Nyob rau niaj hnub no lub ntiaj teb ceev-paced digital, qhov kev thov rau cov khoom siv hluav taws xob me me, sib dua thiab muaj zog dua txuas ntxiv mus. Txhawm rau ua kom tau raws li cov cai no, cov tuam txhab hluav taws xob tau nthuav tawm cov kev sib txuas siab sib txuas (HDI) hloov pauv tau PCB thev naus laus zis.Piv rau cov tsoos flex PCBs,HDI flex PCBsmuab kev tsim kom yooj yim dua, txhim kho kev ua haujlwm, thiab txhim kho kev ntseeg siab. Hauv tsab xov xwm no, peb yuav tshawb xyuas seb HDI flex PCBs yog dab tsi, lawv cov txiaj ntsig, thiab lawv txawv li cas ntawm cov flex PCBs.

1. Nkag siab HDI Flex PCB:

HDI saj zawg zog PCB, tseem hu ua high-density interconnect saj zawg zog luam ntawv Circuit Court board, yog ib tug saj zawg zog Circuit Court board uas muab high circuit density thiab tso cai rau complex thiab

miniaturized tsim. Nws muab cov txiaj ntsig ntawm cov PCB hloov tau yooj yim, paub txog lawv lub peev xwm khoov thiab hloov mus rau cov duab sib txawv, nrog rau kev sib txuas ntawm cov cuab yeej siv high-density.

xa cov kab hluav taws xob ntau dua hauv qhov chaw compact.

1.2 HDI hloov pauv PCB ua li cas?

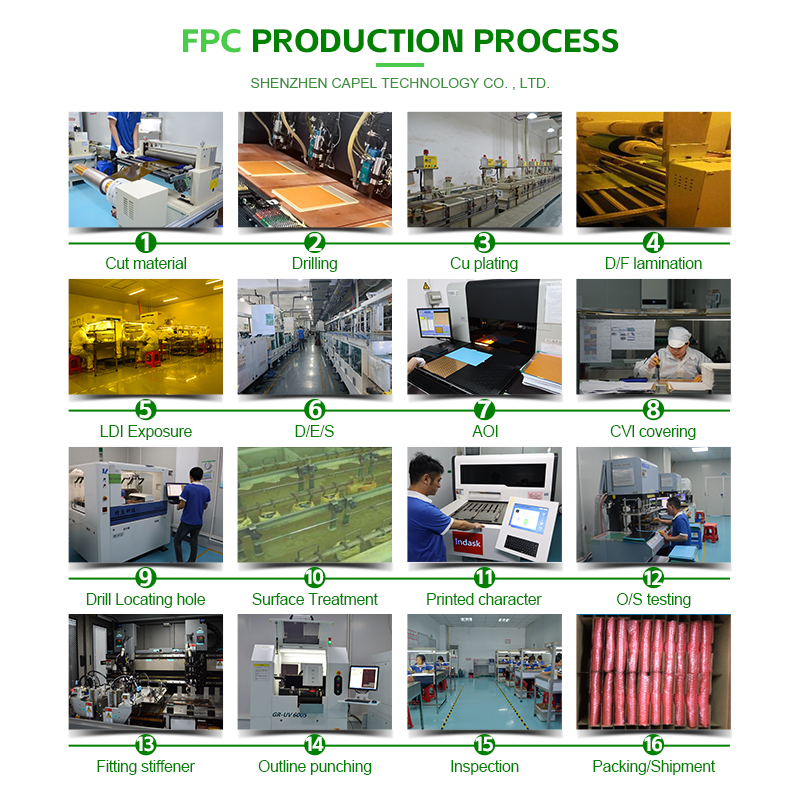

Kev tsim cov txheej txheem ntawm HDI hloov pauv PCBsuav nrog ntau cov kauj ruam tseem ceeb:

Tsim:

Thawj kauj ruam yog los tsim qhov kev teeb tsa hauv Circuit Court, xav txog qhov loj, zoo li cas thiab kev teeb tsa ntawm cov khoom thiab cov haujlwm uas xav tau.

Khoom siv:

Xaiv thiab npaj cov ntaub ntawv xav tau rau cov PCB hloov tau yooj yim, xws li cov ntawv ci tooj liab, cov nplaum nplaum, thiab cov ntaub ntawv hloov pauv tau yooj yim.

Txheej txheej stacking:

