Flexible printed circuit boards (PCBs), tseem hu ua flex PCBs, tau dhau los ua neeg nyiam nyob rau xyoo tas los no vim lawv lub peev xwm khoov thiab sib tw. Cov kab hluav taws xob hloov tau yooj yim no muaj ntau yam thiab pom cov ntawv thov hauv ntau qhov kev lag luam, suav nrog tsheb, khoom siv hluav taws xob, kev kho mob, thiab kev sib txuas lus. Thaum txiav txim siab flex PCBs, nws yog ib qho tseem ceeb kom nkag siab txog cov yam tseem ceeb uas cuam tshuam rau lawv cov nqi thiaj li ua tiav cov txiaj ntsig zoo thiab ua haujlwm tau zoo.Nyob rau hauv tsab xov xwm no, peb yuav delve rau hauv cov ntsiab lus tseem ceeb uas cuam tshuam rau flex PCB hais, ua rau koj txiav txim siab paub thaum muab xaj. Los ntawm kev paub txog cov xwm txheej no, koj tuaj yeem txhim kho koj cov peev nyiaj thiab xyuas kom meej tias koj cov kev cai PCB ua raws li koj cov kev xav tau tshwj xeeb thiab cov qauv kev lag luam.

1.Design Complexity: Ib qho ntawm cov ntsiab lus tseem ceeb cuam tshuam rau kev hloov pauv ntawm PCB cov lus hais yog tsim tsis yooj yim.

Tsim complexity plays lub luag haujlwm tseem ceeb hauv kev txiav txim siab tsim cov nqi ntawm flex PCBs. Complex designs feem ntau koom nrog complex circuitry, advanced functionality, thiab tshwj xeeb cov kev cai uas yuav tsum tau tshwj xeeb cov cuab yeej thiab cov txheej txheem. Cov kev xav tau ntxiv no nce lub sijhawm tsim khoom thiab kev siv zog, ua rau cov nqi tsim khoom ntau dua.

Ib feem ntawm qhov tsim complexity yog kev siv cov khoom zoo suab. Fine-pitch Cheebtsam muaj nqaim pitches, uas yuav tsum tau ntau dua precision nyob rau hauv lub manufacturing txheej txheem. Qhov no yuav tsum muaj cov cuab yeej tshwj xeeb thiab cov txheej txheem los xyuas kom meej haum. Cov kauj ruam ntxiv thiab kev ceev faj yuav tsum tau ua kom zoo-pitch Cheebtsam ntxiv rau kev tsim khoom nyuaj thiab nqi.

Me me khoov radii yog lwm yam cuam tshuam rau kev tsim complexity. Cov ntawv luam tawm yooj yim tau paub txog lawv lub peev xwm khoov thiab sib tw, tab sis thaum khoov radii me me, qhov no tsim kev txwv ntawm cov txheej txheem tsim khoom. Kev ua tiav me me khoov radii yuav tsum tau ua tib zoo xaiv cov khoom siv thiab cov txheej txheem dabtsi yog khoov kom tsis txhob muaj kev puas tsuaj los yog deformation. Cov kev txiav txim siab ntxiv no ua rau kev tsim khoom nyuaj thiab nqi.

Tsis tas li ntawd, complex circuit routing yog lwm yam uas cuam tshuam rau kev tsim complexity. Cov qauv tsim tshwj xeeb feem ntau xav tau cov teeb liab sib txuas, kev faib hluav taws xob, thiab cov dav hlau hauv av. Kev ua tiav qhov tseeb ntawm kev ua haujlwm hauv flex PCBs tuaj yeem nyuaj thiab yuav xav tau cov kauj ruam ntxiv xws li cov txheej txheem tshwj xeeb tooj liab plating lossis siv qhov muag tsis pom thiab faus vias. Cov kev xav tau ntxiv no ua rau kev tsim khoom nyuaj thiab nqi.

2.Kev xaiv cov ntaub ntawv: Lwm qhov tseem ceeb hauv kev txiav txim siab hloov pauv cov lus hais PCB yog kev xaiv cov ntaub ntawv.

Kev xaiv cov khoom siv yog qhov tseem ceeb hauv kev txiav txim siab tus nqi ntawm PCB hloov tau. Cov substrates sib txawv muaj ntau theem ntawm kev ua tau zoo thiab cov nqi cuam tshuam. Kev xaiv cov ntaub ntawv yog nyob ntawm qhov kev thov tshwj xeeb.

