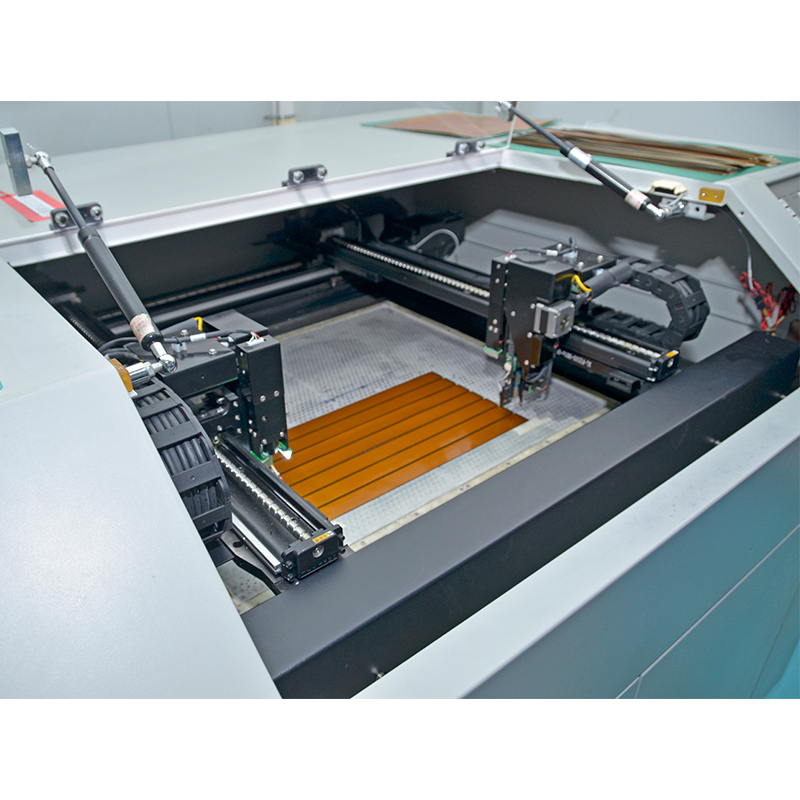

PCB qauv kev sib dhos tshuab ua lub luag haujlwm tseem ceeb hauv kev tsim khoom thiab sib dhos ntawm cov laug cam.Cov thev naus laus zis no ua kom muaj txiaj ntsig zoo, muaj txiaj ntsig zoo thiab kev lag luam ntawm cov qauv tsim hluav taws xob.Hauv tsab ntawv tshaj tawm no, peb yuav tshawb txog qee cov txheej txheem PCB prototyping los ua ke. Ua ntej yuav mus rau hauv cov ntsiab lus, cia peb luv luv qhia Capel, lub tuam txhab nrog 15 xyoo ntawm kev paub nyob rau hauv Circuit Court board kev lag luam, nrog ib tug kws tshaj lij pab neeg, advanced circuit board prototype assembly technology, thiab nws tus kheej ntau lawm thiab sib dhos Hoobkas.

Capel tau ua tus thawj coj hauv kev lag luam Circuit Court board rau ntau tshaj 15 xyoo, mob siab rau ua tau raws li qhov xav tau ntawm nws cov neeg siv khoom.Lub tuam txhab muaj ib pab pawg neeg paub txog cov kws tshaj lij uas tau txais kev paub zoo tshaj plaws hauv kev tsim khoom thiab kev sib sau ua ke ntawm Circuit Board. Capel's advanced circuit board prototyping los ua ke thev naus laus zis ua kom cov qauv zoo tshaj plaws thiab cov txheej txheem tsim tau zoo.

Muaj nws tus kheej Circuit Court board ntau lawm thiab cov nroj tsuag sib dhos ua rau Capel muaj kev sib tw kom zoo dua.Qhov kev teeb tsa no tso cai rau lub tuam txhab los tswj cov txheej txheem tsim khoom zoo dua, ua kom cov khoom xa tuaj raws sijhawm thiab tswj xyuas kev tswj hwm zoo. Tsis tas li ntawd, lub tuam txhab kev txawj ntse hauv PCB ntau lawm thiab kev sib dhos ua rau nws muab cov neeg siv khoom nrog cov kev daws teeb meem zoo thiab nqi.

Tam sim no peb paub txog Capel thiab nws lub peev xwm, cia peb tshawb xyuas PCB prototyping los ua ke cov txheej txheem uas feem ntau siv hauv

kev lag luam.

1. Nto mount technology (SMT):

Surface mount technology (SMT) yog ib qho ntawm feem ntau siv PCB los ua ke technologies. Nws suav nrog cov khoom txuas ncaj qha rau ntawm PCB nto. SMT muaj ntau qhov zoo, suav nrog kev muaj peev xwm ua kom haum cov khoom me me, cov khoom siv ntau dua, thiab kev ua haujlwm ntawm hluav taws xob zoo dua.