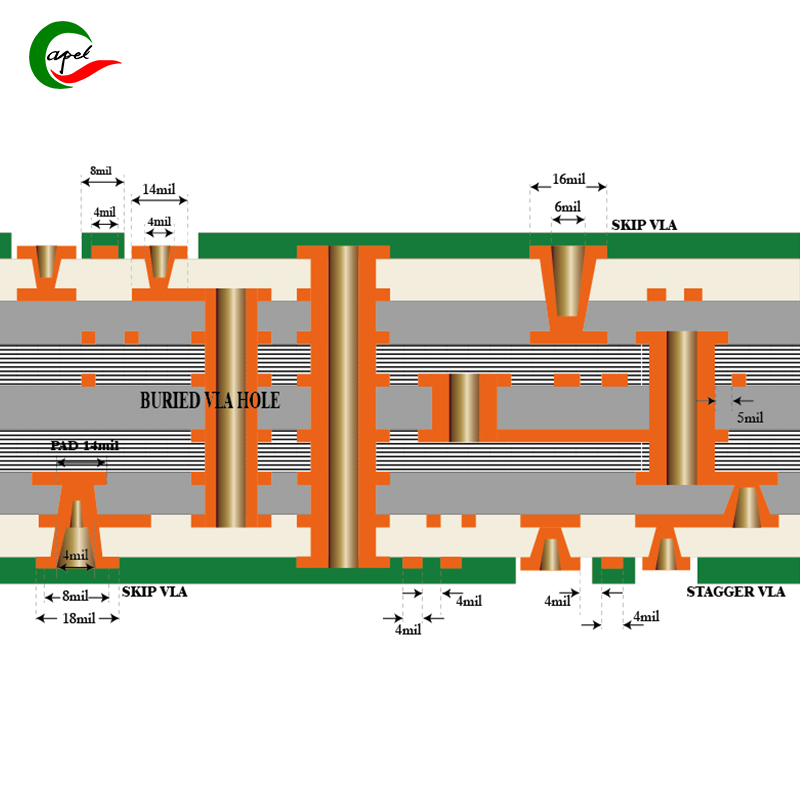

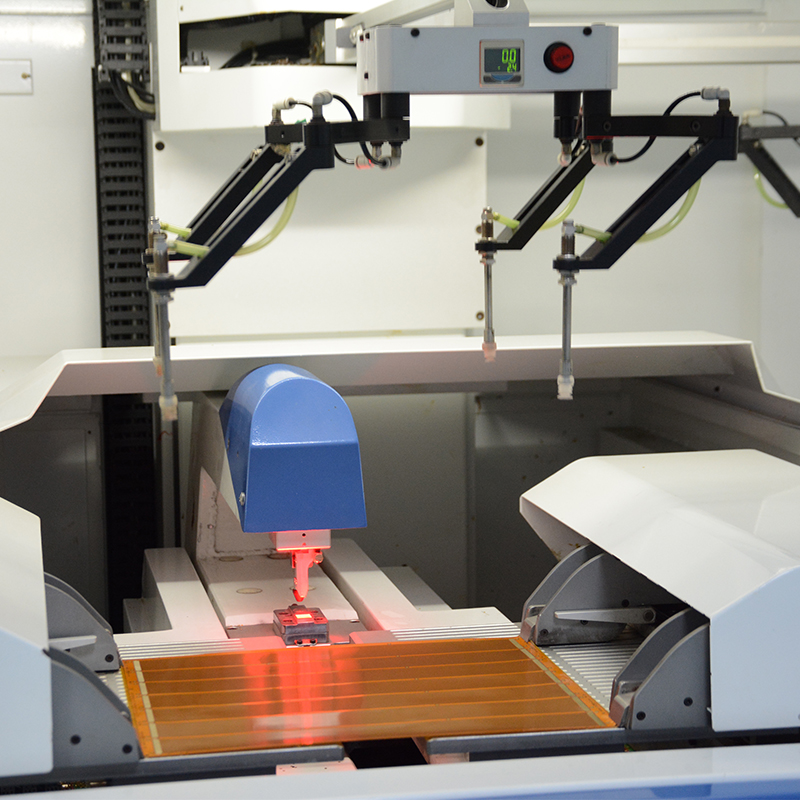

Ntau txheej ntawm cov khoom siv tau yooj yim, cov ntawv ci tooj liab, thiab cov nplaum nplaum tau muab tso ua ke los ua lub hauv paus ntawm lub voj voog. Laser Drilling: Laser drilling yog siv los tsim cov qhov me me lossis vias uas txuas cov txheej sib txawv ntawm lub voj voog. Qhov no tso cai rau kev xaim hauv qhov chaw nruj.

Copper Plating:

Qhov tsim los ntawm laser drilling yog plated nrog tooj liab kom ntseeg tau tias hluav taws xob sib txuas ntawm cov txheej txheem sib txawv.

Circuit Court etching:

Tsis tsim nyog tooj liab yog etched tam sim ntawd, tawm hauv cov kab uas xav tau.

Daim ntawv thov Solder Mask:

Lub npog ntsej muag yog siv los tiv thaiv circuits thiab tiv thaiv luv luv Circuit Court thaum sib dhos.

Mounting Cheebtsam:

Cov Cheebtsam xws li kev sib txuas sib txuas, cov resistors, thiab capacitors yog mounted rau ntawm lub PCB hloov tau siv lub tshuab nto mount (SMT) lossis lwm txoj hauv kev.

Kuaj thiab tshuaj xyuas:

Ua tiav HDI flex PCBs raug kuaj xyuas kom zoo thiab tshuaj xyuas kom ntseeg tau tias kev ua haujlwm zoo thiab zoo.

1.3 Qhov zoo ntawm HDI saj zawg zog PCB:

Qhov zoo ntawm HDI saj zawg zog PCB Piv nrog cov tsoos hloov tau yooj yim PCB, HDI saj zawg zog PCB muaj ntau yam zoo, suav nrog:

Nce Circuit Court ceev:

HDI Technology Pab kom siab dua ntom ntom ntom kauj voos tsheb kauj vab ncig, enabling ntau cov khoom sib xyaw kom muab tso rau hauv ib txoj kev taug meter me me. Qhov no ua rau lub miniaturized thiab compact tsim.

Txhim kho teeb liab kev ncaj ncees:

Qhov luv luv routing nrug hauv HDI flex PCBs ua rau muaj kev cuam tshuam ntawm electromagnetic tsawg (EMI), uas ua rau muaj teeb meem zoo dua qub, txo cov teeb liab distortion thiab ua kom ntseeg tau kev ua tau zoo.

Txhim khu kev ntseeg tau:

Piv rau cov tsoos flex PCBs, HDI flex PCBs muaj cov ntsiab lus kev ntxhov siab tsawg dua thiab zoo dua rau kev co, khoov, thiab thermal stress. Qhov no txhim kho tag nrho kev ntseeg siab thiab lub neej ntawm lub voj voog.

Tsim yooj yooj yim:

HDI thev naus laus zis ua rau kev tsim qauv hauv Circuit Court, tso cai rau kev sib xyaw ua ke ntawm ntau txheej, qhov muag tsis pom thiab faus vias, cov khoom siv suab zoo, thiab cov teeb liab ceev ceev.

Kev txuag nqi:

Txawm hais tias nws cov complexity thiab miniaturization, HDI flex PCBs tuaj yeem txuag cov nqi los ntawm kev txo tag nrho qhov loj thiab qhov hnyav ntawm cov khoom kawg, ua rau lawv muaj txiaj ntsig zoo rau cov ntawv thov uas qhov chaw thiab qhov hnyav yog qhov tseem ceeb.

2.Kev sib piv ntawm HDI saj zawg zog PCB thiab ib txwm saj zawg zog PCB:

2.1 Qhov sib txawv hauv cov qauv:

Qhov sib txawv tseem ceeb ntawm cov qauv yooj yim ntawm HDI saj zawg zog PCB thiab ib txwm hloov pauv PCB yog nyob rau hauv Circuit Court ceev thiab siv cov cuab yeej sib txuas.

