Quick-Tig PCB Prototyping 6 Txheej High-Density Multi-Layer Flexible Boards Rau Automotive

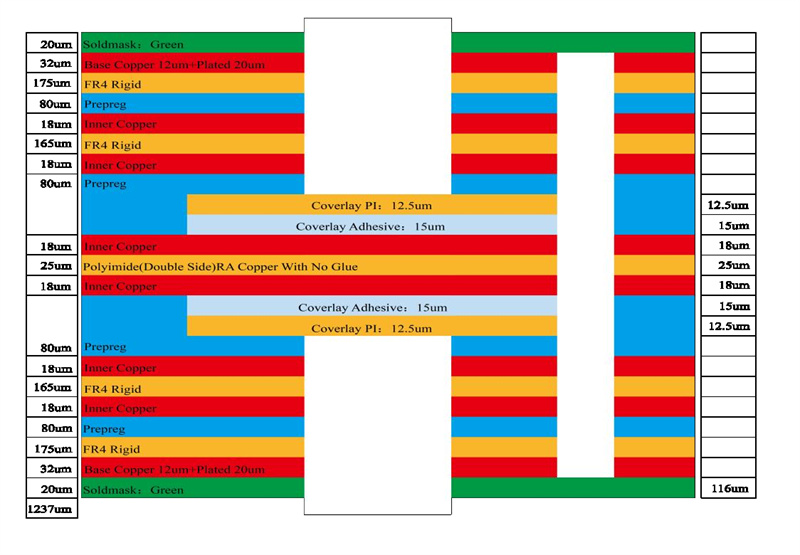

Specification

| Qeb | Txheej Txheem Muaj Peev Xwm | Qeb | Txheej Txheem Muaj Peev Xwm |

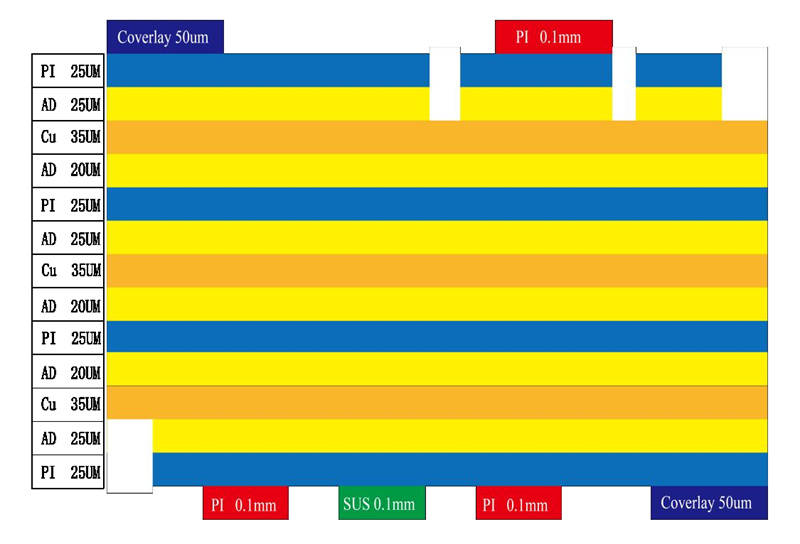

| Hom kev tsim khoom | Ib txheej FPC / Ob txheej FPC Multi-layer FPC / Aluminium PCBs Rigid-Flex PCBs | Txheej Number | 1-16 txheej FPC 2-16 txheej Rigid-FlexPCB HDI Printed Circuit Boards |

| Max Tsim Loj | Ib txheej FPC 4000mm Doulbe txheej FPC 1200mm Multi-txheej FPC 750mm Rigid-Flex PCB 750 hli | Insulating Txheej Thickness | 27.5um / 37.5 / 50um / 65 / 75um / 100um / 125 hli / 150 hli |

| Board Thickness | FPC 0.06mm - 0.4 hli Rigid-Flex PCB 0.25-6.0 hli | Tolerance ntawm PTH Loj | ± 0.075 hli |

| Nto tiav | Immersion Kub / Immersion Nyiaj / Kub Plating / Tin Plat ing / OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Qhov loj me ntawm semicircle Orifice | Min 0.4mm | Min Kab Qhov Chaw / dav | 0.045mm / 0.045 hli |

| Thickness kam rau ua | ± 0.03 hli | Impedance | 50Ω-120Ω |

| Copper Ntawv Nyiaj Thickness | 9um / 12um / 18um / 35um / 70um / 100um | Impedance Tswj tau Ua siab ntev | ± 10% |

| Tolerance ntawm NPTH Loj | ± 0.05 hli | Min Flush Width | 0.80mm ib |

| Min Via Qhov | 0.1 hli | Ua Txuj | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013 III |

