim substrate nrog zoo saj zawg zog thiab mechanical zog yuav tsum tau siv. Flexible polyimide (PI) yog ib qho kev xaiv vim nws zoo heev thermal stability thiab yooj.

Circuit Court layout:Kev tsim hluav taws xob tsim nyog yog qhov tseem ceeb los xyuas kom meej tias cov kab hluav taws xob thiab cov khoom siv tau muab tso rau hauv ib txoj hauv kev uas txo cov kev ntxhov siab thaum lub sij hawm khoov. Nws raug nquahu kom siv cov ces kaum sib npaug es tsis txhob siv cov ces kaum ntse.

Kev txhawb zog thiab txhawb cov qauv:Ntxiv kev txhawb zog los yog kev txhawb nqa cov qauv raws qhov chaw khoov tseem ceeb tuaj yeem pab faib kev ntxhov siab ntau dua thiab tiv thaiv kev puas tsuaj lossis delamination. Cov khaubncaws sab nraud povtseg lossis cov ribs tuaj yeem siv rau cov chaw tshwj xeeb los txhim kho tag nrho cov neeg kho tshuab kev ncaj ncees.

Bending Radius:Yam tsawg kawg bending radii yuav tsum tau txhais thiab txiav txim siab thaum lub sij hawm tsim. Tshaj qhov qis qis qis qis yuav ua rau muaj kev ntxhov siab ntau dhau thiab ua tsis tiav.

Kev Tiv Thaiv thiab Encapsulation:Kev tiv thaiv xws li cov coatings conformal los yog cov ntaub ntawv encapsulation tuaj yeem muab cov khoom siv dag zog ntxiv thiab tiv thaiv circuits ntawm ib puag ncig xws li ya raws, plua plav, thiab tshuaj lom neeg.

Testing thiab validation:Kev ua tiav kev sim thiab kev siv tau, suav nrog kev kho tshuab khoov thiab kev sim flex, tuaj yeem pab ntsuas qhov kev ntseeg tau thiab ua haujlwm ntev ntawm FPC hloov pauv lub rooj tsav xwm hauv lub ntiaj teb tiag tiag.

Sab hauv ntawm qhov chaw nkhaus yog siab, thiab sab nraud yog tensile. Qhov loj ntawm kev ntxhov siab yog cuam tshuam nrog lub thickness thiab dabtsi yog khoov vojvoog ntawm FPC saj zawg zog pawg thawj coj saib. Kev ntxhov siab ntau dhau yuav ua rau FPC hloov pauv hauv Circuit Court board lamination, tooj liab foil tawg thiab lwm yam. Yog li ntawd, cov qauv lamination ntawm FPC hloov tau yooj yim Circuit Court board yuav tsum tau teem caij tsim nyog, thiaj li hais tias ob qhov kawg ntawm txoj kab nruab nrab ntawm qhov nkhaus ntawm qhov chaw yuav tsum sib luag kom deb li deb tau. Nyob rau tib lub sij hawm, qhov tsawg kawg nkaus khoov vojvoog yuav tsum tau xam raws li qhov sib txawv ntawm daim ntawv thov.

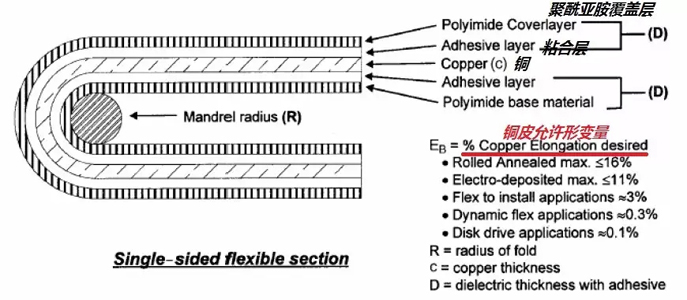

Qhov xwm txheej 1. Qhov tsawg kawg yog dabtsi yog khoov ntawm ib leeg-ib sab FPC hloov tau lub rooj tsavxwm yog qhia hauv daim duab hauv qab no:

Nws qhov tsawg kawg nkaus dabtsi yog khoov vojvoog tuaj yeem xam los ntawm cov qauv hauv qab no: R = (c/2) [(100-Eb) / Eb]-D

Qhov tsawg kawg nkaus dabtsi yog khoov vojvoog ntawm R =, lub thickness ntawm c = tooj liab daim tawv nqaij (unit m), lub thickness ntawm lub D = npog zaj duab xis (m), qhov tso cai deformation ntawm EB = tooj liab daim tawv nqaij (tseem los ntawm feem pua).

Lub deformation ntawm daim tawv nqaij tooj liab txawv nrog ntau hom tooj liab.

Qhov siab tshaj plaws deformation ntawm A thiab nias tooj liab yog tsawg dua 16%.

Qhov siab tshaj plaws deformation ntawm B thiab electrolytic tooj liab yog tsawg dua 11%.

Ntxiv mus, cov ntsiab lus tooj liab ntawm cov khoom siv tib yam kuj sib txawv hauv kev siv sib txawv. Rau ib qho kev khoov ib zaug, tus nqi txwv ntawm lub xeev tseem ceeb ntawm kev puas tsuaj yog siv (tus nqi yog 16%). Rau kev tsim kho khoov, siv qhov tsawg kawg nkaus deformation tus nqi teev los ntawm IPC-MF-150 (rau dov tooj liab, tus nqi yog 10%). Rau dynamic saj zawg zog daim ntaub ntawv, lub deformation ntawm tooj liab daim tawv nqaij yog 0.3%. Rau daim ntawv thov ntawm lub taub hau sib nqus, qhov deformation ntawm daim tawv nqaij yog 0.1%. Los ntawm kev teeb tsa qhov tso cai deformation ntawm daim tawv nqaij tooj liab, qhov tsawg kawg nkaus lub vojvoog ntawm curvature tuaj yeem suav tau.