Traditional flex PCBs feem ntau muaj ib txheej ntawm cov khoom siv hloov pauv tau yooj yim xws li polyimide, nrog cov kab tooj liab etched ntawm qhov chaw. Cov laug cam no feem ntau muaj qhov txwv tsis pub siv hluav taws xob vim tsis muaj ntau txheej txheej thiab kev sib tshuam sib tshuam.

Ntawm qhov tod tes, HDI saj zawg zog PCB txais kev sib txuas ntawm cov cuab yeej siv high-density, uas tuaj yeem xa cov kab hluav taws xob ntau dua hauv qhov chaw compact. Qhov no yog ua tiav los ntawm kev siv ntau txheej ntawm cov khoom siv flex stacked ua ke nrog cov kab tooj liab thiab cov nplaum. HDI saj zawg zog PCBs feem ntau siv qhov muag tsis pom thiab faus vias, uas yog qhov drilled los ntawm cov txheej txheem tshwj xeeb los txuas cov kab hluav taws xob hauv lub rooj tsavxwm, yog li txhim kho tag nrho cov peev txheej.

Tsis tas li ntawd, HDI flex PCBs tuaj yeem siv microvias, uas yog qhov me me uas tso cai rau cov kab khiav tawm. Kev siv cov microvias thiab lwm yam kev sib txuas thev naus laus zis tuaj yeem ua rau muaj kev sib txuas ntau dua piv rau cov tsoos flex PCBs.

2.2 Qhov tseem ceeb ntawm HDI hloov pauv PCB:

HDI flex PCBs tau dhau los ua qhov tseem ceeb thiab kev nce qib ntau xyoo. Qee qhov kev nce qib loj hauv HDI hloov pauv PCB thev naus laus zis suav nrog:

Miniaturization:

HDI thev naus laus zis tso cai rau cov khoom siv hluav taws xob me me los ntawm kev tso cai rau cov kab hluav taws xob ntau dua los ntawm qhov chaw tsawg dua. Qhov no ua rau txoj hauv kev rau kev tsim cov khoom me me, ntau cov khoom lag luam xws li smartphones, cov cuab yeej siv tau zoo thiab cov khoom siv kho mob.

Nce Circuit Court ceev:

Piv nrog rau cov PCB hloov tau yooj yim, kev siv ntau txheej, qhov muag tsis pom kev faus vias, thiab microvias hauv HDI hloov pauv PCBs ua rau muaj kev sib tw ntau dua. Qhov no ua rau nws muaj peev xwm ua kom muaj kev sib koom ua ke ntau dua thiab cov qauv tsim hluav taws xob siab tshaj hauv ib cheeb tsam me.

Siab ceev thiab teeb liab kev ncaj ncees:

HDI flex PCBs tuaj yeem pab txhawb cov teeb liab ceev thiab txhim kho cov teeb liab kev ncaj ncees raws li qhov kev ncua deb ntawm cov khoom thiab kev sib tshuam txo qis. Qhov no ua rau lawv tsim nyog rau cov ntawv thov uas xav tau kev xa cov teeb liab txhim khu kev qha, xws li kev sib txuas lus ntau zaus lossis cov khoom siv siv cov ntaub ntawv.

Fine-pitch Cheebtsam layout:

HDI thev naus laus zis pab txhawb kev teeb tsa ntawm cov khoom zoo-pitch, uas txhais tau hais tias cov khoom tuaj yeem muab tso rau ze zog ua ke, ua rau ntxiv me me thiab qhov ntom ntom ntawm kev teeb tsa hauv Circuit Court. Fine-pitch Cheebtsam kev tso kawm yog qhov tseem ceeb rau cov ntawv thov siab heev uas xav tau cov khoom siv hluav taws xob ua haujlwm siab.

Txhim kho thermal tswj:

HDI flex PCBs muaj peev xwm tswj tau cov thermal zoo dua vim yog siv ntau txheej txheej thiab nce qhov chaw rau cov cua sov dissipation. Qhov no tso cai rau kev tuav tau zoo thiab

cua txias ntawm cov khoom siv hluav taws xob siab, ua kom lawv cov kev ua haujlwm siab tshaj plaws.

2.3 Kev ua haujlwm thiab kev sib piv:

Thaum muab piv rau kev ua haujlwm thiab kev ua haujlwm ntawm HDI flex PCBs rau cov tsoos flex PCBs, muaj ntau yam los xav txog:

Circuit Court ceev:

Piv rau cov tsoos flex PCBs, HDI flex PCBs muaj ntau dua Circuit Court ceev. HDI thev naus laus zis tuaj yeem sib xyaw ua ke ntau txheej, qhov muag tsis pom kev, faus vias, thiab microvias, ua kom muaj ntau txoj hauv kev thiab denser Circuit Court tsim.

Teeb liab kev ncaj ncees:

Qhov kev ncua deb ntawm cov kab thiab kev siv cov txheej txheem kev sib txuas siab heev hauv HDI flex PCBs txhim kho cov teeb liab kev ncaj ncees. Qhov no txhais tau tias zoo dua cov teeb liab kis tau tus mob thiab txo cov teeb liab distortion piv rau cov pa flex PCBs.

Ceev thiab Bandwidth:

HDI flex PCBs muaj peev xwm txhawb nqa cov teeb liab ceev dua vim kev txhim kho cov teeb liab kev ncaj ncees thiab txo cov hluav taws xob cuam tshuam. Pa flex PCBs tuaj yeem muaj kev txwv ntawm cov teeb liab kis ceev thiab bandwidth, tshwj xeeb tshaj yog hauv cov ntawv thov uas xav tau cov ntaub ntawv siab.

Tsim yooj yooj yim:

Piv nrog rau cov tsoos flex PCBs, HDI flex PCBs muab ntau dua tsim yooj yim. Lub peev xwm los sib txuas ntau cov khaubncaws sab nraud povtseg, qhov muag tsis pom thiab faus vias, thiab microvias tso cai rau ntau qhov kev tsim hluav taws xob. Qhov kev hloov pauv no yog qhov tseem ceeb tshwj xeeb rau cov ntawv thov uas xav tau kev tsim qauv compact lossis muaj qhov txwv tshwj xeeb.

