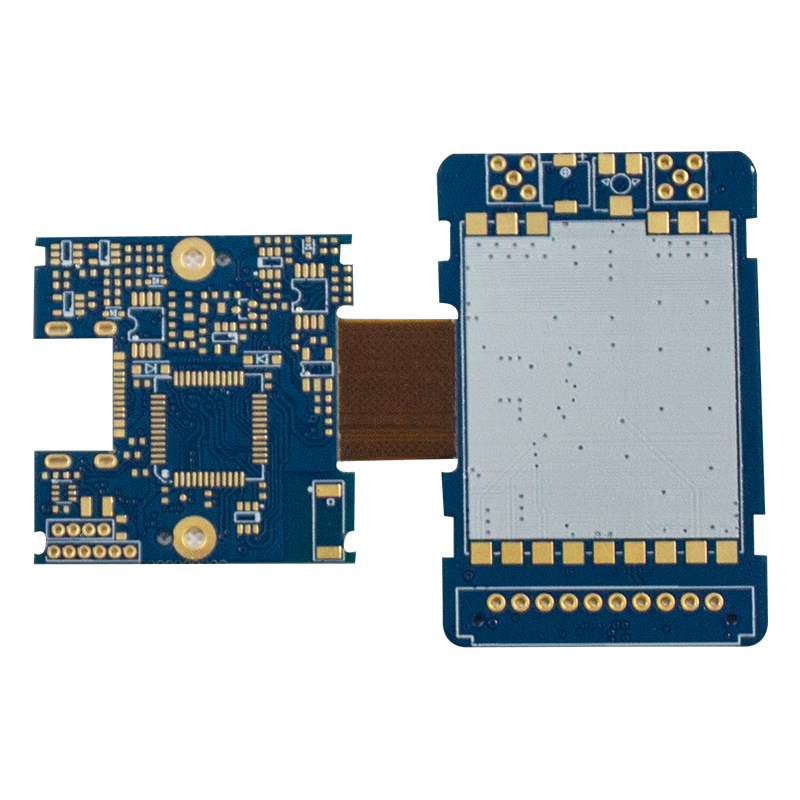

Hauv lub ntiaj teb ntawm cov ntawv luam tawm Circuit Board (PCBs), kev xaiv cov khoom siv thiab cov txheej txheem tsim khoom tuaj yeem cuam tshuam rau qhov zoo thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. Ib qho piv txwv zoo li no yog cov kub kub PCB, uas muaj qhov tshwj xeeb zoo dua li cov qauv PCBs.Ntawm no peb lub hom phiaj los muab kev nkag siab zoo ntawm cov tuab kub PCB, piav qhia nws cov ntsiab lus, qhov zoo, thiab qhov sib txawv ntawm cov khoom siv PCBs.

1.Kev nkag siab tuab kub PCB

Thick kub PCB yog ib hom tshwj xeeb ntawm lub rooj tsav xwm luam tawm uas muaj cov txheej kub kub ntawm nws qhov chaw.Lawv yog tsim los ntawm ntau txheej ntawm tooj liab thiab dielectric cov ntaub ntawv nrog ib tug kub txheej ntxiv rau saum. Cov PCBs no yog tsim los ntawm cov txheej txheem electroplating uas ua kom cov txheej kub yog sib npaug thiab ruaj khov. Kub thickness ntawm tus qauv PCB feem ntau yog hais txog 1-2 micro inches los yog 0.025-0.05 microns. Nyob rau hauv kev sib piv, tuab kub PCBs feem ntau muaj ib tug kub txheej thickness ntawm 30-120 micro inches los yog 0.75-3 microns.

2.Qhov zoo ntawm tuab kub PCB

Cov kub kub PCBs muaj ntau yam zoo dua li cov qauv kev xaiv, suav nrog kev txhim kho durability, txhim kho conductivity thiab kev ua tau zoo dua.

Durability:

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm cov kub kub PCBs yog lawv qhov tshwj xeeb ruaj khov. Cov boards no tau tsim tshwj xeeb los tiv thaiv ib puag ncig hnyav, ua rau lawv zoo tagnrho rau cov ntawv thov uas nquag raug rau qhov kub thiab txias lossis hnyav hnyav. Lub thickness ntawm cov kub plating muab ib txheej ntawm kev tiv thaiv corrosion, oxidation thiab lwm yam kev puas tsuaj, ua kom lub neej ntev PCB.