Dynamic saj zawg zog: qhov tshwm sim ntawm daim tawv nqaij daim ntawv thov no yog pom tau los ntawm deformation. Piv txwv li, phosphor mos txwv nyob rau hauv daim npav IC yog ib feem ntawm daim npav IC tso rau hauv nti tom qab tso rau ntawm daim npav IC. Nyob rau hauv tus txheej txheem ntawm insertion, lub plhaub yog deformed tsis tu ncua. Daim ntawv thov scene no hloov tau thiab dynamic.

Qhov tsawg kawg nkaus dabtsi yog khoov vojvoog ntawm ib leeg-txhim kho PCB nyob ntawm ntau yam, nrog rau cov khoom siv, thickness ntawm lub rooj tsavxwm, thiab cov kev cai tshwj xeeb ntawm daim ntawv thov. Feem ntau, lub vojvoog khoov tau ntawm lub rooj tsavxwm flex yog li 10 npaug ntawm lub rooj tsavxwm. Piv txwv li, yog hais tias lub thickness ntawm lub rooj tsavxwm yog 0.1 hli, qhov tsawg kawg nkaus khoov vojvoog yog hais txog 1 hli. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias kev khoov lub rooj tsavxwm hauv qab qhov tsawg kawg nkaus khoov lub vojvoog yuav ua rau muaj kev ntxhov siab, ua rau muaj kev cuam tshuam ntawm cov kab hluav taws xob, thiab tejzaum nws tawg lossis delamination ntawm lub rooj tsavxwm. Yuav kom tswj tau qhov hluav taws xob thiab kev ua haujlwm zoo ntawm lub voj voog, nws yog ib qho tseem ceeb uas yuav tsum ua raws li qhov pom zoo khoov radii. Nws raug nquahu kom sab laj rau cov chaw tsim khoom lossis tus neeg muag khoom ntawm lub rooj tsavxwm hloov tau yooj yim rau cov lus qhia tshwj xeeb dabtsi yog khoov vojvoog thiab xyuas kom meej tias cov qauv tsim thiab daim ntawv thov tau ua tiav. Tsis tas li ntawd, ua qhov kev sim thiab kev siv tau zoo tuaj yeem pab txiav txim siab qhov siab tshaj plaws ntawm lub rooj tsavxwm tuaj yeem tiv taus yam tsis muaj kev cuam tshuam nws cov haujlwm thiab kev ntseeg tau.

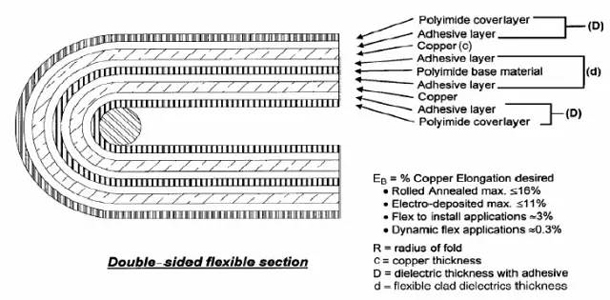

Qhov xwm txheej 2, ob-sided board ntawm FPC hloov tau lub rooj tsavxwm raws li hauv qab no:

Ntawm lawv: R = yam tsawg kawg nkaus dabtsi yog khoov vojvoog, unit m, c = tooj liab daim tawv nqaij thickness, unit m, D = kev pab them nqi zaj duab xis thickness, unit mm, EB = tooj liab daim tawv nqaij deformation, ntsuas los ntawm feem pua.

Tus nqi ntawm EB yog tib yam li hais saum toj no.

D = interlayer nruab nrab thickness, unit M

Qhov tsawg kawg nkaus dabtsi yog khoov vojvoog ntawm ob sab FPC (Flexible Printed Circuit) hloov tau yooj yim Circuit Court board feem ntau yog ntau dua li ntawm ib sab vaj huam sib luag. Qhov no yog vim ob tog vaj huam sib luag muaj cov kab hluav taws xob ntawm ob sab, uas muaj kev cuam tshuam ntau dua rau kev ntxhov siab thiab kev nyuaj siab thaum khoov. Qhov tsawg kawg nkaus khoov vojvoog ntawm ob sab FPC flex pcb baord feem ntau yog li 20 npaug ntawm lub thickness ntawm lub rooj tsavxwm. Siv tib yam piv txwv li ua ntej, yog tias lub phaj yog 0.1 hli tuab, qhov tsawg kawg nkaus khoov vojvoog yog li 2 hli. Nws yog ib qho tseem ceeb heev uas yuav tau ua raws li cov chaw tsim khoom cov lus qhia thiab cov lus qhia tshwj xeeb rau kev khoov ob sab FPC pcb boards. Tshaj qhov kev pom zoo khoov lub vojvoog yuav ua rau cov kab hluav taws xob puas, ua rau cov txheej txheem delamination, lossis ua rau lwm yam teeb meem uas cuam tshuam rau kev ua haujlwm hauv Circuit Court thiab kev ntseeg tau. Nws raug nquahu kom sab laj rau cov chaw tsim khoom lossis cov chaw muag khoom rau cov lus qhia tshwj xeeb khoov lub vojvoog, thiab ua qhov kev sim thiab kev tshuaj xyuas kom ntseeg tau tias lub rooj tsavxwm tuaj yeem tiv taus qhov yuav tsum tau khoov yam tsis muaj kev cuam tshuam nws qhov kev ua tau zoo.

Post lub sij hawm: Jun-12-2023

Rov qab