2. Tshaj-qhov tshuab (THT):

Los ntawm-qhov tshuab (THT) yog cov cuab yeej siv qub qub uas suav nrog cov khoom sib txuas los ntawm kev ntxig rau hauv lub qhov hauv PCB thiab soldering rau sab nraud. THT feem ntau yog siv rau cov khoom siv uas yuav tsum tau siv zog ntxiv lossis loj dhau rau SMT.

3. Tsis siv neeg kho qhov muag tshuaj ntsuam xyuas (AOI):

Automated optical inspection (AOI) yog ib qho cuab yeej siv los tshuaj xyuas cov PCBs sib dhos rau qhov ua yuam kev lossis qhov tsis xws luag. AOI systems siv lub koob yees duab thiab cov duab paub txog cov txheej txheem los tshuaj xyuas ntau yam ntawm PCB, xws li cov khoom tso, cov pob qij txha, thiab polarity. Cov cuab yeej no ua kom muaj kev sib koom ua ke zoo thiab txo txoj hauv kev ntawm cov khoom puas tuaj yeem ncav cuag cov neeg siv khoom.

4. X-ray kuaj:

Kev kuaj X-ray yog ib qho kev tshuaj ntsuam xyuas uas tsis muaj kev puas tsuaj uas siv los tshuaj xyuas PCBs rau cov yam ntxwv zais, xws li cov pob qij txha los yog cov khoom siv hauv qab cov khoom. X-ray tshuaj xyuas pab tshawb xyuas cov teeb meem xws li cov khoom siv tsis txaus, cov pob qij txha txias, lossis cov voids uas yuav tsis pom los ntawm kev tshuaj xyuas qhov muag.

5. Rework thiab kho:

Rework thiab kho cov txheej txheem yog qhov tseem ceeb los kho qhov tsis xws lossis hloov cov khoom tsis raug ntawm cov khoom sib dhos PCBs. Cov kws tshaj lij siv cov cuab yeej tshwj xeeb thiab cov cuab yeej siv los rhuav tshem thiab hloov cov khoom yam tsis muaj kev puas tsuaj rau PCB. Cov txheej txheem no txo cov khoom pov tseg thiab khaws cov khoom tsis zoo, txuag lub sijhawm thiab cov peev txheej.

6. Xaiv vuam:

Selective soldering yog ib qho txheej txheem siv los ua cov khoom siv los ntawm lub qhov ntawm PCB yam tsis muaj kev cuam tshuam rau cov khoom siv ntawm cov khoom siv. Nws muab qhov tseeb ntau dua thiab txo txoj hauv kev ua kom puas cov khoom nyob ze.

7. Online Test (ICT):

Hauv-circuit testing (ICT) siv cov cuab yeej tshwj xeeb los kuaj xyuas kev ua haujlwm ntawm cov khoom siv hluav taws xob ntawm PCB. Nws pab txheeb xyuas cov khoom tsis raug, qhib lossis luv luv lossis cov khoom tsis raug. ICT muab cov lus qhia muaj txiaj ntsig los txhim kho cov txheej txheem tsim thiab sib dhos.

Cov no tsuas yog qee yam ntawm PCB prototyping sib dhos cov txheej txheem siv los ntawm cov tuam txhab xws li Capel. Kev txhim kho txuas ntxiv ntawm thev naus laus zis tso cai rau cov tuam txhab lag luam tshawb nrhiav cov txheej txheem tshiab thiab tsim kho tshiab hauv kev sib koom ua ke ntawm Circuit Board.

Capel qhov kev paub dhau los thiab kev txawj ntse hauv kev lag luam hauv Circuit Board, ua ke nrog nws cov txheej txheem PCB qib siab sib dhos tshuab, ua rau nws muaj kev ntseeg siab rau nws cov neeg siv khoom.Lub tuam txhab kev cog lus los muab kev ua tau zoo, kev ua haujlwm siab thiab kev lag luam tsim hluav taws xob tsim hluav taws xob thiab cov kev pabcuam sib dhos ua rau nws sib nrug hauv kev ua lag luam.

Hauv cov ntsiab lus, nkag siab txog cov txheej txheem PCB prototyping los ua ke yog qhov tseem ceeb rau cov tuam txhab thiab cov neeg siv khoom.Cov tuam txhab xws li Capel siv lawv cov kev txawj ntse, kev paub dhau los, thiab cov thev naus laus zis siab heev los muab cov khoom siv hluav taws xob zoo tshaj plaws thiab cov kev daws teeb meem sib dhos. Los ntawm kev xaiv tus khub txhim khu kev qha zoo li Capel, cov neeg siv khoom tau txais txiaj ntsig los ntawm cov txheej txheem ua tau zoo, kev tswj hwm zoo dua thiab cov kev daws teeb meem zoo.

Post lub sij hawm: Oct-19-2023

Rov qab