cia peb delve rau hauv cov txheej txheem tsim khoom ntawm cov khoom siv hluav taws xob hloov tau yooj yim thiab nkag siab tias vim li cas lawv tau siv dav hauv ntau yam lag luam.

Flexible circuits, tseem hu ua flexible printed circuits lossis FPCs, yog nrov thoob plaws ntau yam lag luam. Los ntawm cov neeg siv khoom siv hluav taws xob mus rau cov khoom siv kho mob, cov khoom siv hluav taws xob hloov pauv tau hloov pauv txoj kev siv hluav taws xob tsim thiab tsim khoom. Raws li qhov kev thov rau cov khoom siv hluav taws xob sib txuas thiab lub teeb yuag txuas ntxiv mus ntxiv, nws yog ib qho tseem ceeb kom nkag siab txog cov txheej txheem tsim khoom ntawm cov khoom siv hluav taws xob hloov pauv thiab yuav ua li cas lawv tau dhau los ua ib feem ntawm cov cuab yeej siv niaj hnub no.

Flex circuits yog qhov tseem ceeb ntawm kev sib xyaw ua ke ntawm ntau txheej txheej ntawm cov khoom siv tau yooj yim, xws li polyester lossis polyimide, mus rau cov kab hluav taws xob, cov ntaub qhwv, thiab cov khoom siv. Cov kab hluav taws xob no hloov tau yooj yim thiab tuaj yeem folded lossis dov, ua rau lawv zoo tagnrho rau cov ntawv thov uas qhov chaw txwv.

1. Tsim layout hauv flex circuit manufacturing:

Thawj kauj ruam hauv kev tsim ib lub voj voog hloov tau yog qhov tsim thiab txheej txheem txheej txheem. Cov kws tsim qauv thiab cov kws tsim qauv ua haujlwm ua ke los tsim cov txheej txheem uas ua tau raws li qhov tshwj xeeb ntawm daim ntawv thov. Layout suav nrog kev tso chaw ntawm cov kab hluav taws xob, cov khoom siv, thiab lwm yam ntxiv uas yuav xav tau.

2. Cov khoom xaiv hauv flex circuit fabrication:

Tom qab lub sijhawm tsim, cov kauj ruam tom ntej yog xaiv cov khoom tsim nyog rau lub voj voog hloov tau. Kev xaiv cov khoom yog nyob ntawm yam xws li xav tau kev hloov pauv, kev ua haujlwm kub, thiab xav tau hluav taws xob thiab cov khoom siv kho tshuab. Polyimide thiab polyester feem ntau siv cov ntaub ntawv vim lawv zoo heev yooj thiab thermal stability.

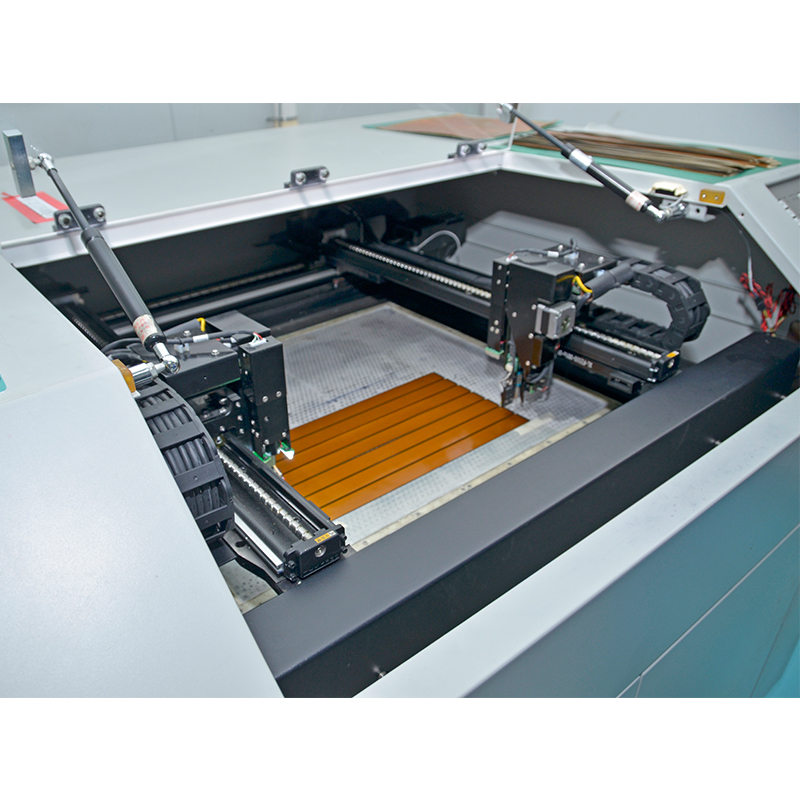

3. Kev tsim cov hauv paus substrate hauv flex Circuit Court ua:

Thaum cov khoom raug xaiv, fabrication ntawm lub hauv paus substrate pib. Lub substrate feem ntau yog txheej nyias ntawm polyimide lossis polyester zaj duab xis. Lub substrate yog ntxuav, coated nrog nplaum, thiab laminated nrog conductive tooj liab ntawv ci. Lub thickness ntawm cov ntawv ci tooj liab thiab substrate tuaj yeem sib txawv nyob ntawm seb cov ntawv thov tshwj xeeb.