Tus nqi:

HDI flex PCBs zoo li yuav kim dua li cov tsoos flex PCBs vim yog qhov nyuaj ntxiv thiab cov txheej txheem kev sib txuas siab heev koom nrog. Txawm li cas los xij, qhov miniaturization thiab txhim kho kev ua tau zoo muab los ntawm HDI flex PCBs feem ntau tuaj yeem ua pov thawj tus nqi ntxiv thaum tag nrho cov nqi ntawm cov khoom kawg raug txiav txim siab.

2.4 Reliability thiab Durability Factors:

Kev ntseeg tau thiab kav ntev yog qhov tseem ceeb rau txhua yam khoom siv hluav taws xob lossis qhov system. Ntau yam tuaj rau hauv kev ua si thaum muab piv rau kev ntseeg siab thiab ua haujlwm ntev ntawm HDI flex PCBs rau cov tsoos flex PCBs:

Mechanical Flexibility:

Ob leeg HDI thiab cov tsoos flex PCBs muab cov neeg kho tshuab hloov tau yooj yim, tso cai rau lawv hloov mus rau cov duab sib txawv thiab khoov yam tsis muaj kev tawg. Txawm li cas los xij, HDI flex PCBs tuaj yeem muaj cov txheej txheem ntxiv, xws li cov khaubncaws sab nraud povtseg lossis ribs ntxiv, txhawm rau txhawb kev sib zog ua kom muaj zog. Qhov kev txhawb nqa no txhim kho tag nrho kev ntseeg siab thiab ua haujlwm ntev ntawm HDI flex PCB.

Anti-vibration thiab shock:

Piv nrog rau cov tsoos hloov pauv PCB, HDI hloov pauv PCB tuaj yeem muaj peev xwm tiv thaiv kev vibration zoo dua thiab poob siab. Kev siv qhov muag tsis pom, faus, thiab microvias hauv HDI boards pab faib kev ntxhov siab ntau dua, txo qhov muaj feem cuam tshuam los yog kev ua haujlwm tsis zoo vim muaj kev ntxhov siab.

Thermal Management:

Piv nrog rau cov tsoos flex PCB, HDI flex PCB muaj ntau txheej txheej thiab thaj chaw loj dua, uas tuaj yeem muab kev tswj xyuas thermal zoo dua. Qhov no txhim kho cov cua kub dissipation thiab pab ua kom tag nrho cov kev ntseeg tau thiab lifespan ntawm electronics.

Lifespan:

Ob HDI thiab ib txwm flex PCBs tuaj yeem muaj lub neej ntev yog tias tsim thiab tsim tau zoo. Txawm li cas los xij, qhov kev sib txuas ntxiv ntawm qhov ceev thiab cov txheej txheem kev sib txuas siab siv hauv HDI flex PCBs yuav tsum tau ua tib zoo xav txog yam xws li thermal stress, cov khoom siv sib xws, thiab kev ntsuam xyuas kev ntseeg siab kom ntseeg tau tias kev ua haujlwm ntev.

Environmental factor:

HDI flex PCBs, zoo li tsoos flex PCBs, yuav tsum tau tsim thiab tsim los tiv thaiv ib puag ncig yam xws li av noo, kub hloov pauv, thiab raug tshuaj lom neeg. HDI flex PCBs yuav xav tau cov txheej txheem tiv thaiv ntxiv los yog encapsulation kom ntseeg tau tias muaj kev tiv thaiv ib puag ncig.

HDI flex PCBs muaj ntau qhov zoo dua li cov tsoos flex PCBs nyob rau hauv cov nqe lus ntawm Circuit Court ceev, teeb liab kev ncaj ncees, tsim yooj, thiab kev ntseeg tau. Kev siv qib siabCov txheej txheem kev sib txuas thiab cov txheej txheem me me ua rau HDI flex PCBs haum rau cov ntawv thov uas xav tau cov khoom siv hluav taws xob ua haujlwm siab hauv daim ntawv cog lus.Txawm li cas los xij, cov txiaj ntsig zoo no tuaj ntawm tus nqi siab dua thiab cov kev cai tshwj xeeb ntawm daim ntawv thov yuav tsum tau ua tib zoo txiav txim siab txog qhov tsim nyog tshaj plaws PCB technology.

3.Qhov zoo ntawm HDI Flexible PCB:

HDI (High Density Interconnect) flex PCBs tau txais kev muaj koob npe hauv kev lag luam hluav taws xob vim lawv qhov zoo heev ntawm cov khoom siv flex PCBs.

3.1 Miniaturization thiab qhov chaw optimization:

Miniaturization thiab qhov chaw optimization: Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm HDI hloov pauv PCB yog qhov miniaturization thiab qhov chaw optimization ntawm cov khoom siv hluav taws xob.Kev siv cov cuab yeej siv high-density interconnection tso cai rau cov kab hluav taws xob ntau ntxiv mus rau hauv qhov chaw compact. Qhov no nyob rau hauv lem pab txoj kev loj hlob ntawm me me, compact electronics. HDI flex PCBs feem ntau yog siv rau hauv cov ntawv thov xws li smartphones, ntsiav tshuaj, cov khoom siv, thiab cov khoom siv kho mob uas qhov chaw txwv thiab qhov loj me yog qhov tseem ceeb.

3.2 Txhim kho teeb liab kev ncaj ncees:

Txhim kho cov teeb liab kev ncaj ncees: Cov teeb liab kev ncaj ncees yog ib qho tseem ceeb ntawm cov khoom siv hluav taws xob, tshwj xeeb tshaj yog nyob rau hauv high-speed thiab high-frequency applications.HDI flex PCBs ua tau zoo ntawm kev xa cov teeb liab siab dua vim qhov txo qis ntawm cov khoom sib txuas thiab kev sib tshuam. Advanced interconnection technologies siv hauv HDI flex PCBs, xws li dig muag vias, faus vias, thiab microvias, tuaj yeem txo cov teeb liab poob thiab cuam tshuam ntawm electromagnetic. Txhim kho teeb liab kev ncaj ncees ua kom ntseeg tau cov teeb liab kis tau tus mob thiab txo cov kev pheej hmoo ntawm cov ntaub ntawv yuam kev, ua HDI flex PCBs tsim nyog rau cov ntawv thov uas muaj cov ntaub ntawv ceev thiab kev sib txuas lus.