Polyimide (PI) paub txog nws cov khoom ua tau zoo, nrog rau kev ruaj ntseg zoo heev thiab yooj yim. Nws tuaj yeem tiv taus qhov kub thiab txias thiab tsim nyog rau kev siv nrog kev ua haujlwm siab dua. Txawm li cas los xij, qhov ua tau zoo tshaj ntawm polyimide los ntawm tus nqi siab dua piv nrog lwm cov ntaub ntawv. Qhov no yog vim qhov nyuaj thiab raug nqi tsim khoom ntawm polyimide raw khoom.

Polyester (PET) yog lwm hom substrate rau hloov tau PCBs. Nws yog pheej yig dua li polyimide thiab muaj qhov yooj yim. Polyester-raws li flex PCBs yog tsim rau cov ntawv thov uas muaj qhov kub thiab txias. Txawm li cas los xij, thermal stability ntawm polyester tsis zoo li ntawm polyimide, thiab nws cov kev ua tau zoo tag nrho yuav qis dua. Rau cov nqi-sensitive daim ntaub ntawv nrog tsawg xav tau kev khiav hauj lwm tej yam kev mob, polyesters yog ib tug siv tau thiab nqi-zoo xaiv.

PEEK (polyetheretherketone) yog cov khoom siv ua haujlwm siab dav siv hauv kev thov. Nws muaj cov khoom siv zoo heev thiab thermal thiab tsim nyog rau cov xwm txheej huab cua. Txawm li cas los xij, PEEK yog kim dua li polyimide thiab polyester. Nws feem ntau raug xaiv rau cov ntawv thov uas yuav tsum tau ua haujlwm zoo dua thiab cov nqi khoom siv ntau dua tuaj yeem ua ncaj ncees.

Ntxiv nrog rau cov khoom siv substrate, lwm cov ntaub ntawv siv hauv kev tsim khoom, xws li laminates, npog zaj duab xis thiab cov ntaub ntawv nplaum, kuj cuam tshuam rau tag nrho cov nqi. Tus nqi ntawm cov khoom siv ntxiv no yuav txawv nyob ntawm lawv qhov zoo thiab cov yam ntxwv ua haujlwm. Piv txwv li, cov laminates zoo nrog cov khoom siv hluav taws xob zoo dua lossis cov yeeb yaj kiab tshwj xeeb nrog kev tiv thaiv ib puag ncig tuaj yeem ntxiv rau tag nrho cov nqi ntawm PCB hloov tau.

3.Quantity thiab puzzle: Qhov kom muaj nuj nqis ntawm saj zawg zog PCB xav tau plays lub luag hauj lwm tseem ceeb hauv kev txiav txim siab hais.

Qhov yuav tsum tau muaj yog qhov tseem ceeb thaum tus nqi flex PCBs. Cov neeg tsim khoom feem ntau xyaum ua kom muaj nuj nqis raws li tus nqi, uas txhais tau hais tias qhov ntau dua, tus nqi qis dua. Qhov no yog vim qhov kev txiav txim loj dua tso cai rau kev lag luam zoo ntawm cov nplai thiab yog li txo cov nqi tsim khoom