Peb ua ntau txheej txheej boards nrog 15 xyoo kev paub nrog peb cov kws tshaj lij

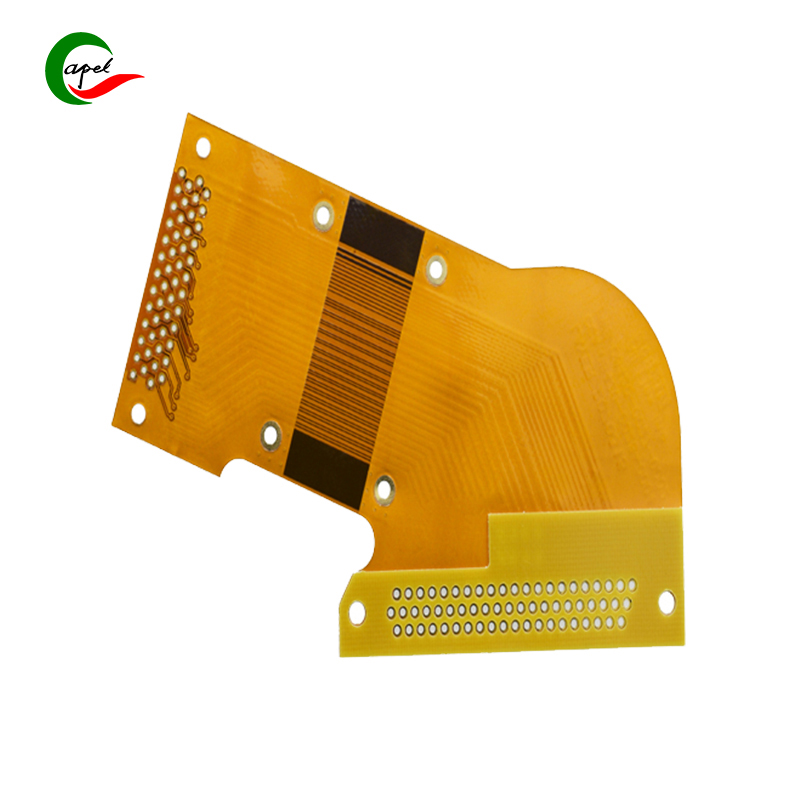

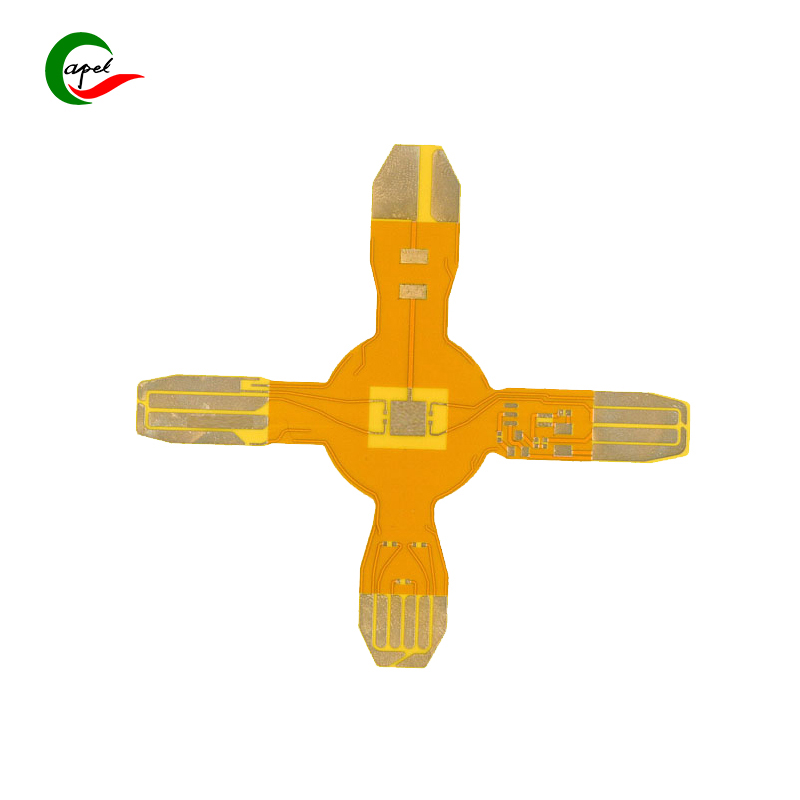

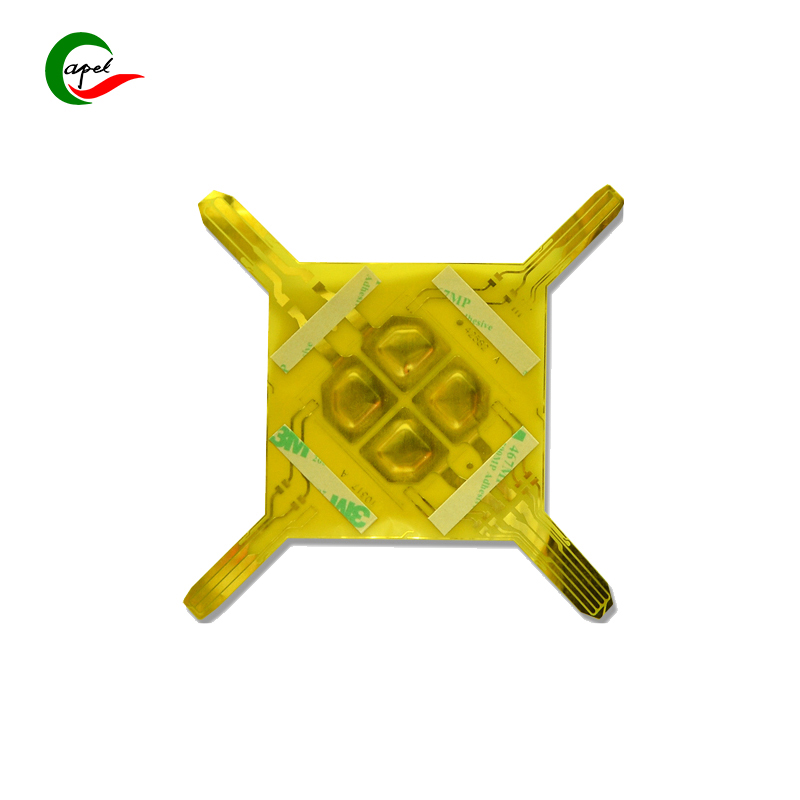

3 txheej Flex PCBs

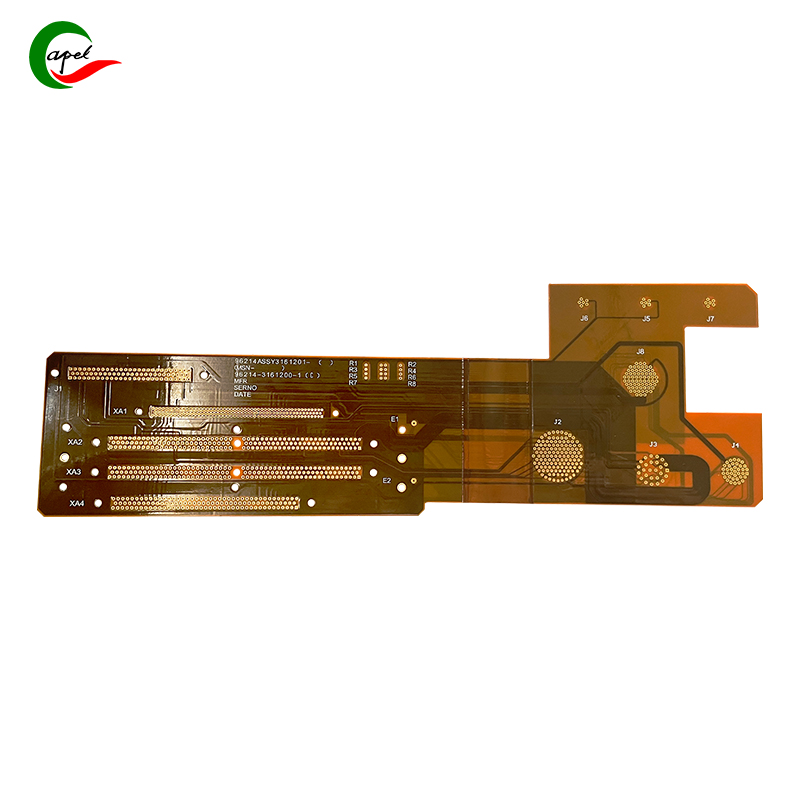

8 txheej Rigid-Flex PCBs

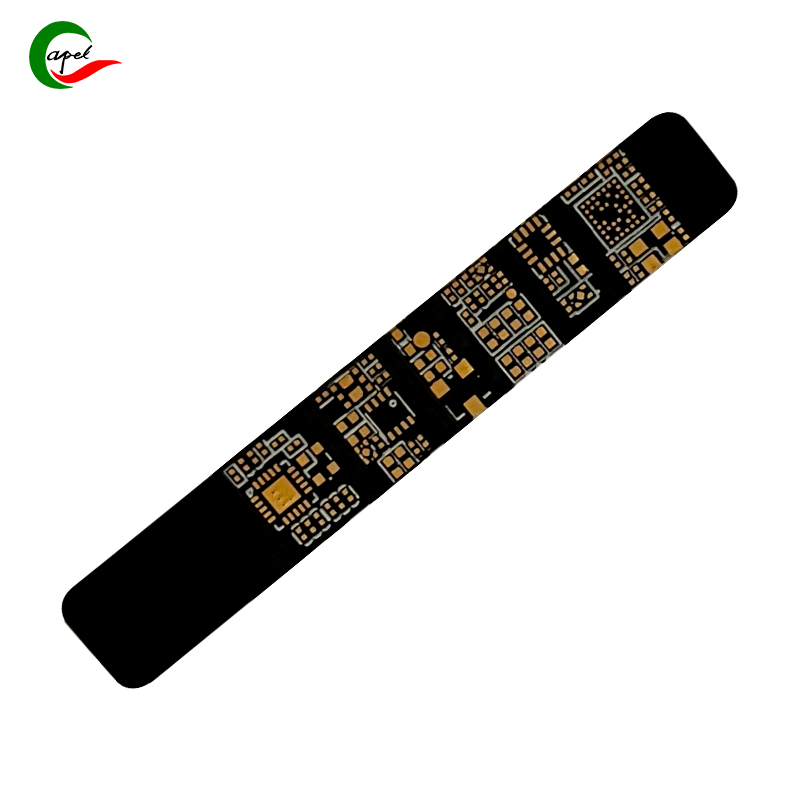

8 txheej HDI Printed Circuit Boards

Cov khoom siv kuaj thiab tshuaj xyuas

Microscope Test

AOI Inspection

2D Kev Xeem

Kev ntsuas impedance

Kev xeem RoHS

Flying Probe

Kab rov tav Tester

Khoov Teste

Peb cov txheej txheem ntau txheej boards Service

. Muab kev txhawb nqa kev muag khoom ua ntej thiab tom qab muag;

. Custom mus txog 40 khaubncaws sab nraud povtseg, 1-2days ceev tig txhim khu kev qha prototyping, Component procurement, SMT Assembly;