3.3 Txhim khu kev faib hluav taws xob:

Txhim khu kev faib hluav taws xob: Lwm qhov zoo ntawm HDI flex PCB yog nws lub peev xwm los txhim kho lub zog xa khoom.Nrog rau qhov nyuaj ntawm cov khoom siv hluav taws xob ntau ntxiv thiab qhov xav tau ntawm cov khoom siv hluav taws xob ntau dua, HDI flex PCBs muab cov kev daws teeb meem zoo rau kev faib hluav taws xob zoo. Siv ntau txheej txheej thiab cov txheej txheem kev siv hluav taws xob siab ua kom zoo dua lub rooj tsav xwm thoob plaws lub zog, txo qis hluav taws xob thiab hluav taws xob poob. Txhim khu kev faib hluav taws xob ua kom muaj kev ruaj ntseg ntawm cov khoom siv hluav taws xob tshaib plab thiab txo qhov kev pheej hmoo ntawm overheating, ua kom muaj kev nyab xeeb thiab ua haujlwm zoo.

3.4 Cov khoom siv siab dua:

Kev tivthaiv ntau dua: Piv nrog cov khoom siv hloov pauv tau yooj yim PCB, HDI hloov pauv tau PCB tuaj yeem ua tiav cov khoom siv ntau dua.Kev siv cov txheej txheem ntau txheej thiab cov thev naus laus zis sib cuam tshuam tso cai rau kev sib koom ua ke ntawm cov khoom siv hluav taws xob ntau dua hauv qhov chaw me me. Hdi Flex PCBS tuaj yeem ua kom haum thiab siv cov txheej txheem hluav taws xob tsim kho, uas yog qhov tseem ceeb rau cov ntawv thov siab uas yuav tsum tau ua haujlwm yam tsis muaj kev ua haujlwm tsis muaj kev cuam tshuam loj. Nrog cov khoom siv ntau dua, cov tuam ntxhab tuaj yeem tsim thiab tsim cov khoom siv hluav taws xob muaj txiaj ntsig thiab muaj txiaj ntsig zoo.

3.5 Txhim kho cua sov dissipation:

Txhim kho cov cua sov kom zoo: Thaum tshav kub kub dissipation yog ib qho tseem ceeb ntawm kev tsim khoom siv hluav taws xob, vim tias cov cua kub ntau dhau tuaj yeem ua rau kev ua haujlwm tsis zoo, cov khoom tsis ua haujlwm thiab txawm tias lub cev puas tsuaj.Piv nrog rau cov PCB hloov tau yooj yim, HDI saj zawg zog PCB muaj kev ua haujlwm zoo dua tshav kub. Kev siv ntau cov khaubncaws sab nraud povtseg thiab nce qhov chaw saum npoo tso cai rau kom muaj cua sov zoo dua, tshem tawm tau zoo thiab dissipating cov cua sov uas tsim los ntawm cov khoom siv hluav taws xob tshaib plab. Qhov no ua kom muaj kev ua tau zoo thiab kev ntseeg siab ntawm cov khoom siv hluav taws xob, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas muaj kev tswj xyuas thermal yog qhov tseem ceeb.

HDI flex PCBs muaj ntau qhov zoo uas ua rau lawv xaiv zoo rau cov khoom siv hluav taws xob niaj hnub no. Lawv lub peev xwm los ua qhov me me thiab qhov chaw optimized ua rau lawv zoo tagnrho rau cov ntawv thov uas qhov loj me yog qhov tseem ceeb. Txhim kho teeb liab kev ncaj ncees kom ntseeg tau cov ntaub ntawv xa mus, thaum txhim kho lub zog faib ua kom muaj zog ntawm cov khoom siv. Hdi Flex PCB PCB lub zog sib xyaw ntau dua thiab cov nta, thaum txhim kho cua sov dissipation ua kom muaj kev ua tau zoo thiab ntev ntawm cov khoom siv hluav taws xob. Nrog rau cov txiaj ntsig zoo no, HDI flex PCBs tau dhau los ua qhov tsim nyog hauv ntau yam kev lag luam xws li cov khoom siv hluav taws xob, kev sib txuas lus, tsheb, thiab khoom siv kho mob.

4.Daim ntawv thov ntawm HDI saj zawg zog PCB:

HDI saj zawg zog PCB muaj ntau yam kev siv hauv kev lag luam sib txawv. Lawv lub peev xwm me me, txhim kho cov teeb liab kev ncaj ncees, txhim kho kev faib hluav taws xob, cov khoom sib txuas siab dua, thiab kev ua kom sov zoo dua ua rau lawv zoo tagnrho rau cov neeg siv khoom siv hluav taws xob, cov khoom siv kho mob, kev lag luam tsheb, aerospace thiab tiv thaiv systems, thiab Internet ntawm Yam thiab wearables. cov khoom tseem ceeb hauv lub cuab yeej. HDI flex PCBs pab cov tuam txhab tsim cov khoom siv hluav taws xob compact, ua haujlwm siab kom tau raws li qhov xav tau ntawm cov kev lag luam no.

4.1 Consumer Electronics:

HDI hloov pauv PCB muaj ntau yam kev siv hauv kev lag luam khoom siv hluav taws xob.Nrog rau qhov kev thov txuas ntxiv rau cov khoom me me, thinner, thiab ntau yam khoom muaj txiaj ntsig, HDI flex PCBs pab cov tuam txhab ua kom tau raws li cov kev xav tau no. Lawv siv hauv smartphones, ntsiav tshuaj, laptops, smart watches thiab lwm yam khoom siv hluav taws xob portable. Lub peev xwm miniaturization ntawm HDI hloov pauv PCBs tso cai rau kev sib koom ua ke ntawm ntau lub luag haujlwm hauv qhov chaw sib cog lus, ua rau kev txhim kho ntawm cov khoom siv hluav taws xob zoo nkauj thiab kev ua haujlwm siab.