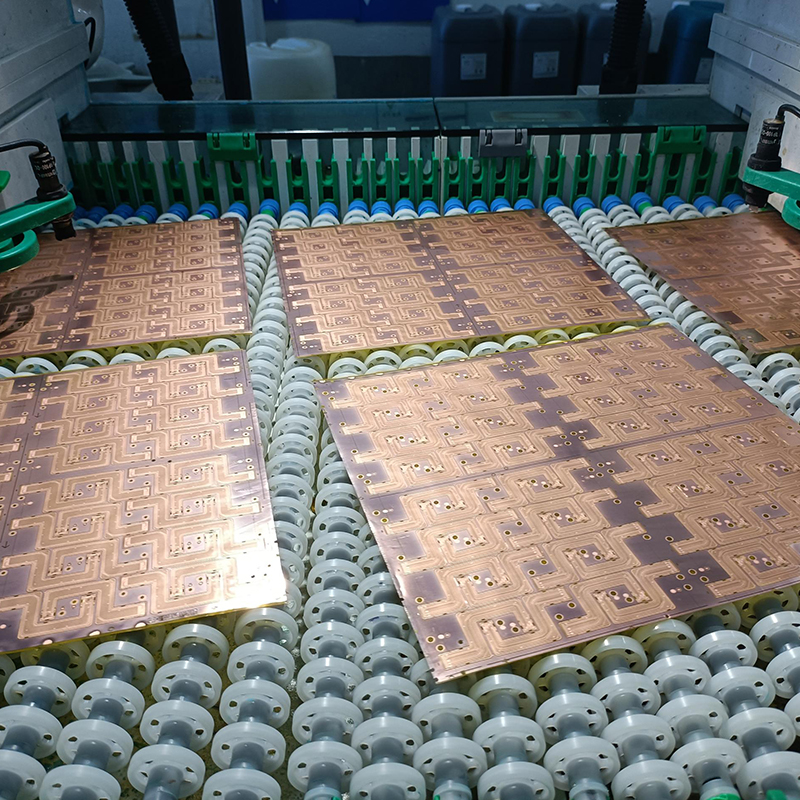

Lwm txoj hauv kev los txhim kho kev siv cov khoom siv thiab kev tsim khoom zoo yog panelization. Panelization suav nrog kev sib txuas ntau cov PCBs me rau hauv lub vaj huam sib luag loj. Los ntawm kev npaj cov qauv tsim ntawm cov vaj huam sib luag, cov tuam ntxhab tuaj yeem txo cov khoom pov tseg thiab ua kom muaj txiaj ntsig zoo tshaj plaws thaum lub sijhawm tsim khoom.

Panelization muaj ntau yam txiaj ntsig. Ua ntej, nws txo cov khoom pov tseg los ntawm kev siv ntau qhov chaw muaj nyob rau ntawm lub vaj huam sib luag. Hloov chaw tsim cov PCBs cais nrog lawv tus kheej ciam teb thiab qhov sib txawv, cov chaw tsim khoom tuaj yeem tso ntau yam qauv ntawm ib lub vaj huam sib luag, ua rau feem ntau ntawm qhov chaw tsis siv nyob nruab nrab. Qhov no ua rau kev txuag cov khoom tseem ceeb thiab txo tus nqi.

Tsis tas li ntawd, panelization simplifies cov txheej txheem tsim. Nws ua rau cov txheej txheem ntau lawm thiab ua haujlwm tau zoo vim ntau yam PCBs tuaj yeem ua tiav ib txhij. Qhov no ua rau cov khoom lag luam nce ntxiv thiab txo lub sijhawm tsim khoom, ua rau lub sijhawm luv luv thiab cov nqi qis dua. Kev ua haujlwm tau zoo yuav tsum tau ua tib zoo npaj thiab txiav txim siab txog yam xws li PCB qhov loj me, kev tsim qauv, thiab kev tsim muaj peev xwm. Cov neeg tsim khoom tuaj yeem siv cov cuab yeej tshwj xeeb software los pab hauv cov txheej txheem panelization, ua kom pom kev sib raug zoo thiab siv cov ntaub ntawv zoo.

Ntxiv rau, lub vaj huam sib luag tsim tau yooj yim dua los tuav thiab thauj. Tom qab cov txheej txheem tsim khoom tiav, cov panels tuaj yeem muab cais ua ib tus PCBs. Qhov no ua kom yooj yim ntim thiab txo qhov kev pheej hmoo ntawm kev puas tsuaj thaum thauj khoom, uas thaum kawg txuag nyiaj.

4.Surface Finish thiab Copper Nyhav: Nto tiav thiab qhov hnyav tooj liab yog qhov tseem ceeb hauv kev txiav txim siab.flexible PCB manufacturing txheej txheem.

Nto tiav yog ib qho tseem ceeb ntawm PCB kev tsim khoom raws li nws cuam tshuam ncaj qha rau cov solderability thiab durability ntawm lub rooj tsavxwm. Txoj kev kho saum npoo tsim cov txheej txheem tiv thaiv dhau ntawm cov kab tooj liab raug, tiv thaiv oxidation thiab ua kom cov pob qij txha txhim khu kev qha. Kev kho deg sib txawv muaj cov nqi sib txawv thiab cov txiaj ntsig.