Txhim kho hluav taws xob conductivity:

Cov kub kub PCBs muaj cov khoom siv hluav taws xob zoo heev, ua rau lawv xaiv thawj zaug rau cov ntawv thov uas xav tau kev sib kis tau zoo. Lub thickness ntawm kub plating txo qhov tsis kam thiab txhim kho hluav taws xob kev ua tau zoo, kom ntseeg tau tias seamless teeb liab kis tau tus mob thoob plaws lub rooj tsavxwm. Qhov no yog qhov tseem ceeb tshwj xeeb rau kev lag luam xws li kev sib txuas lus, aerospace thiab cov cuab yeej kho mob, qhov twg cov ntaub ntawv raug thiab txhim khu kev qha yog qhov tseem ceeb.

Txhim kho solderability:

Lwm qhov zoo ntawm cov kub kub PCBs yog lawv cov kev txhim kho solderability. Ua kom kub plating thickness tso cai rau kom zoo dua solder txaus thiab ntub dej, txo qhov yuav tshwm sim ntawm solder reflow teeb meem thaum lub sij hawm tsim khoom. Qhov no ua kom cov pob qij txha muaj zog thiab txhim khu kev qha, tshem tawm cov teeb meem tsis zoo thiab txhim kho tag nrho cov khoom zoo.

Tiv tauj lub neej:

Hluav taws xob tiv tauj ntawm tuab kub PCBs kav ntev dua vim qhov kub plating thickness. Qhov no txhim kho kev ntseeg tau ntawm kev sib cuag thiab txo qhov kev pheej hmoo ntawm cov teeb liab degradation lossis kev sib txuas tsis sib xws thaum lub sijhawm. Yog li ntawd, cov PCBs no tau siv dav hauv cov ntawv thov nrog kev nkag siab / rho tawm mus, xws li daim npav txuas lossis cov cim nco, uas xav tau kev sib cuag ntev.

Txhim kho hnav tsis kam:

Cov kub kub PCBs ua tau zoo nyob rau hauv daim ntawv thov uas yuav tsum tau rov hnav thiab tsim kua muag. Lub thickness ntawm cov kub plating muab ib qho kev tiv thaiv kev tiv thaiv uas pab tiv thaiv kev txhuam thiab txhuam los ntawm kev rov siv dua. Qhov no ua rau lawv zoo tagnrho rau cov khoom sib txuas, touchpads, cov nyees khawm thiab lwm yam khoom uas muaj kev sib cuag nrog lub cev tas li, ua kom lawv lub neej ntev thiab kev ua haujlwm zoo ib yam.

Txo cov teeb liab poob:

Teeb liab poob yog ib qho teeb meem tshwm sim hauv kev siv ntau zaus. Txawm li cas los xij, tuab kub PCBs muab cov kev daws teeb meem uas tuaj yeem txo cov teeb liab poob vim lawv cov kev ua tau zoo dua qub. Cov PCBs no muaj kev tiv thaiv tsawg los xyuas kom pom cov teeb liab kev ncaj ncees, txo qis cov ntaub ntawv xa mus los thiab ua kom lub zog ua haujlwm tau zoo. Yog li ntawd, lawv tau siv dav hauv kev lag luam xws li kev sib txuas lus, khoom siv wireless, thiab cov cuab yeej siv siab.

3.Qhov tseem ceeb ntawm kev nce kub plating thickness rau tuab kub PCBs:

Qhov nce thickness ntawm kub plating nyob rau hauv tuab kub PCBs pab ob peb lub hom phiaj tseem ceeb.Ua ntej, nws muab kev tiv thaiv ntxiv tiv thaiv oxidation thiab corrosion, kom ntseeg tau ntev thiab ruaj khov txawm nyob rau hauv ib puag ncig hnyav. Cov kub plated tuab ua raws li kev thaiv, tiv thaiv cov tshuaj lom neeg ntawm cov kab hauv qab tooj liab thiab cov huab cua sab nraud, tshwj xeeb tshaj yog tias raug cov dej noo, av noo, los yog muaj cov kab mob.

Thib ob, cov txheej kub kub ua kom lub zog tag nrho thiab cov teeb liab kis tau zoo ntawm PCB.Kub yog ib qho khoom siv hluav taws xob zoo heev, txawm tias zoo dua li tooj liab feem ntau siv rau cov kab hluav taws xob hauv cov qauv PCBs. Los ntawm kev nce cov ntsiab lus kub ntawm qhov chaw, tuab kub PCBs tuaj yeem ua tiav qhov kev tiv thaiv qis dua, txo qis cov teeb liab poob thiab ua kom muaj kev ua tau zoo dua, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov ntau zaus lossis cov teeb liab qis.