4.2 Cov khoom siv kho mob:

Kev lag luam khoom siv kho mob cia siab ntau rau HDI flex PCBs vim tias lawv muaj kev ntseeg siab, yoog raws, thiab daim ntawv me me.Cov khoom siv hluav taws xob hauv cov khoom siv kho mob xws li cov pacemakers, cov khoom siv hnov lus, ntsuas ntshav qabzib thiab cov cuab yeej siv tshuaj ntsuam xyuas yuav tsum muaj qhov tseeb. HDI flex PCBs tuaj yeem ua tau raws li cov cai no los ntawm kev muab cov kev sib txuas siab ceev thiab txhim kho cov teeb liab kev ncaj ncees. Tsis tas li ntawd, lawv qhov kev hloov pauv tuaj yeem ua ke zoo dua rau hauv cov khoom siv kho mob uas siv tau rau cov neeg mob kev nplij siab thiab yooj yim.

4.3 Auto Kev Lag Luam:

HDI flex PCBs tau dhau los ua ib feem tseem ceeb ntawm cov tsheb niaj hnub.Kev lag luam automotive xav tau cov khoom siv hluav taws xob ua haujlwm siab uas tuaj yeem tiv taus ib puag ncig nyuaj thiab xa cov kev ua haujlwm zoo. HDI flex PCBs muab qhov tsim nyog kev ntseeg siab, ua haujlwm ntev thiab qhov chaw zoo rau kev siv tsheb. Lawv tau siv nyob rau hauv ntau lub tshuab tsheb suav nrog infotainment systems, navigation systems, powertrain control modules thiab advanced driver help systems (ADAS). HDI flex PCBs tuaj yeem tiv taus qhov kub thiab txias hloov, kev co thiab cov neeg kho tshuab kev ntxhov siab, ua rau lawv haum rau qhov hnyav hauv tsheb.

4.4 Aerospace thiab Defense:

Kev lag luam aerospace thiab kev tiv thaiv yuav tsum muaj kev ntseeg siab hauv tshuab hluav taws xob uas tuaj yeem tiv taus huab cua, kev co thiab kev xa cov ntaub ntawv ceev.HDI flex PCBs yog qhov zoo tshaj plaws rau cov ntawv thov no vim tias lawv muab cov kev sib txuas siab ceev, txhim kho cov teeb liab kev ncaj ncees, thiab tiv thaiv ib puag ncig. Lawv siv nyob rau hauv avionics systems, satellite kev sib txuas lus, radar systems, tub rog khoom thiab drones. Lub peev xwm miniaturization ntawm HDI flex PCBs pab txhim kho lub teeb yuag, compact electronic systems uas ua kom muaj kev ua tau zoo dua thiab ua haujlwm ntau dua.

4.5 IoT thiab Wearable Devices:

Is Taws Nem ntawm Yam (IoT) thiab cov khoom siv hnav tau hloov pauv kev lag luam xws li kev noj qab haus huv thiab kev noj qab haus huv mus rau hauv tsev automation thiab kev saib xyuas kev lag luam.HDI flex PCBs yog cov khoom tseem ceeb hauv IoT thiab cov khoom siv coj los siv vim lawv cov qauv me me thiab hloov tau yooj yim. Lawv ua kom muaj kev sib koom ua ke ntawm cov sensors, wireless kev sib txuas lus modules, thiab microcontrollers hauv cov khoom siv xws li smart watches, Fitness trackers, smart home devices, and industrial sensors. Kev sib txuas thev naus laus zis hauv HDI flex PCBs ua kom ntseeg tau cov ntaub ntawv xa mus, kev faib hluav taws xob, thiab teeb pom kev ncaj ncees, ua rau lawv tsim nyog rau cov kev xav tau ntawm IoT thiab cov khoom siv hnav.

5.Design Considerations rau HDI Flex PCB:

Tsim kom muaj HDI flex PCB yuav tsum tau ua tib zoo xav txog cov txheej txheej txheej txheej, kab sib nrug, kev tso kawm, cov txheej txheem tsim kev kub ceev, thiab cov teeb meem cuam tshuam nrog kev sib dhos thiab kev tsim khoom. Los ntawm kev hais daws cov kev xav tau zoo no, Capel tuaj yeem tsim kev ua haujlwm siab HDI flex PCBs haum rau ntau yam kev siv.

5.1 Txheej stacking thiab routing:

HDI flex PCBs feem ntau xav tau ntau txheej txheej kom ua tiav cov kev sib tshuam siab.Thaum tsim cov txheej txheej, yam xws li teeb liab kev ncaj ncees, kev faib hluav taws xob, thiab kev tswj xyuas thermal yuav tsum raug txiav txim siab. Ua tib zoo txheej txheej txheej pab txhim kho cov teeb liab routing thiab txo qis crosstalk ntawm kab. Routing yuav tsum tau npaj kom txo cov teeb liab skew thiab xyuas kom meej impedance txuam. Qhov chaw txaus yuav tsum tau muab faib rau cov vias thiab cov ntaub qhwv kom yooj yim rau kev sib txuas ntawm cov khaubncaws sab nraud povtseg.

5.2 Txoj kab sib nrug thiab impedance tswj:

Hdi Flex PCBs feem ntau muaj qhov ua kom siab ntev ntawm cov kab, kev tswj hwm txoj kev kom tsim nyog yog qhov tseem ceeb los tiv thaiv kev cuam tshuam ntawm kev cuam tshuam ntawm kev cuam tshuam rau cov teeb liab thiab kev hla dej.Cov neeg tsim qauv yuav tsum txiav txim siab txoj kab dav dav thiab qhov sib txawv raws li qhov xav tau impedance. Kev tswj hwm impedance yog qhov tseem ceeb rau kev tswj cov teeb liab kev ncaj ncees, tshwj xeeb tshaj yog rau cov teeb liab ceev. Cov neeg tsim qauv yuav tsum ua tib zoo xam thiab tswj cov kab dav dav, qhov sib nrug, thiab dielectric tas li kom ua tiav qhov xav tau impedance tus nqi.