Ib qho kev ua tiav yog HASL (Hot Air Solder Leveling), uas suav nrog siv txheej txheej ntawm cov khoom siv rau cov kab tooj liab thiab tom qab ntawd siv cov cua kub kom qib lawv. HASL yog tus nqi-zoo thiab muaj cov khoom siv zoo, tab sis tej zaum yuav tsis haum rau cov khoom zoo-pitch lossis nplua-pitch Cheebtsam vim qhov tsis sib xws ntawm qhov nws tsim.

ENIG (Electroless Nickel Immersion Kub) yog lwm qhov kev kho mob dav siv. Nws suav nrog tso ib txheej nyias ntawm npib tsib xee hla cov kab tooj liab, ua raws li txheej kub. ENIG qhov zoo tshaj plaws solderability, tiaj tus nto, thiab corrosion kuj ua rau nws haum rau nplua-pitch Cheebtsam thiab high-density designs. Txawm li cas los xij, ENIG muaj tus nqi siab piv rau lwm yam kev kho mob saum npoo.

OSP (Organic Solderability Preservative) yog ib qho kev kho mob saum npoo uas suav nrog daim ntawv thov txheej nyias ntawm cov khoom siv organic los tiv thaiv cov kab tooj liab. OSP muab cov khoom zoo, kev sib luag thiab kev ua haujlwm zoo. Txawm li cas los xij, nws tsis zoo li lwm cov khoom tiav thiab yuav tsum tau ceev faj thaum sib dhos.

Qhov hnyav (hauv ounces) ntawm tooj liab hauv PCB txiav txim siab qhov kev coj ua thiab kev ua haujlwm ntawm lub rooj tsavxwm. Thicker txheej ntawm tooj liab muab kev tiv thaiv qis dua thiab tuaj yeem tswj cov dej ntws ntau dua, ua rau lawv tsim nyog rau kev siv fais fab. Txawm li cas los xij, cov khaubncaws sab nraud povtseg tuab dua yuav tsum muaj cov khoom siv ntau dua thiab cov txheej txheem tsim khoom, yog li ua rau tus nqi tag nrho ntawm PCB. Hauv qhov sib piv, cov txheej tooj liab nyias nyias yog tsim rau cov ntawv siv hluav taws xob tsawg lossis cov ntawv thov uas muaj qhov txwv qhov chaw. Lawv xav tau cov khoom siv tsawg dua thiab raug nqi ntau dua. Qhov kev xaiv ntawm qhov hnyav tooj liab nyob ntawm qhov kev xav tau tshwj xeeb ntawm PCB tsim thiab nws txoj haujlwm npaj.

5.Kev Siv Tshuabthiab Pwm: Cov txheej txheem tsim khoom thiab cov cuab yeej siv los tsim cov PCBs hloov tau kuj cuam tshuam tus nqi.