Tsis tas li ntawd, cov txheej kub thicker muab zoo dua solderability thiab muaj zog tivthaiv mounting nto.Kub muaj zoo heev solderability, tso cai rau txhim khu kev qha solder pob qij txha thaum sib dhos. Qhov no yog qhov tseem ceeb heev vim tias yog tias cov pob qij txha tsis muaj zog lossis tsis sib xws, nws tuaj yeem ua rau tsis sib xws lossis ua tiav Circuit Court tsis ua haujlwm. Ua kom kub tuab kuj txhim kho cov khoom siv dag zog, ua kom tuab kub PCBs tsis tshua muaj kev cuam tshuam rau hnav thiab tsim kua muag thiab tiv taus ntau yam kev ntxhov siab thiab kev co.

Nws yog ib nqi sau cia hais tias qhov nce thickness ntawm kub txheej nyob rau hauv tuab kub PCBs kuj coj cov nqi siab dua piv rau cov qauv PCBs.Cov txheej txheem kub plating ntau yuav tsum tau siv sijhawm ntxiv, cov peev txheej thiab kev txawj ntse, uas ua rau cov nqi tsim khoom nce ntxiv. Txawm li cas los xij, rau cov ntawv thov uas xav tau kev ua tau zoo, kev ntseeg tau thiab kev siv tau ntev, kev nqis peev hauv cov kub kub PCBs feem ntau tshaj qhov muaj peev xwm txaus ntshai thiab cov nqi cuam tshuam nrog kev siv cov qauv PCBs.

4.Qhov txawv ntawm tuab kub PCB thiab txheem PCB:

Txheem PCBs feem ntau yog ua los ntawm cov khoom siv epoxy nrog txheej tooj liab ntawm ib lossis ob sab ntawm lub rooj tsavxwm. Cov txheej tooj liab no tau etched thaum lub sijhawm tsim khoom los tsim qhov tsim nyog circuitry. Qhov tuab ntawm cov txheej tooj liab tuaj yeem sib txawv nyob ntawm daim ntawv thov, tab sis feem ntau yog nyob rau hauv 1-4 oz ntau.

Cov kub kub PCB, raws li lub npe qhia, muaj cov txheej txheem kub plating piv rau tus qauv PCB. Standard PCBs feem ntau muaj kub plating thickness ntawm 20-30 micro inches (0.5-0.75 microns), thaum tuab kub PCBs muaj kub plating thickness ntawm 50-100 micro inches (1.25-2.5 microns).

Qhov sib txawv tseem ceeb ntawm cov kub kub PCBs thiab cov qauv PCBs yog kub txheej thickness, kev tsim complexity, nqi, daim ntawv thov cheeb tsam, thiab txwv tsis pub siv rau high-temperature ib puag ncig.

Kub txheej thickness:

Lub ntsiab sib txawv ntawm tuab kub PCB thiab txheem PCB yog lub thickness ntawm kub txheej. Thick kub PCB muaj txheej txheej kub plating dua li txheej txheem PCB. Qhov tuab ntxiv no pab txhim kho PCB lub zog thiab kev ua haujlwm hluav taws xob. Cov txheej kub tuab muab cov txheej txheem tiv thaiv uas txhim kho PCB tiv thaiv corrosion, oxidation thiab hnav. Qhov no ua rau PCB muaj zog dua nyob rau hauv ib puag ncig hnyav, kom ntseeg tau tias kev ua haujlwm ntev ntev. Thicker kub plating kuj tso cai rau kev siv hluav taws xob zoo dua, tso cai rau kev sib kis tau zoo. Qhov no yog qhov tshwj xeeb tshaj yog nyob rau hauv daim ntawv thov uas yuav tsum tau high-frequency los yog high-ceev teeb liab kis tau tus mob, xws li kev sib txuas lus, khoom kho mob, thiab aerospace systems.