5.3 Qhov chaw tso chaw:

Kev tso kawm kom raug yog qhov tseem ceeb rau kev txhim kho txoj kev teeb liab, txo cov suab nrov thiab txo qhov loj ntawm HDI flex PCB.Cov Cheebtsam yuav tsum tau muab tso rau hauv lub tswv yim kom txo cov teeb liab kab ntev thiab optimize lub teeb liab ntws. High-speed Cheebtsam yuav tsum tau muab tso rau ze ua ke kom txo tau lub teeb liab propagation qeeb thiab txo cov kev pheej hmoo ntawm teeb liab distortion. Cov neeg tsim qauv tseem yuav tsum xav txog kev tswj xyuas thermal thiab xyuas kom meej tias cov khoom raug muab tso rau hauv ib qho uas tso cai rau cov cua sov dissipation.

5.4 High-speed design technology:

HDI flex PCBs feem ntau ua rau cov ntaub ntawv xa mus ceev uas qhov teeb meem kev ncaj ncees yog qhov tseem ceeb.Cov txheej txheem tsim kev kub ceev kom zoo, xws li kev tswj xyuas impedance routing, sib txawv khub routing, thiab matched trace lengths, yog ib qho tseem ceeb rau txo cov teeb liab attenuation. Cov cuab yeej ntsuas ntsuas kev ncaj ncees tuaj yeem siv los simulate thiab txheeb xyuas qhov kev ua tau zoo ntawm kev tsim qauv siab.

5.5 Kev Sib Koom Tes thiab Kev Lag Luam Kev Lag Luam:

Kev sib dhos thiab tsim khoom ntawm HDI flex PCBs nthuav qhia ntau qhov kev sib tw.Qhov hloov tau yooj yim ntawm PCBs yuav tsum tau ua tib zoo tuav thaum lub rooj sib txoos kom tsis txhob ua kom cov kab thiab cov khoom puas. Kev muab cov khoom pov thawj thiab kev sib txuas yuav tsum tau siv cov cuab yeej tshwj xeeb thiab cov txheej txheem. Cov txheej txheem fabrication yuav tsum tau xyuas kom meej meej sib dhos ntawm cov khaubncaws sab nraud povtseg thiab zoo adhesion ntawm lawv, uas tej zaum yuav muaj ntxiv cov kauj ruam xws li laser drilling los yog laser ncaj imaging.

Tsis tas li ntawd, qhov me me thiab qhov hnyav ntawm HDI flex PCBs tuaj yeem tsim teeb meem rau kev tshuaj xyuas thiab kev sim. Kev tshuaj xyuas tshwj xeeb xws li kev kuaj X-ray yuav tsum tau kuaj xyuas qhov tsis xws lossis tsis ua haujlwm hauv PCBs. Tsis tas li ntawd, txij li HDI flex PCBs feem ntau siv cov khoom siv thiab thev naus laus zis, kev xaiv thiab kev tsim nyog ntawm cov neeg muag khoom yog qhov tseem ceeb los xyuas kom meej qhov zoo thiab kev ntseeg siab ntawm cov khoom kawg.

6. Yav tom ntej tiam sis ntawm HDI saj zawg zog PCB tshuab:

Lub neej yav tom ntej ntawm HDI saj zawg zog PCB thev naus laus zis yuav yog tus cwj pwm los ntawm kev sib koom ua ke thiab kev nyuaj, kev siv cov khoom siv siab heev, thiab nthuav dav ntawm IoT thiab kev siv thev naus laus zis. Cov qauv no yuav tsav kev lag luam los tsim cov khoom me me, muaj zog dua, thiab ntau yam khoom siv hluav taws xob.

6.1 Ntxiv kev sib xyaw ua ke thiab complexity:

HDI saj zawg zog PCB thev naus laus zis yuav txuas ntxiv txhim kho nyob rau hauv kev coj ua ntawm kev sib koom ua ke thiab kev nyuaj.Raws li cov khoom siv hluav taws xob ua ntau dua thiab muaj txiaj ntsig zoo, muaj kev xav tau ntau ntxiv rau HDI flex PCBs nrog ntau dua circuit density thiab cov qauv me me. Cov qauv no yog tsav los ntawm kev nce qib hauv cov txheej txheem tsim khoom thiab tsim cov cuab yeej uas ua kom muaj cov kab sib tw zoo dua, cov vias me me, thiab kev sib txuas sib txuas ntxiv. Kev sib xyaw ua ke ntawm cov khoom siv hluav taws xob sib txawv thiab sib txawv ntawm ib qho yooj yim PCB yuav dhau los ua ntau dua

common, txo qhov loj me, hnyav thiab tag nrho cov nqi system.

6.2 Siv cov khoom siv siab heev:

Txhawm rau ua kom tau raws li qhov xav tau ntawm kev sib koom ua ke thiab kev ua haujlwm siab dua, HDI hloov pauv PCB yuav siv cov khoom siv siab heev.Cov ntaub ntawv tshiab nrog kev txhim kho hluav taws xob, thermal thiab mechanical zog yuav ua kom lub teeb pom kev zoo dua qub, txhim kho cov cua sov thiab kev ntseeg siab dua. Piv txwv li, kev siv cov khoom siv hluav taws xob tsawg tsawg yuav tso cai rau kev ua haujlwm ntau dua, thaum cov ntaub ntawv thermal conductivity tuaj yeem txhim kho thermal tswj peev xwm ntawm flex PCBs. Tsis tas li ntawd, kev nce qib hauv cov khoom siv hluav taws xob xws li tooj liab alloys thiab cov khoom siv hluav taws xob polymer yuav ua rau muaj peev xwm nqa tau ntau dua tam sim no thiab kev tswj hwm impedance zoo dua.