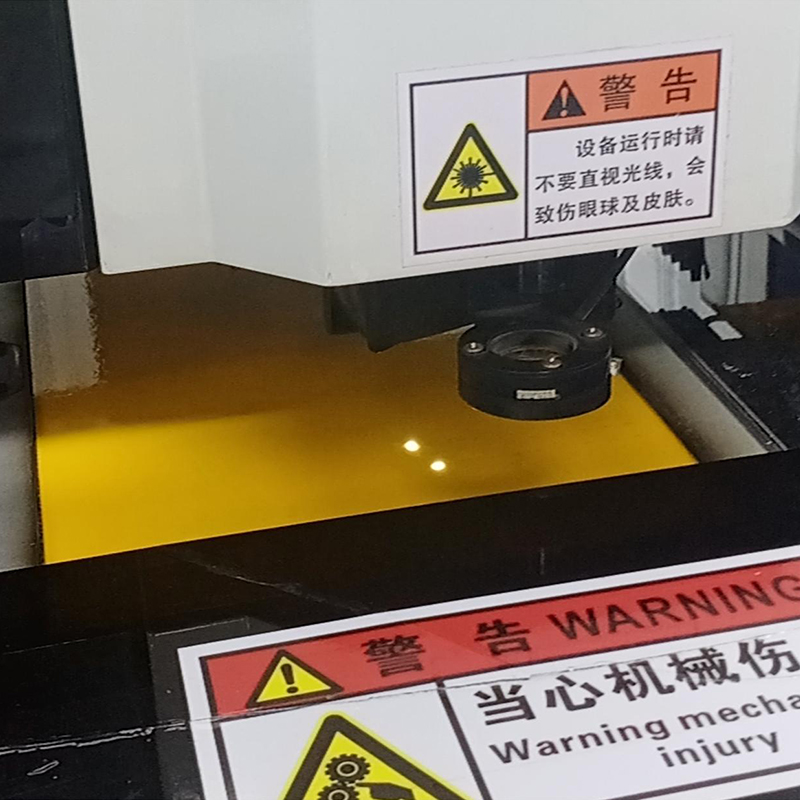

Kev tsim khoom siv thev naus laus zis ua lub luag haujlwm tseem ceeb hauv kev tsim cov PCB hloov tau yooj yim thiab muaj kev cuam tshuam loj rau tus nqi. Advanced technologies, xws li laser drilling thiab sequential build-up (SBU), muaj peev xwm tsim complex thiab meej, tab sis cov txheej txheem no feem ntau tuaj nrog ntau dua cov nqi. Laser drilling tuaj yeem tsim cov vias zoo thiab cov qhov me me, ua kom muaj cov kab hluav taws xob siab hauv cov PCB hloov tau. Txawm li cas los xij, kev siv tshuab laser thiab precision yuav tsum tau rau cov txheej txheem nce nqi ntau lawm.

Sequential build up (SBU) yog lwm cov txheej txheem tsim khoom siab heev uas koom nrog kev sib koom ua ke ntau lub voj voog flex los tsim cov qauv tsim ntau dua. Cov thev naus laus zis no nce kev tsim qauv yooj yim thiab ua kom muaj kev sib koom ua ke ntawm ntau yam haujlwm hauv ib qho yooj yim PCB. Txawm li cas los xij, kev nyuaj ntxiv hauv cov txheej txheem tsim khoom nce nqi ntau lawm.

Ntxiv nrog rau cov txheej txheem tsim khoom, cov txheej txheem tshwj xeeb koom nrog hauv kev tsim cov PCB hloov pauv tuaj yeem cuam tshuam tus nqi. Cov txheej txheem xws li plating, etching, thiab lamination yog cov kauj ruam tseem ceeb hauv kev tsim cov khoom ua haujlwm siab thiab txhim khu kev qha PCB. Qhov zoo ntawm cov kev ua haujlwm no, suav nrog cov khoom siv thiab qib siab ntawm qhov xav tau, cuam tshuam rau tag nrho cov nqi

Automation thiab cov cuab yeej tshiab pab txhawb kev tsim khoom thiab kev ua haujlwm zoo hauv kev tsim khoom. Automated machinery, robotics, thiab computer-aided manufacturing (CAM) systems tuaj yeem ua kom yooj yim ntau lawm, txo tib neeg kev ua yuam kev, thiab ua kom cov txheej txheem tsim khoom. Txawm li cas los xij, kev siv lub tshuab hluav taws xob zoo li no yuav raug nqi ntxiv, suav nrog kev nqis peev ua ntej hauv cov khoom siv thiab kev cob qhia cov neeg ua haujlwm.

Tsis tas li ntawd, kev siv cov cuab yeej tshiab thiab thev naus laus zis, xws li PCB tsim software thiab cov cuab yeej tshuaj xyuas, tuaj yeem pab txhawb tus nqi. Cov cuab yeej no feem ntau xav tau cov kws tshaj lij, kev saib xyuas thiab kev hloov kho tshiab, txhua yam ntxiv rau tag nrho cov nqi. Cov neeg tsim khoom yuav tsum ua tib zoo xav txog qhov sib npaug ntawm kev tsim cov thev naus laus zis, cov txheej txheem, automation thiab cov cuab yeej tshiab kom ua tiav cov nqi thiab cov txiaj ntsig zoo uas yuav tsum tau ua rau cov khoom siv PCB hloov tau. Los ntawm kev tshuaj xyuas cov kev cai tshwj xeeb ntawm ib qhov project thiab ua haujlwm nrog cov neeg siv khoom, cov neeg tsim khoom tuaj yeem txiav txim siab cov thev naus laus zis thiab cov txheej txheem tsim nyog tshaj plaws thaum txo nqi thiab ua kom cov txiaj ntsig zoo tshaj plaws.