Tus nqi:

Piv nrog cov qauv PCB, cov nqi tsim khoom ntawm cov kub kub PCB feem ntau yog siab dua. Cov nqi siab dua no tau tshwm sim los ntawm cov txheej txheem plating xav tau cov khoom siv kub ntxiv kom ua tiav qhov xav tau tuab. Txawm li cas los xij, kev ntseeg siab ntau dua thiab kev ua tau zoo ntawm cov kub kub PCBs pom tseeb tus nqi ntxiv, tshwj xeeb tshaj yog hauv cov ntawv thov uas xav tau yuav tsum tau ua.

Kev siv thaj chaw:

Standard PCBs yog dav siv nyob rau hauv ntau yam industries, nrog rau cov neeg siv khoom electronics, automotive systems thiab industrial cov khoom. Lawv haum rau cov ntawv thov uas muaj kev ntseeg siab tsis yog qhov tseem ceeb tshaj plaws. Cov kub kub PCBs, ntawm qhov tod tes, feem ntau yog siv rau hauv kev ua haujlwm uas xav tau kev ntseeg siab thiab kev ua tau zoo. Piv txwv ntawm cov ntawv thov no suav nrog kev lag luam aerospace, khoom siv kho mob, khoom siv tub rog, thiab kev sib txuas lus. Hauv cov cheeb tsam no, cov haujlwm tseem ceeb vam khom rau cov khoom siv hluav taws xob zoo thiab cov khoom siv hluav taws xob zoo, yog li cov kub kub PCBs yog thawj qhov kev xaiv.

Manufacturing Complexity:

Piv nrog rau cov qauv PCBs, cov txheej txheem tsim khoom ntawm cov tuab kub PCBs yog qhov nyuaj thiab siv sij hawm ntau. Cov txheej txheem electroplating yuav tsum tau ua tib zoo tswj kom ua tiav qhov xav tau kub txheej tuab. Qhov no ua rau kom qhov nyuaj thiab lub sijhawm xav tau ntawm cov txheej txheem tsim khoom. Kev tswj hwm ntawm cov txheej txheem plating yog qhov tseem ceeb vim tias kev hloov pauv hauv cov txheej kub kub tuaj yeem cuam tshuam rau PCB kev ua tau zoo thiab kev ntseeg tau. Cov txheej txheem tsim khoom zoo no ua rau muaj txiaj ntsig zoo thiab ua haujlwm ntawm cov kub kub PCBs.

Tsawg tsim nyog rau qhov kub thiab txias ib puag ncig:

Thaum tuab kub PCBs ua tau zoo nyob rau hauv ib puag ncig feem ntau, lawv yuav tsis yog qhov kev xaiv zoo tshaj plaws rau kev siv kub. Nyob rau hauv cov huab cua kub heev, cov txheej kub tuab tuaj yeem degrade lossis delaminate, cuam tshuam rau tag nrho cov kev ua tau zoo ntawm PCB.

Hauv qhov no, lwm txoj kev kho deg xws li immersion tin (ISn) lossis immersion silver (IAg) yuav nyiam dua. Cov kev kho mob no muab kev tiv thaiv txaus tiv thaiv qhov tshwm sim ntawm qhov kub thiab txias yam tsis muaj kev cuam tshuam rau kev ua haujlwm ntawm PCB.

Kev xaiv ntawm cov ntaub ntawv PCB tuaj yeem cuam tshuam qhov zoo thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob. Cov kub kub PCBs muab cov txiaj ntsig tshwj xeeb xws li kev txhim kho durability, txhim kho solderability, zoo hluav taws xob conductivity, superior kev ntseeg tau, thiab ntev txee lub neej.Lawv cov txiaj ntsig pom zoo rau cov nqi tsim khoom ntau dua thiab ua rau lawv tshwj xeeb rau cov kev lag luam tshwj xeeb uas muaj kev ntseeg siab ua ntej, xws li aerospace, khoom siv kho mob, khoom siv tub rog, thiab kev sib txuas lus. Kev nkag siab txog qhov muaj pes tsawg leeg, qhov zoo, thiab qhov sib txawv ntawm cov tuab kub PCBs thiab cov qauv PCBs yog qhov tseem ceeb rau cov engineers, designers, thiab manufacturers nrhiav kev ua kom zoo dua qhov kev ua tau zoo thiab kev ua haujlwm ntev ntawm lawv cov khoom siv hluav taws xob. Los ntawm leveraging qhov tshwj xeeb zoo ntawm tuab kub PCBs, lawv tuaj yeem ua kom ntseeg tau thiab cov khoom zoo rau lawv cov neeg siv khoom.

Post lub sij hawm: Sep-13-2023

Rov qab