6.3 Kev nthuav dav ntawm IoT thiab Wearable Technology:

Kev nthuav dav ntawm Is Taws Nem ntawm Yam (IoT) thiab kev siv thev naus laus zis yuav muaj kev cuam tshuam loj rau HDI hloov pauv PCB thev naus laus zis.Raws li tus naj npawb ntawm cov khoom txuas txuas txuas ntxiv mus ntxiv, yuav muaj kev xav tau ntau ntxiv rau cov PCBs hloov tau yooj yim uas tuaj yeem muab tso ua ke rau hauv cov ntawv me thiab ntau yam sib txawv. HDI flex PCBs yuav ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv me me xws li cov watches ntse, lub cev qoj ib ce thiab kev saib xyuas kev noj qab haus huv. Cov khoom siv no feem ntau xav tau PCBs hloov tau yooj yim kom ua raws li lub cev thiab muab kev sib raug zoo thiab txhim khu kev qha.

Ntxiv mus, kev siv dav dav ntawm IoT cov cuab yeej siv hauv ntau qhov kev lag luam xws li lub tsev ntse, tsheb, thiab kev lag luam automation yuav tsav qhov kev thov rau HDI hloov pauv PCBs nrog cov yam ntxwv zoo xws li cov ntaub ntawv ceev ceev, kev siv hluav taws xob tsawg, thiab kev sib txuas wireless. Cov kev nce qib no yuav xav tau PCBs los txhawb cov teeb liab kev sib txuas, cov khoom siv me me thiab kev koom ua ke nrog cov sensors sib txawv thiab cov actuators.

Hauv cov ntsiab lus, HDI flex PCBs tau hloov pauv kev lag luam hauv hluav taws xob nrog lawv cov kev sib xyaw ua ke ntawm kev yooj yim thiab kev sib txuas siab. Cov PCBs no muaj ntau yam zoo dua li ib txwm flex PCBs, suav nrog kev ua haujlwm me me, qhov chaw ua kom zoo dua qub, txhim kho cov teeb liab kev ncaj ncees, kev faib hluav taws xob zoo, thiab muaj peev xwm ua kom haum rau cov khoom siv siab. Cov khoom no ua rau HDI flex PCBs haum rau siv ntau yam kev lag luam, suav nrog cov khoom siv hluav taws xob, khoom siv kho mob, tshuab tsheb, thiab kev siv aerospace. Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum xav txog cov kev xav txog kev tsim thiab kev tsim khoom lag luam uas cuam tshuam nrog cov PCBs siab heev. Cov neeg tsim qauv yuav tsum ua tib zoo npaj layout thiab routing los xyuas kom meej lub teeb pom kev zoo thiab kev tswj thermal. Tsis tas li ntawd, kev tsim cov txheej txheem ntawm HDI flex PCBs yuav tsum muaj cov txheej txheem siab heev thiab cov txheej txheem kom ua tiav qhov yuav tsum tau ua ntawm qhov tseeb thiab kev ntseeg tau. Mus rau pem hauv ntej, HDI hloov tau PCBs yuav tsum txuas ntxiv hloov zuj zus raws li kev siv thev naus laus zis. Raws li cov khoom siv hluav taws xob ua me me thiab nyuaj, qhov xav tau rau HDI flex PCBs nrog qib siab ntawm kev sib koom ua ke thiab kev ua tau zoo tsuas yog nce ntxiv. Qhov no yuav ua rau muaj kev hloov pauv tshiab thiab kev nce qib hauv kev ua haujlwm, ua rau muaj txiaj ntsig zoo thiab ntau yam khoom siv hluav taws xob thoob plaws kev lag luam.

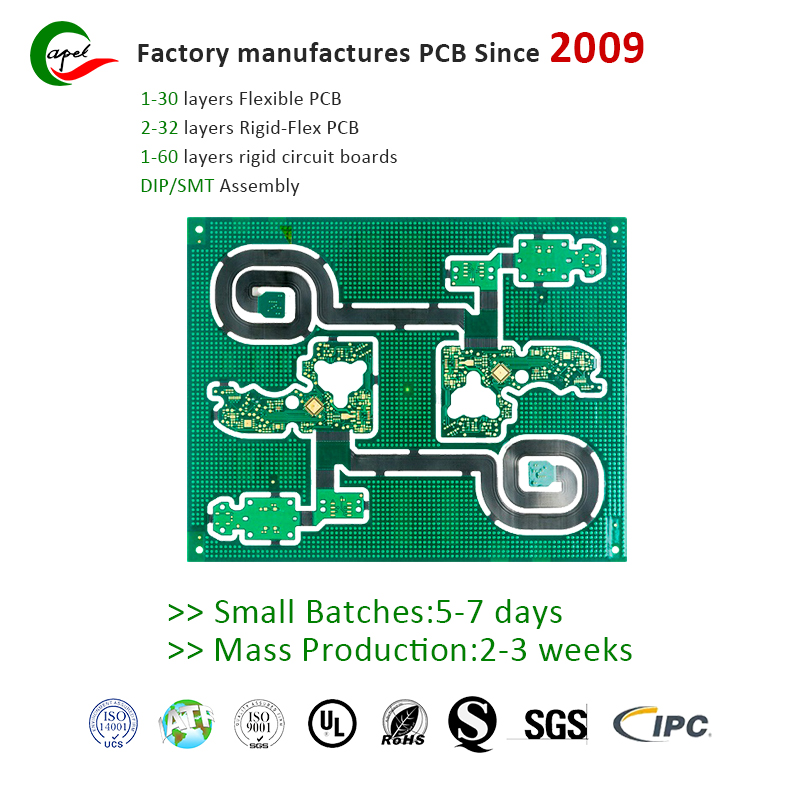

Shenzhen Capel Technology Co., Ltd. tau tsim cov khoom lag luam yooj yim luam tawm Circuit Board (PCBs) txij li xyoo 2009.Tam sim no, peb muaj peev xwm muab kev cai 1-30 txheej hloov tau yooj yim luam tawm Circuit Court boards. Peb HDI (High Density Interconnect) saj zawg zog PCB manufacturing technology yog heev paub tab. Tshaj li 15 xyoo dhau los, peb tau tsim cov thev naus laus zis tsis tu ncua thiab tau txais kev paub nplua nuj hauv kev daws teeb meem ntsig txog qhov project rau cov neeg siv khoom.

Post lub sij hawm: Aug-31-2023

Rov qab