6.Lub sij hawm xa tuaj thiab shipping: Lub sijhawm ua haujlwm yuav tsum yog qhov tseem ceeb cuam tshuam rau qhov hloov pauv PCB hais.

Thaum nws los txog rau lub sijhawm hloov pauv PCB, lub sijhawm ua haujlwm tseem ceeb. Lub sijhawm txhuas yog lub sijhawm nws siv rau cov chaw tsim khoom kom ua tiav ntau lawm thiab npaj rau kev txiav txim rau nkoj. Lub sij hawm txhuas raug cuam tshuam los ntawm ntau yam, suav nrog qhov nyuaj ntawm kev tsim, tus naj npawb ntawm PCBs xaj, thiab cov chaw tsim khoom tam sim no ua haujlwm.

Kev txiav txim maj nrawm lossis lub sijhawm nruj feem ntau xav kom cov tuam txhab tsim khoom lag luam ua ntej thiab faib cov peev txheej ntxiv kom tau raws li lub sijhawm. Hauv cov xwm txheej zoo li no, kev tsim khoom yuav tsum tau nrawm dua, uas yuav ua rau muaj nqi ntau dua. Cov neeg tsim khoom tuaj yeem them tus nqi nrawm lossis siv cov txheej txheem tshwj xeeb los xyuas kom meej tias cov PCBs hloov tau raug tsim thiab xa tawm hauv lub sijhawm tau teev tseg.

Shipping nqi kuj cuam tshuam rau tag nrho cov nqi ntawm flex PCB. Cov nqi thauj khoom yog txiav txim los ntawm ntau yam. Ua ntej, qhov chaw xa khoom ua lub luag haujlwm tseem ceeb hauv tus nqi thauj khoom. Kev xa khoom mus rau qhov chaw nyob deb lossis deb tuaj yeem cuam tshuam cov nqi ntau dua vim tias cov nqi thauj khoom nce ntxiv. Tsis tas li ntawd, qhov ceev ntawm kev xa khoom yuav cuam tshuam rau tus nqi thauj khoom. Yog tias tus neeg siv khoom xav tau kev xa khoom xa tuaj lossis hmo ntuj, tus nqi thauj khoom yuav siab dua piv rau cov qauv kev thauj khoom.

Tus nqi xaj kuj tseem cuam tshuam cov nqi thauj khoom. Qee cov tuam txhab lag luam tuaj yeem muab kev xa khoom dawb lossis luv nqi rau kev txiav txim loj raws li kev txhawb siab rau cov neeg siv khoom kom tso cov xaj ntau. Ntawm qhov tod tes, rau qhov kev txiav txim me me, cov nqi xa khoom tuaj yeem raug siab los them cov nqi koom nrog hauv kev ntim khoom thiab tuav.

Txhawm rau kom muaj kev xa khoom zoo thiab txo tus nqi tsawg, cov neeg tsim khoom tuaj yeem ua haujlwm ze nrog cov neeg muab kev pabcuam logistics los txiav txim siab tus nqi thauj khoom zoo tshaj plaws. Qhov no tuaj yeem koom nrog kev xaiv cov khoom thauj khoom thauj khoom zoo, sib tham txog cov nqi xa khoom zoo, thiab ua kom zoo dua ntim kom txo qhov hnyav thiab qhov loj me.