. Caters rau ob qho khoom siv kho mob, Kev Tswj Lag Luam, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications thiab lwm yam.

. Peb pab pawg engineers thiab cov kws tshawb fawb tau mob siab rau ua kom tiav koj cov kev xav tau nrog precision thiab kev tshaj lij.

Yuav ua li cas yog cov kev cai ntawm automotive PCBs rau multi-layer flexible boards?

1. Durability: Automotive PCBs yuav tsum muaj peev xwm tiv taus cov kev ua haujlwm hnyav ntawm lub tsheb, nrog rau qhov kub thiab txias, kev vibration, thiab ya raws. Lawv cog lus tias lub neej ua haujlwm ntev dua thiab zoo heev mechanical stability.

2. High Density: Multi-layer flexible PCB tso cai rau kev sib txuas hluav taws xob ntau dua thiab cov khoom sib xyaw ua ke rau hauv ib qho chaw compact. Cov qauv tsim high-density enables routing npaum thiab txo qhov loj ntawm PCB, txuag qhov chaw muaj txiaj ntsig hauv lub tsheb.

3. Flexibility thiab bendability: Flexible PCBs tuaj yeem yooj yim folded, twisted los yog khoov kom haum rau qhov chaw nruj los yog ua raws li cov duab ntawm lub tsheb. Lawv yuav tsum tswj xyuas lawv cov hluav taws xob thiab kev ua haujlwm zoo thaum rov khoov thiab flexing.

4. Teeb liab kev ncaj ncees: Yuav tsum muaj cov teeb liab tsawg tsawg lossis suab nrov cuam tshuam ntawm PCB kom ntseeg tau tias kev sib txuas lus zoo ntawm cov khoom siv hluav taws xob sib txawv. Siv cov tswv yim xws li kev tswj hwm impedance thiab cov av kom zoo los tswj cov teeb liab kev ncaj ncees.