4. Etching thiab laminating hauv flex Circuit Court ntau lawm:

Tom qab cov txheej txheem lamination tiav lawm, cov tshuaj etchant yog siv los tshem tawm cov ntawv nyiaj ntau dhau, tawm hauv cov kab uas xav tau thiab cov ntaub qhwv. Tswj cov txheej txheem etching los ntawm kev siv lub ntsej muag etch-resistant los yog cov txheej txheem photolithography. Thaum lub etching tiav lawm, lub voj voog hloov tau raug ntxuav thiab npaj rau theem tom ntej ntawm kev tsim khoom.

5. Cov khoom sib dhos hauv flex circuit manufacturing:

Tom qab cov txheej txheem etching tiav, lub voj voog hloov tau yog npaj rau kev sib dhos. Surface mount technology (SMT) feem ntau yog siv rau kev muab tso rau hauv qhov chaw raws li nws ua kom meej meej thiab automated sib dhos. Siv cov nplaum nplaum nplaum rau cov ntaub qhwv cov ntaub qhwv thiab siv lub tshuab tuaj tos thiab tso cov khoom. Tom qab ntawd lub flex Circuit Court yog rhuab, ua rau lub solder ua raws li cov conductive pads, tuav cov khoom nyob rau hauv qhov chaw.

6. Kev kuaj thiab tshuaj xyuas hauv flex circuit manufacturing:

Thaum cov txheej txheem sib dhos ua tiav, flex Circuit Court raug kuaj xyuas kom zoo thiab tshuaj xyuas. Kev ntsuas hluav taws xob ua kom ntseeg tau tias cov kab hluav taws xob thiab cov khoom siv tau ua haujlwm raws li qhov xav tau. Cov kev ntsuam xyuas ntxiv, xws li thermal cycling thiab mechanical stress testing, kuj tuaj yeem ua tau los ntsuas qhov ua tau ntev thiab kev ntseeg tau ntawm cov khoom siv hluav taws xob hloov tau. Txhua qhov tsis zoo lossis teeb meem pom thaum kuaj tau txheeb xyuas thiab kho.

7. Flexible coverage thiab tiv thaiv nyob rau hauv flex circuit manufacturing:

Txhawm rau tiv thaiv kev hloov pauv hloov pauv los ntawm ib puag ncig yam xwm txheej thiab kev ntxhov siab txhua yam, cov ntaub npog hloov tau yooj yim lossis cov txheej tiv thaiv raug siv. Cov txheej no tuaj yeem yog daim npog ntsej muag, txheej txheej, lossis ob qho tib si ua ke. Lub npog yuav txhim khu lub durability ntawm lub flex Circuit Court thiab ncua nws cov kev pab cuam lub neej.

8. Kev tshuaj xyuas zaum kawg thiab ntim hauv flex circuit manufacturing:

Tom qab lub flex Circuit Court tau dhau los ntawm tag nrho cov txheej txheem tsim nyog, nws ua tiav qhov kev tshuaj xyuas zaum kawg kom ntseeg tau tias nws ua tau raws li qhov xav tau tshwj xeeb. Flexible circuits tau ua tib zoo ntim los tiv thaiv lawv los ntawm kev puas tsuaj thaum thauj thiab khaws cia.

Hauv cov ntsiab lus, kev tsim cov txheej txheem ntawm kev hloov pauv hloov pauv muaj ntau cov kauj ruam nyuaj, suav nrog kev tsim, xaiv cov khoom, fabrication, sib dhos, kuaj, thiab kev tiv thaiv.Kev siv cov thev naus laus zis niaj hnub thiab cov khoom siv siab ua kom ntseeg tau tias cov kev hloov pauv hloov tau raws li qhov xav tau ntawm ntau yam kev lag luam. Nrog lawv cov kev yooj yim thiab compact tsim, hloov tau yooj yim circuits tau dhau los ua ib feem tseem ceeb ntawm kev txhim kho cov khoom siv hluav taws xob tshiab thiab txiav-ntug. Los ntawm cov xov tooj smartphones mus rau cov khoom siv kho mob, cov khoom siv hluav taws xob hloov tau hloov pauv txoj kev siv hluav taws xob sib xyaw ua ke hauv peb lub neej niaj hnub.

Post lub sij hawm: Sep-21-2023

Rov qab