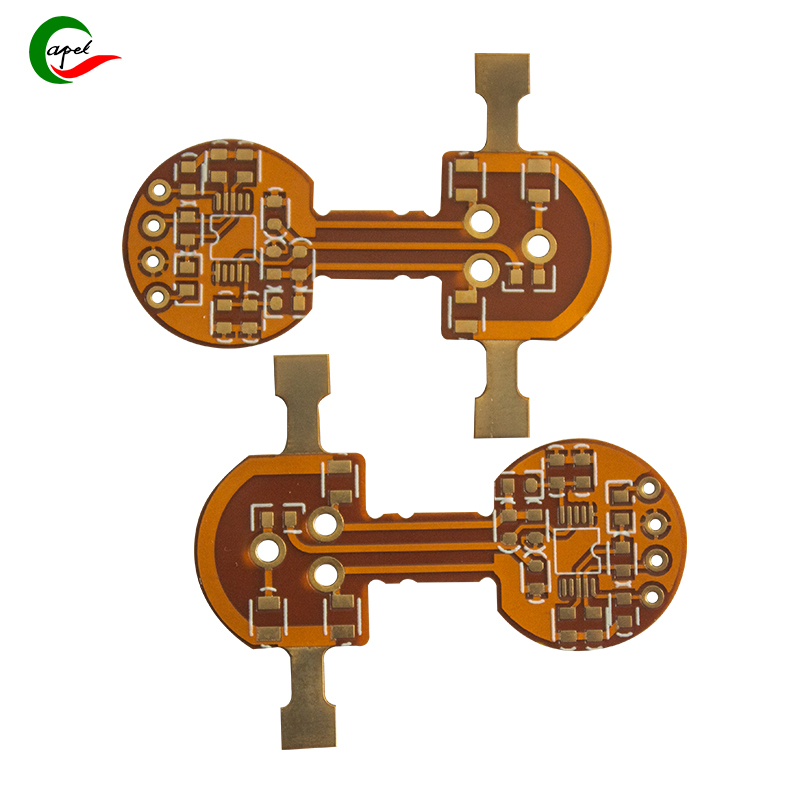

Los xaus,muaj ntau yam uas cuam tshuam rau kev hais lus ntawm cov PCB hloov tau. Cov neeg siv khoom nrog kev nkag siab meej txog cov xwm txheej no tuaj yeem txiav txim siab paub thiab ua kom zoo dua lawv cov txheej txheem tsim khoom.Tsim complexity, xaiv cov khoom thiab kom muaj nuj nqis yog lub ntsiab yam tseem ceeb cuam tshuam tus nqi ntawm saj zawg zog PCB.Qhov ntau qhov kev tsim qauv, tus nqi ntau dua. Kev xaiv cov khoom siv, xws li xaiv qhov zoo tshaj plaws substrate lossis nto tiav, tuaj yeem cuam tshuam tus nqi. Tsis tas li ntawd, kev txiav txim ntau ntau feem ntau ua rau muaj kev txo nqi ntau. Lwm yam, xws li vaj huam sib luag, qhov hnyav tooj liab, kev tsim cov txheej txheem thiab cov cuab yeej, kuj ua lub luag haujlwm hauv kev txiav txim siab tus nqi. Paneling tso cai rau kev siv cov ntaub ntawv zoo thiab txo cov nqi. Qhov hnyav ntawm tooj liab cuam tshuam rau cov tooj liab siv, uas cuam tshuam rau tus nqi thiab kev ua haujlwm ntawm flex PCB. Kev tsim cov txheej txheem thiab cov cuab yeej siv, xws li kev siv cov cuab yeej siv siab heev lossis cov cuab yeej tshwj xeeb, tuaj yeem cuam tshuam rau tus nqi. Thaum kawg, lub sijhawm ua khoom xa tuaj thiab xa khoom yog qhov tseem ceeb rau kev txiav txim siab. Cov nqi ntxiv tuaj yeem thov rau kev txiav txim nrawm lossis nrawm nrawm, thiab cov nqi thauj khoom yog nyob ntawm qhov xwm txheej xws li qhov chaw, ceev, thiab tus nqi xaj. Los ntawm ua tib zoo tshuaj xyuas cov xwm txheej no thiab ua haujlwm nrog cov chaw tsim khoom PCB uas paub txog thiab txhim khu kev qha, cov tuam txhab tuaj yeem hloov kho tus nqi-zoo thiab ua tau zoo PCB hloov tau raws li lawv cov kev xav tau tshwj xeeb.Shenzhen Capel Technology Co., Ltd. tau tsim cov khoom lag luam yooj yim luam tawm Circuit Board (PCBs) txij li xyoo 2009.Tam sim no, peb muaj peev xwm muab kev cai 1-30 txheej hloov tau yooj yim luam tawm Circuit Court boards. Peb HDI (High Density Interconnect) saj zawg zog PCB manufacturing technology yog heev paub tab. Tshaj li 15 xyoo dhau los, peb tau tsim cov thev naus laus zis tsis tu ncua thiab tau txais kev paub nplua nuj hauv kev daws teeb meem ntsig txog qhov project rau cov neeg siv khoom.

Post lub sij hawm: Aug-31-2023

Rov qab