5. Thermal tswj: Automotive circuit boards yuav tsum tau zoo dissipate lub tshav kub generated thaum lub sij hawm ua hauj lwm. Kev tswj xyuas cov txheej txheem thermal zoo, xws li siv cov dav hlau tooj liab zoo thiab thermal vias, yog qhov tsim nyog los tiv thaiv overheating thiab ua kom ruaj khov.

6. EMI/RFI shielding: Txhawm rau tiv thaiv electromagnetic cuam tshuam (EMI) thiab xov tooj cua zaus cuam tshuam (RFI), automotive PCBs yuav tsum muaj cov txheej txheem tiv thaiv kom raug. Qhov no suav nrog kev siv cov ntaub thaiv npog lossis cov dav hlau hauv av kom txo qis cov teebmeem ntawm sab nraud electromagnetic signals.

7. Kev kuaj hauv online: Tus qauv tsim PCB yuav tsum ua kom yooj yim rau kev sim thiab tshuaj xyuas ntawm cov khoom sib dhos PCB. Kev nkag mus tau zoo rau cov ntsiab lus ntsuas thiab cov kev soj ntsuam kuaj yuav tsum tau muab los xyuas kom meej thiab muaj txiaj ntsig kev sim thaum tsim khoom thiab tu.

8. Kev ua raws li cov qauv kev tsav tsheb: Kev tsim thiab tsim cov tsheb PCB yuav tsum ua raws li cov qauv kev lag luam tsheb, xws li AEC-Q100 thiab ISO/TS 16949. Kev ua raws li cov qauv no ua kom muaj kev ntseeg siab, kev nyab xeeb thiab zoo ntawm PCBs.

Vim li cas thiaj xav tau Quick-tig PCB Prototyping?

1. Ceev: Rapid PCB prototyping accelerates cov khoom tsim kev voj voog. Nws pab txo lub sij hawm xav tau los rov hais dua, sim, thiab txhim kho PCB tsim, ua kom cov engineers ua tau raws li lub sijhawm teem sijhawm los yog teb sai sai rau kev xav tau ntawm kev lag luam.

2. Kev Tshawb Fawb Tsim: PCB Prototyping tso cai rau cov engineers los xyuas qhov kev ua haujlwm, kev ua haujlwm thiab kev tsim khoom ntawm lawv cov PCB tsim ua ntej mus rau ntau lawm. Nws pab txheeb xyuas thiab daws cov teeb meem tsim lossis kev ua kom zoo dua qub, txuag sijhawm thiab nyiaj txiag ntev.

3. Txo kev pheej hmoo: Kev nrawm PCB prototyping pab txo cov kev pheej hmoo cuam tshuam nrog kev tsim PCB loj. Los ntawm kev sim thiab siv tau cov qauv tsim hauv cov khoom me me, txhua qhov kev ua yuam kev lossis teeb meem tuaj yeem raug ntes tau ntxov, tiv thaiv tus nqi tsis raug thiab rov ua haujlwm thaum lub sijhawm tsim khoom tag nrho.

4. Kev txuag nqi: Kev ceev PCB prototyping tuaj yeem ua kom muaj txiaj ntsig zoo ntawm cov khoom siv thiab cov khoom siv. Los ntawm kev ntes cov teeb meem tsim ntxov thiab ua qhov tsim nyog hloov kho, engineers tuaj yeem txuag cov khoom siv khib nyiab thiab raug nqi tsim kho dua tshiab.

5. Kev ua lag luam ua lag luam: Hauv kev lag luam nrawm, muaj peev xwm txhim kho sai thiab nthuav tawm cov khoom tshiab tuaj yeem ua rau lub tuam txhab muaj txiaj ntsig zoo. Rapid PCB prototyping ua rau cov tuam txhab ua lag luam sai sai rau cov kev xav tau ntawm kev lag luam, hloov cov qauv lossis cov hauv kev tshiab, ua kom cov khoom lag luam tawm raws sijhawm.

6. Customization thiab innovation: Prototyping pab txhawb customization thiab innovation. Cov kws tshaj lij tuaj yeem tshawb nrhiav cov tswv yim tsim tshiab, sim cov yam ntxwv sib txawv, thiab sim nrog cov thev naus laus zis siab. Nws ua rau lawv thawb ciam teb thiab txhim kho cov khoom lag luam.